Introduction

In today's fast-paced manufacturing landscape, laser tube cutting has emerged as a game-changer, revolutionizing how industries approach metal fabrication. This advanced technology utilizes focused laser beams to achieve precise cuts on various materials, ensuring that the production process is both efficient and accurate. As businesses strive for higher quality and lower costs, understanding the intricacies of laser cutting becomes essential.

The Basics of Laser Tube Cutting

Laser tube cutting is a technique that employs a laser cutting machine to slice through metal tubes with unparalleled precision. By directing a concentrated beam of light onto the material, this method not only minimizes waste but also produces clean edges that often require little to no finishing work. The ability to manipulate complex geometries makes this technology particularly appealing for manufacturers looking to enhance their product offerings.

Advantages of Laser Cutting Technologies

The advantages of laser cutting technologies are numerous and impactful. First and foremost, they provide exceptional precision and accuracy in every cut, which is crucial for industries where tolerances are tight and quality standards are high. Additionally, the speed and efficiency offered by modern laser machinery allow businesses to meet demanding production schedules without compromising on quality or incurring excessive costs.

Applications of Laser Cutting in Industry

Laser metal cutting finds applications across various sectors, including automotive, aerospace, construction, and art design. From creating intricate components for vehicles to crafting artistic sculptures from metal sheets, the versatility of laser tube cutting knows no bounds. As industries continue to evolve and innovate, the demand for reliable cutting machine lasers will only increase, solidifying their role in modern manufacturing practices.

Understanding Laser Tube Cutting

Laser tube cutting is a state-of-the-art technology that utilizes focused laser beams to cut through various types of metal tubes with exceptional precision. This method has revolutionized the manufacturing industry by providing a clean, efficient, and accurate way to achieve intricate designs and shapes in metal fabrication. With advancements in laser machinery, businesses can now produce complex components that meet stringent industry standards while minimizing waste.

What is Laser Tube Cutting

At its core, laser tube cutting involves directing a high-powered laser beam onto the surface of a metal tube to create precise cuts. This technique is particularly advantageous for crafting components used in automotive, aerospace, and construction industries where accuracy is paramount. The ability to cut various materials—from stainless steel to aluminum—makes laser tube cutting an invaluable process for modern manufacturing.

How Laser Cutting Machines Operate

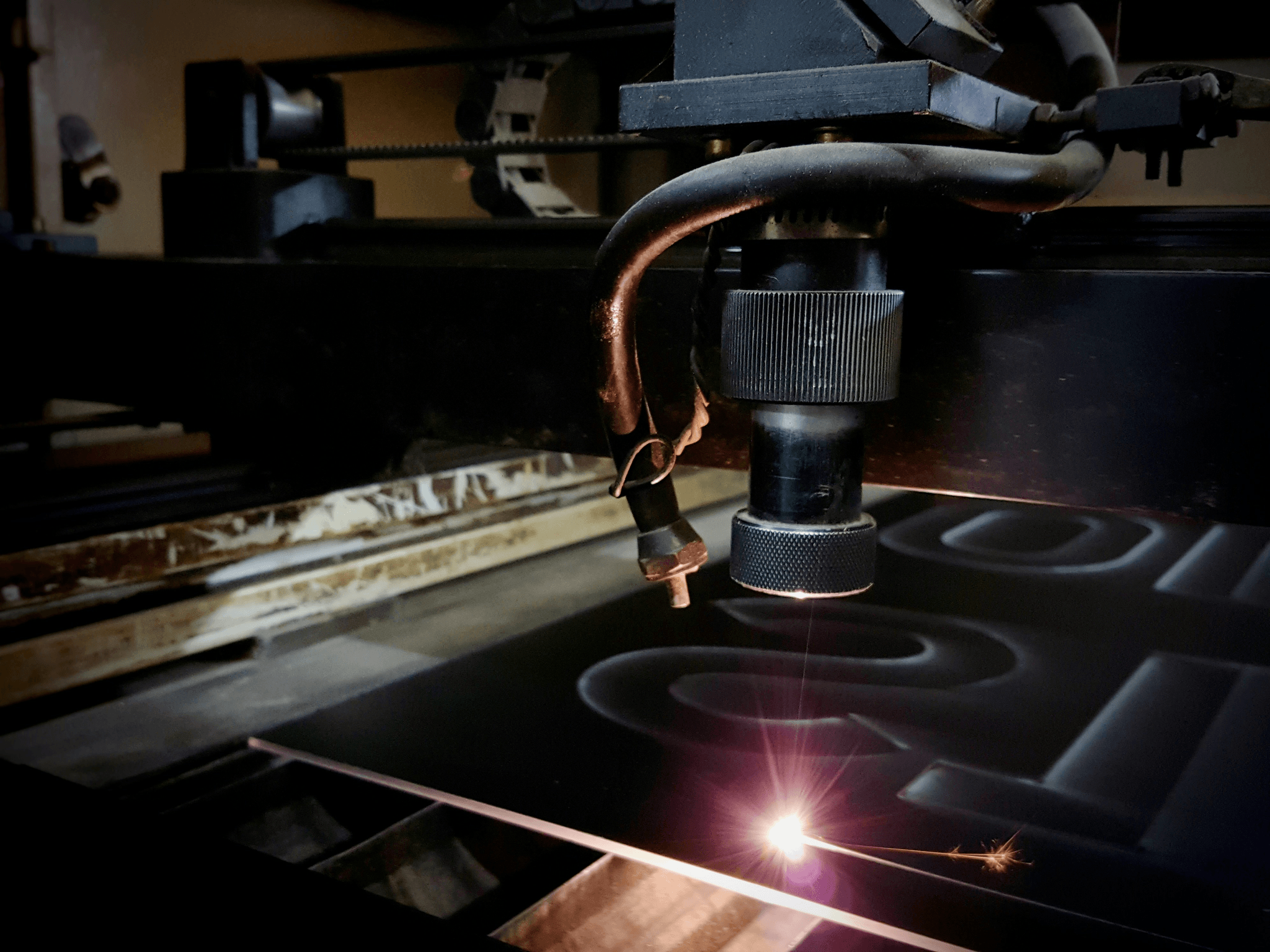

Laser cutting machines operate by employing a combination of optics and CNC (Computer Numerical Control) technology to guide the laser beam along predetermined paths. The machine cut metal process begins when the operator inputs design specifications into the computer system, which then translates these into movements for the laser head. As the cutting machine laser moves along the designated path, it melts or vaporizes the material at an incredibly fast rate, resulting in clean edges and minimal thermal distortion.

Types of Laser Cutting Technologies

There are several types of laser cutting technologies available today, each suited for different applications and materials. CO2 lasers are commonly used for thicker materials due to their high power levels and efficiency with non-metal substrates; meanwhile, fiber lasers excel at cutting thin metals with remarkable speed and precision. Additionally, solid-state lasers offer versatility across various applications but may require more maintenance than their CO2 counterparts—understanding these distinctions helps businesses choose the right equipment for their specific needs.

The Benefits of Laser Metal Cutting

Laser metal cutting has revolutionized the manufacturing landscape, offering numerous advantages that set it apart from traditional methods. This technology not only enhances the quality of machine cut metal but also optimizes production processes across various industries. With a laser cutting machine, businesses can achieve remarkable results that translate into increased productivity and profitability.

Precision and Accuracy in Cutting

One of the standout features of laser tube cutting is its unparalleled precision and accuracy. Laser machinery utilizes focused beams to create intricate cuts with minimal tolerance for error, ensuring that every piece meets exact specifications. This level of precision is particularly beneficial when working with complex designs or tight tolerances, making it a go-to choice for engineers and designers alike.

Speed and Efficiency of Operations

When it comes to speed, nothing quite matches the capabilities of a laser metal cutting machine. These machines can operate at high speeds without sacrificing quality, significantly reducing production times compared to traditional methods. Moreover, the efficiency of laser cutting means less material waste and lower operational costs—an appealing prospect for any manufacturer looking to streamline their processes.

Versatility in Material Types

Another significant advantage of using a cutting machine laser is its versatility in handling various materials. From metals like steel and aluminum to softer materials such as plastics or wood, a laser machine can adapt to different substrates with ease. This flexibility allows manufacturers to diversify their product offerings without needing multiple machines for different materials, ultimately enhancing operational efficiency.

The Role of Kiant Machinery

Kiant Machinery plays a pivotal role in the landscape of laser tube cutting, offering innovative solutions that cater to diverse industrial needs. With a focus on advanced technology and user-friendly designs, their products are engineered to enhance efficiency and precision in laser cutting processes. The company’s extensive range of offerings ensures that businesses can find the perfect fit for their specific requirements, whether it’s a compact laser machine for small workshops or large-scale laser metal cutting machines for industrial applications.

Overview of Kiant Machinery's Offerings

Kiant Machinery boasts an impressive lineup of laser cutting machines designed for various applications in the realm of machine cut metal. Their state-of-the-art laser metal cutting machines utilize advanced technology to deliver exceptional precision and speed, making them ideal for both small and large production runs. From entry-level models to high-end systems equipped with automation features, Kiant’s offerings ensure that users have access to the best tools available for effective laser tube cutting.

Why Choose Kiant for Laser Cutting Solutions

Choosing Kiant Machinery means opting for reliability and innovation in the world of laser cutting solutions. Their commitment to quality is evident in every product they offer, ensuring that customers receive machines built to withstand rigorous use while maintaining high standards of accuracy. Additionally, Kiant provides tailored solutions that align with specific business needs, making them a go-to choice for companies seeking efficient and effective cutting machine lasers.

Customer Support and After-Sales Services

One of the standout features of Kiant Machinery is their robust customer support and after-sales services, which set them apart from competitors in the market. They understand that investing in a laser machine is significant; therefore, they provide comprehensive training programs and ongoing technical support to ensure customers get the most out of their equipment. This dedication not only enhances user experience but also fosters long-term relationships with clients who can rely on Kiant as their trusted partner in all things related to laser tube cutting.

Comparative Analysis of Laser Cutting Methods

When it comes to precision and efficiency in manufacturing, laser tube cutting stands tall against traditional cutting methods. Traditional methods often rely on mechanical processes like sawing or shearing, which can be slower and less accurate. In contrast, laser cutting machines utilize focused beams of light to slice through materials with incredible precision, making them a game changer for industries looking to enhance productivity.

Laser Cutting vs. Traditional Cutting Methods

Laser cutting technology offers distinct advantages over traditional cutting methods such as plasma or flame cutting. For instance, the heat-affected zone in laser tube cutting is significantly smaller than that produced by traditional methods, which means less distortion and cleaner edges. Additionally, while traditional techniques may require extensive post-processing work to achieve smooth finishes, laser machinery delivers high-quality cuts straight off the machine.

Another key difference lies in the versatility of materials that can be processed using a laser metal cutting machine. Traditional methods may struggle with certain materials or thicknesses, whereas laser machines can effortlessly cut through metals like steel, aluminum, and even more exotic materials with ease. This adaptability makes laser tube cutting an attractive option for businesses aiming to diversify their offerings without investing in multiple types of equipment.

Machine Cut Metal Advantages

Machine cut metal using laser technology provides a level of accuracy that is hard to match with other methods. The precision of a laser cutting machine allows for intricate designs and tight tolerances that are essential in industries such as aerospace and automotive manufacturing. Not only does this lead to better-fitting components but it also reduces material waste since the cuts are so precise.

Moreover, the speed at which a laser machine operates cannot be overlooked; it significantly outpaces traditional techniques when it comes to production rates. This increased efficiency means businesses can fulfill orders faster while maintaining high-quality standards—a win-win situation! As companies strive for leaner operations and quicker turnaround times, embracing machine cut metal through advanced technologies becomes not just beneficial but necessary.

Cost Efficiency of Cutting Machine Laser

Investing in a cutting machine laser may seem daunting initially due to higher upfront costs compared to traditional equipment; however, the long-term savings often outweigh these concerns significantly. The operational costs associated with maintenance tend to be lower for laser machinery since they have fewer moving parts compared to mechanical cutters prone to wear and tear over time. Furthermore, reduced material wastage from precise cuts translates directly into cost savings—who wouldn’t want more bang for their buck?

Additionally, the ability of a laser metal cutting machine to handle various tasks without needing multiple machines saves both space and capital investment in equipment diversification. Businesses can streamline operations by relying on one versatile piece of machinery instead of several specialized tools—this leads not only to cost reduction but also simplifies training processes for staff members who need less specialization on different machines!

In summary, while traditional methods have served us well over time, it's clear that adopting innovative technologies like laser tube cutting presents compelling advantages—from unparalleled precision and speed to significant cost efficiencies that modern industries crave.

Future Trends in Laser Technology

The future of laser technology is bright and filled with possibilities that promise to revolutionize the way industries approach manufacturing processes. As businesses increasingly adopt advanced solutions, laser tube cutting stands at the forefront, showcasing innovations that enhance efficiency and precision. The evolution of laser cutting machinery is not just about improving existing technologies but also about integrating smart features that optimize operations.

Innovations in Laser Machinery

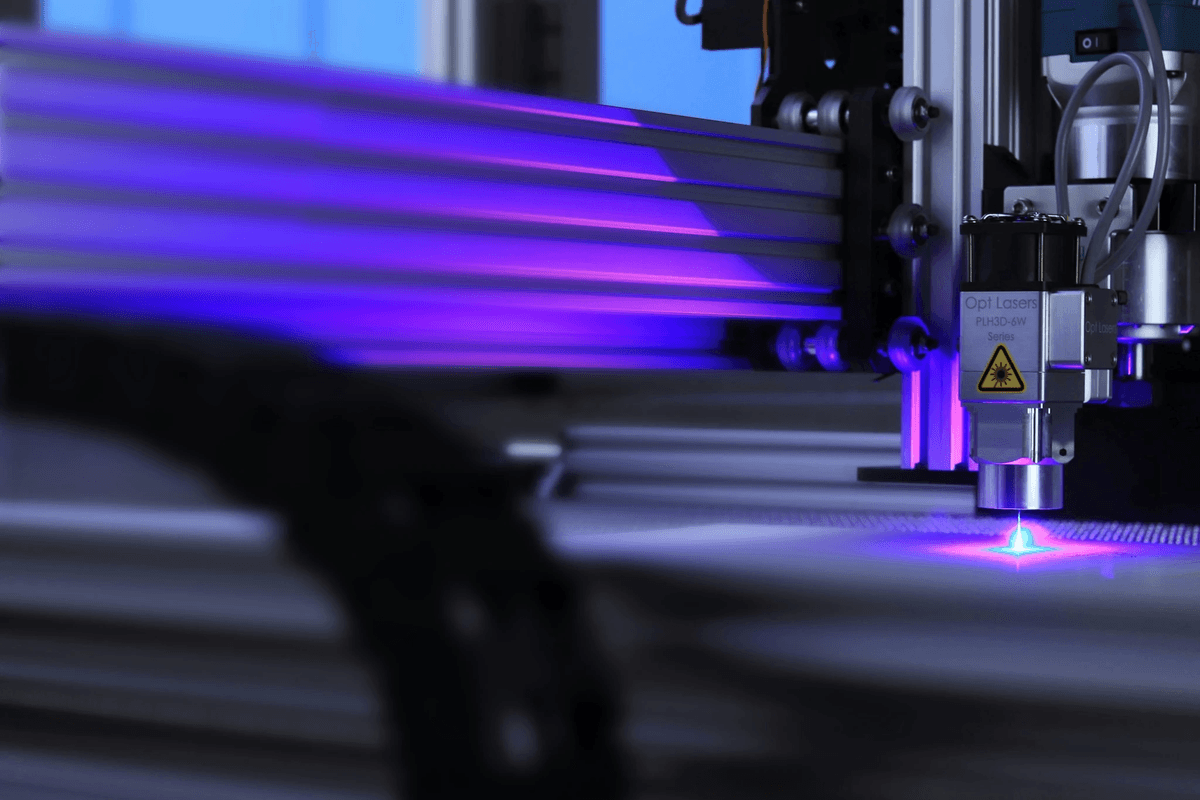

Innovations in laser machinery are transforming the landscape of manufacturing and production. With advancements such as fiber lasers and ultra-fast lasers, the capabilities of laser cutting machines are expanding exponentially, allowing for intricate designs and faster processing times. These new technologies enable machine cut metal with unparalleled precision, making them ideal for a wide range of applications from automotive to aerospace.

Furthermore, manufacturers are now focusing on automation in their laser cutting processes, integrating robotics with laser metal cutting machines to reduce human error and increase throughput. This shift towards automated systems not only boosts productivity but also enhances safety within the workspace. As these innovations continue to unfold, we can expect even more sophisticated features that will redefine what’s possible in laser tube cutting.

Industry Predictions and Expectations

Industry experts predict that the demand for laser cutting technologies will only grow stronger as sectors seek more efficient production methods. With ongoing developments in materials science and engineering, we can anticipate a broader range of materials being compatible with advanced laser machinery—further broadening its application scope across various industries. Additionally, sustainability concerns are driving innovations aimed at reducing waste during the cutting process while maintaining high-quality standards.

Companies are expected to invest heavily in upgrading their equipment to stay competitive; this includes transitioning from traditional methods to modern cutting machine lasers that offer superior performance metrics. Consequently, we may witness a surge in small-to-medium enterprises adopting these technologies as they become more accessible through competitive pricing strategies offered by leading manufacturers like Kiant Machinery. The future looks promising as industries embrace these advancements for better operational efficiency.

How Technology is Shaping Manufacturing

Technology is reshaping manufacturing by introducing smart solutions that enhance productivity while minimizing costs associated with traditional processes. Laser tube cutting exemplifies this transformation by offering unmatched speed and versatility compared to conventional methods like plasma or mechanical cutting techniques. As businesses leverage data analytics alongside advanced software integrated into their laser metal cutting machines, they can optimize workflows based on real-time feedback.

Moreover, cloud computing plays a pivotal role in enabling remote monitoring and control over manufacturing processes; this means operators can adjust settings on their laser machinery from anywhere at any time—further streamlining operations and reducing downtime significantly. The integration of Artificial Intelligence (AI) into these systems allows predictive maintenance which anticipates equipment failures before they occur—ensuring consistent performance without unexpected interruptions.

In summary, technology's impact on manufacturing extends beyond mere machinery improvements; it encompasses an entire ecosystem where efficiency meets innovation head-on—especially evident through advancements in laser tube cutting applications across various sectors.

Conclusion

In summary, laser tube cutting has revolutionized the way industries approach metal fabrication. The precision and efficiency offered by laser cutting technologies make it an invaluable tool for modern manufacturing processes. As we've seen, the benefits of machine cut metal using a laser cutting machine extend far beyond mere aesthetics; they enhance productivity and reduce waste.

Recap of Laser Tube Cutting Benefits

Laser tube cutting stands out for its unparalleled accuracy and speed, allowing manufacturers to achieve intricate designs with minimal effort. The versatility in material types that a laser metal cutting machine can handle means that businesses can tackle a wider range of projects without needing multiple machines. Ultimately, this technology not only boosts production rates but also ensures high-quality results every time.

Kiant Machinery’s Impact on Efficiency

Kiant Machinery has positioned itself as a leader in the field of laser machinery, providing state-of-the-art solutions tailored to meet diverse industrial needs. Their commitment to innovation ensures that clients receive cutting-edge equipment that maximizes efficiency in operations involving laser tube cutting and other applications. With exceptional customer support and after-sales services, Kiant empowers businesses to fully leverage their investment in cutting machine lasers.

The Future of Laser Cutting in Industries

Looking ahead, the future of laser cutting seems brighter than ever as advancements in technology continue to emerge at a rapid pace. Innovations in laser machinery promise even greater speeds and capabilities, which will further transform how industries approach manufacturing challenges. As technology shapes the landscape of production, businesses that embrace these changes will undoubtedly maintain a competitive edge through enhanced efficiency and quality.