Introduction

In the ever-evolving landscape of manufacturing, fiber laser tube cutting is at the forefront of innovation, transforming traditional methods into highly efficient processes. This advanced laser cutting technique significantly enhances precision and speed, making it a game-changer for industries that rely on quality and efficiency. With the rise of this technology, businesses are not only improving their production capabilities but also redefining what is possible with a laser cutter.

Revolutionizing Tube Cutting Techniques

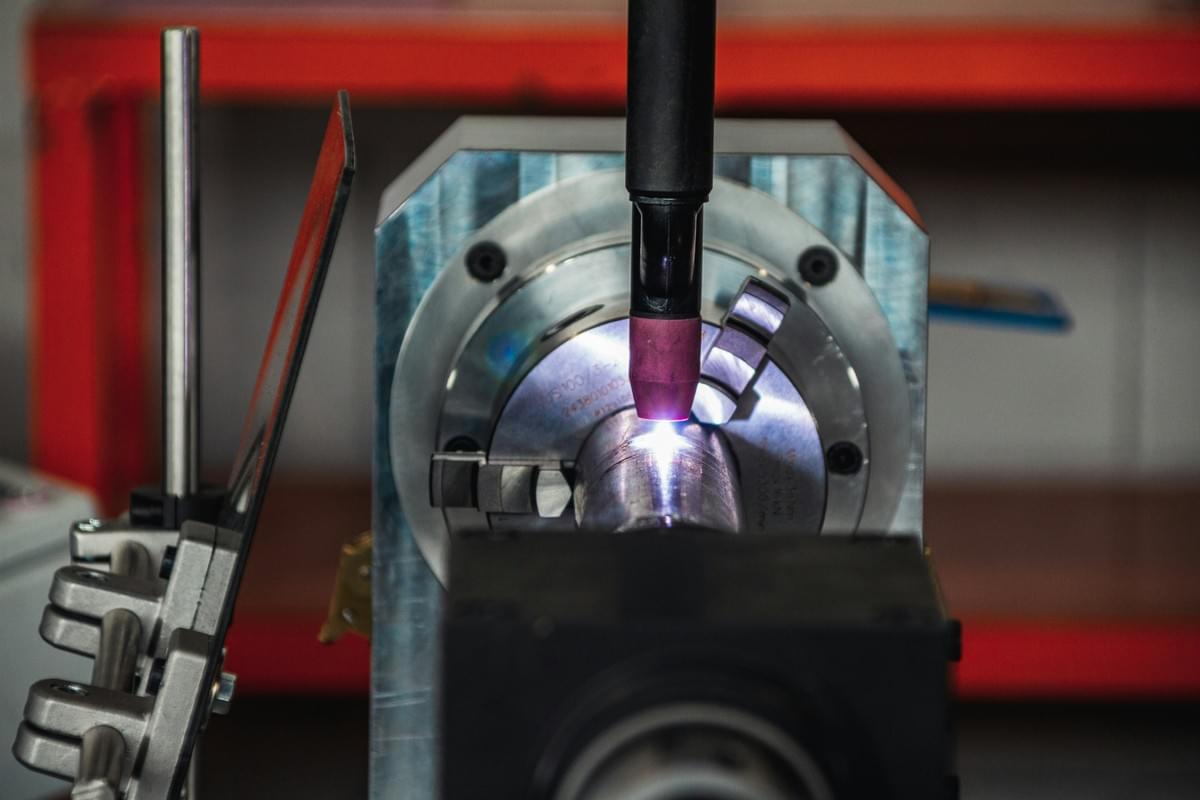

The advent of fiber laser tube cutting has revolutionized how manufacturers approach tube processing. Unlike conventional methods, this cutting machine laser utilizes focused light to achieve clean cuts with minimal waste, allowing for intricate designs that were previously challenging to execute. As a result, companies are embracing these advanced techniques to stay competitive in an increasingly demanding market.

Benefits of Fiber Laser Tube Cutting

Fiber laser tube cutting offers numerous benefits that enhance manufacturing efficiency and reduce operational costs. One key advantage is its ability to cut through various materials with exceptional speed and accuracy, which translates into higher productivity levels for businesses using a laser machine. Moreover, the reduced maintenance requirements associated with these machines lead to lower downtime and increased profitability over time.

Future Trends in Laser Cutting

Looking ahead, the future trends in laser cutting indicate an even greater integration of automation and smart technologies within manufacturing processes. As industries continue to adopt cutting-edge solutions like fiber laser tube cutting, we can expect advancements such as real-time monitoring systems and AI-driven optimization tools to become commonplace in production environments. These innovations will not only streamline operations but also pave the way for more sustainable practices across various sectors.

Advanced Laser Cutting Technologies

The world of laser cutting is evolving rapidly, with fiber laser tube cutting leading the charge in innovation and efficiency. As manufacturers seek to optimize their processes, understanding the nuances between different laser technologies becomes crucial. This section will delve into the comparison of fiber lasers and CO2 lasers, highlight innovations in laser machine design, and explore the benefits of automation in cutting processes.

Comparison of Fiber Laser vs CO2 Lasers

One significant advantage of a fiber laser cutter is its maintenance requirements; these machines typically require less upkeep than their CO2 counterparts due to fewer moving parts. This translates into reduced downtime and lower operational costs over time. Furthermore, advancements in technology have made fiber laser machines more compact and versatile, allowing them to fit seamlessly into existing production lines.

In summary, while both types of lasers have their merits, fiber lasers stand out for their energy efficiency, lower maintenance needs, and superior performance on thinner materials. As industries continue to evolve towards more precise manufacturing techniques, the shift towards fiber technology appears inevitable.

Innovations in Laser Machine Design

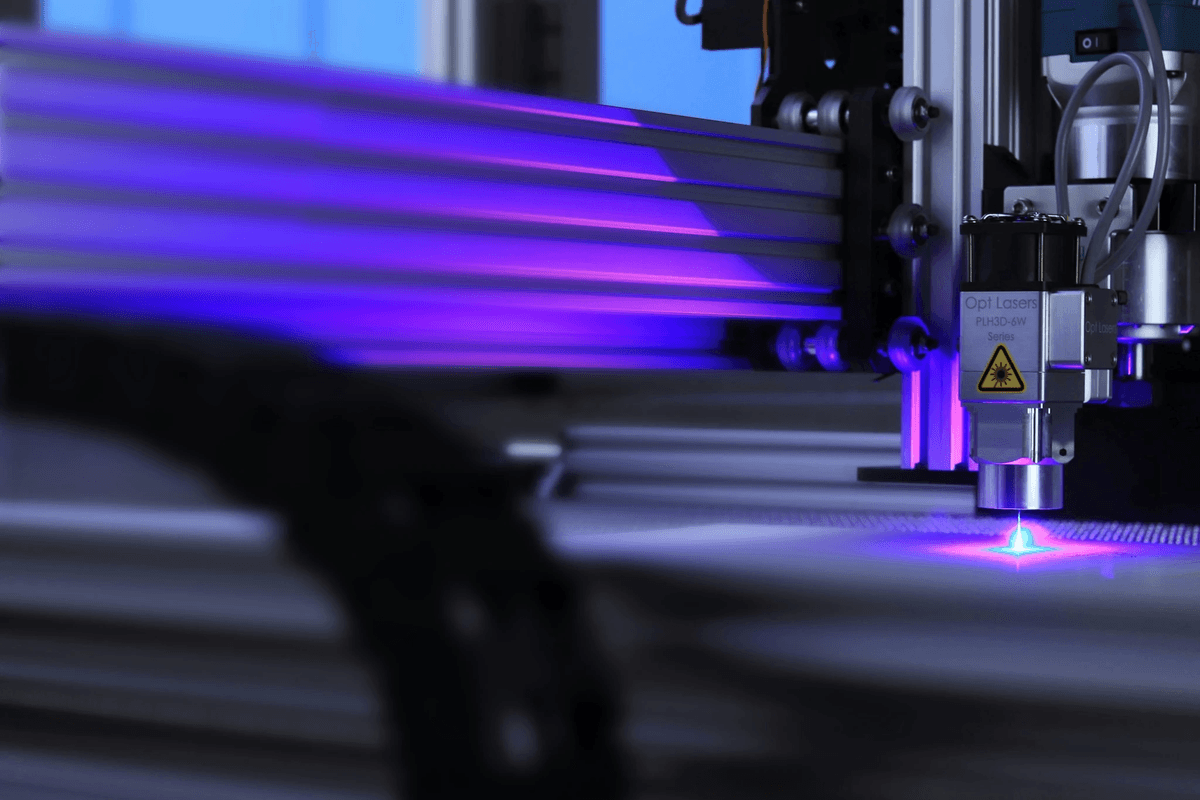

Innovations in laser machine design are revolutionizing how we approach cutting tasks across various industries. Modern cutting machines now feature integrated software that allows operators to program complex cuts with ease—saving time and reducing human error during setup. The latest models also incorporate advanced cooling systems that ensure optimal performance during extended operations.

Moreover, advancements in robotic integration are enhancing the capabilities of a laser cutter by automating loading and unloading processes. This not only improves production speed but also minimizes workplace injuries by reducing manual handling requirements. With smart technologies like IoT (Internet of Things) being integrated into these machines, manufacturers can monitor performance metrics remotely for proactive maintenance.

As companies invest in state-of-the-art equipment that includes these innovative features, they can expect significant improvements in overall productivity and product quality from their cutting machine laser systems. The future looks bright as designers continue pushing boundaries with new functionalities tailored specifically for various applications.

Benefits of Automation in Cutting Processes

The integration of automation into laser cutting processes is transforming how manufacturers operate on a daily basis. By employing automated systems alongside a fiber laser tube cutting setup or any other type of cutter machine; businesses can achieve remarkable gains in efficiency while reducing labor costs significantly. Automation streamlines workflows by minimizing manual intervention—allowing teams to focus on higher-level tasks that drive growth instead.

Additionally, automated systems enhance precision by ensuring consistent cuts across multiple batches without variations caused by human error or fatigue—a common issue with manual operations using traditional methods like CO2 lasers or even older models of machine tools! With real-time monitoring capabilities built-in through advanced software solutions available today; companies can quickly identify bottlenecks within production lines before they escalate into larger problems down the road.

Ultimately embracing automation within your manufacturing process not only elevates productivity but also contributes positively toward sustainability efforts through optimized resource usage—all while maintaining high-quality standards expected from top-tier equipment such as modern-day fiber-laser cutters!

Case Studies of Successful Implementations

The adoption of fiber laser tube cutting technology has surged across various industries, showcasing its transformative impact on manufacturing processes. Companies are increasingly turning to laser cutting solutions to enhance their operational efficiency and reduce production costs. By examining notable case studies, we can glean valuable insights into how this cutting-edge technology is reshaping the landscape of tube cutting.

Notable Companies Using Fiber Laser Tube Cutting

Several leading companies have embraced fiber laser tube cutting, setting benchmarks in their respective industries. For instance, a prominent automotive manufacturer integrated a state-of-the-art laser machine for precision tube fabrication, significantly improving their production line's speed and accuracy. Similarly, a well-known furniture design company utilized a laser cutter to create intricate designs from metal tubes, allowing for greater creativity while maintaining structural integrity.

These organizations illustrate how adopting advanced laser machine technologies can lead to remarkable outcomes. With the ability to cut various materials with precision and minimal waste, these companies have positioned themselves at the forefront of innovation in manufacturing. As they continue to invest in fiber laser tube cutting capabilities, they set an example for others aiming to enhance productivity and quality.

Efficiency Improvements in Manufacturing

The implementation of fiber laser tube cutting has led to substantial efficiency improvements within manufacturing operations. By utilizing a high-speed cutting machine laser, companies can achieve faster turnaround times while maintaining exceptional quality standards. This increase in operational efficiency not only streamlines production but also allows businesses to respond more rapidly to market demands.

Moreover, the automation features incorporated into modern laser machines play a pivotal role in optimizing workflow processes. With automated material handling systems integrated into the setup, manufacturers can minimize downtime and maximize output levels significantly. As a result, many organizations report enhanced productivity metrics that directly correlate with their investment in advanced laser cutting technologies.

Cost Reductions Achieved with Laser Cutting

One of the most compelling advantages of adopting fiber laser tube cutting is the significant cost reductions it offers manufacturers. The precision and speed of a modern laser cutter minimize material waste during production—a critical factor when dealing with expensive raw materials like metals or specialized alloys. Consequently, companies experience lower operational costs while simultaneously boosting their profit margins.

Additionally, reduced labor costs contribute further to overall savings as automated processes lessen reliance on manual labor for intricate cuts and setups using traditional methods. Many businesses have reported that switching from conventional techniques to advanced laser machine solutions has resulted in considerable financial benefits over time. It’s clear that investing in fiber laser tube cutting technology is not just about enhancing capabilities; it’s also about achieving substantial cost efficiencies that can redefine business viability.

Choosing the Right Laser Cutting Machine

Selecting the right laser cutting machine is crucial for optimizing your fiber laser tube cutting operations. With a variety of options available, it’s essential to consider key features that will enhance efficiency and productivity. Understanding these components will help you make an informed decision and invest wisely in your future.

Key Features to Look for in a Cutting Machine

When evaluating a cutting machine laser, prioritize features that maximize performance and versatility. Look for advanced control systems that allow for precise adjustments, ensuring that your laser cutter can handle various materials with ease. Additionally, consider machines equipped with automated loading and unloading systems to streamline operations and reduce manual labor.

Another important feature is the power output of the laser machine; higher wattage can lead to faster cutting speeds and cleaner edges in fiber laser tube cutting applications. You should also assess the size of the cutting bed to ensure it meets your project requirements—larger beds accommodate bigger materials, providing greater flexibility in design choices. Lastly, don’t overlook customer support options; reliable service can save you time and money in case of any issues down the line.

Understanding Different Laser Machine Types

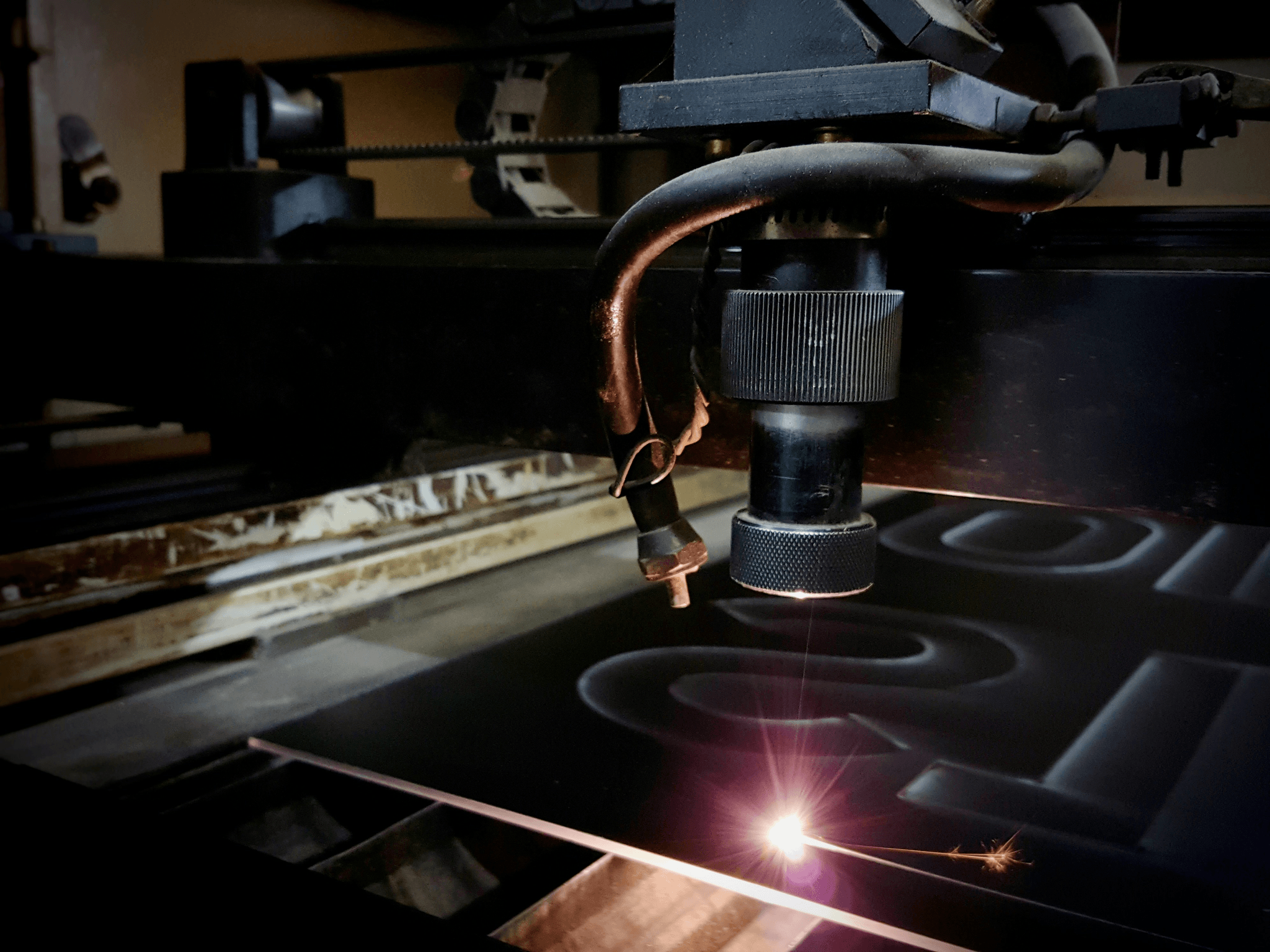

There are several types of laser machines available on the market, each designed for specific applications within the realm of laser cutting. Fiber lasers are particularly popular due to their efficiency and ability to cut through a wide range of metals with precision—making them ideal for fiber laser tube cutting tasks. Conversely, CO2 lasers are better suited for non-metal materials like wood or acrylic but typically lack the speed and efficiency offered by fiber lasers.

Moreover, it's essential to understand whether you need a flatbed or 3D laser cutter based on your projects' requirements. Flatbed cutters excel at processing sheets while 3D models offer more versatility for complex shapes and designs—ideal if your work involves intricate tube profiles or custom designs. Familiarizing yourself with these different types will empower you to choose a machine tailored specifically to meet your needs.

Recommendations from Kiant Machinery

Kiant Machinery offers an impressive lineup of advanced laser machines designed specifically for fiber laser tube cutting applications. Their models incorporate state-of-the-art technology that guarantees precision cuts while minimizing waste material—a win-win situation! With robust automation features like intelligent loading systems, Kiant’s machines significantly enhance productivity while reducing operational costs.

For those just venturing into the world of laser cutting, Kiant Machinery provides excellent entry-level models that balance affordability with high performance capabilities—perfect for small businesses looking to scale up their production without breaking the bank! Additionally, their expert team is always ready to offer personalized recommendations based on your unique business needs and objectives.

Investing in a quality cutting machine from Kiant Machinery not only ensures superior results but also positions you well within an ever-evolving industry landscape where innovation is key!

Best Practices for Laser Cutting Operations

Laser cutting operations can be a game-changer in manufacturing, especially with the rise of fiber laser tube cutting technology. To truly harness the potential of a laser cutter, it's essential to implement best practices that optimize performance and ensure safety. This section will delve into optimizing material flow, maintenance tips for longevity, and adhering to safety standards.

Optimizing Material Flow and Setup

Efficient material flow is crucial in maximizing the productivity of your laser machine. Start by organizing your workspace to minimize unnecessary movement; this means positioning raw materials and finished products strategically around the cutting machine laser setup. Additionally, using software that tracks material usage can help streamline processes, ensuring that your fiber laser tube cutting operations run smoothly without interruptions.

Another key aspect of optimizing setup is proper calibration of the laser cutter before each job. Ensuring that the cutting machine laser is correctly aligned with the material will lead to precise cuts and reduce waste significantly. By investing time in these initial setups, manufacturers can enjoy not only improved efficiency but also enhanced quality in their final products.

Lastly, consider implementing automated systems for loading and unloading materials during laser cutting jobs. Automation can drastically reduce manual handling time while increasing throughput rates—especially beneficial in high-volume production settings where fiber laser tube cutting shines.

Maintenance Tips for Longevity of Equipment

Maintaining your laser machine is paramount for ensuring its longevity and consistent performance over time. Regular inspections should include checking optical components like lenses and mirrors; keeping these clean will enhance beam quality during fiber laser tube cutting operations. Furthermore, establishing a routine maintenance schedule helps catch potential issues early before they escalate into costly repairs or downtime.

Another vital aspect is monitoring coolant levels if your cutting machine uses them; maintaining optimal temperature reduces wear on components significantly. Additionally, keeping an eye on mechanical parts such as belts and bearings ensures smooth operation without unexpected failures during critical production times.

Lastly, don’t underestimate the importance of software updates for your laser cutter's operating system; these updates often come with performance enhancements or new features that can improve efficiency or safety protocols within your operations. By prioritizing maintenance across all facets—mechanical, optical, and software—you’ll ensure that your investment in a high-quality laser machine pays off long term.

Safety Standards in Fiber Laser Tube Cutting

Safety should always be at the forefront when operating any type of machinery—especially one as powerful as a fiber laser tube cutter! First off, make sure all operators are trained on standard safety protocols specific to using a cutting machine laser; this includes understanding emergency shut-off procedures and proper equipment handling techniques to prevent accidents.

Personal protective equipment (PPE) is non-negotiable when working around lasers; appropriate eyewear designed to block harmful wavelengths must be worn at all times during operation sessions involving any form of laser cutting—this protects vision from potential damage caused by stray beams or reflections from surfaces being cut.

Finally, establishing clear guidelines regarding workspace organization contributes significantly toward creating a safe environment around the fiber laser tube cutting area. Ensure pathways are clear from obstructions so operators can move freely without risk while maintaining adequate signage about hazards associated with high-powered equipment like lasers—a little caution goes a long way!

Training and Support for Laser Cutting Success

In the rapidly evolving world of fiber laser tube cutting, proper training and support are paramount for achieving operational excellence. As businesses integrate advanced laser cutting technologies into their manufacturing processes, the need for skilled operators becomes increasingly critical. A well-trained team can maximize the capabilities of a laser cutter, ensuring precision and efficiency while minimizing downtime.

Importance of Operator Training

Operator training is vital to harnessing the full potential of a cutting machine laser. Skilled operators not only understand how to operate the equipment but also know how to troubleshoot common issues that may arise during laser cutting operations. With comprehensive training, they can optimize settings for different materials, leading to improved cut quality and reduced waste.

Moreover, effective operator training enhances safety standards in fiber laser tube cutting environments. Trained personnel are more aware of safety protocols and best practices, reducing risks associated with operating powerful machinery like a laser machine. Ultimately, investing in operator education translates into higher productivity and better overall performance in manufacturing processes.

Kiant Machinery’s Support Services

Kiant Machinery recognizes that ongoing support is essential for successful laser cutting operations. Their dedicated support services include technical assistance, routine maintenance checks, and prompt response times for any issues that may arise with your laser machine. This commitment ensures that your fiber laser tube cutting systems remain operational and efficient.

Additionally, Kiant Machinery offers tailored training programs designed specifically for their machines. These programs cover everything from basic operation to advanced techniques in using a laser cutter effectively, making sure that your team is well-equipped to handle any challenge they face in the production line. With such robust support services at your disposal, you can rest assured that your investment in a cutting machine will yield significant returns.

Adapting to New Technologies in Laser Cutting

The landscape of laser cutting technology is ever-changing; staying ahead requires adaptability and continuous learning. As new advancements emerge—such as enhanced software integration or improved automation features—it's crucial for operators to familiarize themselves with these innovations within their existing fiber laser tube cutting systems. Embracing these changes not only boosts efficiency but also provides a competitive edge in the market.

Kiant Machinery encourages its clients to keep abreast of technological developments through workshops and seminars focused on emerging trends in fiber laser technology. By fostering an environment where learning is prioritized, companies can ensure their teams are prepared to integrate new tools seamlessly into their workflows using advanced machines like a state-of-the-art laser machine machine. In this way, adapting to new technologies becomes less daunting and more rewarding.

Conclusion

The world of manufacturing is undergoing a seismic shift, largely driven by innovative methods like fiber laser tube cutting. This advanced technology not only enhances precision but also streamlines production processes, making it a game-changer for industries worldwide. By integrating laser cutting techniques into their operations, manufacturers are experiencing unprecedented levels of efficiency and productivity.

Transforming Manufacturing with Innovative Methods

Fiber laser tube cutting is at the forefront of this transformation, offering superior accuracy compared to traditional methods. With the ability to cut through various materials seamlessly, a laser cutter has become an essential tool in modern manufacturing environments. As companies adopt these innovative techniques, they are finding that the benefits extend far beyond mere speed; they encompass quality improvements and reduced waste as well.

The Role of Kiant Machinery in Your Success

Kiant Machinery stands out as a leader in providing high-quality laser machines tailored for diverse applications in fiber laser tube cutting. Their commitment to innovation ensures that businesses have access to cutting machines that meet evolving industry standards and demands. With expert guidance and support services from Kiant Machinery, manufacturers can fully leverage the capabilities of their laser machine to achieve optimal results.

Embracing the Future of Tube Cutting Technology

As we look ahead, it’s clear that embracing advancements in laser cutting technology will be crucial for staying competitive. The future promises even more sophisticated developments in laser machine design and automation, further enhancing performance and efficiency in operations. By investing in state-of-the-art solutions today, businesses position themselves to thrive tomorrow with fiber laser tube cutting at their core.