Introduction

In the fast-paced world of manufacturing, laser pipe cutting technology has emerged as a game-changer, offering unparalleled precision and efficiency. This innovative approach to cutting metal has revolutionized how industries handle their metal fabrication needs, allowing for intricate designs and high-quality finishes with minimal waste. With the advent of advanced laser pipe cutting equipment, businesses can now achieve results that were once deemed impossible with traditional methods.

Overview of Laser Pipe Cutting Technology

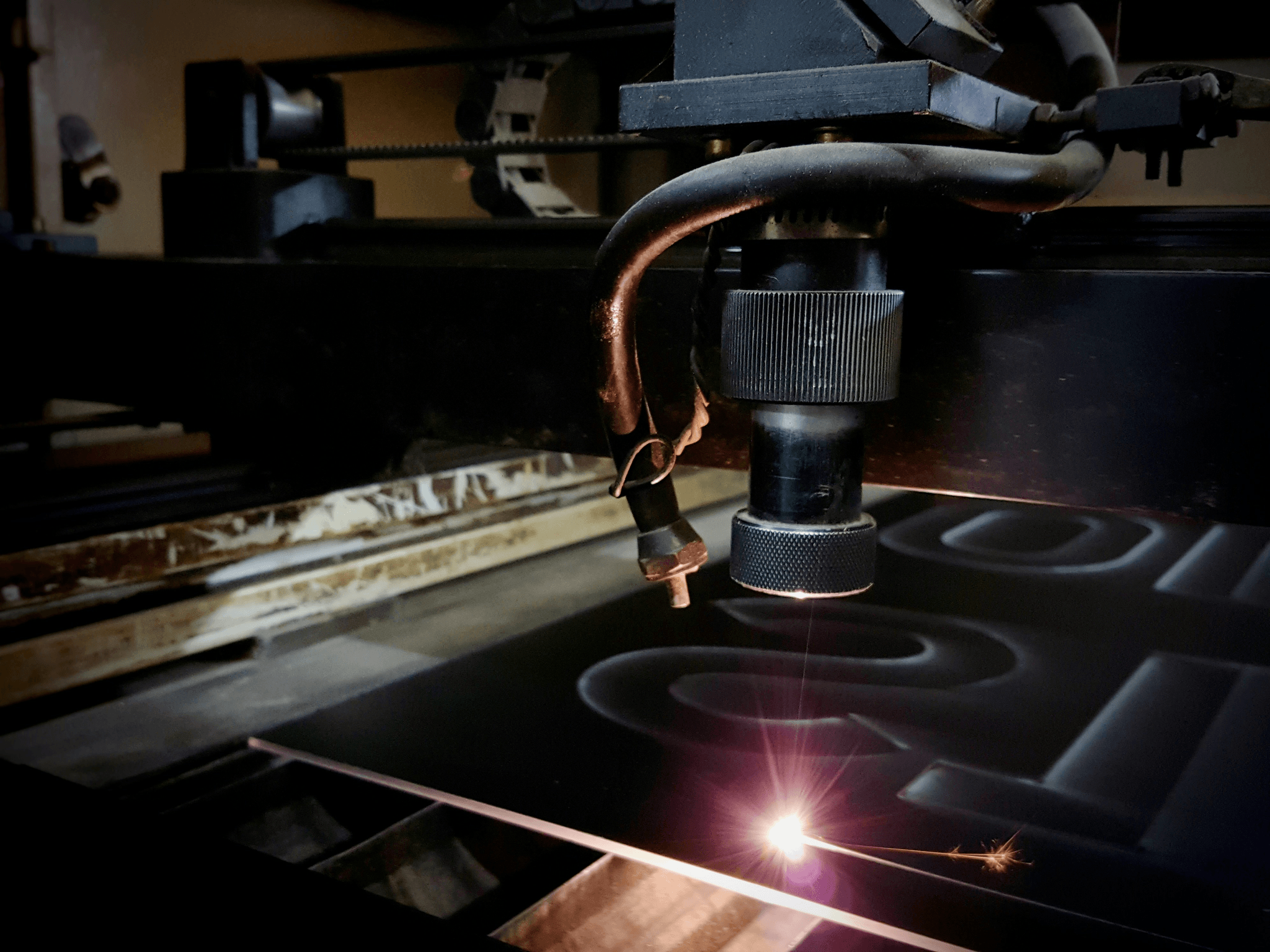

Laser pipe cutting technology utilizes focused beams of light to slice through various types of metal with incredible accuracy. The process involves directing a concentrated laser beam onto the material, which is then melted or vaporized away in a controlled manner. This method not only enhances the quality of machine cut metal but also significantly reduces production time compared to conventional cutting methods.

Importance of Heavy-Duty Cutters

Heavy-duty cutters are essential in industries where durability and performance are paramount. These robust machines are designed to handle thicker materials and more demanding workloads without compromising on precision or speed. Investing in heavy-duty laser cutting machinery ensures that businesses can meet high-volume demands while maintaining consistent quality in their products.

Advancements in Laser Cutting Equipment

Recent advancements in laser cutting equipment have introduced features such as improved software integration, enhanced safety measures, and greater energy efficiency. Modern cutting machines leverage state-of-the-art technology to optimize performance and minimize downtime during operations. As manufacturers continually seek ways to improve productivity, these innovations make it easier than ever to incorporate cutting laser metal techniques into everyday practices.

Understanding Laser Pipe Cutting Equipment

When it comes to modern manufacturing, laser pipe cutting equipment stands at the forefront of innovation. These machines are designed to deliver precision and efficiency in cutting metal tubes and pipes, making them indispensable for a variety of industries. Understanding how these machines work, their key features, and how to choose the right one for your needs can greatly enhance your production capabilities.

How Laser Cutters Work

Laser cutting technology employs a focused beam of light to melt or vaporize material, allowing for intricate designs and clean cuts in metal. The cutting machine laser uses a high-powered laser that is directed through optics onto the surface of the material being cut, resulting in minimal waste and maximum accuracy. This process is not only efficient but also versatile enough to handle different types of metals with varying thicknesses.

The core mechanism involves directing a concentrated beam onto the metal's surface while simultaneously moving it along predetermined paths. This allows for complex shapes and designs that traditional cutting methods struggle to achieve. With advancements in technology, modern laser machinery can now be equipped with features such as automatic height sensing and real-time monitoring to optimize performance further.

Key Features of Heavy-Duty Models

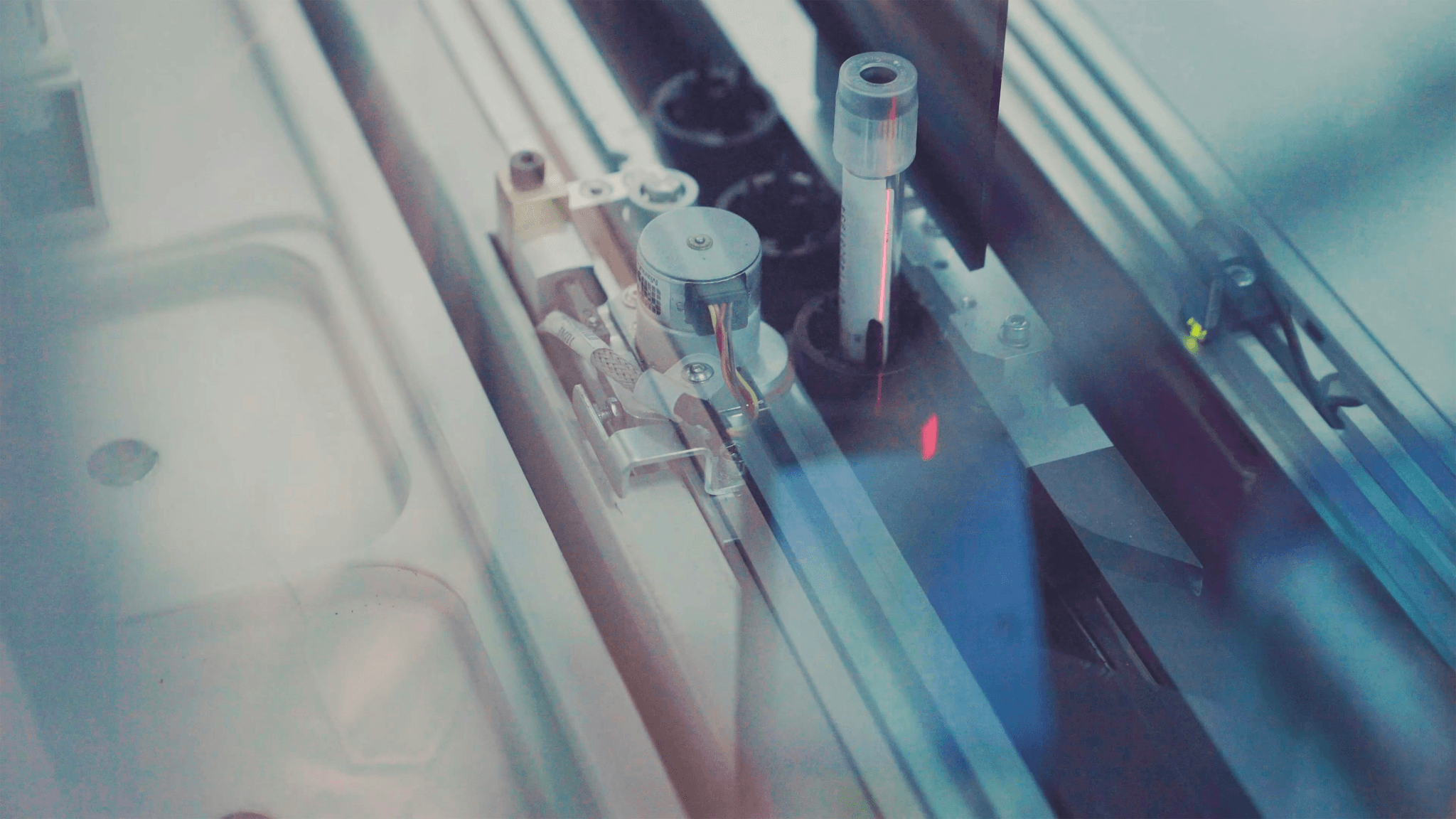

Heavy-duty models of laser pipe cutting equipment are built with robust components that ensure reliability under demanding conditions. One key feature is their increased power output, enabling them to cut through thicker materials without compromising speed or quality—ideal for industrial applications where machine cut metal needs precision and durability. Additionally, these models often come equipped with advanced cooling systems that prevent overheating during prolonged usage.

Another standout feature is automation capabilities; many heavy-duty lasers offer automated loading and unloading systems that streamline production processes significantly. Enhanced software integration allows operators to program complex patterns easily while maintaining high levels of accuracy throughout the cutting process. Furthermore, user-friendly interfaces make it easier for operators at all skill levels to navigate the machine’s functions effectively.

Choosing the Right Equipment for Your Needs

Selecting the right laser pipe cutting equipment hinges on understanding your specific requirements—such as material type, thickness, and production volume. It’s essential first to assess what you will be primarily using your cutting machine laser for; this helps narrow down options based on power requirements and additional features needed for optimal performance. Consulting with manufacturers or industry experts can provide valuable insights into which model will best suit your operational demands.

Budget considerations also play a critical role; while investing in high-quality laser machinery may seem daunting initially, it often pays off through enhanced productivity and reduced operational costs over time. Look beyond just price—consider warranty options, customer support services offered by brands like Kiant Machinery, and potential maintenance costs associated with different models before making your decision.

Lastly, don’t forget about scalability—selecting equipment that can grow alongside your business ensures you won’t need frequent replacements as demand changes over time. By carefully evaluating these factors when choosing a cutting laser metal system tailored to your needs, you’ll be well-equipped for success in today’s competitive manufacturing landscape.

Benefits of Using a Tube Laser Cutter

When it comes to modern manufacturing, the advantages of utilizing a tube laser cutter are hard to ignore. This innovative laser pipe cutting equipment offers solutions that traditional cutting methods simply can't match. From precision engineering to cost-effective production, the benefits are numerous and profound.

Increased Precision and Accuracy

One of the standout features of laser cutting technology is its unparalleled precision and accuracy. The laser cutting machine directs an intense beam that can cut through metal with incredible exactness, ensuring every piece meets stringent specifications. This level of detail is particularly beneficial in industries where machine cut metal components must fit together seamlessly, eliminating costly errors and rework.

Enhanced Production Speed

Speed is another area where laser machinery excels, significantly boosting overall productivity in manufacturing environments. Unlike traditional cutting methods that may require multiple steps or manual adjustments, a cutting machine laser can operate continuously with minimal downtime. This efficiency not only accelerates production timelines but also allows businesses to respond more quickly to customer demands.

Cost Efficiency in Manufacturing

Investing in a tube laser cutter can lead to substantial cost savings over time, making it an attractive option for manufacturers looking to optimize their operations. The precision cuts produced by this equipment reduce material waste, while the enhanced speed translates into lower labor costs per unit produced. Additionally, the durability and reliability of modern laser pipe cutting equipment mean less frequent repairs and replacements—further contributing to long-term financial benefits.

Applications of Laser Tube Cutting

Laser tube cutting has become a game-changer in various industries, offering not just precision but also versatility. The ability to machine cut metal with unparalleled accuracy makes laser cutting machines indispensable in manufacturing environments. As we explore the applications of laser pipe cutting equipment, it’s clear that this technology is shaping the future of production.

Industries That Benefit Most

Several industries have reaped the rewards of integrating laser pipe cutting equipment into their operations. The automotive sector, for instance, utilizes these machines to create intricate components that require high precision and speed. Similarly, the construction and architecture fields benefit from using a cutting machine laser to produce customized metal frameworks and supports efficiently.

In addition to automotive and construction, the aerospace industry also relies heavily on laser machinery for fabricating lightweight yet strong parts that meet rigorous safety standards. These sectors appreciate how laser cutting enhances productivity while maintaining quality control across various applications. Ultimately, any industry that requires machine cut metal can find significant advantages in adopting advanced laser tube cutting technology.

Customization Capabilities

One of the standout features of modern laser cutting technology is its incredible customization capabilities. Unlike traditional methods, which often involve extensive tooling changes for different designs, a laser cutting machine allows for quick adjustments between projects without sacrificing quality or speed. This flexibility means businesses can respond rapidly to customer demands for unique designs or specifications.

Moreover, advanced software integrated with these machines enables operators to create complex shapes and patterns that would be nearly impossible with conventional techniques. Whether it's intricate engravings or bespoke parts tailored to specific requirements, the versatility offered by a cutting laser metal system makes it an invaluable asset in any workshop seeking innovation and differentiation in their offerings.

Case Studies of Successful Implementations

To illustrate the impact of laser pipe cutting equipment further, consider a case study from an automotive manufacturer who adopted this technology to streamline their production line. By switching from traditional machining methods to a state-of-the-art laser cutting machine, they reported a 30% increase in production efficiency while reducing material waste significantly—talk about hitting two birds with one stone!

Another compelling example comes from a custom furniture company that utilized heavy-duty lasers for crafting bespoke metal frames for their products. The precision achieved through their new setup allowed them not only to improve product quality but also reduce lead times dramatically—customers were thrilled! These success stories highlight how companies across various sectors are leveraging advanced laser machinery to enhance productivity and innovate their offerings.

Selecting the Right Brand

When it comes to laser pipe cutting equipment, selecting the right brand is crucial for ensuring quality and reliability. With a plethora of options available, it can be overwhelming to navigate through the noise and find a manufacturer that truly meets your needs. A well-chosen brand not only enhances your production capabilities but also aligns with your long-term business goals.

Why Choose Kiant Machinery

Kiant Machinery stands out in the competitive landscape of laser cutting machines due to its commitment to innovation and quality. Their laser pipe cutting equipment is designed with advanced technology that allows for precise cuts in various materials, making machine cut metal projects easier and more efficient. Furthermore, their heavy-duty models are built to withstand rigorous industrial environments, ensuring durability and longevity.

In addition to robust machinery, Kiant offers a range of customizable options tailored to specific industry needs, allowing clients to maximize productivity. Their investment in research and development means they continually improve their product offerings, keeping pace with advancements in laser technology. Choosing Kiant Machinery not only secures high-quality equipment but also positions businesses at the forefront of manufacturing excellence.

Comparing Top Brands in the Industry

While Kiant Machinery has its merits, it's essential to compare other top brands in the industry before making a decision on your laser cutting machine. Some competitors may offer unique features or specialized services that could better suit specific applications or budget constraints. When assessing these brands, consider factors such as precision cutting capabilities, speed of operation, and overall cost-effectiveness of their cutting machines.

Many brands boast impressive specifications; however, it's vital to evaluate real-world performance through customer reviews and case studies. This will help you gauge how well these brands deliver on their promises regarding laser machinery efficiency and reliability over time. Ultimately, thorough research will empower you to make an informed choice that aligns with your operational goals.

Evaluating Customer Support and Service

Customer support is often overlooked when selecting a brand for laser pipe cutting equipment but is critical for long-term satisfaction and success. A reputable company will provide comprehensive service options including installation assistance, regular maintenance checks, and prompt troubleshooting support for any issues that arise with your cutting machine laser system.

Evaluate how responsive potential suppliers are when addressing inquiries about their products or services; this can be indicative of future support experiences post-purchase. Additionally, consider warranty offerings as they reflect confidence in their products while providing peace of mind during your investment journey into advanced laser technology for machine cut metal applications.

Maintenance Tips for Longevity

Maintaining your laser pipe cutting equipment is crucial for ensuring optimal performance and longevity. Regular upkeep not only enhances the efficiency of your cutting machine laser but also minimizes unexpected breakdowns that could halt production. By following a few best practices, you can keep your laser cutting machinery in tip-top shape, ready to tackle any metal-cutting challenge.

Best Practices for Upkeep

First and foremost, regular cleaning is essential for any laser cutting machine. Dust and debris can accumulate on lenses and mirrors, obstructing the beam path and affecting precision when you’re machine cut metal. Make it a habit to clean these components frequently with appropriate materials to avoid damage and maintain clarity in the cutting process.

Additionally, keep an eye on the coolant levels in your laser machinery; proper cooling is vital for preventing overheating during extended use. Regularly check hoses for leaks or wear that could lead to inefficiencies or damage to your equipment. Lastly, ensure that all moving parts are lubricated according to the manufacturer's guidelines; this simple step can significantly extend the life of your cutting laser metal equipment.

Troubleshooting Common Issues

Even with diligent maintenance, issues may arise with your laser pipe cutting equipment from time to time. One common problem is inconsistent cut quality, which may result from misaligned optics or worn-out components within the machine cut metal setup. If you notice uneven edges or excessive dross on cut pieces, it’s wise to inspect these areas closely before assuming more complex issues are at play.

Another frequent issue involves software glitches that can affect operation efficiency of your cutting machine laser. Ensure that you keep software up-to-date and regularly back up settings; this will help prevent potential headaches down the line when trying to troubleshoot operational hiccups. Finally, if you're experiencing power fluctuations during operation, consider checking electrical connections as well as ensuring that voltage settings match manufacturer specifications.

When to Seek Professional Help

While many maintenance tasks can be handled in-house, some situations warrant professional intervention—especially when dealing with advanced laser machinery features or complex repairs. If you've exhausted troubleshooting options without resolution—like persistent error messages or severe performance drops—it might be time to call in an expert familiar with your specific model of laser pipe cutting equipment.

Additionally, if you find yourself needing repairs more frequently than expected despite regular upkeep practices, this could indicate underlying problems requiring specialized knowledge or tools beyond what’s available at your facility. Don't hesitate; investing in professional service now can save you significant downtime later on.

In conclusion, keeping up with maintenance practices ensures that your laser pipe cutting equipment continues performing at its best while reducing costs associated with repairs or replacements down the road.

Conclusion

Laser pipe cutting technology has dramatically transformed the landscape of manufacturing, ushering in an era where precision meets efficiency. With advancements in laser cutting equipment, businesses can now achieve intricate designs and flawless finishes that were once deemed impossible with traditional methods. This revolution not only enhances productivity but also elevates the quality of machine cut metal products, making laser cutting an indispensable tool in modern fabrication.

Revolutionizing Manufacturing with Laser Cutters

The introduction of laser pipe cutting equipment has redefined manufacturing standards across various industries. Unlike conventional methods, which often involve considerable waste and time, a cutting machine laser operates with pinpoint accuracy, minimizing material loss and maximizing output. As a result, companies are not just keeping up with demand; they’re setting new benchmarks for quality and efficiency.

The Future of Laser Pipe Cutting

Looking ahead, the future of laser pipe cutting seems brighter than ever. Innovations in laser machinery promise even greater capabilities—think enhanced automation and smarter software integration that streamlines operations. As industries continue to embrace these technologies, we can expect to see further reductions in costs and improvements in production speed—benefits that will undoubtedly keep businesses competitive in a fast-paced market.

Investing in Quality Equipment for Growth

Investing in high-quality laser cutting machines is not merely a financial decision; it’s a strategic move towards sustainable growth. While initial costs may seem daunting, the long-term benefits of using robust cutting laser metal technology far outweigh them through increased efficiency and reduced operational costs. By choosing reliable brands and prioritizing maintenance for your equipment, you’ll ensure that your investment continues to pay dividends for years to come.