Introduction

In the ever-evolving world of manufacturing, fiber laser tube cutters have emerged as a game-changer in the realm of metal processing. These machines offer unparalleled precision and efficiency, making them an essential investment for businesses looking to stay competitive. This introduction will delve into the best options available, explore why investing in a tube laser cutting machine is a smart move, and highlight the numerous benefits that come with this advanced technology.

Explore the Best Fiber Laser Tube Cutters

From high-speed cutting capabilities to advanced automation features, there’s a plethora of choices tailored for diverse industrial needs. By exploring the best fiber laser tube cutters, businesses can discover machines that not only cut metal with precision but also deliver long-term value at competitive tube laser cutting machine prices.

Why Invest in a Tube Laser Cutting Machine

Investing in a tube laser cutting machine can drastically enhance production efficiency and reduce operational costs. With their ability to handle various materials and complex geometries, these machines are ideal for industries ranging from automotive to aerospace. Moreover, as companies seek to optimize their manufacturing processes, choosing a reliable metal cutting machine becomes crucial for maintaining quality while meeting market demands.

Understanding Tube Laser Cutting Benefits

The benefits of using a metal cutting laser cutter extend beyond mere speed; they encompass quality and versatility as well. For instance, these machines produce clean cuts with minimal waste, which translates into cost savings over time. Additionally, understanding how these technologies work enables businesses to utilize them effectively—transforming how they approach projects involving intricate designs or large-scale production runs.

Overview of Fiber Laser Tube Cutting Machines

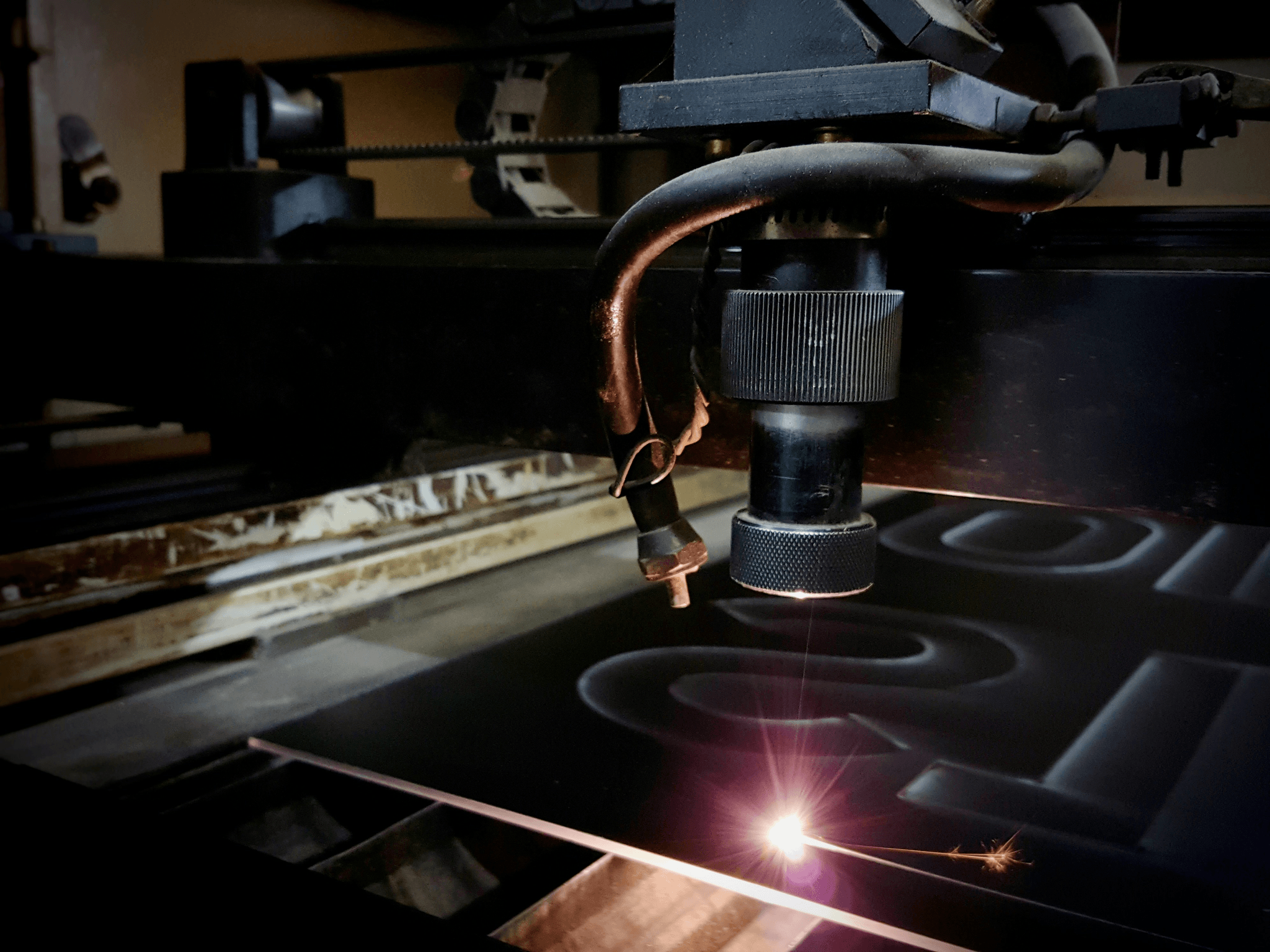

Fiber laser tube cutting machines are revolutionizing the way industries approach metal fabrication. These machines utilize a high-powered fiber laser to cut through various types of metal tubes with precision and speed, making them an essential tool in modern manufacturing. The efficiency and accuracy of these machines mean that businesses can produce intricate designs and complex shapes without compromising on quality.

What is a Fiber Laser Tube Cutting Machine

A fiber laser tube cutting machine is a specialized piece of equipment designed to cut metal tubes using advanced fiber laser technology. Unlike traditional methods, this machine employs a concentrated beam of light that can be focused on the material, allowing for clean and precise cuts. With capabilities to handle various materials such as stainless steel, aluminum, and carbon steel, it serves as a versatile solution for fabricators looking to enhance their production capabilities.

Key Features of Modern Laser Cutters

Modern laser cutters come packed with features that set them apart from older models or alternative cutting methods. One significant advantage is their ability to operate at high speeds while maintaining exceptional accuracy—this directly impacts the overall productivity and efficiency of any metal cutting operation. Additionally, many machines are equipped with automated loading systems and advanced software that streamline the process from design to finished product, reducing labor costs associated with manual operations.

Applications in Various Industries

The applications for fiber laser tube cutting machines are vast and varied across multiple industries. From automotive manufacturers needing precise cuts for exhaust systems to furniture makers creating intricate designs in metal tubing, these machines cater to numerous sectors requiring high-quality metal components. Moreover, industries such as aerospace and construction also benefit from the enhanced capabilities provided by these powerful metal machine cutters—making them invaluable assets in today’s competitive market.

Top Brands in Fiber Laser Tube Cutting

These manufacturers have established themselves as leaders in the industry by offering advanced technology that meets the diverse needs of metal fabrication. In this section, we’ll explore three top brands: Kiant Machinery, Trumpf, and BYSTRONIC.

Kiant Machinery: Industry Leader

Kiant Machinery has carved out a reputation as an industry leader in the realm of tube laser cutting machines. Their machines are known for combining robust performance with user-friendly interfaces, making them ideal for both seasoned professionals and newcomers to metal cutting. With competitive tube laser cutting machine prices, Kiant ensures that businesses of all sizes can access high-quality equipment without breaking the bank.

One of the standout features of Kiant’s offerings is their ability to machine cut metal with remarkable speed and accuracy. This efficiency translates into reduced operational costs and increased productivity for manufacturers seeking to optimize their workflow. Additionally, their commitment to after-sales support means customers can rely on expert assistance whenever needed.

Key Factors Influencing Tube Laser Cutting Machine Price

When it comes to investing in a tube laser cutting machine, understanding the price dynamics is crucial. Various factors contribute to the overall cost, from equipment specifications to brand reputation and market trends. By dissecting these elements, potential buyers can make informed decisions that align with their budget and production needs.

Equipment Specifications and Functionality

The specifications of a metal cutting machine are paramount in determining its price. Machines designed for high precision or those equipped with advanced features like automatic loading systems tend to command higher prices due to their enhanced functionality. Moreover, if you require a laser cutter for metal that can handle thicker materials or intricate designs, expect the tube laser cutting machine price to reflect those capabilities.

Functionality also plays a significant role; machines that offer versatile cutting options or faster processing times will generally be more expensive than basic models. Additionally, consider the power output of the laser; higher wattage typically means higher costs but can lead to increased efficiency and productivity in your operations. Thus, when evaluating equipment specifications, keep in mind how they align with your specific metal cutting needs.

Brand Reputation and Service Offerings

The brand behind your chosen metal machine cutter significantly impacts its price point as well as its overall value proposition. Established brands like Kiant Machinery and Trumpf often charge a premium due to their reputation for reliability and quality service offerings. Investing in a reputable brand ensures not just superior performance but also access to robust after-sales support, which can save you money down the line on repairs or maintenance.

Moreover, consider what warranties and service packages are included with your purchase; these offerings can vary widely among manufacturers and influence long-term operational costs associated with your laser cutter for metal. A strong support network often translates into less downtime—an essential factor when calculating the total cost of ownership for any tube laser cutting machine price you encounter.

Market Trends and Demand Analysis

Market trends play an undeniable role in shaping tube laser cutting machine prices as well. As industries increasingly adopt automation technologies, demand for advanced metal cutting laser cutters has surged, driving up prices across the board. Keeping an eye on these trends helps businesses plan their investments strategically; waiting too long might mean paying considerably more later on.

Additionally, fluctuations in raw material costs can impact manufacturing expenses for these machines, which may ultimately be passed on to consumers through higher prices. Therefore, staying informed about market conditions not only aids in budgeting but also enables companies to seize opportunities when prices dip or new technologies emerge that enhance productivity without breaking the bank.

Comparison of Laser Cutting Technologies

When it comes to laser cutting technologies, two prominent contenders often come to mind: fiber and CO2 laser cutting. Each technology has its own set of advantages and drawbacks, making it essential for businesses to understand which one aligns best with their specific needs. In this section, we’ll explore the differences between these two systems, the benefits of metal cutting laser cutters, and how to choose the right technology for your operations.

Fiber vs. CO2 Laser Cutting

Fiber laser cutting machines utilize a solid-state laser source that generates a highly concentrated beam of light through optical fibers. This results in faster cutting speeds and greater efficiency compared to traditional CO2 lasers, which rely on gas systems that can be bulkier and less energy-efficient. The tube laser cutting machine price also tends to reflect these differences; fiber lasers generally offer lower operating costs over time due to their energy efficiency and minimal maintenance requirements.

On the other hand, CO2 lasers excel at cutting non-metal materials such as plastics or wood but struggle with thicker metals compared to their fiber counterparts. This makes fiber lasers more versatile in industries where metal is a primary material for production. Businesses looking for a metal machine cutter will find that fiber technology offers superior performance when it comes to precision cuts on various types of metals.

Ultimately, the choice between fiber and CO2 comes down to your specific applications and materials involved in your projects. For those focused primarily on metal fabrication, investing in a fiber tube laser cutter can lead to significant long-term savings while ensuring high-quality results every time.

Benefits of Metal Cutting Laser Cutters

Metal cutting laser cutters have revolutionized the way manufacturers approach fabrication tasks by providing unparalleled precision and speed. One major benefit is their ability to produce intricate designs with minimal waste; this is particularly important when considering tube laser cutting machine price since reduced material waste directly contributes to cost savings over time. Furthermore, these machines can handle various thicknesses and types of metals without compromising quality.

Another significant advantage is flexibility; modern metal machine cutters can easily switch between different materials or configurations without requiring extensive retooling or downtime—ideal for businesses that operate on tight schedules or need rapid prototyping capabilities. With advancements in technology, many laser cutters now come equipped with automated features that enhance productivity even further by minimizing manual intervention during operations.

Lastly, investing in a high-quality metal cutting laser cutter not only boosts efficiency but also improves workplace safety by minimizing hazardous processes associated with traditional machining methods like sawing or grinding. As industries continue embracing automation and precision engineering techniques, it’s clear why these machines are becoming indispensable tools across various sectors.

How to Choose the Right Technology

Selecting the right technology for your business involves assessing several key factors tailored specifically toward your production needs and budget constraints—particularly when considering tube laser cutting machine price options available on the market today! Start by evaluating what materials you’ll primarily be working with; if you’re mostly dealing with metals (especially thicker varieties), then opting for a fiber-based solution would likely yield better results than other alternatives.

Next up: production volume! If you anticipate high demand or rapid turnaround times, investing in advanced features such as automated loading/unloading systems may prove beneficial down the line as they can significantly reduce cycle times associated with manual handling processes typically encountered during operation phases involving traditional methods like plasma or oxy-fuel setups.

Lastly—and perhaps most importantly—consider after-sales support from manufacturers before making any commitments regarding purchases! Reliable service offerings ensure not only smooth installation but also ongoing maintenance assistance whenever needed so that your investment remains productive long into its life cycle while keeping operational disruptions at bay!

Tips for Selecting the Right Metal Cutting Machine

Choosing the right metal cutting machine can feel like searching for a needle in a haystack, especially with so many options available. However, by honing in on your specific needs and understanding key factors, you can streamline your decision-making process. Here are some essential tips to help you navigate the world of laser cutters for metal.

Assess Your Production Needs

Before diving into the world of tube laser cutting machines, it's crucial to assess your production requirements. Consider factors such as material types, thicknesses, and the volume of work you expect to handle. Understanding these specifics will guide you toward selecting a machine that not only meets your current demands but also has the capacity to grow with your business.

Additionally, think about the complexity of designs you'll be cutting. If you're frequently working with intricate patterns or high precision cuts, investing in a higher-end metal machine cutter might be necessary. By clearly defining your production needs upfront, you can avoid overspending on features you'll never use or under-investing in capabilities that could enhance efficiency.

Budgeting for Your Laser Cutter Investment

Include costs related to installation, maintenance, and any additional software or accessories that may be required for optimal operation. Remember that while cheaper options may seem appealing at first glance, they could lead to higher long-term expenses due to inefficiencies or breakdowns.

It's also wise to consider financing options if you're looking at more expensive models—many manufacturers offer attractive payment plans that make investing in quality equipment more manageable. Keep an eye on tube laser cutting machine prices across different brands and models; this will give you insight into what features are worth splurging on versus those that might not add significant value.

Importance of After-Sales Support

After-sales support is often overlooked but is critical when selecting a metal cutting laser cutter that suits your operations best. Having reliable customer service means you'll have access to assistance if something goes awry during operation or if maintenance issues arise down the road—both scenarios can impact productivity significantly if not handled promptly.

Consider companies known for their robust after-sales support programs; warranties and service contracts can save you from unexpected costs down the line while ensuring minimal downtime should problems occur with your machine cut metal processes. Ultimately, investing in a brand with strong after-sales support can provide peace of mind as you embark on your journey into advanced tube laser cutting technology.

Conclusion

In the fast-paced world of manufacturing, maximizing efficiency with laser technology is not just a luxury—it's a necessity. The advancements in tube laser cutting machines have revolutionized how industries approach metal cutting, allowing for higher precision and reduced waste. Investing in a high-quality laser cutter for metal can significantly enhance production capabilities, making it a wise choice for businesses aiming to stay competitive.

Maximizing Efficiency with Laser Technology

Laser cutting has emerged as one of the most efficient methods for machine cut metal applications. With their ability to produce intricate designs and clean edges, metal cutting laser cutters save time and resources compared to traditional methods. By adopting these technologies, companies can streamline operations and boost overall productivity while keeping an eye on tube laser cutting machine price.

Selecting Ideal Equipment for Your Operations

Choosing the right metal machine cutter involves careful consideration of your specific production needs and budget constraints. It's essential to evaluate the features of different models and how they align with your operational goals. Additionally, understanding the long-term benefits associated with investing in a quality laser cutter for metal can lead to significant savings down the line.

Future Trends in Tube Laser Cutting Machines

The future of tube laser cutting machines looks promising, with innovations continuously emerging that enhance functionality and reduce costs. As manufacturers push for greater efficiency, we can expect more advanced features such as automation and AI integration in these systems. Keeping an eye on market trends will help businesses adapt quickly to changes in technology while staying informed about fluctuations in tube laser cutting machine price.