Introduction

In the realm of modern fabrication, laser cutting has emerged as a game-changer, offering unmatched precision and versatility. Whether you're crafting intricate designs or simple shapes, a laser cutter for aluminum can elevate your projects to new heights. This introduction will guide you through the essentials of laser cutting, specifically focusing on aluminum and what you need to know when choosing the right laser machine.

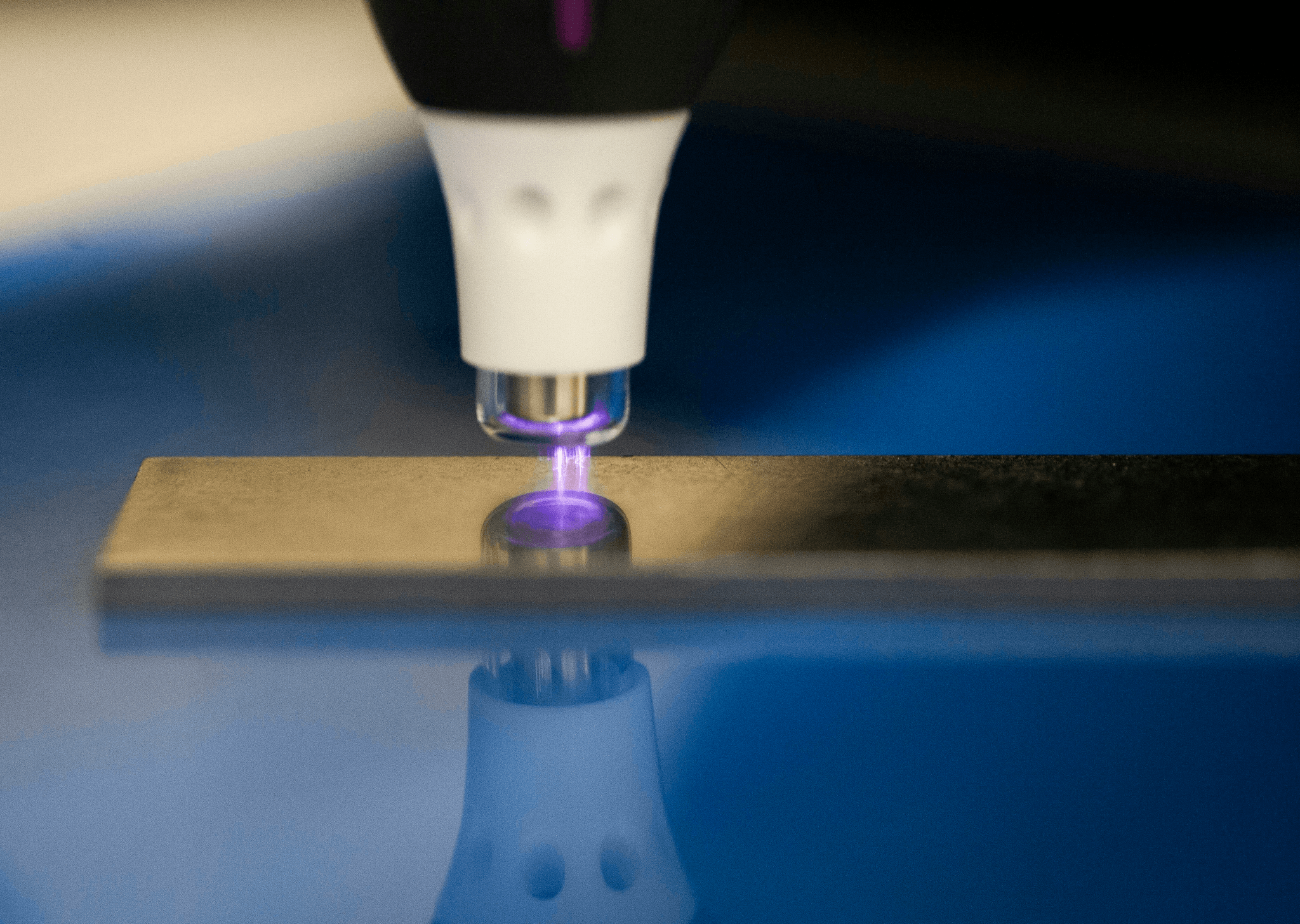

Harnessing Precision with Laser Cutting

Laser cutting technology has revolutionized how we approach metal fabrication. With its ability to deliver clean edges and intricate designs, a laser cutting machine is indispensable for anyone serious about metal CNC cutting.

Why Choose Aluminum for Your Projects

Aluminum is a lightweight yet robust material that lends itself beautifully to various applications—from automotive parts to artistic sculptures. Its corrosion resistance and excellent thermal conductivity make it an ideal choice for projects requiring durability and efficiency. Plus, when paired with a laser cutter for metal sheets, aluminum can be transformed into stunning pieces that showcase both functionality and style.

Discovering the Right Laser Machine

Choosing the right laser machine can feel overwhelming given the plethora of options available today. It's essential to consider factors such as power output, bed size, and compatibility with sheet metal for laser cutting when making your decision. By understanding your specific needs and comparing models designed for metal CNC cutting, you can find a laser cutter that perfectly fits your project requirements.

Understanding Laser Cutters for Aluminum

When diving into the world of metal fabrication, particularly with aluminum, understanding the nuances of laser cutters is paramount. A laser cutter for aluminum is not just any machine; it’s designed specifically to handle the unique properties of this lightweight yet durable material. With advancements in technology, choosing the right laser cutting machine can significantly enhance your projects and streamline your workflow.

What Makes a Laser Cutter Ideal

An ideal laser cutter for aluminum should possess high precision and speed to ensure clean cuts without excessive heat distortion. The ability to adjust power settings allows for varying thicknesses of sheet metal for laser cutting, making it versatile across different projects. Additionally, features such as a robust cooling system and advanced optics contribute to maintaining optimal performance during extended use.

The Benefits of Laser Cutting Machines

Laser cutting machines offer unparalleled advantages over traditional cutting methods, especially when working with materials like aluminum. One major benefit is their ability to produce intricate designs with minimal waste; this efficiency is crucial in metal CNC cutting where every fraction counts. Furthermore, the clean edges resulting from a cutting laser metal process reduce or eliminate the need for extensive post-processing work.

Key Features to Look For

When shopping for a laser cutter for metal sheets, certain key features should be at the forefront of your decision-making process. Look for machines equipped with high wattage lasers that can handle thick materials while providing precise cuts consistently. Other important aspects include user-friendly software compatibility and automation capabilities that enhance productivity and ease of operation in any workshop setting.

Selecting the Right Laser Machine

Choosing the right laser machine can feel like navigating a labyrinth, especially with so many options available for metal CNC cutting. Whether you're a hobbyist or a professional fabricator, selecting a laser cutter for aluminum requires careful consideration of your specific needs and project goals. This section will guide you through comparing models, understanding influencing factors, and recommending trusted brands to help you make an informed decision.

Comparing Models for Metal CNC Cutting

Some machines excel at precision and speed while others may focus on versatility and ease of use, particularly when working with sheet metal for laser cutting. Take into account factors such as power output, cutting thickness capabilities, and software compatibility; these aspects can greatly influence the efficiency of your cutting laser metal projects.

Additionally, consider the type of materials you plan to work with; some machines are better suited for thicker aluminum sheets while others shine in thin metal applications. Look at user reviews and performance benchmarks to gauge reliability and overall satisfaction among users who have similar needs as yours. Ultimately, finding the right balance between features and price will lead you to the perfect machine tailored to your specific requirements.

Factors Influencing Your Choice

Several key factors come into play when selecting a laser cutter for aluminum that aligns with your project demands. First off is budget; high-end machines may offer advanced features but could break the bank if you're just starting out or working on smaller projects. It's essential to evaluate how much you're willing to invest while keeping in mind potential future needs as your skills evolve.

Another important factor is the intended use—are you planning on doing intricate designs or larger cuts? Some machines cater more towards detailed work than others that might be optimized for bulk processing of metal sheets. Lastly, consider support services offered by manufacturers; reliable customer service can save you headaches down the line should any issues arise with your laser machine.

Recommendations for Laser Cutter Brands

One notable brand is Epilog Laser; renowned for their precision engineering and user-friendly interfaces that make them ideal for both beginners and seasoned professionals alike. Their machines are particularly effective at handling various thicknesses of aluminum without sacrificing cut quality.

Another strong contender is Trotec Laser; known specifically for their high-speed cutting capabilities paired with exceptional accuracy—perfect if you're looking to maximize productivity without compromising on detail in your projects involving cutting laser metal techniques. Lastly, don’t overlook Boss Laser; they provide excellent value-for-money options that cater well to small businesses or hobbyists seeking reliable machinery without breaking their budget.

Preparing Your Project for Cutting

Preparing your project for laser cutting is a crucial step that sets the stage for precision and quality. Whether you’re working with intricate designs or simple shapes, understanding the nuances of your materials and design will make all the difference. Let’s dive into how to set yourself up for success with aluminum and your laser cutting machine.

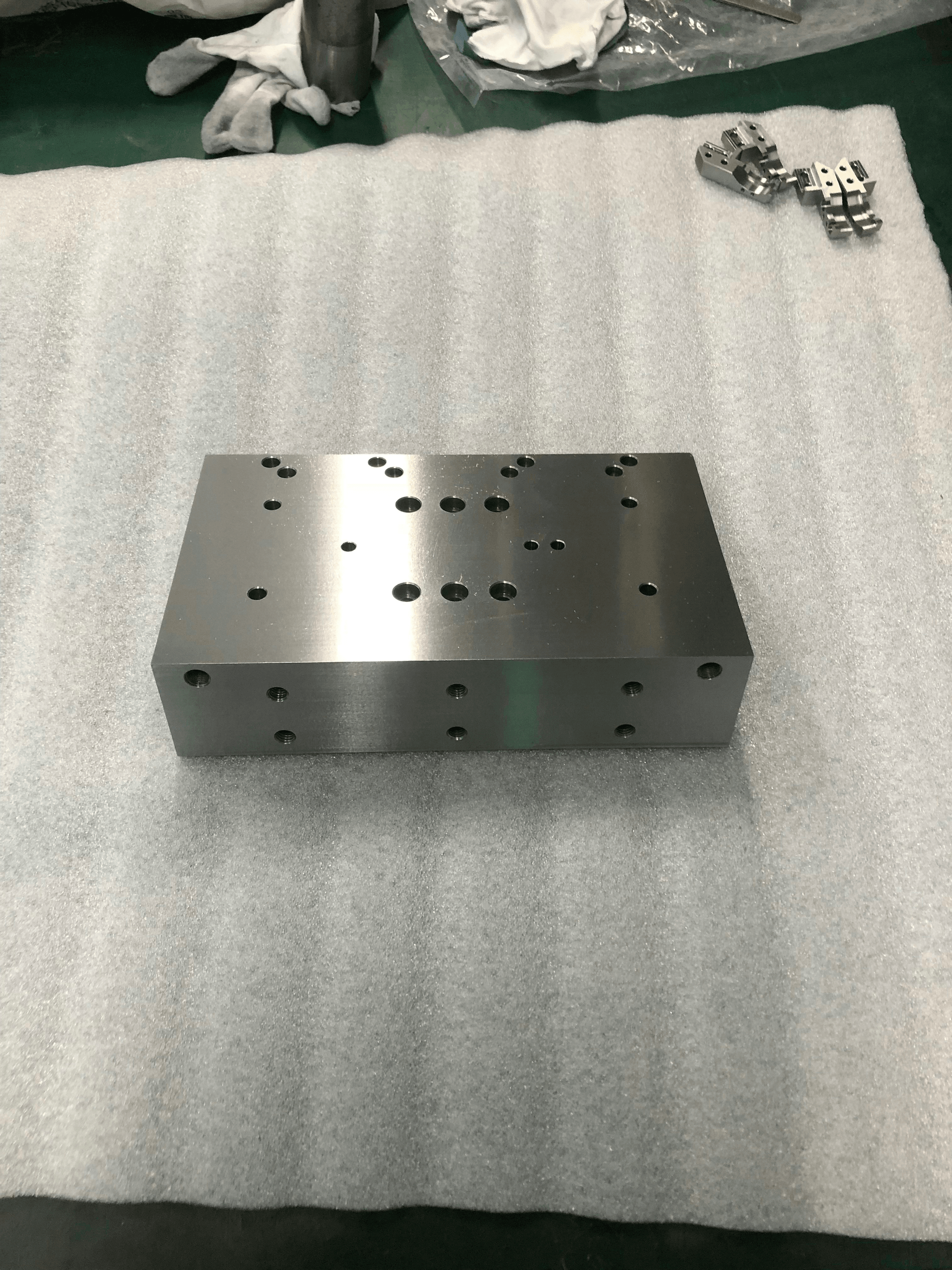

Choosing the Right Sheet Metal for Laser Cutting

Selecting the appropriate sheet metal for laser cutting is essential, especially when dealing with aluminum. Aluminum is favored in many projects due to its lightweight nature and resistance to corrosion, making it perfect for both functional and aesthetic applications. When choosing sheet metal for laser cutting, consider factors like thickness, alloy type, and surface finish; these can significantly affect how well your laser cutter for aluminum performs.

For optimal results, aim for high-quality sheets that are free from defects such as dents or scratches. The right thickness will depend on your specific project needs—thinner sheets allow more intricate cuts while thicker sheets provide sturdiness but require more powerful machines. Ultimately, investing time in selecting the right sheet metal will enhance the performance of your laser machine and yield better outcomes.

Designing Your Project for Optimal Results

Designing your project effectively is vital when using a laser cutter for metal sheets. Start by creating a digital model that takes full advantage of your laser cutting machine's capabilities; this includes incorporating precise measurements and considering kerf—the material removed during cutting—to ensure accuracy in dimensions. Use vector graphics software to create clean lines and shapes that will translate seamlessly into cut paths on your chosen sheet metal.

It's also wise to consider nesting techniques when arranging multiple pieces on a single sheet of aluminum; this maximizes material usage while minimizing waste—an eco-friendly approach! Additionally, keep in mind that certain designs may require tabs or bridges to prevent parts from falling during the cutting process; these small considerations can save you time during assembly later on.

Essential Software for Laser Cutting

Having the right software is just as crucial as having a reliable laser machine when preparing projects for cutting laser metal. Programs like Adobe Illustrator or CorelDRAW are popular choices among designers because they allow users to create detailed vector files compatible with most CNC machines used in metal fabrication. These tools help streamline design processes by offering features tailored specifically to preparing files for a laser cutter.

Moreover, many modern laser cutters come equipped with their own proprietary software designed specifically to optimize settings based on material type and thickness—this ensures you get flawless results every time you cut aluminum sheets! Don't forget about post-processing software either; programs that simulate cuts can help identify potential issues before you even fire up your machine.

Mastering the Laser Cutting Process

Mastering the laser cutting process is essential for achieving precision and quality in your projects. With a well-set-up laser cutter for aluminum, you can transform sheet metal into intricate designs with ease. This section will guide you through the setup, safety measures, and troubleshooting techniques necessary for successful metal CNC cutting.

Step-by-Step Setup for Your Laser Cutter

Setting up your laser cutter for aluminum involves several key steps to ensure optimal performance. First, begin by placing your laser cutting machine on a stable surface, ensuring it’s level and free from obstructions. Next, connect the power supply and make sure all cables are securely attached to avoid any mishaps during operation.

Once powered on, calibrate your laser machine according to the manufacturer’s guidelines—this typically includes adjusting the focus lens and bed height based on the thickness of your sheet metal for laser cutting. After calibration, load your design file into compatible software that communicates with your machine; this is crucial for accurate cuts in metal CNC cutting projects. Finally, conduct a test run on scrap material before diving into your actual project to fine-tune settings as needed.

Safety Precautions When Using a Laser Machine

Safety should always be at the forefront when operating a laser cutter for metal sheets. Begin by wearing appropriate personal protective equipment (PPE), including safety goggles designed to filter out harmful wavelengths emitted by the cutting laser metal process. Additionally, ensure that your workspace is well-ventilated to mitigate any fumes generated during cutting.

Keep flammable materials away from the vicinity of your laser machine; sparks can fly unexpectedly during operation! It’s also wise to familiarize yourself with emergency shut-off procedures—being prepared can save time and prevent accidents if something goes awry while using your laser cutter for aluminum projects.

Troubleshooting Common Issues

Even seasoned users may encounter hiccups while using their laser cutting machines; knowing how to troubleshoot common issues can save both time and frustration. One frequent problem is inconsistent cuts which may stem from improper focus or speed settings—double-check these parameters against recommendations specific to aluminum sheet thicknesses used in metal CNC cutting.

Another issue might be related to software glitches or communication errors between design files and the machine itself; ensure that you are using compatible formats and that drivers are up-to-date before starting a job. Lastly, if you notice excessive slag or burn marks on cut edges of your sheet metal for laser cutting, consider adjusting power levels or using different gas assist options available in some advanced models.

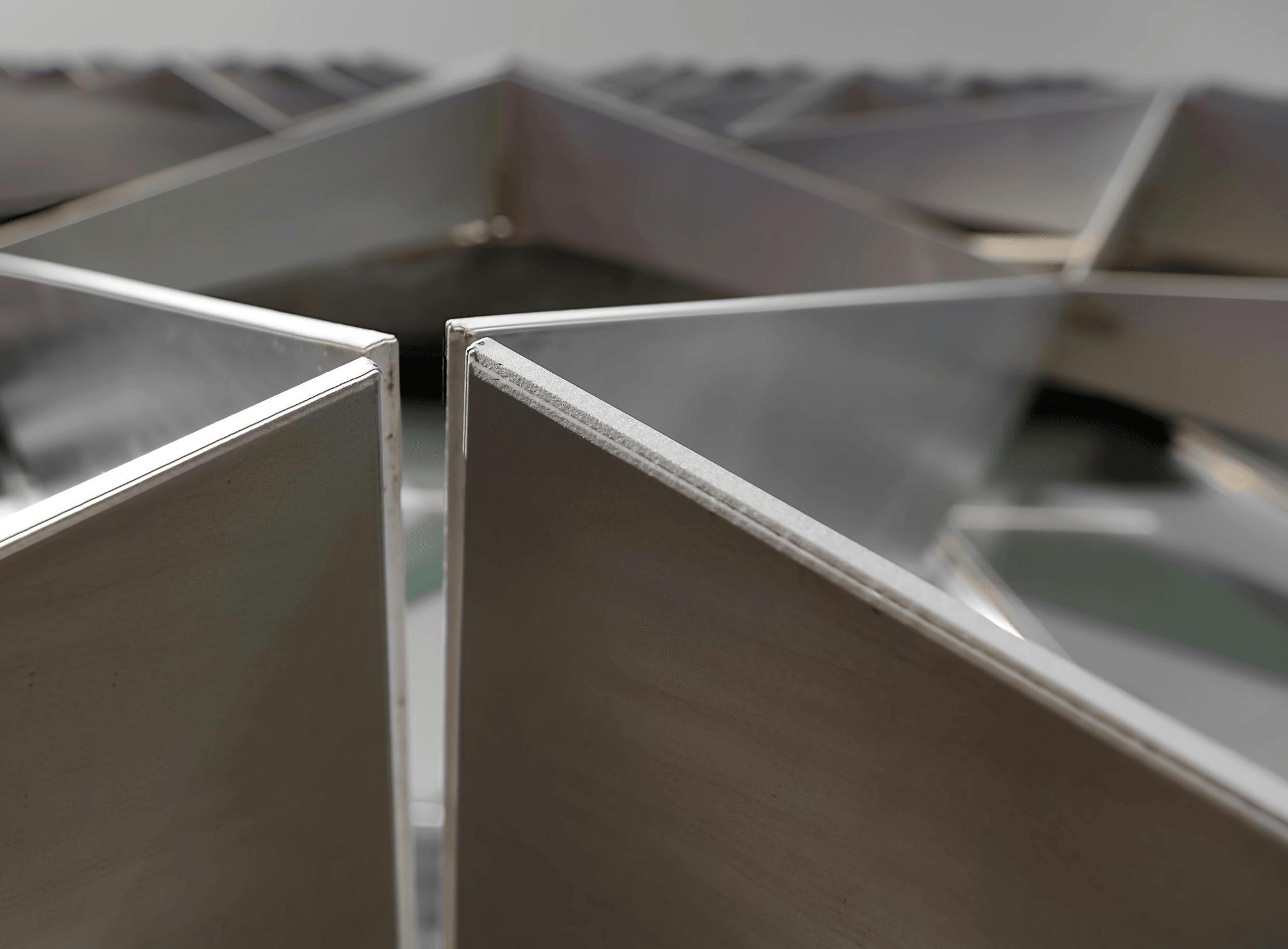

Post-Cutting Techniques and Finishing Touches

Once you've completed your cutting process using a laser cutter for aluminum, it’s time to focus on post-cutting techniques that will elevate your project. The finishing touches can make a significant difference in the overall appearance and functionality of your aluminum pieces. Whether you’re working with intricate designs or simple shapes, these techniques will ensure that your work shines.

Techniques for a Clean Finish

Achieving a clean finish after using a laser cutting machine is crucial for enhancing the aesthetic appeal of your projects. Start by removing any slag or residue left on the edges of the cut; this can often be done with a soft brush or compressed air to avoid scratching the surface. Additionally, consider using sandpaper or a deburring tool to smooth out rough edges, ensuring that your sheet metal for laser cutting has that professional touch.

Another effective technique is applying a protective coating after cleaning to prevent oxidation and maintain the luster of the metal. This not only enhances durability but also provides an attractive sheen that gives your project an extra edge. Remember, attention to detail in this stage can elevate even the simplest designs into stunning works of art.

Advanced Methods for Cutting Laser Metal

For those looking to push their projects further, exploring advanced methods for cutting laser metal can yield impressive results. Techniques such as multi-pass cutting allow you to achieve greater depth and precision in thicker materials, making it easier to handle complex designs without compromising quality. Utilizing different speeds and power settings on your laser machine can also help fine-tune cuts based on material thickness and type.

You might also want to experiment with gas assist options like oxygen or nitrogen during the cutting process; these can enhance speed and reduce dross formation significantly. By mastering these advanced methods, you’ll be able to create intricate patterns and features that stand out in any project involving metal CNC cutting. Keep pushing boundaries—your creativity is your only limit!

Enhancing Your Projects with Aftercare

Aftercare is where you truly transform good projects into great ones! Once you've finished cutting with your laser cutter for metal sheets, consider polishing or anodizing surfaces for enhanced aesthetics and protection against wear over time. Polishing brings out the natural shine of aluminum while anodizing adds color options along with corrosion resistance—perfect for outdoor applications!

Additionally, if you're looking at custom designs or branding opportunities, engraving with your laser machine offers an excellent way to personalize each piece further. This step not only adds value but also creates unique identifiers that set your work apart from mass-produced alternatives in today’s market landscape. With proper aftercare techniques applied thoughtfully, every project becomes a testament to craftsmanship.

Conclusion

In the world of fabrication, mastering the art of laser cutting can truly elevate your craft. Whether you're working on intricate designs or large-scale projects, a laser cutter for aluminum offers precision and efficiency that traditional methods simply can't match. By embracing this technology, you not only enhance your capabilities but also open doors to new creative possibilities.

Elevate Your Craft with Laser Cutting

Utilizing a laser cutting machine allows artisans and manufacturers alike to achieve unparalleled accuracy in their work. With the ability to cut through various materials, including sheet metal for laser cutting, you can bring your wildest designs to life with ease. The fine detail and smooth edges produced by a laser machine make it possible to create stunning pieces that stand out in any market.

Moreover, investing in a reliable laser cutter for metal sheets can significantly streamline your production process. The speed at which these machines operate means you can take on larger projects without sacrificing quality or precision. As you harness the power of cutting laser metal technology, you'll find that your craftsmanship reaches new heights, setting you apart from competitors and delighting customers.

Future Trends in Laser Technology

As technology continues to evolve, so too does the landscape of laser cutting machines. Innovations such as fiber lasers are becoming increasingly popular due to their efficiency and versatility when it comes to metal CNC cutting applications. This trend is likely to shape the future of fabrication processes, making them faster and more environmentally friendly.

Additionally, advancements in software integration are enhancing how we design projects for optimal results before they even reach the laser cutter for aluminum stage. With improved CAD tools and simulation software at our disposal, fabricators can visualize their projects more accurately than ever before. This synergy between hardware and software is paving the way for smarter manufacturing practices across industries.

Kiant Machinery: Your Partner in Precision Cutting

Their range of high-quality laser cutters is specifically designed for aluminum and other metals, ensuring you have access to top-tier equipment that meets all project demands. With a commitment to customer satisfaction and support, Kiant Machinery empowers users at every step of their fabrication journey.

By choosing Kiant Machinery's products, you're not just purchasing equipment; you're investing in a partnership dedicated to helping you thrive in an increasingly competitive market. Their expertise ensures that whether you're using a basic model or an advanced system tailored for complex designs, you'll always have access to essential resources like training materials and troubleshooting assistance related to metal CNC cutting techniques.

In conclusion, embracing the capabilities offered by advanced laser machines will undoubtedly elevate your craft while keeping you ahead of industry trends—especially with trusted partners like Kiant Machinery by your side.