Introduction

When diving into the world of laser cutting machines, it's essential to first understand your specific cutting needs. Whether you're a hobbyist looking for a cheap laser cutter or an entrepreneur seeking an industrial laser cutter, knowing what you require will guide your decision-making process. Each application may demand different features and capabilities from a laser cutter machine, so clarity on your needs is key.

Understand Your Laser Cutting Needs

Different projects call for different types of laser cutters, which can range from compact models perfect for small workshops to robust industrial machines designed for high-volume production. It's important to assess what materials you will be working with and the complexity of the designs you intend to create with your cutting machine laser. By understanding these factors, you can narrow down the options that best fit your requirements.

Compare Different Laser Cutter Types

The market offers various types of laser cutter machines, each suited for particular applications and budgets. From CO2 lasers ideal for organic materials like wood and acrylic to fiber lasers that excel at cutting metal, knowing the differences can save you time and money in the long run. Comparing these types helps ensure that you're investing in a machine that aligns with both your current projects and future aspirations.

Identify Your Material Compatibility

Material compatibility is crucial when selecting a laser cutting machine; not all cutters work well with every type of material. Whether you're planning to cut plastics, metals, or textiles, it's vital to choose a laser cutter that can handle those materials effectively without compromising quality or efficiency. Understanding which materials are compatible with your chosen cutting machine laser will help avoid costly mistakes down the line.

Assess Your Budget for a Laser Cutting Machine

Finding Quality with a Cheap Laser Cutter

The market is flooded with cheap laser cutters, but finding one that delivers quality results is key. While affordability is important, you should never sacrifice performance for price; after all, what's the point of buying a cutting machine laser that can't cut straight? Researching user reviews and product specifications can help identify models that offer reliability without costing an arm and a leg.

Many manufacturers offer entry-level models that are surprisingly capable despite their lower price points. These cheap laser cutters often come equipped with essential features needed for small businesses or hobbyists without overwhelming complexity. Always remember that even if you're opting for a budget-friendly option, quality should still be your guiding star.

Investment vs. Cost-Effectiveness

Investing in a laser cutter isn't just about the upfront cost; it's also about understanding cost-effectiveness over time. A more expensive industrial laser cutter may seem daunting at first glance, but its efficiency and durability can yield significant savings down the line. By evaluating how often you'll use your cutting machine laser and what materials you'll work with, you can make an informed decision.

Consider how many projects you'll complete each month—this will give you insight into whether investing in higher-quality equipment pays off in productivity gains or reduced operational costs. Sometimes, spending more initially leads to fewer headaches later on as you avoid constant repairs or replacements associated with cheaper models. Ultimately, think of your purchase as an investment in your future capabilities rather than just an expense.

Total Cost of Ownership

The total cost of ownership (TCO) encompasses all expenses related to acquiring and operating your laser cutter over its lifespan—not just the purchase price alone. This includes maintenance costs, energy consumption, replacement parts, and any software required for optimal operation of your cutting machine laser. Understanding TCO allows you to evaluate which model truly fits within your financial framework.

When assessing TCO, don't forget to factor in potential downtime due to repairs or inefficiencies caused by low-quality machines—these can add up quickly! Additionally, look into warranty options and service agreements offered by manufacturers; they can significantly impact long-term expenses related to maintaining your equipment's performance over time. By keeping TCO at the forefront of your decision-making process, you'll ensure you're making a financially sound choice when selecting a laser cutting machine.

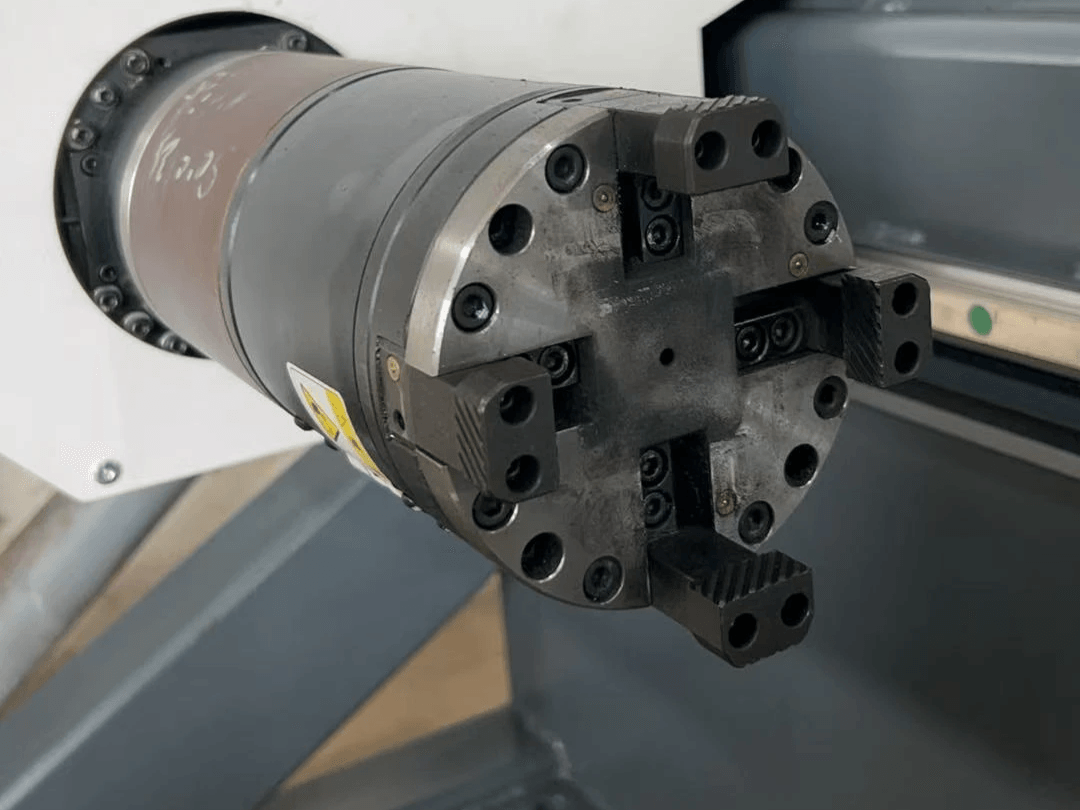

Evaluate Laser Cutter Sizes and Formats

When it comes to selecting a laser cutting machine, size matters more than you might think. Depending on your projects, the choice between a compact laser cutter and an industrial laser cutter can greatly impact your workflow and efficiency. Understanding the differences in sizes and formats will help you make an informed decision that suits your specific needs.

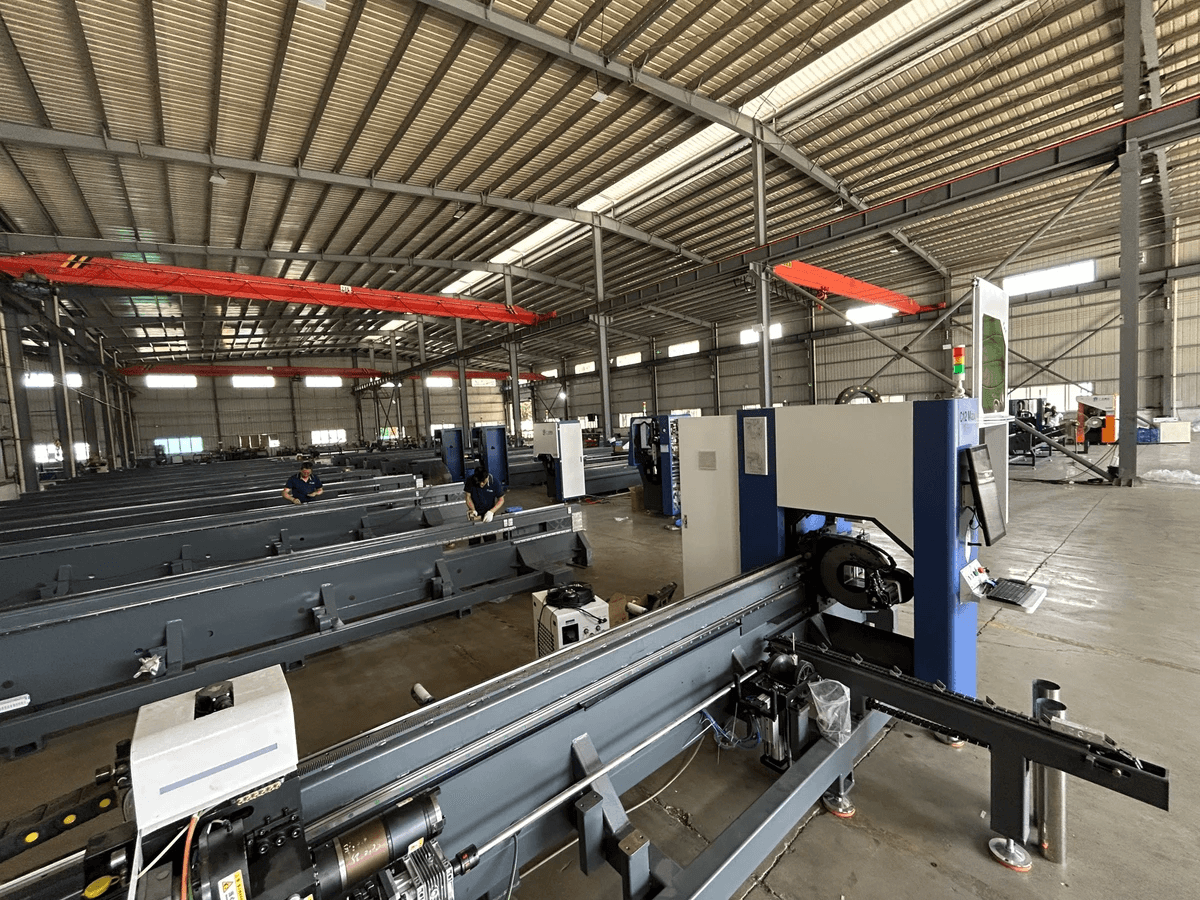

Compact vs. Industrial Laser Cutter

Compact laser cutters are perfect for small workshops or home-based businesses looking for a cheap laser cutter option without sacrificing quality. These machines offer versatility and can handle various materials, making them ideal for hobbyists or startups venturing into the world of laser cutting. On the other hand, industrial laser cutters are designed to tackle large-scale production with high speed and precision, catering to businesses that require heavy-duty performance.

Choosing between these two types of machines often boils down to your production volume and workspace availability. If you're just starting out or have limited space, a compact laser cutter may be your best bet; however, if you're in an industry that demands continuous operation with larger materials, investing in an industrial laser cutter could pay off significantly in the long run. Ultimately, consider how each option aligns with your current needs while keeping future growth in mind.

Workspace Considerations

Before purchasing a cutting machine laser, it’s essential to evaluate your workspace environment. The size of the machine should not only fit within your available area but also allow for safe operation and maintenance access around it. Proper ventilation is another crucial aspect; some lasers generate fumes or particles that need to be effectively managed during operation.

In addition to physical space, consider how the layout affects workflow efficiency as well as any additional equipment you may need alongside your new laser cutter machine. For instance, if you're using multiple machines for different processes—like engraving or finishing—you'll want enough room for seamless transitions between tasks without bottlenecks forming in production lines. A well-planned workspace ensures that you maximize productivity while minimizing potential hazards associated with operating powerful machinery.

Scalability for Future Needs

When investing in a new laser cutting machine, think about scalability—how well can it adapt to future demands? As businesses grow or change directions based on market trends or customer requests, having a flexible solution is vital for staying competitive without needing constant upgrades or replacements of machinery. Look for features like modular designs that allow easy upgrades in power output or additional functionalities when necessary.

Additionally, consider whether the chosen model can accommodate larger materials if demand increases over time; this foresight helps prevent costly disruptions down the line when you find yourself needing more capacity than initially anticipated from your cheap laser cutter purchase decision! Ultimately, selecting a scalable solution today means fewer headaches tomorrow as you navigate through evolving business landscapes.

Explore Laser Cutting Machine Technology

When diving into the world of laser cutting machines, understanding the technology behind them is crucial. The two primary types of laser cutters are CO2 and fiber laser cutting machines, each designed for specific applications and materials. Knowing the differences can help you make an informed decision about which cutting machine laser is right for your needs.

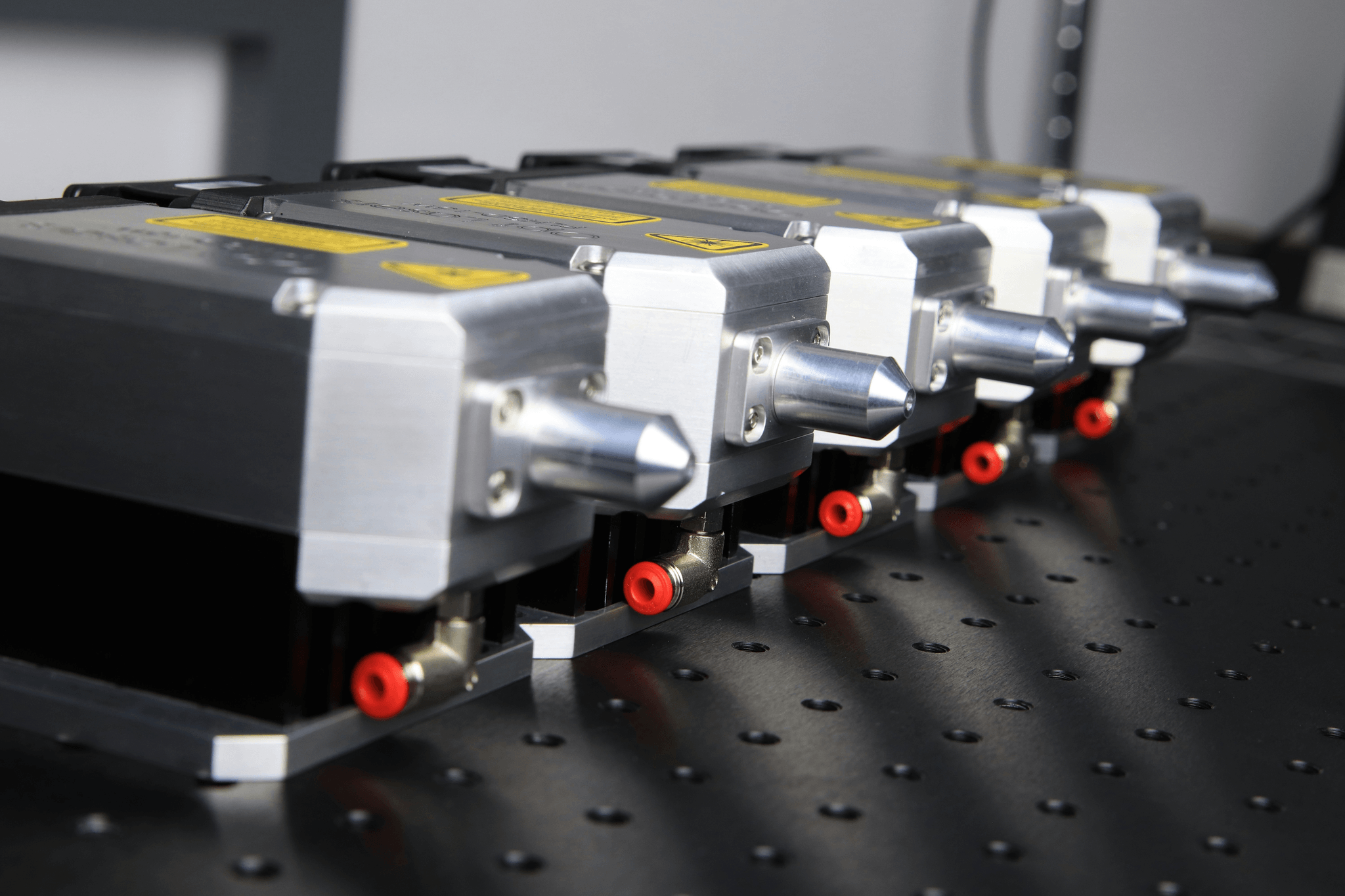

CO2 vs. Fiber Laser Cutting Machines

CO2 lasers are well-known for their versatility and ability to cut a wide range of materials, including wood, plastics, and textiles. They produce a longer wavelength that allows for effective absorption by non-metal materials, making them ideal for various industries. On the other hand, fiber laser cutting machines shine when it comes to processing metals; their shorter wavelength means they can cut through thicker sheets of steel or aluminum with exceptional precision.

If you're considering a cheap laser cutter for your workshop, CO2 models might be more budget-friendly upfront but may incur higher operational costs over time due to maintenance and consumables. Conversely, although fiber lasers typically require a larger initial investment, they often provide lower operating costs in the long run due to their efficiency and durability. Ultimately, assessing your specific applications will guide you toward the right choice between these two powerful technologies.

Advancements in Laser Technology

The landscape of laser technology is constantly evolving with innovations that enhance performance and efficiency in laser cutter machines. Recent advancements include improved beam quality and faster cutting speeds that significantly increase productivity while reducing energy consumption—an appealing feature for any industrial laser cutter user looking to optimize operations without breaking the bank on electricity bills! Additionally, automation features such as smart sensors have been integrated into modern laser machines to ensure precise cuts while minimizing human error.

These technological improvements not only boost performance but also expand capabilities; newer models can handle complex designs with ease thanks to advanced software integration that streamlines workflows from design to production. As you explore your options in purchasing a cutting machine laser, keep an eye out for these advancements—they can make all the difference in achieving high-quality results efficiently!

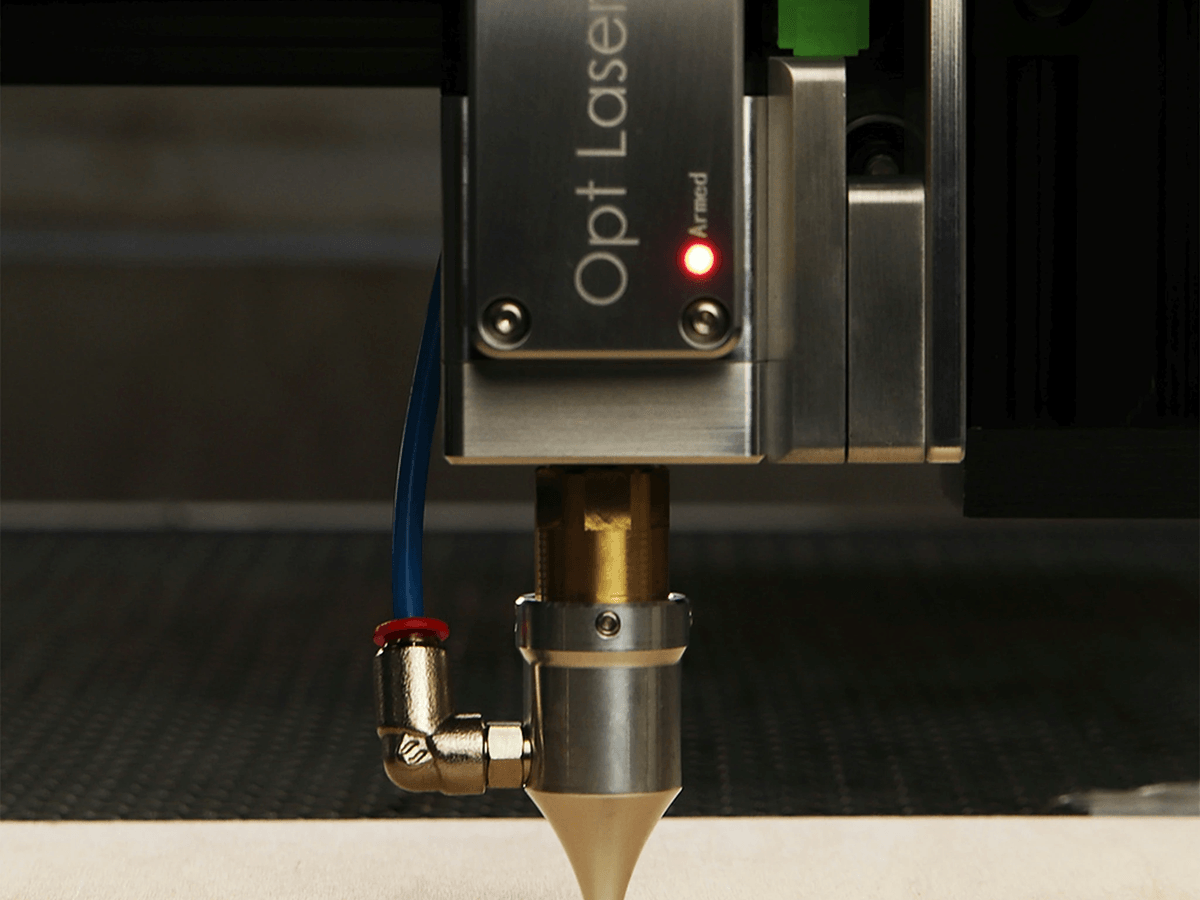

Choosing the Right Power Output

Selecting the appropriate power output for your laser cutter machine is essential based on what you'll be cutting most frequently. For instance, if you're primarily working with thin materials like paper or fabric, a lower wattage CO2 machine will suffice without overwhelming those delicate substrates—think around 30-50 watts here! However, if metalwork is your focus or if you plan on tackling thicker materials down the line, investing in a higher-wattage fiber laser (often upwards of 1000 watts) will give you both speed and precision.

It's also important to consider future scalability when choosing power output; opting for a more robust industrial laser cutter now could save you from needing an upgrade later as your business grows or diversifies its offerings. Don't forget: while it's tempting to go with cheaper options initially available on the market—ensure they meet not just current needs but future demands too!

Research Brand Reputation and Support

When diving into the world of laser cutting machines, brand reputation plays a crucial role in ensuring you make a wise investment. Manufacturers like Kiant Machinery have built a solid name in the industry by delivering reliable products and exceptional service. A trustworthy manufacturer not only provides quality laser cutter machines but also fosters confidence that your investment will stand the test of time.

Trustworthy Manufacturers Like Kiant Machinery

Kiant Machinery is renowned for its commitment to producing high-quality cutting machine lasers that cater to various needs, from hobbyists to industrial applications. Their range of products includes both compact and industrial laser cutters, ensuring there's something for everyone. When considering a cheap laser cutter, it's essential to look for established brands like Kiant that offer durability alongside affordability.

Importance of After-Sales Support

After purchasing your laser cutter machine, after-sales support becomes invaluable for smooth operation and longevity of your equipment. Quality manufacturers provide comprehensive support services, including troubleshooting assistance and access to replacement parts when needed. This kind of backing can be the difference between a minor hiccup and major downtime, especially if you're relying on an industrial laser cutter for business operations.

User Reviews and Industry Recommendations

User reviews are gold mines for insights into how well a particular laser cutting machine performs in real-world scenarios. Positive feedback from fellow users can guide you toward making informed decisions about which cutting machine laser will best suit your needs. Additionally, industry recommendations often highlight brands known for their reliability and customer satisfaction—key factors when investing in any machinery.

Consider Software Compatibility

When investing in a laser cutting machine, software compatibility is paramount. The efficiency of your cutting machine laser relies heavily on the software that drives it, ensuring seamless design-to-production workflows. A well-integrated system not only enhances productivity but also minimizes errors during the cutting process.

Essential CAD/CAM Software for Laser Cutters

To get the most out of your laser cutter machine, you'll want to invest in essential CAD/CAM software tailored for laser applications. Programs like AutoCAD, Adobe Illustrator, and CorelDRAW are popular choices that allow users to create intricate designs ready for the industrial laser cutter. Additionally, specialized software like LightBurn can provide advanced features specifically designed for controlling and optimizing your cutting machine laser.

Having the right software ensures that you can maximize the capabilities of your cheap laser cutter or high-end industrial models alike. It’s crucial to choose a solution that supports various file formats to accommodate different design needs. Ultimately, this investment in quality software will pay off by streamlining operations and enhancing creativity.

Integration with Existing Systems

Another key consideration is how well the new software integrates with your existing systems and processes. If you already have design tools in place, ensure that your chosen CAD/CAM software can communicate effectively with them; this will save time and reduce frustration as you adapt to using a new laser cutting machine. An integrated setup allows for smoother transitions between design creation and production stages.

Moreover, compatibility with other machinery or systems you might have is also vital—especially if you're running multiple types of equipment in tandem with your industrial laser cutter. The more cohesive your operation is, the less downtime you'll experience due to technical issues or troubleshooting problems related to incompatible systems.

User-Friendly Interfaces

Let’s face it: nobody wants to wrestle with complicated interfaces when trying to operate their laser cutter machine! A user-friendly interface can make all the difference between a smooth operation and a frustrating experience filled with hiccups and headaches. Look for software solutions that prioritize usability while still offering powerful features tailored for advanced users.

A clean layout coupled with intuitive controls will enable both beginners using a cheap laser cutter and seasoned pros operating complex machines alike to hit the ground running without extensive training sessions. Additionally, good documentation and customer support can further enhance user experience by providing quick solutions when questions arise during operation or setup.

Assess Maintenance and Durability

When investing in a laser cutting machine, understanding maintenance and durability is crucial for ensuring long-term performance. Regular maintenance can prevent minor issues from escalating into costly repairs, extending the lifespan of your laser cutter. Moreover, keeping your cutting machine laser in top shape means more reliable operation and consistent quality in your projects.

Importance of Regular Maintenance

Regular maintenance is the unsung hero of any successful industrial laser cutter operation. Just like a car needs oil changes and tire rotations, your laser cutter requires routine check-ups to keep it running smoothly. Neglecting these tasks can lead to decreased efficiency, reduced precision, and ultimately a higher risk of breakdowns—something no one wants when working with a cheap laser cutter!

Taking the time to develop a comprehensive maintenance schedule will pay off in the long run. This includes cleaning lenses, checking alignment, replacing worn parts, and ensuring software updates are applied promptly. By prioritizing regular maintenance for your laser machine, you not only enhance its performance but also safeguard your investment against unforeseen repair costs.

Longevity of Different Laser Cutter Machines

The longevity of your chosen laser cutter can vary significantly based on its type and usage conditions. Generally speaking, industrial laser cutters are built with robust components designed for heavy-duty applications; thus they often outlast their cheaper counterparts used in lighter settings. However, even within the realm of cheap laser cutters, some models offer surprising durability if maintained properly.

Factors such as usage frequency and material compatibility also play essential roles in determining how long a cutting machine laser will last. Machines that are consistently pushed beyond their limits or subjected to incompatible materials may experience shorter lifespans than expected. Therefore, selecting a reliable model while adhering to best practices for use will maximize longevity.

Warranty and Service Agreements

A solid warranty can be just as important as choosing the right features when selecting a laser cutter machine. Warranties often provide peace of mind by covering repairs or replacements during the initial years after purchase—an invaluable safety net for any business relying on their equipment's functionality! Additionally, service agreements can offer ongoing support that keeps your machinery running optimally over time.

When evaluating warranties and service agreements for different brands or models of laser cutting machines, pay attention to what’s included: parts coverage, labor costs during repairs, response times for service calls—all these factors matter! A trustworthy manufacturer should provide clear information regarding what you’re entitled to under warranty terms so there are no surprises later on down the line.

In conclusion, assessing maintenance requirements alongside durability is essential when investing in a new cutting machine laser. By committing to regular upkeep while understanding each model’s expected lifespan—and securing appropriate warranties—you position yourself for success in maximizing both productivity and return on investment with your chosen equipment.

Test-Dive Your Top Choices

When it comes to selecting the right laser cutter for your needs, nothing beats getting a firsthand experience. Testing your top choices allows you to gauge their performance, usability, and overall fit for your projects. By diving deep into the capabilities of various cutting machine lasers, you can ensure you're making a well-informed decision.

Requesting Demonstrations and Samples

One of the best ways to evaluate a laser cutting machine is by requesting live demonstrations from manufacturers or suppliers. This not only gives you a chance to see the machine in action but also allows you to ask questions about its features and capabilities directly from knowledgeable representatives. Additionally, asking for samples of materials processed by the laser cutter can help you assess the quality of the cuts and finishes produced.

Many reputable suppliers are more than willing to provide demonstrations, especially if they believe their industrial laser cutter can meet your specific needs. Don't hesitate to reach out; after all, investing in a cheap laser cutter that doesn’t perform as expected could lead to costly mistakes down the line. Remember, seeing is believing—so make sure you take advantage of this opportunity!

Understanding the User Experience

User experience is crucial when evaluating any laser cutter machine. How intuitive is the interface? Are there any quirks that could hinder productivity? Engaging with current users or reading reviews can provide insights into how easy or complex it is to operate different models.

Look for feedback on software integration as well; compatibility with CAD/CAM programs can significantly influence how smoothly your projects run. The last thing you want is to invest in a cutting machine laser that requires extensive training just to get started! By understanding what actual users think about their experiences with various machines, you'll be better equipped to choose one that fits seamlessly into your workflow.

Hands-On Trials with a Laser Cutter Machine

Nothing beats getting hands-on with a laser cutting machine before making a purchase decision! Many suppliers offer trial periods where potential buyers can use their machines in real-world scenarios—this is an invaluable opportunity! During these trials, pay attention not only to how well the machine performs but also how comfortable it feels during operation.

Feel free to experiment with different materials and settings; this will give you insight into how versatile each model truly is. Plus, hands-on trials allow you to assess maintenance requirements firsthand—after all, no one wants a high-maintenance industrial laser cutter eating up time and resources!

Conclusion

Choosing the right laser cutting machine can feel like navigating a maze, but with the right roadmap, you can find your way. The key factors to consider include your specific cutting needs, material compatibility, and budget constraints. Whether you're eyeing a compact model for hobby projects or an industrial laser cutter for large-scale operations, understanding these elements will guide your decision-making process.

Key Factors in Choosing a Laser Cutter

When selecting a laser cutter, start by identifying what materials you'll be working with and how thick they are; this will significantly influence the type of laser machine you need. Additionally, consider the power output required for your projects—higher wattage means faster cutting speeds and the ability to handle thicker materials. Finally, don't overlook after-sales support and warranty coverage; investing in a cheap laser cutter might save you money upfront but could cost you in repairs down the line.

Compare Brands and Models Effectively

Once you've narrowed down your options based on functionality and budget, it's time to dive into brand comparisons. Look for trusted manufacturers that have built a reputation for quality—brands like Kiant Machinery often come highly recommended by users and industry experts alike. Read user reviews and seek out testimonials to understand how different models perform in real-world scenarios; this will help ensure that your chosen laser cutter machine meets expectations.

Future-Proofing with Your Laser Cutting Machine

Finally, think about scalability when selecting your cutting machine laser; you want something that can grow with your needs over time. A good industrial laser cutter should not only meet current demands but also adapt as technology evolves or as your business expands. By choosing a versatile option now, you’ll save yourself from needing an upgrade sooner than expected—because no one wants to face buyer's remorse just after their purchase!