Introduction

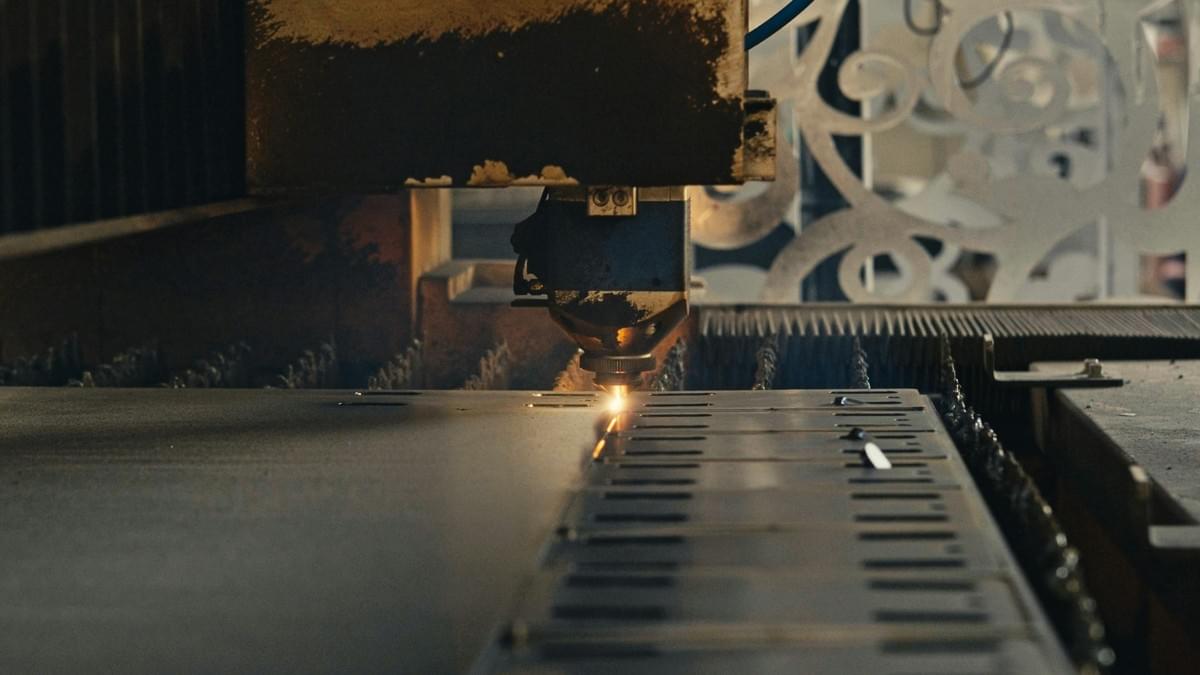

In today's fast-paced manufacturing landscape, laser technology is revolutionizing fabrication processes across various industries. The precision and efficiency offered by a Laser Cutting Machine have transformed how businesses approach metal and non-metal cutting tasks. With the increasing demand for high-quality outputs, understanding the significance of quality laser cutters becomes crucial for any operation aiming to stay competitive.

Revolutionizing Fabrication with Laser Technology

Laser technology has emerged as a game-changer in the world of fabrication, allowing for intricate designs and fast production times that traditional methods simply can't match. From automotive parts to artistic creations, the versatility of a CNC laser cutter enables manufacturers to tackle diverse projects with ease. In particular, CO2 laser machines stand out for their ability to cut through various materials while maintaining exceptional accuracy.

Understanding the Importance of Quality Laser Cutters

Investing in a high-quality laser cutting machine can make all the difference between mediocre results and outstanding production quality. A reliable metal cutting laser cutter ensures that each cut is precise, reducing material waste and improving overall efficiency. Additionally, choosing a reputable brand means you’ll benefit from better support, maintenance options, and longevity—essential factors that can save your business time and money in the long run.

Key Features to Consider in a Laser Cutting Machine

When selecting a laser CNC machine, it's vital to consider several key features that directly impact performance and usability. Factors such as power source type—whether you're opting for a CO2 laser cutter or fiber variant—play an important role in determining what materials you can effectively work with. Other features like software compatibility and user-friendly interfaces also contribute significantly to enhancing workflow efficiency, making it easier than ever to produce high-quality results consistently.

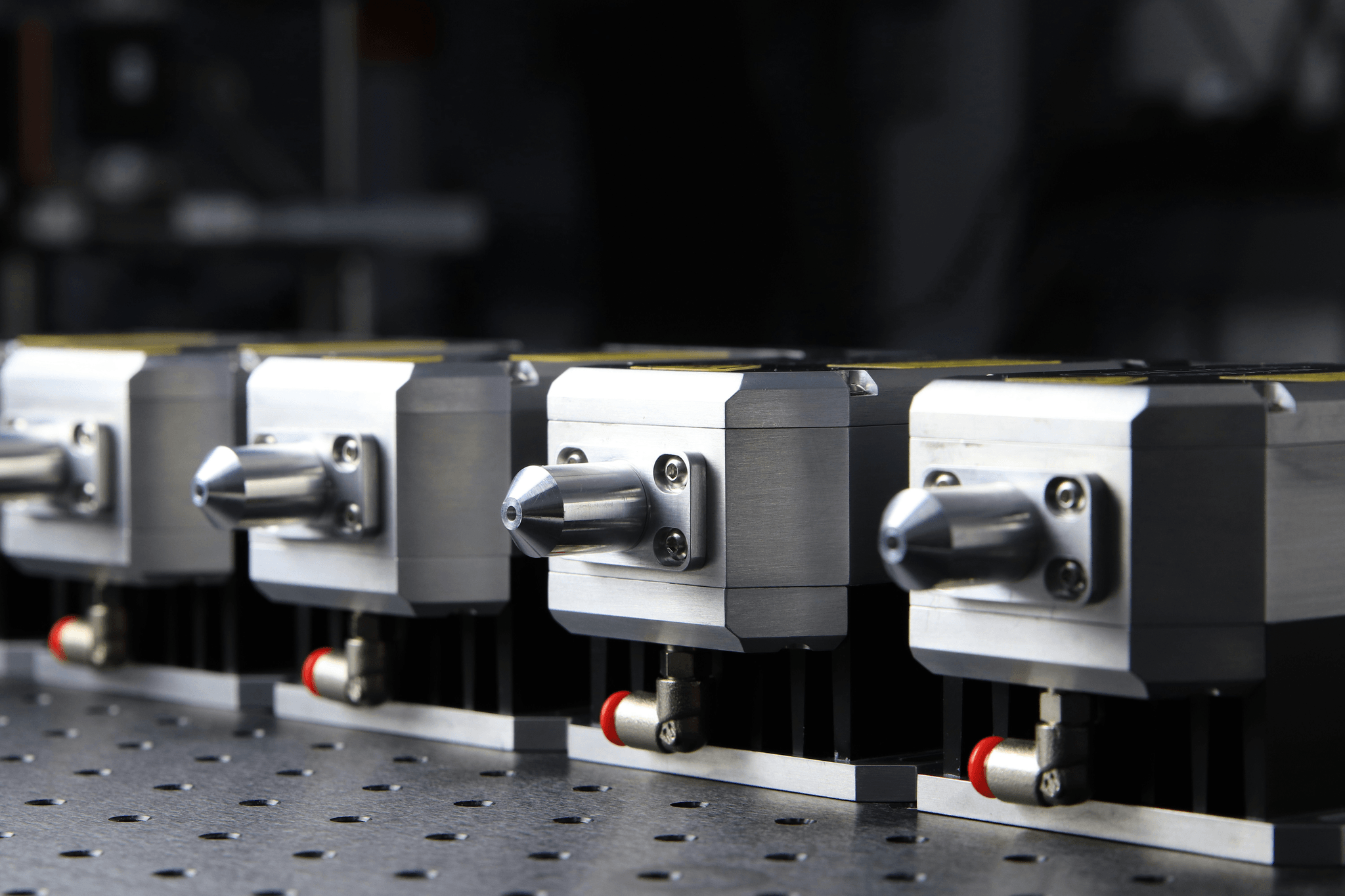

Powerful Laser Sources

Selecting the right type of laser source for your needs can make all the difference, especially if you're in the market for a reliable laser cutting machine. Two primary contenders in this arena are CO2 lasers and fiber lasers, each boasting unique advantages tailored to specific applications.

CO2 Laser Machine Advantages

CO2 laser machines have been a staple in the fabrication world for years, primarily due to their exceptional ability to cut and engrave various materials with high precision. One of their standout features is their effectiveness at cutting non-metal materials such as wood, acrylic, and textiles—making them ideal for industries like signage and fashion design. Additionally, CO2 laser cutters tend to offer a more cost-effective solution for businesses focusing on diverse applications since they can handle multiple materials without requiring extensive modifications.

The versatility of CO2 machines extends beyond just material handling; they also provide a smoother finish on edges compared to some alternatives. This is particularly beneficial when working with intricate designs or detailed patterns that require clean cuts without additional finishing work. For those looking for an all-round performer in their production line, investing in a quality CO2 laser machine could be one of the best decisions you make.

Fiber vs. CO2 Laser Cutter Performance

When comparing fiber lasers to CO2 laser cutters, performance varies significantly based on intended use. Fiber lasers excel at cutting metals—particularly reflective materials like aluminum and copper—thanks to their shorter wavelengths that allow deeper penetration into dense surfaces. Conversely, while metal cutting is possible with CO2 machines, they may struggle with certain reflective metals unless specifically designed for such tasks; thus making fiber lasers often preferred in industrial metalworking environments.

In essence, if your focus lies heavily on metalwork or fast-paced production requirements involving steel sheets or similar materials, a fiber cutter might just edge out its CO2 counterpart—but both have their rightful place depending on your project needs.

Longevity and Maintenance of Laser Sources

The longevity and maintenance requirements of your chosen laser source are paramount considerations when investing in equipment like a CNC laser cutter or metal cutting laser cutter. Generally speaking, fiber lasers boast lower maintenance costs due to fewer moving parts and no need for gas refills—a significant factor if you're planning long-term use within your operations! On the flip side, while CO2 machines may require more regular upkeep (like mirror alignments), many users find them easier to operate thanks to intuitive interfaces.

It's essential not only to consider initial purchase prices but also ongoing operational expenses when evaluating options between these two types of lasers. With proper care—such as routine cleaning and timely replacement of consumables—the lifespan of either system can be extended considerably; hence understanding manufacturer recommendations becomes crucial here! Ultimately though both types offer remarkable capabilities; choosing one will depend largely upon your specific application demands coupled with budgetary constraints.

Precision and Accuracy

In the world of fabrication, precision is paramount, and CNC laser cutter technology stands at the forefront of delivering unmatched accuracy. A laser cutting machine, particularly a CO2 laser cutter or CO2 machine laser, can achieve intricate designs that would be nearly impossible with traditional cutting methods. This level of precision not only enhances the quality of finished products but also significantly reduces material waste.

Importance of CNC Laser Cutter Technology

CNC (Computer Numerical Control) technology revolutionizes how we approach cutting and engraving tasks. With a CNC laser cutter, operators can program complex designs into the machine, ensuring consistent results across each piece produced. The integration of this technology into metal cutting laser cutters has transformed industries by allowing for rapid prototyping and high-volume production without sacrificing quality.

Tolerances and Their Impact on Production

Tolerances are another critical aspect when it comes to precision in manufacturing processes. In the context of a laser CNC machine, even minor deviations can lead to significant issues down the line, affecting everything from assembly to functionality. Understanding how tolerances impact production allows businesses to optimize their processes; using a CO2 laser machine can help maintain tighter tolerances compared to traditional methods.

Features That Enhance Cutting Precision

Several features contribute to enhancing the precision of a laser cutting machine, making it an indispensable tool for manufacturers today. Advanced optics in CO2 machines and high-quality beam control systems ensure clean cuts with minimal kerf width—essential for intricate designs and tight tolerances. Additionally, features like automatic height adjustment in modern metal cutting laser cutters provide real-time feedback during operation, further improving accuracy while reducing operator error.

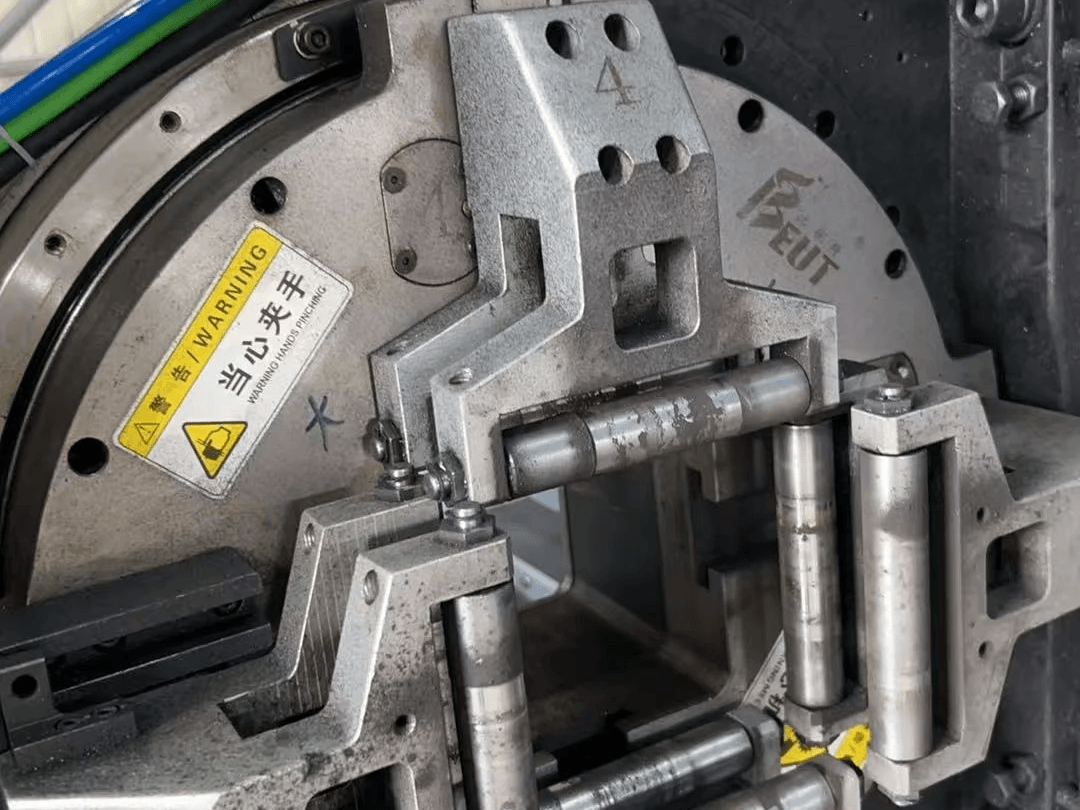

Versatility in Material Handling

Adapting to Different Materials with Laser CNC Machines

Laser CNC machines are designed to handle a diverse array of materials thanks to their advanced technology. From delicate fabrics to robust metals, a CO2 laser machine or fiber laser cutter can be configured for optimal performance across different substrates. This adaptability not only broadens your production capabilities but also allows for creative applications that might otherwise be challenging.

In addition, modern laser cutting machines often come equipped with specialized settings for different materials, allowing operators to switch between tasks seamlessly. This means you can go from cutting intricate designs in acrylics to slicing through thick sheets of metal without missing a beat. Ultimately, investing in a versatile laser cutting machine enhances productivity and opens new avenues for innovation.

Metal Cutting Laser Cutter vs. Non-Metal Applications

When comparing metal cutting laser cutters with those designed for non-metal applications, it's essential to consider the specific needs of your projects. Metal cutting requires higher power levels and more robust components due to the density and thickness of materials involved; thus, a dedicated metal cutting laser cutter is often necessary for optimal results. On the other hand, CO2 machines excel at handling softer materials like wood and plastics.

However, many advanced CNC laser cutters are capable of multitasking between metal and non-metal applications by adjusting settings accordingly. This flexibility allows businesses to maximize their investment by using one machine for multiple purposes instead of purchasing separate units for each material type. It's this kind of versatility that makes choosing the right equipment pivotal in streamlining operations.

The Role of Material Thickness in Selection

Material thickness plays a crucial role when selecting your ideal Laser Cutting Machine or CNC setup. Thicker materials generally require more powerful lasers—like those found in high-end metal cutting laser cutters—to achieve clean cuts without compromising quality or speed. Conversely, thinner materials may benefit from less intense lasers like CO2 machines that provide precision without excessive power consumption.

Understanding how material thickness affects performance can save time and resources during production processes; it ensures that you choose the best tools tailored specifically for your needs while avoiding costly mistakes later on. Moreover, manufacturers often provide guidelines on optimal thickness ranges based on their equipment's capabilities—making it easier than ever to make informed decisions when purchasing a new machine or upgrading an existing one.

User-Friendly Operation

In the fast-paced world of fabrication, user-friendly operation is crucial for maximizing productivity and minimizing downtime. The right laser cutting machine can significantly enhance the user experience, making it easier for operators to achieve precise results without a steep learning curve. With advancements in technology, modern CO2 machines are designed with intuitive interfaces that cater to both novices and seasoned professionals alike.

Intuitive Interfaces of Modern CO2 Machines

Today's CO2 laser cutters come equipped with intuitive interfaces that streamline the cutting process. These user-centric designs often feature touchscreen controls, which allow operators to easily navigate settings and make adjustments on the fly. By simplifying operations, these interfaces reduce the chances of errors, ensuring that your metal cutting laser cutter delivers consistent results every time.

Moreover, many CO2 machines incorporate visual aids and guided workflows that help users understand complex functionalities without extensive training. This means less time fumbling around with buttons and more time focusing on what truly matters—achieving high-quality cuts with your laser CNC machine. Ultimately, an intuitive interface transforms even the most intricate tasks into manageable steps.

Software Compatibility and Workflow Integration

The effectiveness of a laser cutting machine is not solely dependent on its hardware; software compatibility plays a pivotal role as well. Modern CNC laser cutters are designed to integrate seamlessly with various design software programs, enabling users to transition from design to production effortlessly. Whether you're using CAD software or specialized applications for engraving or marking, having compatible tools enhances workflow efficiency.

Additionally, many manufacturers offer proprietary software solutions tailored specifically for their CO2 machines. This ensures that users can maximize their equipment's potential while maintaining consistency across projects—an essential factor when working with intricate designs or batch production processes. With effective software integration, you can transform your ideas into reality faster than ever before.

Training Support from Manufacturers like Kiant Machinery

Even with advanced technology at your fingertips, having access to quality training support is invaluable when operating a sophisticated laser CNC machine. Leading manufacturers like Kiant Machinery provide comprehensive training programs designed to equip users with essential skills needed for effective operation and maintenance of their equipment. These resources can range from online tutorials to hands-on workshops led by experienced technicians.

Moreover, ongoing support ensures that users remain confident in utilizing their metal cutting laser cutter efficiently over time—an investment in knowledge pays dividends in productivity and safety alike! With adequate training from reputable sources, operators can troubleshoot issues independently and optimize their workflow without constant reliance on external assistance.

In conclusion, investing in a user-friendly operation through intuitive interfaces, robust software compatibility, and comprehensive training support will pay off immensely when using any quality laser cutting machine on the market today.

Durability and Build Quality

A robustly constructed machine not only ensures longevity but also enhances performance under various operational conditions. Choosing a high-quality CNC laser cutter means you're opting for a machine that will withstand the rigors of daily use while maintaining precision and efficiency.

Construction Materials of High-Quality Laser Cutters

The construction materials used in high-quality laser cutting machines significantly impact their performance and lifespan. Typically, premium CO2 laser cutters are made from heavy-duty metals like steel and aluminum, which provide stability and reduce vibrations during operation. This is crucial for achieving the exact tolerances required for intricate designs, especially when using a metal cutting laser cutter that demands precision.

In contrast, lower-quality machines might utilize cheaper plastics or lightweight materials that can compromise durability and accuracy over time. Investing in a solidly built CO2 machine laser means you’re less likely to face frequent breakdowns or maintenance issues down the line. Ultimately, the right construction materials not only enhance the machine's life span but also ensure consistent performance with every cut.

Impact of Design on Performance

The design of a laser CNC machine plays an integral role in its overall performance capabilities. Machines designed with user-friendly layouts often feature better airflow management, which is essential for cooling components during prolonged use—especially in high-demand environments like metal fabrication shops. An efficient design can also minimize wear on parts, extending the lifespan of both the CO2 laser machine itself and its components.

Moreover, thoughtful engineering translates into ease of operation; operators can navigate settings more intuitively when controls are logically placed within reach. When considering a purchase, remember that aesthetics matter too; a well-designed machine not only looks good but functions better under pressure while maintaining accuracy across various applications—from delicate engraving to robust metal cutting tasks.

Choosing Reliable Brands for Long-Term Use

Selecting reliable brands when investing in a CO2 laser cutter is crucial for ensuring long-term satisfaction and performance consistency. Renowned manufacturers often have established reputations based on years of innovation and customer service excellence—look out for brands known for producing some of the best laser marking machines on the market today! These companies typically offer comprehensive warranties as well as ongoing support that makes troubleshooting easier down the road.

Additionally, consider brands that have garnered positive reviews from users who’ve tested their machines across different applications—this real-world feedback can guide you toward making an informed choice about your next CNC laser cutter purchase. Remember: investing in quality now will save you time, money, and headaches later on!

Conclusion

In the world of fabrication, investing in a quality laser cutting machine is akin to buying a Swiss Army knife for your workshop—it’s versatile, efficient, and pays off in the long run. A well-chosen CNC laser cutter can elevate your production capabilities, ensuring that you not only meet but exceed industry standards. Remember, quality is not just about the initial purchase; it's about longevity and consistent performance that keeps your operations running smoothly.

Why Investing in Quality Matters

When it comes to laser cutting machines, quality truly matters. A high-quality CO2 laser cutter or fiber laser machine can significantly improve your production speed and accuracy while reducing the frequency of maintenance issues. Opting for a reliable metal cutting laser cutter ensures that you’ll produce clean cuts with minimal waste—saving both time and resources.

How Features Influence Cost Efficiency

The features of a laser CNC machine directly impact its cost efficiency over time. Investing in advanced technology like a CO2 machine laser or a best laser marking machine may seem pricey upfront but will save you money through reduced operational costs and increased productivity. The right features—such as precision control and material versatility—ensure that every dollar spent translates into tangible benefits for your business.

Making the Right Choice for Your Needs

Choosing the right laser cutting machine requires careful consideration of your specific needs and applications. Whether you're leaning towards a powerful CO2 laser cutter or exploring options for non-metal materials, understanding what each type offers will guide your decision-making process effectively. Take the time to evaluate brands known for durability and customer support; after all, investing wisely now means reaping rewards later on.