Introduction

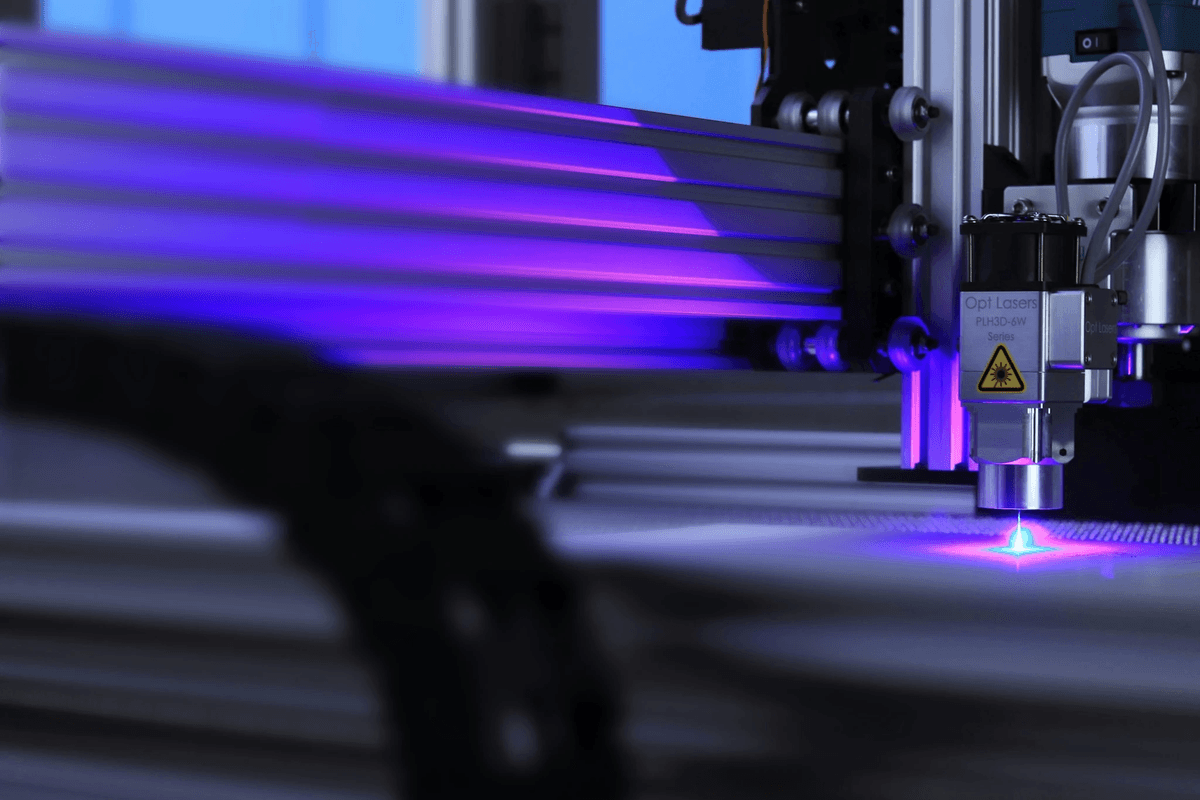

In today's fast-paced manufacturing landscape, businesses are increasingly turning to an all-in-one laser cutting solution to streamline their operations and enhance productivity. These advanced systems integrate various functionalities into a single machine, offering unparalleled versatility and efficiency. With the rise of industrial laser technology, companies can now achieve precision cutting and engraving with minimal waste and maximum speed.

What is an All-In-One Laser Cutting Solution?

An all-in-one laser cutting solution combines multiple capabilities into a single piece of equipment, allowing for a seamless workflow in various industrial applications. This innovative approach means that businesses can utilize fiber laser machines for cutting, engraving, and marking without needing separate devices for each task. By investing in such laser machinery, companies can significantly reduce operational costs while improving overall production efficiency.

The Rise of Industrial Laser Technology

The adoption of industrial lasers has surged in recent years due to their ability to provide precise cuts with exceptional speed and accuracy. Fiber laser machines have become particularly popular because they offer improved energy efficiency and lower operating costs compared to traditional cutting methods. As industries continue to embrace these advanced industrial laser solutions, the demand for high-quality laser machinery is expected to grow even further.

Why Choose Kiant Machinery?

When it comes to selecting the right partner for your laser needs, Kiant Machinery stands out as a leader in the field of industrial lasers. Their commitment to innovation ensures that customers receive state-of-the-art fiber laser machines equipped with user-friendly features designed for maximum productivity. With comprehensive support services ranging from installation to ongoing maintenance, Kiant Machinery proves to be an invaluable ally in your quest for efficient industrial laser solutions.

Understanding Industrial Laser Solutions

In the world of manufacturing, industrial laser solutions have revolutionized how businesses operate. These advanced technologies provide unparalleled precision and efficiency, making them indispensable in various industries. Understanding the types of laser machines available can help businesses choose the right equipment for their specific needs.

Types of Industrial Lasers

Industrial lasers come in several varieties, each designed for different applications and materials. The most common types include CO2 lasers, fiber lasers, and solid-state lasers. Fiber laser machines are particularly popular due to their versatility and ability to cut through a range of materials with exceptional speed and accuracy.

CO2 lasers are ideal for cutting non-metal materials like wood, plastics, and fabrics, while solid-state lasers are often used for precise engraving tasks. On the other hand, fiber laser machines excel in cutting metals such as steel and aluminum with minimal waste. Understanding these distinctions is crucial when selecting industrial laser solutions that align with your production goals.

Benefits of Fiber Laser Machines

Fiber laser machines stand out in the crowded field of industrial laser technology due to their numerous advantages. One significant benefit is their energy efficiency; fiber lasers consume less power compared to traditional CO2 systems while delivering higher output quality. This translates into cost savings on energy bills and a lower carbon footprint for environmentally conscious businesses.

Another advantage is their low maintenance requirements; fiber lasers have fewer moving parts than other types of industrial lasers, which reduces downtime and service costs over time. Additionally, they offer fast processing speeds that enhance productivity without compromising on quality—an essential factor in today’s competitive market landscape. By investing in fiber laser machinery, companies can achieve greater operational efficiency while meeting customer demands quickly.

How Laser Machines Enhance Production

Laser machines play a pivotal role in enhancing production capabilities across various sectors by streamlining processes and improving product quality. With precise cutting abilities, these machines minimize material waste while ensuring intricate designs are executed flawlessly—a win-win for both manufacturers and customers alike! Moreover, the automation features integrated into modern industrial laser solutions further boost productivity by reducing manual labor requirements.

The speed at which laser machinery operates allows businesses to scale up production without sacrificing accuracy or detail—perfectly aligning with just-in-time manufacturing practices that many industries adopt today. Furthermore, advancements such as real-time monitoring systems enable operators to track performance metrics closely—ensuring optimal machine operation at all times! When it comes down to it, adopting advanced industrial laser technology is not just about keeping up; it's about leading your industry into the future.

The Technology Behind Kiant Machinery

In the rapidly evolving world of industrial laser solutions, Kiant Machinery stands out with its cutting-edge technology. By combining advanced engineering with user-centric design, Kiant has developed a range of laser machines that not only meet but exceed industry standards. This section delves into the sophisticated techniques and features that make Kiant's laser machinery a top choice for businesses aiming to enhance their production capabilities.

Advanced Laser Cutting Techniques

Kiant Machinery employs state-of-the-art advanced laser cutting techniques that redefine efficiency and precision in the industrial sector. Utilizing fiber laser machines, these techniques enable rapid processing of various materials, from metals to plastics, ensuring clean cuts and minimal waste. The integration of automation in these processes allows for faster turnaround times without compromising on quality, making it an ideal solution for high-demand environments.

Moreover, the adaptability of Kiant's industrial lasers means they can handle complex designs and intricate details with ease. This versatility is crucial for industries like automotive and aerospace, where precision is paramount. With continuous advancements in technology, Kiant ensures that their laser machinery remains at the forefront of innovation.

User-Friendly Features of Kiant Laser Machinery

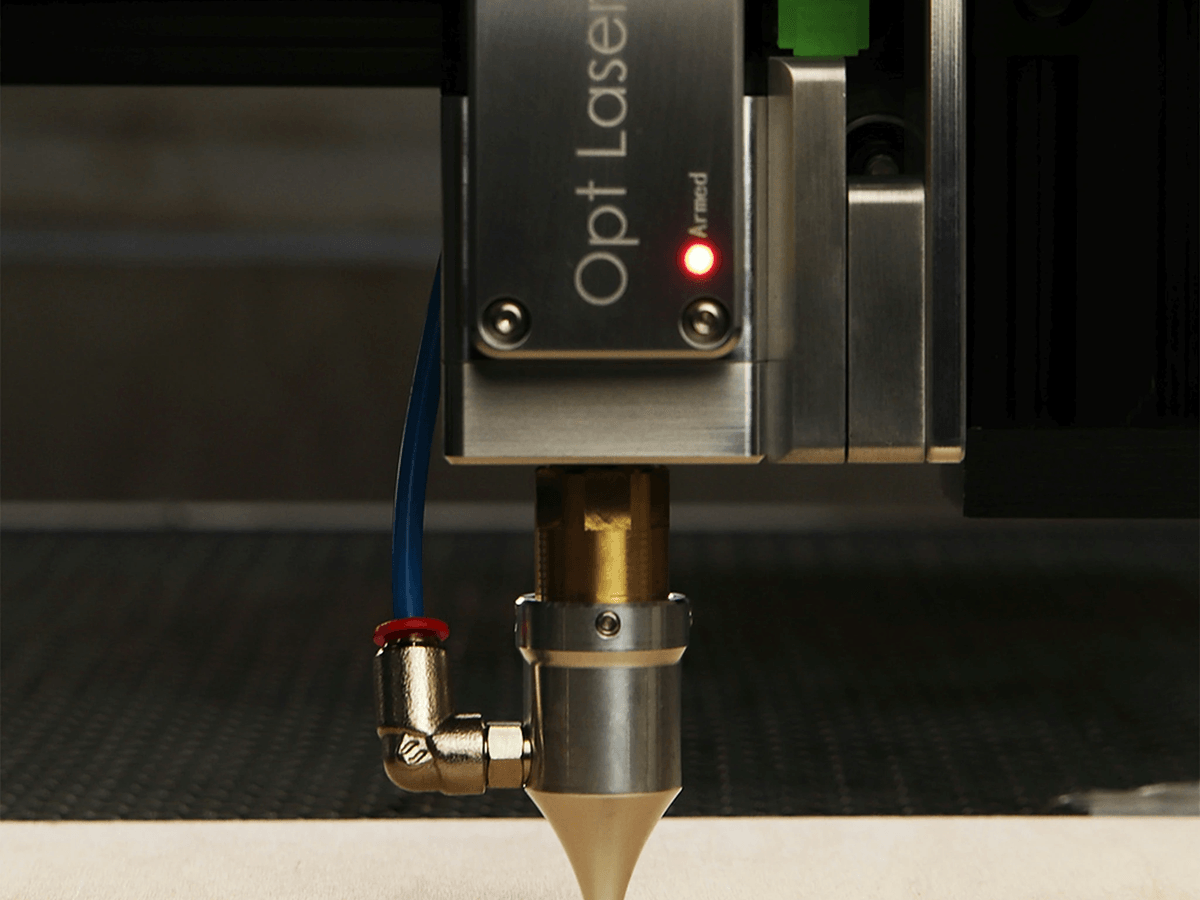

One of the standout aspects of Kiant’s laser machinery is its user-friendly design, which simplifies operation without sacrificing performance. Equipped with intuitive interfaces and advanced software systems, even operators with minimal experience can quickly learn to use these industrial lasers effectively. Features like real-time monitoring and automated adjustments further enhance usability while reducing downtime during production runs.

Additionally, safety is a paramount concern when operating any industrial laser machine. Kiant incorporates multiple safety features into their equipment to protect operators while maintaining optimal performance levels. This commitment to user experience not only boosts productivity but also fosters a safer working environment.

Innovation in Laser Tube Cutting Equipment

Kiant Machinery has made significant strides in the realm of laser tube cutting equipment—an area often overlooked by traditional manufacturers. Their innovative approach allows businesses to cut tubular materials efficiently while maintaining high accuracy levels essential for various applications such as structural components or custom fabrication projects. With specialized fiber laser machines designed specifically for tube cutting, companies can achieve complex geometries that were previously challenging or impossible.

This innovation extends beyond just functionality; it also includes enhancements in speed and material adaptability compared to conventional methods. As industries continue to seek ways to streamline operations and reduce costs, having access to state-of-the-art tube cutting technology becomes increasingly vital for competitive advantage. With its focus on pioneering solutions within this niche market segment, Kiant positions itself as a leader in providing tailored industrial laser solutions.

Applications of Laser Machines in Various Industries

Laser machines have revolutionized various sectors, driving efficiency and precision to new heights. From automotive to aerospace, the impact of industrial laser solutions is profound, enabling manufacturers to produce intricate designs with unmatched accuracy. As we explore these applications, it’s clear that fiber laser machines are at the forefront of innovation.

Automotive Industry Advancements

The automotive industry has embraced industrial lasers for cutting and welding components with remarkable speed and precision. Laser machinery allows manufacturers to create complex parts while reducing waste material, which is a win-win for both productivity and sustainability. With fiber laser machines, automakers can achieve cleaner cuts on metals like steel and aluminum, leading to improved vehicle performance and safety.

Moreover, the ability to perform intricate designs means that car manufacturers can innovate without compromising on quality. This advancement not only enhances production lines but also allows for customization options that cater to consumer preferences. In essence, the integration of industrial laser technology in automotive manufacturing has paved the way for smarter vehicles equipped with advanced features.

Aerospace Manufacturing Processes

In aerospace manufacturing, where every detail counts, laser machines play a crucial role in creating lightweight yet durable components essential for flight safety and efficiency. The precision offered by fiber laser machines ensures that parts such as brackets and panels are manufactured within tight tolerances required by aviation standards. This level of accuracy minimizes errors during assembly while enhancing overall structural integrity.

Furthermore, industrial laser solutions facilitate the processing of advanced materials like titanium and composites often used in aircraft construction. These materials require specialized handling that only high-quality laser machinery can provide without compromising their properties. As a result, aerospace companies benefit from reduced production times while maintaining compliance with stringent regulations.

Custom Fabrication and Design Solutions

Custom fabrication is another area where industrial lasers shine brightly; they enable businesses to transform creative ideas into tangible products swiftly and accurately. Laser machinery allows artisans and engineers alike to experiment with intricate designs that were once deemed too complex or expensive to produce efficiently. Whether it’s custom signage or bespoke metalwork pieces, fiber laser machines make it possible to bring unique visions to life.

Additionally, these solutions support rapid prototyping processes by allowing quick adjustments during development phases without incurring significant costs or delays typically associated with traditional methods. The flexibility offered by industrial lasers empowers businesses across various sectors—from small startups to large enterprises—to adapt quickly in an ever-changing market landscape. Ultimately, this capability fosters innovation while enhancing customer satisfaction through tailored offerings.

Choosing the Right Laser Machine

Selecting the perfect laser machine for your business can feel like finding a needle in a haystack. With numerous options available in the realm of industrial laser solutions, it’s crucial to consider various factors that align with your specific needs. From production capacity to material compatibility, making an informed choice can significantly enhance your operational efficiency and output quality.

Factors to Consider for Your Business

When choosing an industrial laser machine, several key factors should be at the forefront of your decision-making process. First and foremost, assess the types of materials you’ll be working with; different fiber laser machines excel with specific substrates such as metals, plastics, or wood. Additionally, consider the thickness and complexity of the materials you intend to cut or engrave—this will help you determine the necessary power and precision required from your laser machinery.

Another critical factor is production speed; if you're aiming for high-volume output, investing in a high-speed fiber laser machine could be beneficial. Don’t forget about your workspace—ensure you have adequate room for installation and operation while considering ventilation and safety measures associated with industrial lasers. Lastly, factor in budget constraints as well as potential return on investment; sometimes paying a little more upfront can lead to significant savings down the line through increased productivity.

Comparing Different Laser Machinery Options

With so many options on the market today, comparing different laser machinery can seem daunting but is essential for finding the right fit. Start by evaluating specifications such as wattage, cutting speed, and versatility across various materials; these elements directly influence performance quality and operational efficiency. It’s also wise to look into user reviews and testimonials which provide insights into real-world applications of each machine.

Don’t overlook after-sales support either—some manufacturers offer comprehensive maintenance packages that can save you time and money in repairs down the line. You may also want to explore features like automation capabilities or software compatibility that could streamline operations further when using industrial laser solutions. Ultimately, taking time to compare these aspects will help ensure that you choose a fiber laser machine that meets both current demands and future growth potential.

The Importance of Equipment Selection

Selecting appropriate equipment is not merely about fulfilling immediate needs; it lays the foundation for long-term success within your industry sector. An ill-suited industrial laser may result in inefficiencies that hinder productivity or compromise product quality—both of which can lead to lost revenue over time. Conversely, investing wisely in high-quality laser machinery tailored specifically for your business requirements positions you for sustained growth.

Moreover, prioritizing equipment selection fosters innovation by enabling businesses to explore new applications or markets previously deemed unattainable due to technological limitations. This adaptability is especially crucial given today’s rapidly evolving manufacturing landscape where staying ahead often means embracing cutting-edge industrial laser solutions before competitors do so first! Ultimately, thoughtful selection not only enhances operational capabilities but also solidifies brand reputation among customers who value precision-engineered products delivered promptly.

Comprehensive Support from Kiant Machinery

When it comes to investing in industrial laser solutions, having robust support is just as crucial as the machinery itself. Kiant Machinery understands that your success hinges on seamless integration and ongoing assistance. From initial setup to continuous maintenance, our comprehensive support ensures that your laser machine operates at peak performance.

Installation and Training Services

Kiant Machinery offers expert installation services for all our laser machinery, ensuring a hassle-free setup process tailored to your facility's unique needs. Our experienced technicians not only install the equipment but also provide hands-on training sessions for your team, enabling them to operate the fiber laser machine with confidence right from day one. This commitment to training means you're not just getting a piece of industrial laser technology; you're acquiring the skills needed to maximize its potential.

Ongoing Maintenance and Support

To keep your industrial laser solutions running smoothly, Kiant Machinery provides ongoing maintenance and support tailored specifically for each client’s needs. Regular check-ups and timely repairs help prevent unexpected downtime, allowing you to maintain productivity levels without interruption. Our dedicated support team is always just a call away, ready to assist with any questions or issues regarding your laser machine.

Customer Testimonials and Success Stories

Don’t just take our word for it—our customers rave about their experiences with Kiant Machinery! Numerous success stories highlight how our fiber laser machines have transformed operations across various industries, leading to increased efficiency and reduced costs. These testimonials reflect our commitment to quality service and innovation in the field of industrial lasers, making us a trusted partner in advancing your business.

Conclusion

In the ever-evolving landscape of manufacturing, embracing advanced technology is crucial for staying competitive. Industrial laser solutions, particularly those offered by Kiant Machinery, have proven to be game-changers for businesses looking to elevate their production capabilities. By integrating a reliable laser machine into your operations, you not only enhance efficiency but also unlock new possibilities for innovation and customization.

Elevating Your Business with Laser Technology

Investing in a fiber laser machine can significantly boost your operational efficiency and product quality. These machines are designed to provide precision cutting that traditional methods simply can't match, making them essential in a fast-paced industrial environment. With enhanced speed and accuracy, your business can meet increasing customer demands while reducing waste and production costs.

Long-Term Growth with Kiant Machinery

Kiant Machinery stands out as a trusted partner in your journey toward long-term growth through industrial laser solutions. Their commitment to quality ensures that you receive not just a machine but an entire ecosystem of support and innovation tailored to your needs. As industries evolve, partnering with Kiant means you're equipped with cutting-edge technology that adapts alongside market trends.

The Future of Industrial Laser Solutions

The future of industrial laser machinery looks promising as advancements continue to unfold at an unprecedented pace. Innovations in laser technology are paving the way for even more efficient processes across various sectors, from automotive to aerospace manufacturing. By choosing Kiant Machinery today, you position your business at the forefront of this exciting evolution, ready to leverage the full potential of state-of-the-art fiber laser machines.