Introduction

In the realm of modern manufacturing, the laser cutting machine for metal stands out as a game-changer. This advanced technology has transformed the way industries approach precision cutting, offering unparalleled accuracy and efficiency. With its ability to handle various materials and thicknesses, the industrial laser cutter has become an indispensable tool in sectors ranging from automotive to aerospace.

Overview of Laser Cutting Machines

Laser cutting machines utilize focused beams of light to cut through metal with remarkable precision. These machines come in various types, including fiber lasers and CO2 lasers, each designed for specific applications and material compatibility. The versatility of these industrial laser cutting machines makes them suitable for both large-scale production and custom fabrication projects.

Advantages of Laser Cutting for Metal

One of the primary advantages of using a laser cutting machine for metal is its ability to deliver intricate designs with minimal waste. Unlike traditional cutting methods, which can produce rough edges and require additional finishing work, laser cutting creates clean cuts that often eliminate the need for secondary processes. Additionally, industrial laser machines operate at high speeds without sacrificing quality, significantly boosting productivity across various manufacturing environments.

Key Features of Industrial Laser Cutters

Industrial laser cutters are equipped with several key features that enhance their performance and usability. These include advanced control systems that enable precise adjustments during operation and automated loading systems that streamline workflow efficiency. Furthermore, many modern laser machines incorporate safety features such as enclosed workspaces and automatic shut-off mechanisms to protect operators while ensuring optimal performance.

Understanding Laser Cutting Technology

Laser cutting technology has revolutionized the manufacturing landscape, particularly in metal fabrication. This technique utilizes focused laser beams to slice through materials with incredible precision, making it an invaluable tool for industries that demand high-quality cuts. Whether you're working with steel, aluminum, or other metals, a laser cutting machine for metal can deliver results that traditional methods struggle to match.

What is Laser Cutting?

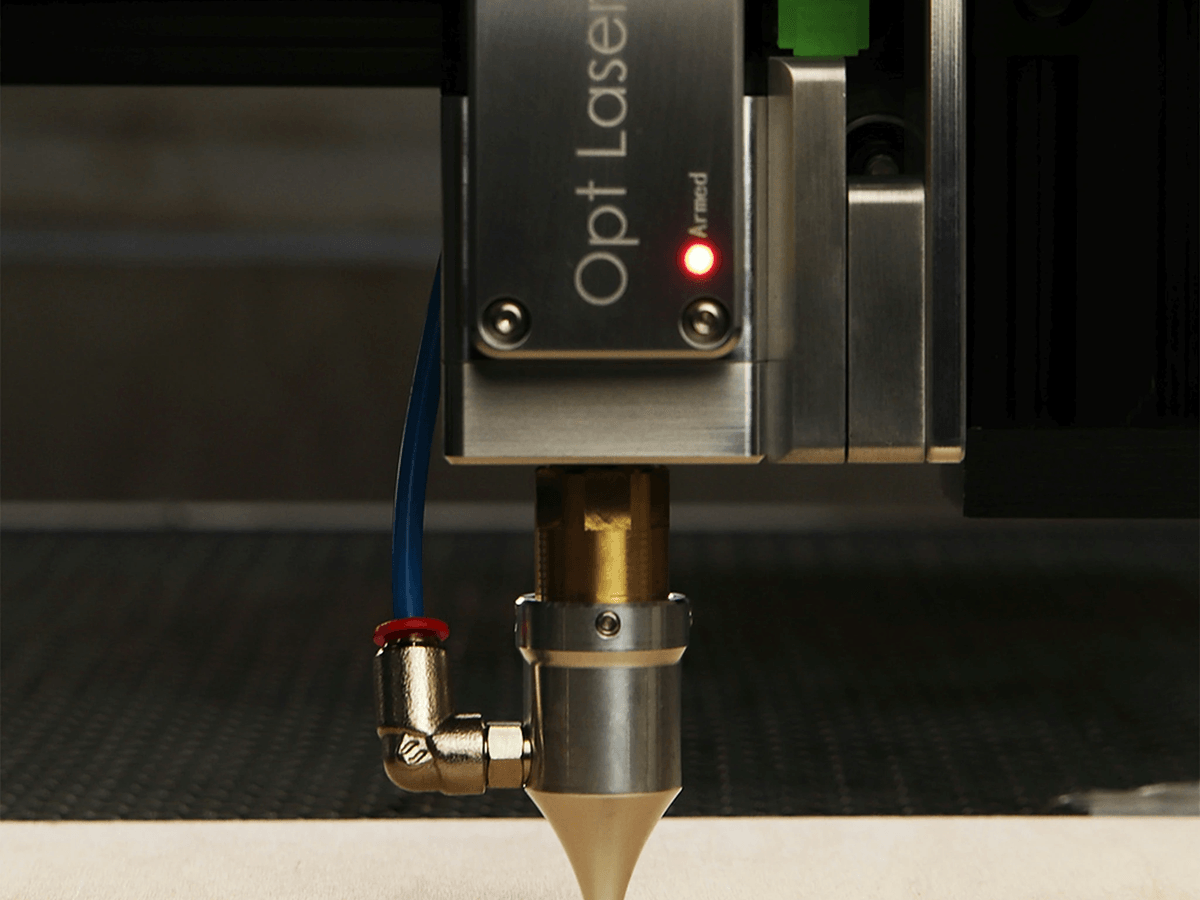

At its core, laser cutting is a process that employs a powerful laser beam to cut through materials with remarkable accuracy. The laser heats the material to its melting point and then blows away the molten material using a jet of gas—typically nitrogen or oxygen—resulting in clean edges and minimal thermal distortion. This method not only enhances the quality of cuts but also allows for intricate designs that would be challenging to achieve with conventional tools.

Laser cutting machines come in various configurations suited for different applications, but they all share one thing in common: they rely on lasers as their primary cutting tool. From industrial laser cutters used in large factories to smaller models suitable for workshops, these machines are designed to handle diverse metal types and thicknesses efficiently. Ultimately, understanding what laser cutting entails sets the stage for appreciating its advantages and capabilities.

Types of Laser Cutting Machines

There are primarily two types of lasers used in industrial applications: CO2 lasers and fiber lasers. CO2 lasers are well-known for their ability to cut non-metal materials like wood and plastics but can also effectively handle metals; however, they tend to be slower compared to fiber lasers. Fiber lasers have gained popularity due to their efficiency when working with metals; they produce a concentrated beam of light that allows for faster cuts while maintaining superior precision.

When choosing an industrial laser cutting machine, it's essential to consider your specific requirements—such as the type of metal you'll be working with and the thickness involved. Fiber lasers excel at cutting thin sheets of metal at high speeds while offering lower operational costs over time due to reduced energy consumption. On the other hand, CO2 machines might be better suited for applications requiring versatility across various materials beyond just metals.

How a Laser Machine Works

Understanding how a laser machine operates provides insight into why these devices are so effective at metal fabrication tasks. At its heart lies a resonator where energy is converted into light; this light is then amplified before being directed through optics that focus it into an intense beam capable of melting or vaporizing materials upon contact. The precision movement systems allow this focused beam to traverse across surfaces accurately based on programmed designs.

The entire process is controlled by sophisticated software that dictates how the industrial laser cutter will perform each task—from initial setup through execution—ensuring consistent quality throughout production runs. Additionally, modern systems often feature real-time monitoring capabilities that help maintain optimal performance levels during operation by adjusting parameters like speed or power output as needed. In essence, understanding these mechanics highlights why investing in an industrial laser cutting machine can significantly enhance productivity and quality control within any manufacturing setting.

Benefits of Using a Laser Cutting Machine for Metal

When it comes to metal fabrication, the advantages of utilizing a laser cutting machine for metal are hard to overlook. These machines have revolutionized the way industries approach cutting processes, offering unparalleled benefits that traditional methods simply can't match. From precision engineering to material versatility, industrial laser cutters are redefining efficiency in manufacturing.

Precision and Accuracy

One of the most compelling reasons to invest in an industrial laser cutting machine is its remarkable precision and accuracy. Laser cutting technology allows for intricate designs and tight tolerances that are crucial in industries like aerospace and automotive manufacturing. With a laser machine, you can achieve cuts that are not only clean but also consistently repeatable, minimizing waste and maximizing productivity.

The ability to maintain such high levels of accuracy means that parts fit together seamlessly during assembly processes, reducing the likelihood of costly errors down the line. This level of precision is particularly important when working with complex geometries or thin materials where even minor deviations can lead to significant issues. In short, if you're looking for a way to enhance your production quality, investing in an industrial laser cutter is a smart move.

Versatile Material Compatibility

Another standout feature of modern laser cutting machines is their versatile material compatibility. Whether you're working with stainless steel, aluminum, or even softer metals like copper and brass, these machines can handle it all with ease. Fiber lasers excel at cutting through reflective materials without compromising on quality or speed—something traditional methods often struggle with.

This versatility opens up new avenues for creativity and innovation in design since fabricators can experiment with various materials without having to switch equipment or processes frequently. Moreover, the ability to cut different types of metals means you can cater to diverse client needs while maintaining efficiency in your operations. Ultimately, this adaptability makes industrial laser machines an invaluable asset across multiple sectors.

Increased Efficiency and Speed

In today's fast-paced manufacturing environment, speed is king—and that's where industrial laser machines shine brightest! A laser cutting machine for metal operates at lightning speeds compared to traditional cutting methods like plasma or waterjet systems. This increased efficiency not only boosts production rates but also helps businesses meet tight deadlines without sacrificing quality.

Moreover, many modern industrial laser cutters come equipped with advanced automation features that streamline operations further—think automatic loading systems and real-time monitoring capabilities! This level of automation reduces manual intervention and allows operators to focus on more critical tasks while ensuring optimal performance from their equipment. In essence, choosing a fiber laser or other advanced laser machine translates directly into enhanced productivity for any business involved in metal fabrication.

Choosing the Right Laser Cutting Machine

Selecting the right laser cutting machine for metal is crucial for optimizing your production process and achieving high-quality results. With a variety of options available, understanding your specific needs can help you make an informed decision. Factors such as material type, thickness, and desired precision should guide your choice of an industrial laser cutter.

Evaluating Your Needs

Before diving into the world of laser cutting machines, take a moment to evaluate your specific requirements. Consider the types of metals you'll be working with and their thicknesses; this will help determine whether you need a more powerful industrial laser cutting machine or something more versatile. Additionally, think about the volume of work you anticipate—if you're looking at high production rates, investing in a top-tier laser machine could pay off significantly in efficiency and speed.

Another important aspect to consider is the level of precision required for your projects. If you're in industries like aerospace or automotive manufacturing where accuracy is paramount, opting for a fiber laser might be beneficial due to its fine cutting capabilities. Ultimately, aligning your choice with both current and future needs will ensure that you invest wisely in an industrial laser cutter that meets all expectations.

Comparing Fiber Laser vs. CO2 Laser

When it comes to choosing between fiber lasers and CO2 lasers, understanding their differences can steer you toward the best option for your operations. Fiber lasers are known for their superior efficiency when cutting metals; they offer faster processing speeds and lower operational costs compared to CO2 lasers. This makes them particularly appealing if you're focusing on high-volume metal fabrication or require intricate designs.

On the flip side, CO2 lasers excel at cutting non-metal materials like wood or acrylic, making them versatile but less efficient for metal applications. If you're primarily working with various metals—especially reflective ones like copper or brass—a fiber laser would likely serve you better than a traditional CO2 setup. Weighing these factors against each other will help clarify which type of laser cutting machine aligns best with your business goals.

Top Brands in the Market

As you navigate through options for an industrial laser cutter, it's vital to consider reputable brands known for their quality and reliability within the market space. Companies like Trumpf have established themselves as leaders by offering innovative solutions tailored specifically toward industrial applications—including advanced fiber lasers that enhance productivity across various sectors. Another brand worth mentioning is Bystronic; they provide user-friendly interfaces along with robust performance suited for both small shops and large-scale manufacturers alike.

Don’t overlook other contenders such as Amada or Mitsubishi; each brings unique features that cater to different aspects of metal fabrication needs—from entry-level models to sophisticated systems designed for heavy-duty tasks. Researching customer reviews and industry feedback can further assist in narrowing down which brand's offerings resonate most with what you're looking for in an industrial laser cutting machine.

Kiant Machinery: Leading the Industry

When it comes to laser cutting machines for metal, Kiant Machinery stands out as a frontrunner in the industry. With a commitment to innovation and quality, they have established themselves as a reliable provider of industrial laser cutting machines that cater to diverse needs. Their advanced technology and superior craftsmanship make them a go-to choice for businesses seeking efficient and precise laser cutting solutions.

Overview of Kiant Machinery

Kiant Machinery has been revolutionizing the field of laser cutting since its inception, offering top-of-the-line industrial laser cutters designed for maximum performance. Their extensive range of products includes fiber lasers and CO2 lasers, each tailored to meet specific manufacturing requirements. With years of experience under their belt, they have become synonymous with reliability and excellence in the realm of industrial laser machines.

Innovative Solutions Offered

Kiant Machinery prides itself on providing innovative solutions that push the boundaries of what is possible with laser cutting technology. Whether it's developing state-of-the-art fiber lasers or enhancing user interfaces for better control, their commitment to research and development ensures that customers receive cutting-edge machinery. This focus on innovation not only improves efficiency but also allows users to explore new applications in various industries.

Customer Support and Training Services

One aspect that truly sets Kiant Machinery apart is their exceptional customer support and training services. They understand that investing in an industrial laser cutter is significant, so they offer comprehensive training programs to help users maximize their machine's capabilities. From troubleshooting assistance to ongoing maintenance support, Kiant's dedicated team ensures that every customer feels confident operating their laser cutting machine for metal effectively.

Applications of Laser Cutting in Various Industries

Laser cutting technology has revolutionized various sectors by providing precise and efficient solutions for metal processing. Its versatility makes it a preferred choice across different industries, from automotive to aerospace and even custom fabrication. Let's delve into how industrial laser cutters are shaping these fields.

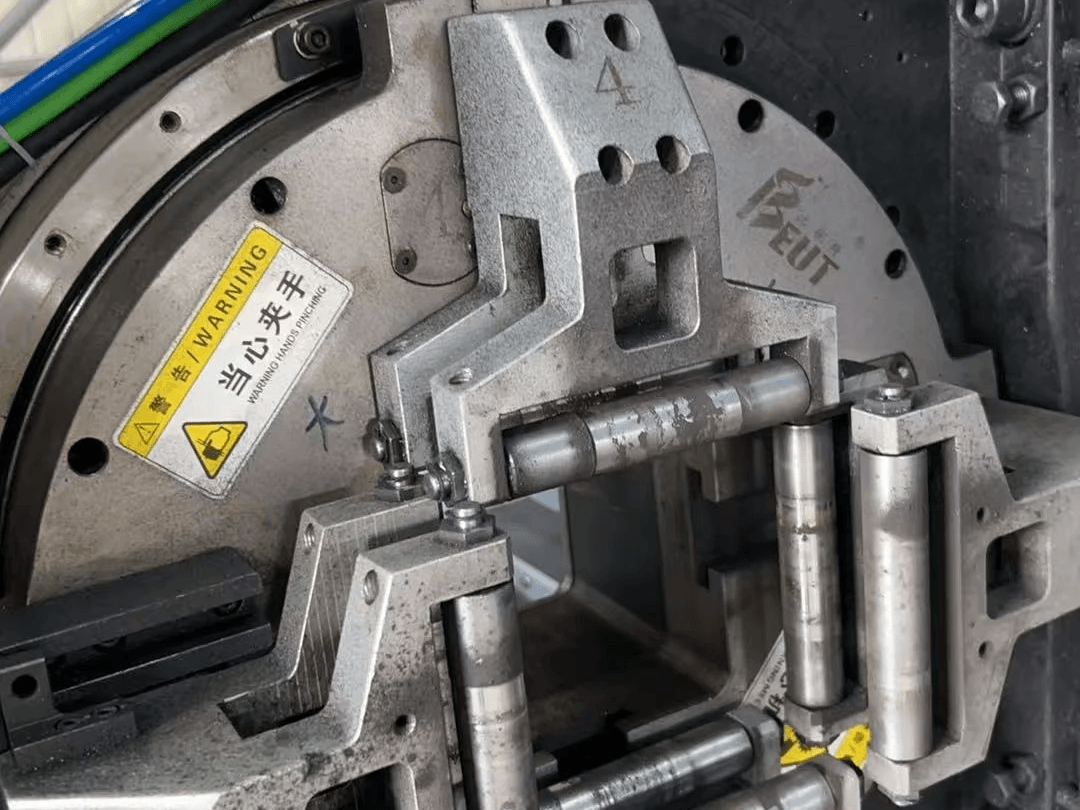

Automotive Industry Uses

In the automotive industry, laser cutting machines for metal play a pivotal role in manufacturing components with high precision. These industrial laser cutting machines are used to create intricate parts such as brackets, chassis components, and exhaust systems, ensuring that each piece meets stringent quality standards. The ability to cut through various metals quickly and accurately translates to faster production times and reduced waste.

Moreover, the flexibility of fiber lasers allows manufacturers to adapt quickly to changing designs or specifications without the need for extensive retooling. This adaptability is crucial in an industry where innovation drives competition. By utilizing advanced laser machines, automotive companies can enhance their production processes while maintaining cost-effectiveness.

Aerospace Manufacturing Applications

The aerospace sector demands exceptional precision due to safety regulations and performance requirements; hence, laser cutting is indispensable here. Industrial laser cutters enable manufacturers to produce lightweight yet strong components from materials like titanium and aluminum with minimal thermal distortion. This capability is vital in creating parts that meet rigorous specifications while optimizing fuel efficiency.

Additionally, the use of fiber lasers has transformed how aerospace manufacturers approach complex designs that require intricate cuts or engravings. These advanced laser machines can handle delicate tasks that traditional methods struggle with, such as detailed etching on turbine blades or structural elements of aircraft fuselages. As a result, companies can achieve enhanced performance metrics while reducing lead times significantly.

Custom Fabrication and Art

The world of custom fabrication thrives on creativity and uniqueness—qualities that laser cutting embodies perfectly! Artists and fabricators utilize industrial laser cutting machines to transform ideas into tangible art pieces or bespoke products efficiently. Whether it's crafting detailed sculptures from metal sheets or producing personalized signage for businesses, the precision offered by a laser machine elevates craftsmanship.

Furthermore, the versatility of these machines allows for experimentation with various materials beyond just metal—think wood, acrylics, or composites! This opens up endless possibilities for artists looking to push boundaries while maintaining high-quality results across projects. With the right industrial laser cutter at their disposal, creators can bring their visions to life more effectively than ever before.

Conclusion

In conclusion, the landscape of laser cutting technology is rapidly evolving, promising exciting advancements that will further enhance efficiency and precision in industrial applications. As industries increasingly adopt these sophisticated laser cutting machines for metal, the future will likely see innovations that make these tools even more accessible and versatile. From improved software integration to enhanced energy efficiency, the next generation of industrial laser cutters is set to revolutionize how we approach metal fabrication.

Future Trends in Laser Cutting Technology

The future of laser cutting technology is bright, with trends pointing towards greater automation and artificial intelligence integration. These advancements will enable laser machines to optimize their operations autonomously, resulting in even higher productivity levels while minimizing human intervention. Additionally, fiber lasers are becoming more prevalent due to their ability to cut through thicker materials with greater speed and precision compared to traditional CO2 lasers.

Cost-Effectiveness of Industrial Laser Machines

Investing in an industrial laser cutting machine can seem daunting at first glance; however, the long-term cost-effectiveness cannot be overlooked. With lower operational costs and reduced material waste due to the precision of laser cutting techniques, businesses can achieve significant savings over time. Furthermore, the durability and longevity of modern industrial laser cutters mean they remain reliable assets for years to come.

Enhancing Productivity with Laser Cutting Solutions

Laser cutting solutions are designed with productivity in mind, allowing manufacturers to streamline their processes without sacrificing quality. The speed at which a fiber laser operates enables quicker turnaround times for projects while maintaining exceptional accuracy across various materials. By integrating an industrial laser cutter into their workflow, companies can enhance their overall output and remain competitive in a fast-paced market.