Introduction

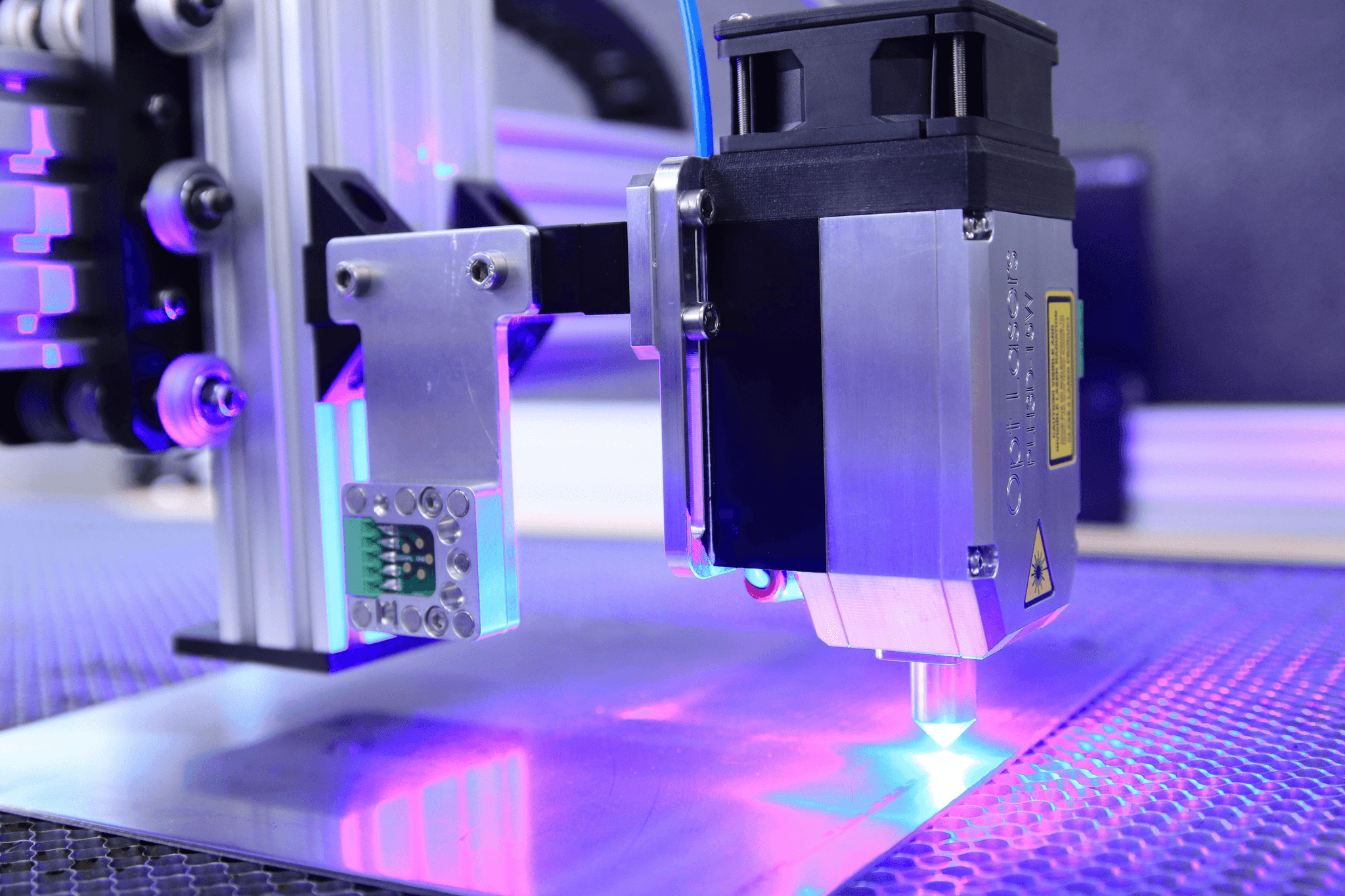

In the world of metal fabrication, the advent of fiber laser cutting technology has revolutionized how materials are processed. This cutting-edge method utilizes high-powered laser beams to achieve precise cuts, making it a preferred choice among manufacturers and fabricators alike. Understanding fiber laser cutting technology is essential for anyone looking to invest in a metal cutting laser cutter that meets their specific needs.

Understanding Fiber Laser Cutting Technology

Fiber lasers operate by using optical fibers doped with rare-earth elements to generate a concentrated beam of light capable of cutting through various metals with remarkable accuracy. Unlike traditional cutting methods, which can be slower and less efficient, fiber lasers provide faster processing times and cleaner edges, significantly enhancing productivity. The efficiency of this technology not only reduces operational costs but also allows for intricate designs that were once thought impossible.

Importance of Choosing the Right Machine

Selecting the right fiber laser cutting machine is crucial for maximizing performance and ensuring quality output in your projects. With a range of options available on the market, understanding features such as power output, build quality, and maintenance requirements can make all the difference in achieving optimal results. A well-chosen machine not only improves efficiency but also offers long-term cost savings by reducing downtime and maintenance expenses.

Overview of Popular Fiber Laser Cutting Machines

Several popular models stand out in the realm of laser machinery today, each catering to different needs and budgets within the industry. The Trumpf TruLaser Series is renowned for its versatility and advanced features, while Bystronic's BySmart Fiber offers an excellent balance between performance and affordability—making it a favorite among newcomers to fiber lasers. Additionally, Kiant Machinery's Laser Tube Cutter specializes in tubular processing, demonstrating that there’s a perfect fit for every type of metalworking project.

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is an advanced tool used for precision cutting of various materials, primarily metals. Utilizing fiber laser technology, these machines generate high-intensity beams that can slice through thick and thin materials with remarkable accuracy. As industries continue to evolve, the demand for efficient and cost-effective metal cutting solutions has made the fiber laser a popular choice among manufacturers.

How Fiber Lasers Work

Fiber lasers work by using optical fibers doped with rare-earth elements like ytterbium to amplify light energy. This amplification process produces a highly concentrated beam that is directed onto the material being cut. The result? A focused, high-energy beam that can effortlessly penetrate and melt metal surfaces, making it a game-changer in the world of cutting machine lasers.

Advantages over Traditional Cutting Methods

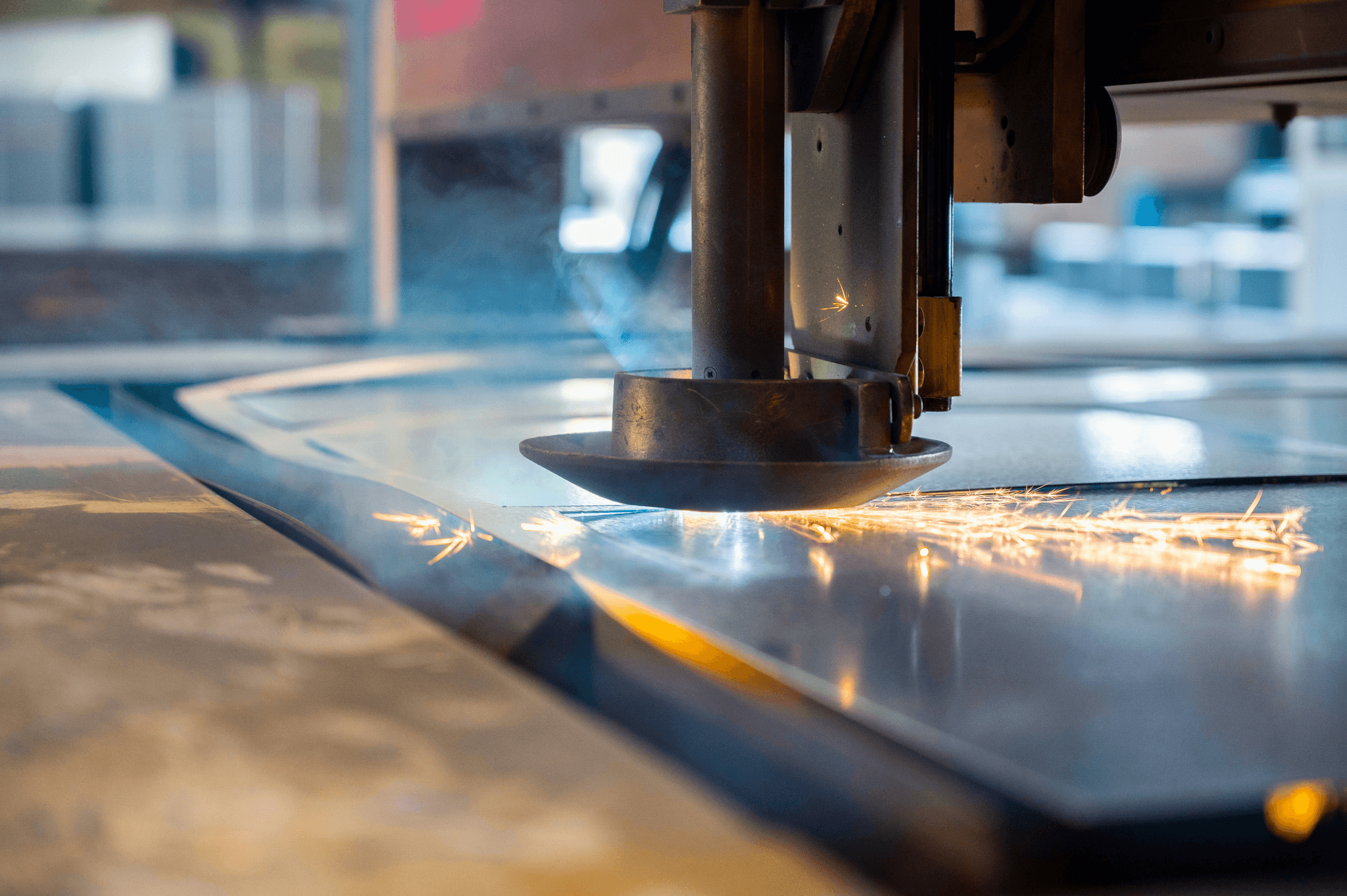

When you compare fiber lasers to traditional cutting methods like plasma or oxy-fuel cutting, the advantages are clear as day. Fiber laser machines offer superior precision and speed, allowing for intricate designs while reducing kerf width – that's the gap left by the cut! Additionally, they are more energy-efficient and have lower operating costs, making them a smart investment when considering fiber laser cutting machine price.

Ideal Applications in Metal Fabrication

The versatility of fiber lasers makes them ideal for various applications in metal fabrication. From automotive manufacturing to aerospace components and even intricate artistic designs, these machines can handle it all with finesse. Their ability to cut through different types of metals—such as stainless steel, aluminum, and brass—makes them indispensable in modern manufacturing environments where quality meets efficiency.

Key Features to Consider

When it comes to selecting the right fiber laser cutting machine, several key features can make or break your investment. Understanding these features will not only help you choose the best metal cutting laser cutter for your needs but also ensure that you're getting the most value for your money. Let's dive into what makes a cutting machine laser truly stand out in today's competitive market.

Cutting Speed and Precision

Cutting speed and precision are paramount when evaluating a fiber laser cutting machine. The faster the machine can cut through materials, the more efficient your operations will be, allowing you to meet tight deadlines without sacrificing quality. Precision is equally important; a high-quality laser machinery ensures clean edges and intricate designs, which is essential for industries requiring detailed metal fabrication.

Moreover, advanced fiber lasers often feature automated systems that enhance both speed and accuracy, making them ideal for high-volume production tasks. By investing in a reliable cutting machine laser with superior speed and precision capabilities, you can significantly boost productivity while minimizing material waste. Ultimately, this balance between speed and accuracy can directly influence your bottom line—especially when considering fiber laser cutting machine prices.

Power Output and Efficiency

The power output of a fiber laser cutter plays a crucial role in determining its versatility and effectiveness across various applications. Machines with higher wattage can cut through thicker materials at faster speeds, making them suitable for heavy-duty tasks without compromising on performance. Additionally, efficiency becomes paramount as it affects operational costs; investing in an energy-efficient model will save you money on electricity bills over time.

When comparing different models of metal cutting laser cutters, look for those that optimize power usage while delivering consistent results across diverse materials like steel, aluminum, and brass. This balance between power output and efficiency not only enhances productivity but also makes sure you're getting great value for your investment—especially when considering overall laser machine prices in relation to performance metrics.

Build Quality and Durability

Lastly, build quality and durability should never be overlooked when choosing a fiber laser cutter. A robust construction ensures that the machine withstands rigorous use over extended periods without frequent breakdowns or maintenance issues—saving you both time and money in repairs or replacements down the line. High-quality components are essential; they contribute not just to longevity but also to consistent performance during operation.

Investing in well-built laser machinery means fewer disruptions during production runs due to unexpected failures or downtime—a critical factor if you're operating under tight schedules or high demand scenarios. Additionally, machines made from durable materials tend to retain their resale value better than cheaper alternatives; thus enhancing overall cost-effectiveness when factoring in long-term ownership expenses related to fiber laser cutting machines.

Top Fiber Laser Cutting Machines on the Market

When it comes to selecting the best fiber laser cutting machines, several key players dominate the market. Each machine offers unique features tailored to various metal fabrication needs. In this section, we’ll explore some of the top contenders, focusing on their capabilities, advantages, and price points.

Trumpf TruLaser Series

The Trumpf TruLaser Series is renowned for its cutting-edge technology and exceptional performance in metal cutting applications. This series boasts a range of models equipped with powerful fiber lasers that ensure high-speed cutting with remarkable precision. The combination of advanced software and robust build quality makes these machines a top choice for businesses looking to invest in reliable laser machinery.

One standout feature of the TruLaser series is its ability to handle various materials and thicknesses efficiently, making it versatile for different projects. With impressive cutting speeds and low operating costs, many users consider the Trumpf TruLaser an excellent investment despite its fiber laser cutting machine price being on the higher end of the spectrum. Overall, this series exemplifies what a high-quality cutting machine laser should offer.

Bystronic BySmart Fiber

Bystronic's BySmart Fiber stands out as an accessible option without compromising on performance or quality in the fiber laser category. This machine is designed for small to medium-sized businesses looking for an efficient metal cutting laser cutter that delivers both speed and accuracy at a competitive price point. Its user-friendly interface allows operators to quickly learn how to maximize productivity while minimizing waste.

What sets the BySmart Fiber apart is its energy efficiency; it operates with lower power consumption compared to traditional methods while maintaining superior cut quality across various materials like stainless steel and aluminum. The flexible configurations available mean that companies can scale up their operations as needed without breaking the bank on additional equipment—making it a smart choice when considering overall laser machine price versus value provided.

Kiant Machinery Laser Tube Cutter

Kiant Machinery's Laser Tube Cutter is specifically designed for those who need precision in tubular or profile applications within metal fabrication industries. This innovative fiber laser cutter excels at delivering clean cuts even at complex angles while ensuring minimal material wastage—a significant advantage when working with expensive metals or large volumes of production runs. Its compact design also allows it to fit into smaller workshops without sacrificing performance.

Another highlight of Kiant Machinery’s offering is its affordability relative to features provided; many find that their fiber laser cutting machine price strikes an appealing balance between budget constraints and advanced capabilities typically seen in higher-end models. Additionally, Kiant Machinery emphasizes after-sales support and training programs which help users maintain optimal operation over time—an essential consideration when investing in any type of laser machinery.

Comparing Prices and Best Value

When it comes to investing in a fiber laser cutting machine, understanding the price spectrum is crucial. Prices can vary significantly based on features, brand reputation, and technology advancements. This section will help you navigate through the complexities of metal cutting laser cutter prices and ensure you get the best value for your investment.

Understanding Fiber Laser Cutting Machine Price

The fiber laser cutting machine price can range from a few thousand dollars for entry-level models to over a million for high-end industrial machines. Factors influencing these prices include power output, cutting speed, and additional features such as automation capabilities. It's essential to evaluate what you need from a cutting machine laser before diving into the purchase; aligning your requirements with your budget helps avoid overspending or under-investing.

Budget vs. High-End Options

When weighing budget versus high-end options in laser machinery, it's important to consider both immediate costs and long-term benefits. Budget machines may seem appealing at first glance due to their lower fiber laser cutting machine price but often lack precision and efficiency found in higher-end models. On the flip side, investing in a top-tier metal cutting laser cutter may require more upfront capital but can lead to significant savings through reduced operational costs and maintenance over time.

Cost-effectiveness of Investing in Laser Machinery

Investing in a quality fiber laser is not just about initial expenditure; it's about evaluating cost-effectiveness over time. While the upfront investment might be daunting, consider factors like lower energy consumption, reduced waste material, and faster production rates that come with advanced laser machines. Ultimately, selecting the right metal cutting laser cutter can enhance productivity and profitability—making it a smart choice for any fabrication business looking toward future growth.

Maintenance and Support Considerations

When investing in a fiber laser cutting machine, it's crucial to consider the maintenance and support that comes with it. Regular maintenance not only prolongs the life of your cutting machine laser but also ensures optimal performance, reducing downtime and unexpected repair costs. Neglecting maintenance can lead to issues that affect precision and efficiency, ultimately impacting your metal fabrication projects.

Importance of Regular Maintenance

Regular maintenance is the backbone of any successful operation involving a metal cutting laser cutter. It keeps your fiber laser running smoothly, ensuring that you achieve consistent cutting quality over time. By adhering to a scheduled maintenance plan, you can catch minor issues before they escalate into costly repairs or replacements, saving you from unexpected increases in fiber laser cutting machine price.

Available Training and After-sales Support

Investing in a laser machine is just the beginning; having access to comprehensive training and after-sales support can make all the difference. Many manufacturers offer training programs that help operators understand their equipment better, enhancing efficiency and safety during operation. Furthermore, responsive after-sales support ensures that any technical issues are addressed promptly, minimizing downtime for your cutting machine laser.

How Kiant Machinery Ensures Reliability

Kiant Machinery stands out by providing exceptional reliability through robust engineering and dedicated customer service. Their commitment to regular updates on best practices for maintaining your fiber laser guarantees optimal performance throughout its lifespan. Additionally, Kiant Machinery offers tailored support packages designed to meet diverse operational needs while keeping an eye on overall costs associated with owning a laser machinery.

Conclusion

In the rapidly evolving world of manufacturing, selecting the right metal cutting laser cutter is crucial for enhancing productivity and efficiency. With a variety of options available, it's essential to evaluate your specific needs against the capabilities of different fiber laser cutting machines. Remember, investing in a high-quality cutting machine laser today can lead to significant long-term savings and operational benefits.

Selecting the Right Metal Cutting Laser Cutter

When choosing a metal cutting laser cutter, consider factors such as your material types, thicknesses, and production volume. The fiber laser's speed and precision often outshine traditional methods, making it an attractive option for many businesses. Additionally, analyzing the fiber laser cutting machine price will help you find a model that fits your budget without compromising on quality.

Long-term Benefits of Fiber Laser Technology

Investing in fiber laser technology can yield substantial long-term benefits for any manufacturing operation. These machines offer exceptional energy efficiency and lower operating costs compared to other types of laser machinery, translating to reduced expenses over time. Moreover, their versatility allows for various applications across industries, ensuring that your investment remains relevant as market demands evolve.

The Future of Laser Machine Innovations

The future looks bright for innovations in laser machines as advancements in technology continue to emerge at a rapid pace. We can expect even more efficient models with enhanced capabilities that will further revolutionize metal fabrication processes. As manufacturers increasingly adopt these technologies, staying informed about trends will help you make educated decisions regarding fiber laser cutting machine price and features.