Introduction

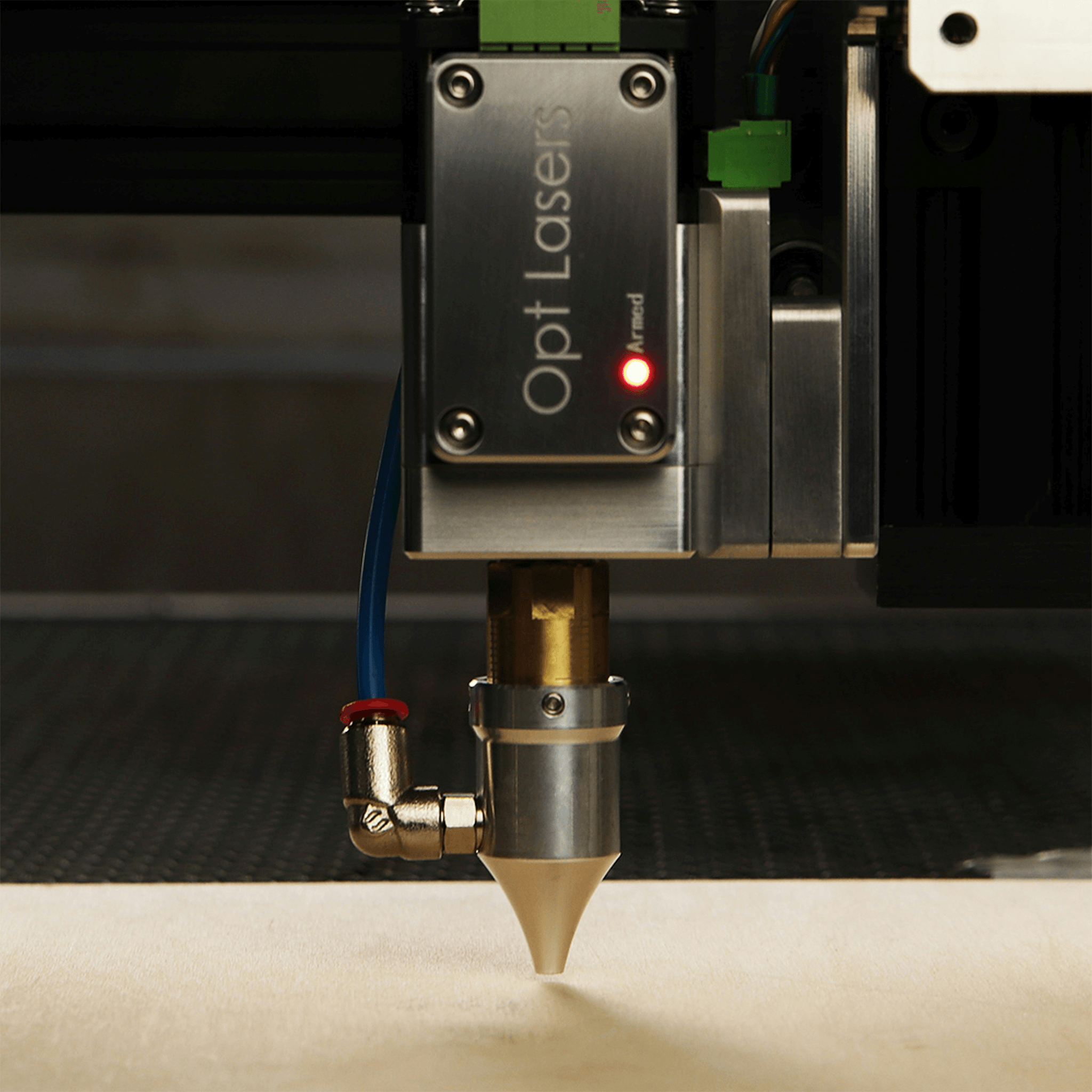

In the world of manufacturing and design, the advent of 3D laser cutting machines has revolutionized the way we approach precision fabrication. These powerful tools not only provide unmatched accuracy but also open up a realm of possibilities for intricate designs that were once deemed impossible. Whether you're an industry veteran or just stepping into the realm of industrial laser machines, understanding how to harness this technology can unlock new levels of efficiency and creativity.

Unlocking the Power of 3D Laser Cutting

The capabilities of a 3D laser cutting machine extend far beyond simple cuts; they offer a blend of speed, precision, and versatility that traditional methods struggle to match. With advancements in laser technology, these cutting machines are now able to handle complex geometries and materials with ease, making them indispensable in various industries from automotive to aerospace. By embracing these industrial laser cutters, businesses can significantly reduce waste and enhance their production timelines.

Why Precision Matters in Laser Cutting

Precision is the name of the game when it comes to laser cutting services; even a minor error can lead to costly mistakes and wasted materials. The accuracy provided by an industrial laser cutting machine ensures that each piece produced meets stringent specifications without compromising quality. In industries where tolerances are tight and details matter, investing in a high-quality cutting machine laser is essential for maintaining competitive advantages.

Your Guide to Efficient Industrial Laser Machines

Navigating the landscape of industrial laser machines might seem daunting at first glance, but this guide aims to demystify everything you need to know about optimizing your operations with these advanced tools. From understanding various machine settings on your CNC laser tube cutter to selecting appropriate materials for your projects, we cover all bases for maximizing efficiency. With expert tips and insights from Kiant Machinery, you'll be well-equipped to make informed decisions about your next steps in harnessing 3D laser cutting technology.

Understanding Your 3D Laser Cutting Machine

Features that Enhance Performance

The modern industrial laser cutting machine packs a punch with its advanced features designed to optimize performance. High-speed motors and precise optics ensure that every cut is clean and consistent, making them perfect for everything from delicate engravings to robust structural components. Additionally, many cutting machines laser now come equipped with software integration options that allow for seamless operation between design and execution, minimizing downtime.

Another standout feature is the ability to adjust settings on-the-fly, which is crucial when switching between different materials or thicknesses. This adaptability means that whether you're using a CNC laser tube cutter or a flatbed model, you can achieve optimal results without compromising on speed or quality. Ultimately, understanding these features will empower you to leverage your 3D laser cutting machine like a pro.

Common Uses Across Industries

The versatility of an industrial laser cutter makes it invaluable across various sectors. In manufacturing, it's commonly used for creating parts in automotive production lines; in aerospace, precision components are cut from lightweight materials to reduce weight without sacrificing strength. Beyond these industries, custom signage makers rely heavily on their laser machines for creating eye-catching displays that require intricate designs.

Moreover, the fashion industry has embraced 3D laser cutting technology to produce unique patterns in fabrics that traditional methods simply can't replicate. Even in architecture and interior design, professionals utilize these machines for detailed models or decorative elements that elevate their projects’ aesthetic appeal. The common thread? No matter the industry, precision cuts are key—and that's where your industrial laser machines shine.

Safety Protocols to Follow

While operating an industrial laser cutting machine can be thrilling due to its capabilities, safety must always take precedence. First off, wearing appropriate personal protective equipment (PPE) such as goggles is non-negotiable; lasers can cause serious eye damage if proper precautions aren’t taken during operation. Furthermore, ensure your workspace is free from flammable materials since high-powered lasers generate heat that could ignite nearby objects.

Regular maintenance checks should also be part of your safety protocol—keeping lenses clean and ensuring all mechanical parts are functioning properly helps prevent accidents caused by equipment failure during operations like those performed by a CNC laser tube cutter or other types of industrial machines. By adhering strictly to safety protocols while harnessing the power of your 3D laser cutting machine, you create not only a productive environment but also one where everyone feels secure.

Choosing the Right Materials

Selecting the right materials for your 3D laser cutting machine is crucial for achieving optimal results. The compatibility of materials with your industrial laser cutter can significantly affect the quality and efficiency of your projects. Understanding which materials work best with your cutting machine laser will enhance both performance and productivity, making it a key consideration in any industrial setting.

Best Materials for Laser Cutting

Metals like aluminum and stainless steel are popular choices due to their strength and durability, while acrylics offer excellent clarity and versatility in design. Additionally, wood is a favorite among artisans, as it can be easily manipulated with a CNC laser tube cutter to create intricate patterns and shapes.

The beauty of using a 3D laser cutting machine lies in its ability to handle various materials efficiently. Whether you’re crafting signage from acrylic or creating metal components for machinery, understanding material properties will lead to better outcomes. Always consider how each material reacts under heat; some may warp or burn if not handled correctly by your industrial laser machines.

Impact of Material Thickness

Material thickness plays a significant role in determining the effectiveness of an industrial laser cutter's performance. Thicker materials generally require more power and slower speeds, which can affect overall production time if not properly adjusted on your cutting machine laser settings. Conversely, thinner materials may allow for faster cuts but can be more prone to burning or melting if the settings are not optimized.

It's important to conduct tests on various thicknesses before committing to large-scale production runs with your 3D laser cutting machine. This experimentation helps you pinpoint the ideal power levels and speed settings needed for different applications across various industries. Ultimately, understanding how thickness impacts both cut quality and efficiency will save time and resources when working with an industrial laser cutting service.

Material Compatibility with Your Machine

Not all materials are created equal when it comes to compatibility with your 3D laser cutting machine or other industrial laser machines you may have at your disposal. Each type of material—be it metal, plastic, or wood—has specific requirements that must be met by the capabilities of your equipment. For instance, certain metals might require higher wattage lasers that only advanced models provide; knowing this ahead of time ensures smooth operations.

Before starting any project using an industrial laser cutter, always consult the manufacturer’s guidelines regarding material compatibility with their equipment specifications. This step is essential because using incompatible materials could lead to poor-quality cuts or even damage to the machine itself—a costly mistake no one wants! By aligning material choices with what your CNC laser tube cutter can handle effectively, you'll maximize both efficiency and output quality.

Mastering Machine Settings

Optimizing Power and Speed

Finding the sweet spot between power and speed is essential for achieving optimal results with your industrial laser cutting machine. Too much power can lead to excessive heat, causing material warping or burn marks, while too little may result in incomplete cuts. Start by experimenting with different settings on your cutting machine laser; a general rule of thumb is to increase speed for thinner materials while reducing it for thicker ones to maintain cut quality.

Moreover, consider the type of material you’re working with; metals often require higher power levels compared to plastics or wood. Regularly calibrating your CNC laser tube cutter ensures that you’re making precise adjustments tailored to each job’s requirements. By fine-tuning these settings consistently, you’ll not only enhance efficiency but also extend the lifespan of your industrial laser machines.

Adjusting for Different Materials

Every material behaves differently under a 3D laser cutting machine's beam; thus, understanding how to adjust settings accordingly is vital. For instance, acrylic might need a faster speed compared to plywood due to its lower melting point and tendency to produce fumes when overheated. Always consult material guidelines provided by manufacturers or experienced professionals in the field when determining appropriate settings.

Additionally, thickness plays a significant role in how you should configure your industrial laser cutter’s parameters. Thicker materials typically require slower speeds and higher power levels for effective penetration without compromising edge quality. Keep a log of successful settings used on various materials; this will serve as an invaluable reference for future projects.

Troubleshooting Common Settings Issues

Even seasoned users of an industrial laser cutting machine encounter hiccups from time to time; knowing how to troubleshoot these issues can save both time and resources. One common problem is inconsistent cut depth—this could be due to varying material thickness or improper focus adjustment on your laser machine. Always ensure that the lens is clean and properly aligned before starting any job.

Another issue might be excessive charring or burning around cut edges; this often indicates either too much power or slow speeds during operation. If you find yourself facing repeated problems despite following best practices, consider reaching out for professional help from reliable laser cutting services who can provide insights based on their expertise with various machines like yours.

Exploring Advanced Techniques

In the world of industrial laser cutting, mastering advanced techniques can significantly enhance your projects' outcomes. By leveraging technology and innovative methods, you can push the boundaries of what your 3D laser cutting machine can achieve. Whether you're designing intricate components or optimizing production processes, these advanced techniques will set you apart from the competition.

Utilizing CAD Software for Design

Computer-Aided Design (CAD) software is a game-changer for anyone working with an industrial laser cutter. It allows you to create precise designs that maximize the capabilities of your cutting machine laser while minimizing material waste. With CAD, you can visualize complex shapes in 3D, making it easier to identify potential issues before engaging your 3D laser cutting machine in actual production.

Using CAD software also streamlines communication between design and production teams, ensuring everyone is on the same page regarding specifications and tolerances. This digital approach not only saves time but also enhances accuracy—two critical factors when working with an industrial laser cutting machine. Plus, many CAD programs offer features tailored specifically for laser cutting services, allowing for seamless integration into your workflow.

Techniques for Complex Shapes

Creating complex shapes with an industrial laser cutter requires both skill and strategy. One effective technique is to break down intricate designs into simpler components that can be easily cut and assembled later. This method not only simplifies the process but also reduces the likelihood of errors during cutting, maximizing efficiency when using a CNC laser tube cutter.

Moreover, consider experimenting with multiple passes at varying speeds and power levels to achieve finer details on challenging shapes without compromising material integrity. The versatility of modern industrial laser machines allows you to explore different approaches that traditional manufacturing methods simply cannot match. Ultimately, mastering these techniques will enable you to produce stunning results that stand out in any industry.

Enhancing Precision with Nested Cuts

Nested cuts are a brilliant way to optimize material usage while enhancing precision during the cutting process with your 3D laser cutting machine. By arranging parts within each other like puzzle pieces on a sheet of material, nested cuts minimize waste and maximize output—ideal for high-volume production runs or when working with expensive materials through an industrial laser cutter.

This technique requires careful planning and sophisticated software capable of calculating optimal layouts based on part sizes and shapes—a feature commonly found in advanced CAD systems designed specifically for use with industrial laser machines. Additionally, employing nested cuts ensures uniformity across all pieces produced since they share common boundaries during the cutting process; this consistency is vital when quality assurance is paramount in any project involving a cutting machine laser.

Incorporating these advanced techniques into your workflow will not only boost productivity but also elevate the quality of your finished products beyond expectations!

Implementing Regular Maintenance

Maintaining your 3D laser cutting machine is crucial to ensure optimal performance and longevity. Regular maintenance can prevent costly repairs and downtime, allowing your industrial laser cutter to operate at peak efficiency. By incorporating routine checks into your operational schedule, you can maximize the effectiveness of your laser machine and enhance the quality of your laser cutting service.

Importance of Routine Checks

Routine checks are the backbone of any effective maintenance strategy for an industrial laser cutting machine. They help identify potential issues before they escalate into significant problems, saving both time and money in the long run. Whether it's checking the alignment of mirrors or ensuring that lenses are clean, these small tasks are essential for maintaining accuracy in every cut made by your CNC laser tube cutter.

Cleaning and Care Tips

Keeping your cutting machine laser clean is as important as any technical adjustment you might make. Dust, debris, and residue can accumulate on optics and components, affecting performance and precision over time. Make it a habit to regularly clean lenses with appropriate solutions, check air filters for clogs, and wipe down surfaces to keep your industrial laser machines in top shape.

When to Seek Professional Help

Even with diligent routine checks and cleaning practices, there may come a time when you need to seek professional help for your 3D laser cutting machine. If you notice persistent issues such as inconsistent cuts or unusual noises that don’t resolve with standard troubleshooting methods, it’s wise to consult experts who specialize in industrial laser cutting machines. Professional technicians have the expertise required to diagnose complex problems accurately—ensuring that your operations remain smooth without unnecessary interruptions.

Training and Skill Development

In the fast-paced world of industrial laser cutting, ensuring that your team is well-trained is not just beneficial; it's essential. Investing in employee training for operating a 3D laser cutting machine can significantly enhance productivity and reduce error rates. A well-trained workforce will not only optimize the use of cutting machine lasers but also contribute positively to the overall efficiency of your operations.

Investing in Employee Training

By investing in comprehensive training programs, you can equip your employees with the skills necessary to operate an industrial laser cutting machine safely and effectively. This investment pays off by minimizing downtime due to operator errors and maximizing the potential of your laser cutting service.

Training ensures that employees understand the intricacies of different materials and how they interact with various settings on a CNC laser tube cutter. Knowledgeable operators can make real-time adjustments based on material thickness or type, which leads to superior results. Plus, ongoing training fosters a culture of safety and innovation within your organization.

Resources for Continuous Learning

The landscape of technology is ever-evolving, especially in industries utilizing advanced machinery like 3D laser cutting machines. To keep pace with these changes, organizations should provide resources for continuous learning. Online courses, workshops, and industry conferences are excellent ways for employees to stay updated on best practices and new technologies related to industrial laser machines.

Additionally, many manufacturers offer tailored training sessions focused on their specific equipment—such as CNC laser tube cutters or other industrial laser cutters—which help maximize the utility of these machines. Encouraging team members to engage with professional networks can also foster knowledge sharing about advancements in techniques or materials used in laser cutting services.

Benefits of Expert Instruction from Kiant Machinery

Their specialized instruction not only covers basic operation but dives deep into advanced techniques that enhance precision and efficiency when working with a 3D laser cutting machine. This expert guidance helps ensure that your team is fully equipped to handle complex projects confidently.

Furthermore, Kiant Machinery provides insights into best practices specifically tailored for their equipment—maximizing your return on investment while minimizing operational hiccups along the way. By leveraging their expertise, you can empower your employees with skills that translate directly into improved performance across all aspects of your production line.

Conclusion

As we wrap up our exploration of the world of 3D laser cutting, it's clear that maximizing efficiency with your industrial laser cutter is not just a goal—it's an ongoing journey. By understanding the intricacies of your cutting machine laser and implementing best practices, you can significantly enhance productivity while maintaining high-quality output. Remember, the key to success lies in regular maintenance, proper training, and staying informed about advancements in technology.

Maximizing Efficiency with Your 3D Laser Cutter

To truly maximize efficiency with your 3D laser cutting machine, focus on optimizing settings for different materials and applications. Fine-tuning power levels and speed settings can lead to faster cuts and reduced waste, ultimately saving time and resources. Additionally, investing in a reliable laser cutting service can provide expert insights that help streamline operations even further.

The Future of Industrial Laser Cutting

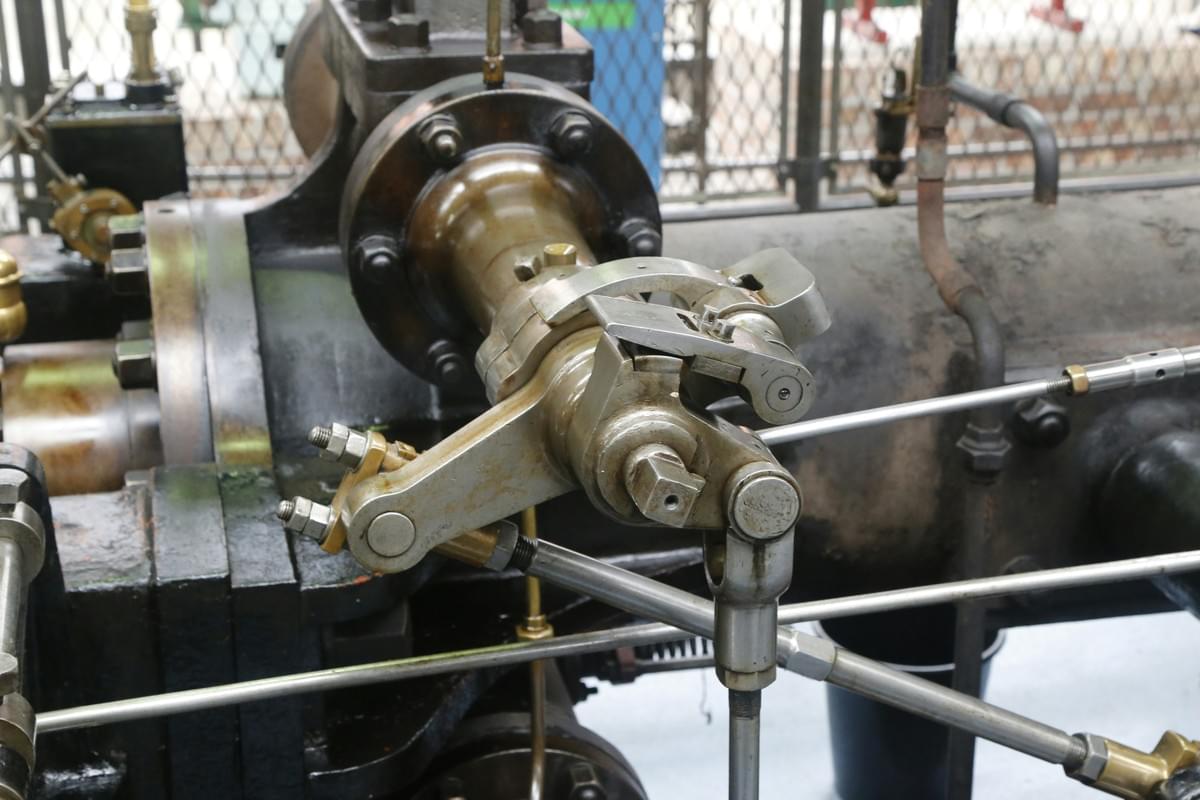

The future of industrial laser cutting is bright and filled with exciting possibilities. With advancements in technology such as AI integration and improved CNC laser tube cutter capabilities, we can expect even greater precision and efficiency from industrial laser machines in the years to come. As industries continue to evolve, embracing these innovations will be key to staying competitive in a rapidly changing market.

Leveraging Expertise from Kiant Machinery

When it comes to navigating the complexities of industrial laser machines, leveraging expertise from Kiant Machinery can make all the difference. Their commitment to quality training and support ensures that you not only have access to top-tier equipment but also the knowledge needed to operate it effectively. With their guidance, you’ll be well-equipped to harness the full potential of your 3D laser cutting machine.