Introduction

In the realm of modern manufacturing, tube laser cutting technology has emerged as a game-changer, revolutionizing how industries approach metal fabrication. This innovative method utilizes a fiber laser tube cutting machine to achieve unparalleled precision and efficiency in cutting various materials. As businesses strive for higher productivity and quality, the adoption of laser machinery is becoming increasingly prevalent.

Overview of Tube Laser Cutting Technology

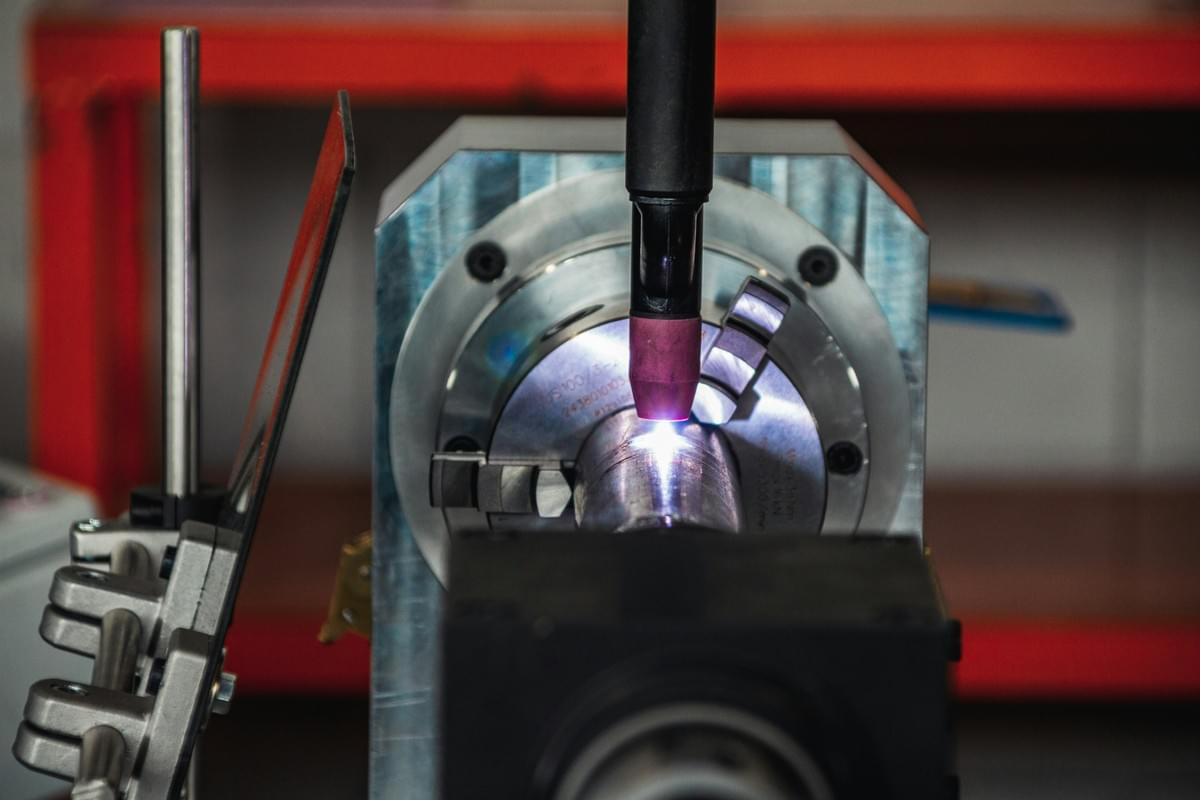

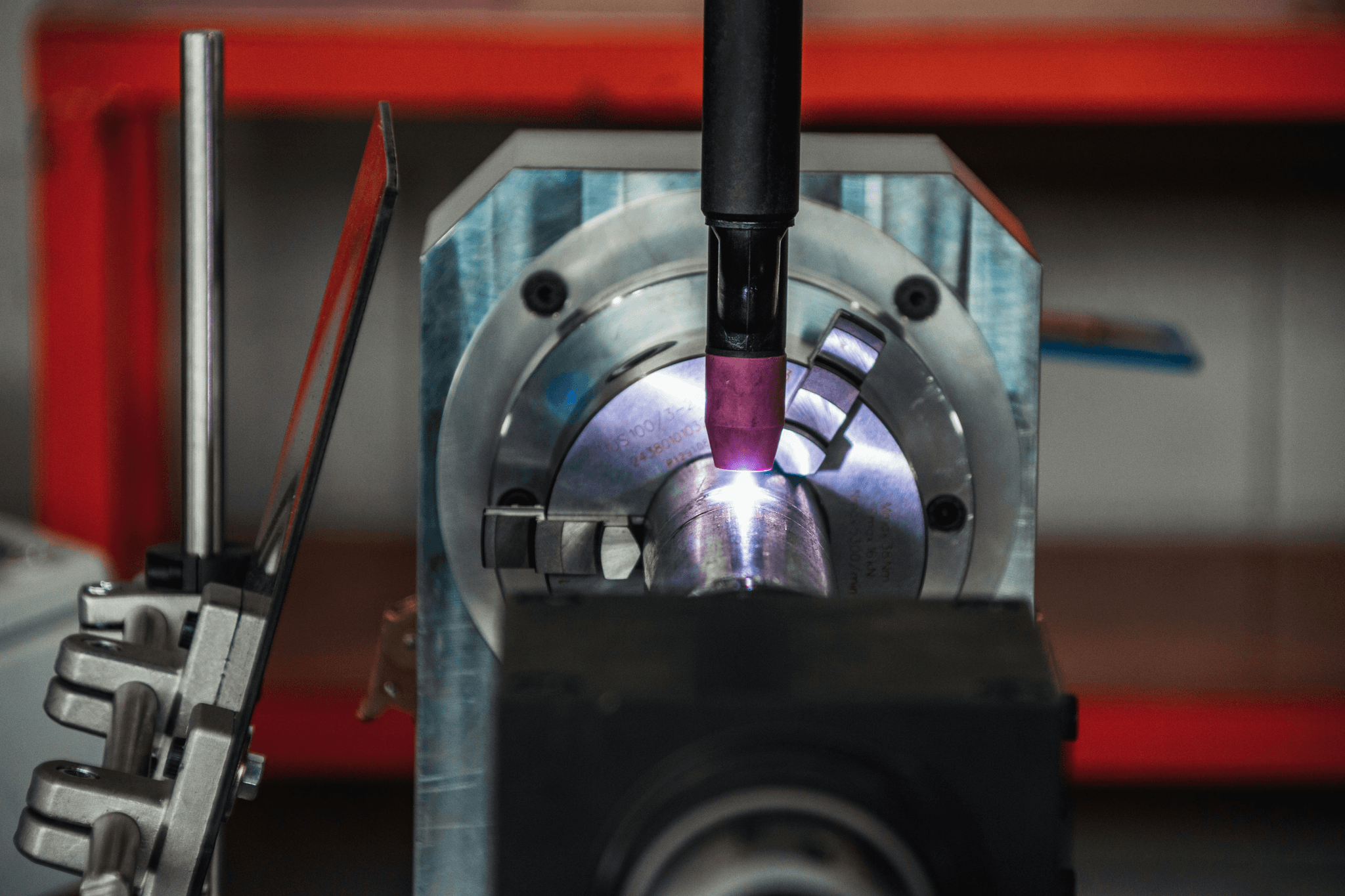

Tube laser cutting technology employs highly focused beams of light to slice through metal with remarkable accuracy. Unlike traditional methods, which often rely on mechanical processes, this cutting machine laser harnesses the power of fiber optics to deliver consistent results across different material types and thicknesses. The ability to cut intricate shapes and designs makes it an invaluable tool for sectors ranging from automotive to aerospace.

Benefits of Using Fiber Laser Machines

The benefits of using fiber laser machines are numerous and compelling. First and foremost, they offer exceptional precision in cuts, allowing manufacturers to produce complex geometries without compromising quality. Additionally, these cutting laser metal systems are remarkably versatile; they can handle a wide range of materials including steel, aluminum, and even plastics with ease—making them ideal for diverse applications.

The Market for Tube Laser Machines

As demand for efficient manufacturing solutions grows, so does the market for tube laser machines. Companies are increasingly investing in advanced laser cutting technologies to stay competitive in an ever-evolving landscape. This surge in interest not only highlights the effectiveness of fiber laser tube cutting machines but also indicates a promising future for innovations within the sector.

What is a Fiber Laser Tube Cutting Machine?

In the world of modern manufacturing, the fiber laser tube cutting machine stands out as a game-changer. This advanced laser cutting technology utilizes high-powered fiber lasers to achieve precise cuts in various materials, particularly metals. With its ability to handle complex shapes and intricate designs, this cutting machine laser has become essential for industries ranging from automotive to aerospace.

Definitions and Key Features

A fiber laser tube cutting machine is designed specifically for cutting tubular materials with remarkable accuracy and speed. Its key features include a robust laser source that generates a concentrated beam of light, which can be finely focused on the material being cut. Additionally, these machines often come equipped with advanced software for programming intricate designs, making them versatile tools in industrial settings.

One standout feature of these laser machines is their ability to cut through various materials such as stainless steel, aluminum, and carbon steel with ease. The precision offered by a cutting laser metal ensures that even the most delicate designs can be executed flawlessly. This level of detail not only enhances product quality but also reduces waste during manufacturing processes.

How It Differs from Traditional Cutting Methods

When comparing a fiber laser tube cutting machine to traditional cutting methods like plasma or oxy-fuel cutting, several differences emerge that highlight its advantages. Traditional methods often struggle with achieving the same level of precision; they may produce rough edges or require additional finishing work after the initial cut. In contrast, the smooth finishes achieved by laser machinery eliminate many post-processing steps.

Moreover, traditional methods typically involve more extensive setup times and can be limited in terms of material thickness they can handle efficiently. On the other hand, a laser cutting machine offers flexibility across varying thicknesses and shapes without compromising speed or quality. This efficiency translates into lower operational costs and faster turnaround times for manufacturers looking to stay competitive.

Applications Across Industries

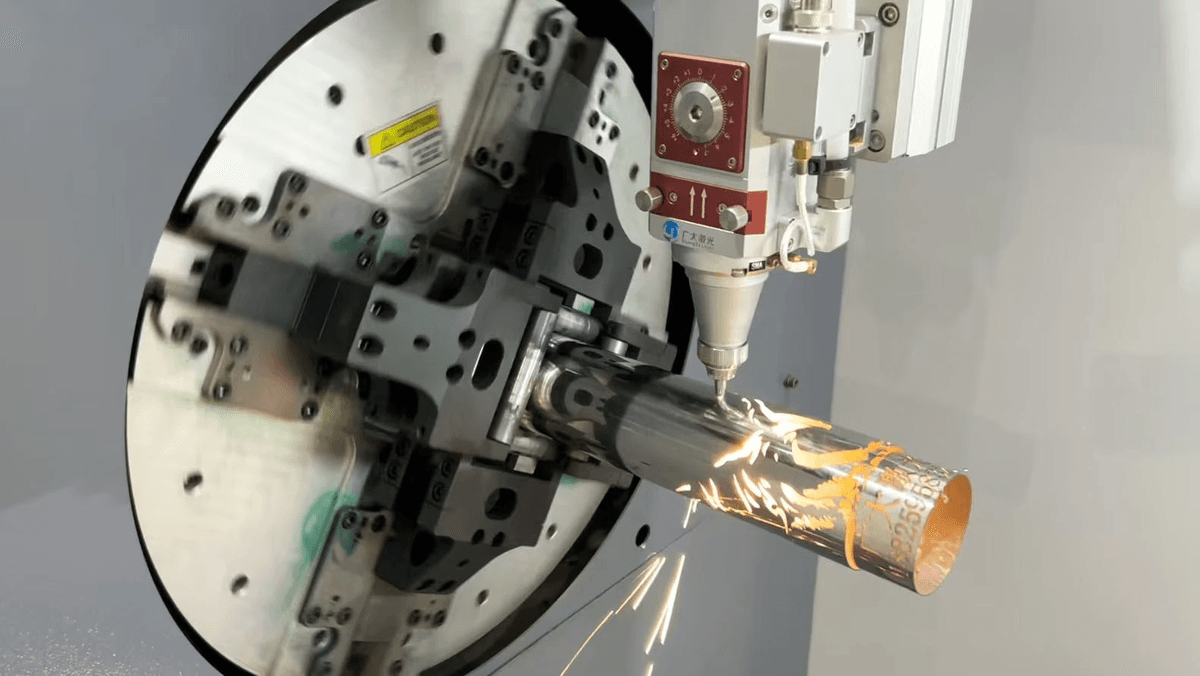

The applications of fiber laser tube cutting machines are vast and varied across multiple industries. In automotive manufacturing, these machines are used to create components such as exhaust systems and chassis parts with high precision—ensuring safety and performance standards are met consistently. Similarly, in the aerospace sector, where weight reduction is critical, these machines help produce lightweight yet strong components essential for flight safety.

Beyond automotive and aerospace applications, industries such as construction utilize these advanced cutting machines for fabricating structural elements like beams and supports made from metal tubing. Additionally, furniture design has embraced fiber lasers for creating intricate patterns on metal surfaces that enhance aesthetic appeal while maintaining structural integrity—proving that creativity knows no bounds when combined with technology.

Advantages of Tube Laser Machines

Precision and Accuracy in Cuts

One of the most significant benefits of a fiber laser tube cutting machine is its unparalleled precision and accuracy. Unlike traditional cutting methods that can leave rough edges or require extensive finishing work, laser cutting delivers clean, precise cuts consistently. This level of accuracy not only enhances product quality but also reduces material waste, making your operations more efficient.

The advanced optics and control systems in a cutting machine laser allow for intricate designs and complex geometries that would be challenging to achieve with conventional methods. Whether you're working with thin-walled tubes or thicker materials, the precision offered by laser machinery ensures that every cut meets exact specifications. This means less time spent on rework or adjustments, allowing manufacturers to focus on what truly matters: delivering high-quality products on time.

Versatility in Material Types

Another standout feature of tube laser machines is their versatility when it comes to material types. These powerful machines can cut through a wide range of materials including steel, aluminum, brass, and even plastics with ease. This flexibility allows businesses to take on diverse projects without needing multiple specialized machines.

Additionally, the ability to handle different thicknesses and shapes makes fiber laser tube cutting machines suitable for various applications across industries such as automotive, aerospace, construction, and furniture design. The adaptability of these systems streamlines production processes by reducing the need for multiple setups or equipment changes when switching between materials or designs. As a result, manufacturers can respond quickly to market demands while maintaining high standards of quality.

Efficiency in Production Processes

Efficiency is key in any manufacturing environment, and tube laser machines excel at optimizing production processes. The speed at which these cutting lasers operate significantly reduces cycle times compared to traditional methods like plasma or mechanical cutting systems. With faster processing speeds combined with minimal setup times for different jobs, companies can increase throughput without sacrificing quality.

Moreover, automation features integrated into many fiber laser tube cutting machines further enhance operational efficiency by minimizing manual intervention during production runs. This not only speeds up operations but also reduces labor costs associated with manual handling and adjustments on older machinery models. By investing in a state-of-the-art cutting machine laser system from reputable brands like Kiant Machinery, businesses position themselves for growth while maximizing their return on investment.

Key Players in the Market

In the rapidly evolving landscape of laser cutting technology, several key players stand out, each contributing to advancements in fiber laser tube cutting machines and laser machinery. Among these companies, Kiant Machinery has established itself as a leader, offering innovative solutions that cater to diverse industrial needs. As the demand for precision and efficiency grows, understanding the offerings of these market leaders becomes crucial for businesses looking to invest in cutting-edge laser cutting machines.

Overview of Kiant Machinery

Kiant Machinery is renowned for its state-of-the-art fiber laser tube cutting machines that combine speed with exceptional precision. The company prides itself on its commitment to quality and innovation, ensuring that each laser machine is equipped with the latest technology for optimal performance. With a focus on customer satisfaction, Kiant Machinery provides tailored solutions that meet specific requirements across various industries.

The range of products offered by Kiant includes not only fiber laser tube cutting machines but also other advanced laser machinery designed for different applications. Their dedication to research and development allows them to stay ahead of industry trends while continuously improving their offerings. This proactive approach has made Kiant a trusted name among manufacturers seeking reliable and efficient cutting solutions.

Notable Competitors and Their Offerings

While Kiant Machinery leads the pack, several notable competitors also contribute significantly to the market for fiber laser tube cutting machines. Companies like Trumpf and Bystronic are recognized for their robust portfolios that include both traditional and innovative laser cutting technologies. These competitors offer a variety of models tailored to different production needs, ensuring there’s a suitable option for every manufacturer.

For instance, Trumpf specializes in high-performance industrial lasers that excel in precision metal fabrication tasks, while Bystronic focuses on integrating automation into their cutting systems for enhanced efficiency. Each competitor brings unique features and capabilities to their respective machines, making it essential for buyers to thoroughly compare specifications before making a decision on which cutting machine is best suited for their operations.

Innovations in Laser Cutting Technology

Innovation is at the heart of advancements in laser cutting technology, particularly within fiber laser tube cutting machines. Recent developments have introduced faster processing speeds and improved energy efficiency, allowing manufacturers to achieve more with less resource consumption during production processes. Moreover, enhancements in software integration have streamlined operations by enabling real-time monitoring and adjustments during cuts.

The advent of AI-driven technology has also transformed how businesses utilize their laser machinery; predictive maintenance tools can now anticipate potential issues before they arise—saving time and reducing downtime costs significantly. Furthermore, innovations such as 3D modeling capabilities allow users to visualize complex cuts before they are executed on metal surfaces using a cutting laser metal approach effectively.

As more companies embrace these technological advancements in their operations, it's clear that investing in modern equipment will be pivotal for maintaining competitiveness within various industries reliant on precise manufacturing processes.

Choosing the Right Machine for Your Needs

Selecting the perfect fiber laser tube cutting machine can feel like navigating a maze. With so many options and specifications, it’s crucial to understand what will best suit your unique production needs. Making an informed decision will not only enhance your efficiency but also ensure that you’re investing wisely in laser machinery.

Factors to Consider When Buying

When purchasing a cutting machine laser, several factors come into play. First, consider the types of materials you’ll be working with; different laser machines excel with various metals and thicknesses. Additionally, think about the volume of production required—some machines are designed for high-speed operations while others are better suited for precision cuts at lower volumes.

Another critical factor is the machine's power and speed capabilities, as these directly affect productivity and quality of cuts. Look for a fiber laser tube cutting machine that offers adjustable settings to accommodate diverse project requirements. Lastly, don’t overlook your budget; while it’s tempting to go for top-of-the-line models, there are plenty of cost-effective options that still deliver excellent performance in laser cutting.

Comparing Specifications and Capabilities

Once you’ve narrowed down your options based on key factors, it’s time to dive into comparing specifications and capabilities of various laser cutting machines. Pay close attention to wattage—higher wattage typically means faster cutting speeds but may not always be necessary depending on your projects. Also consider bed size; larger beds allow for bigger workpieces but may require more space in your facility.

Be sure to evaluate software compatibility as well; many modern cutting machines come equipped with advanced software that enhances user experience and precision in cuts. Take note of features like automatic height adjustment or integrated cooling systems—these can significantly improve operational efficiency and prolong the lifespan of your equipment. Ultimately, a thorough comparison will help you identify which machine aligns best with your specific needs.

The Role of After-Sales Support

After-sales support is an often-overlooked aspect when selecting a fiber laser tube cutting machine but is crucial for long-term satisfaction and performance. A reliable supplier should offer comprehensive support services including installation assistance, training programs, and readily available customer service representatives who can troubleshoot issues as they arise. This level of support ensures that you can maximize the potential of your new laser machinery without unnecessary downtime.

Additionally, inquire about warranty terms and maintenance plans offered by manufacturers; these can save you significant costs down the road if any repairs or adjustments are needed after purchase. A strong after-sales relationship not only provides peace of mind but also fosters ongoing collaboration as technology evolves—keeping you ahead in the competitive landscape of laser cutting metal.

Maintenance and Care for Optimal Performance

Maintaining your fiber laser tube cutting machine is crucial for ensuring optimal performance and longevity. Regular upkeep not only extends the life of the laser cutting machine but also enhances its efficiency, reducing downtime during production. By implementing best practices and being proactive about maintenance, you can keep your cutting laser metal operations running smoothly.

Best Practices for Machine Longevity

To ensure the longevity of your laser machinery, it's essential to establish a routine maintenance schedule. This includes regular cleaning of lenses and mirrors, which are vital for achieving precision cuts with the cutting machine laser. Additionally, checking for any signs of wear on components such as belts and gears can prevent costly repairs down the line.

Another key practice is to maintain proper alignment and calibration of the fiber laser tube cutting machine. Misalignment can lead to inaccuracies in cuts, wasting materials and time. Lastly, keeping an eye on software updates ensures that your laser cutting technology remains at the forefront of efficiency and innovation.

Common Issues and Solutions

Even with diligent care, issues may arise with your laser cutting machine from time to time. One common problem is inconsistent cut quality, which could be attributed to dirty optics or miscalibrated settings on the fiber laser tube cutting machine. Regularly cleaning optical components and recalibrating settings can often resolve these issues quickly.

Another frequent challenge involves overheating during extended operations; this can be mitigated by ensuring adequate cooling systems are in place and functioning correctly. If overheating persists despite cooling measures, it may indicate underlying mechanical problems that require further investigation. Identifying these common pitfalls early allows you to implement solutions swiftly before they escalate into more significant issues.

Importance of Professional Servicing

While regular maintenance can help keep your fiber laser tube cutting machine in top shape, professional servicing is invaluable for comprehensive care. Trained technicians possess specialized knowledge about complex systems within a laser machine that might go unnoticed by untrained eyes. Their expertise ensures that all aspects of the equipment are functioning optimally.

Moreover, professional servicing often includes advanced diagnostic checks that go beyond basic maintenance tasks—catching potential problems before they become major headaches for your production line. Investing in professional care not only safeguards your equipment but also enhances overall productivity by minimizing unexpected downtimes caused by mechanical failures.

In conclusion, taking proper care of your fiber laser tube cutting machine through best practices in maintenance will pay dividends in performance and longevity while addressing common issues promptly keeps operations running smoothly—professional servicing adds an extra layer of assurance that everything remains shipshape!

Conclusion

In the fast-evolving world of manufacturing, laser cutting technology has made significant strides. As industries continue to embrace automation and precision, the fiber laser tube cutting machine stands out as a game-changer. The future will likely see advancements in speed, efficiency, and versatility that will redefine how we approach cutting processes.

Future Trends in Laser Cutting Technology

The landscape of laser cutting is shifting towards greater integration with smart technologies and IoT capabilities. Expect to see more sophisticated cutting machines that leverage artificial intelligence for enhanced precision and real-time monitoring. Additionally, advancements in materials used for laser machinery will allow for even more diverse applications across various sectors.

Investing in Quality Equipment Matters

When it comes to manufacturing, investing in a high-quality laser cutting machine can make all the difference in productivity and output quality. A reliable fiber laser tube cutting machine not only improves efficiency but also reduces long-term operational costs due to lower maintenance needs and higher durability. Choosing a reputable brand ensures you get the best support and technology available on the market today.

How Kiant Machinery Can Help You Grow

Kiant Machinery is at the forefront of providing top-notch fiber laser tube cutting machines tailored to your specific needs. With their commitment to innovation and customer support, they empower businesses to optimize their production processes effectively. By partnering with Kiant Machinery, you’re not just buying a machine; you’re investing in your company’s growth and future success.