Introduction

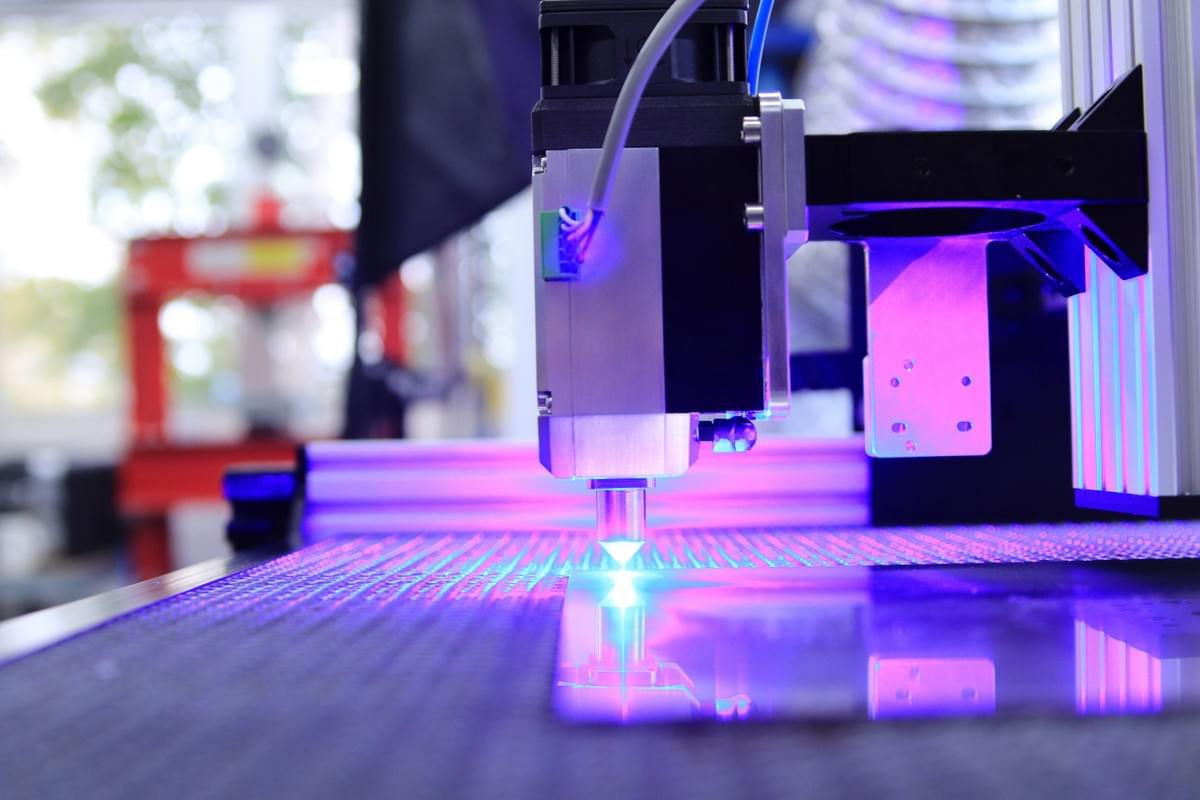

In the world of manufacturing and fabrication, laser cutting machines have revolutionized the way materials are processed. These advanced tools utilize focused beams of light to cut through various materials with precision and speed, making them indispensable in industries ranging from automotive to aerospace. As businesses look to enhance their production capabilities, understanding the nuances of different cutting machine lasers becomes crucial.

Understanding Laser Cutting Machines

Laser cutting machines come in various forms, each designed for specific applications and material types. At their core, these industrial laser cutters use high-powered lasers to melt or vaporize materials, resulting in clean cuts and intricate designs that traditional methods struggle to achieve. Familiarity with the technology behind these machines is essential for selecting the right equipment for your needs.

Importance of Choosing the Right Equipment

Selecting an appropriate industrial laser cutting machine can significantly impact efficiency, cost-effectiveness, and overall production quality. The right equipment not only enhances operational performance but also reduces waste and minimizes downtime during production runs. Therefore, investing time in researching different models and understanding their capabilities is paramount for any business looking to thrive in a competitive market.

Key Features to Consider

When evaluating laser machinery, several key features should be at the forefront of your decision-making process. Factors such as power output, speed settings, material compatibility, and after-sales support can greatly influence your overall satisfaction with a metal cutting laser cutter. By prioritizing these features based on your specific requirements, you can ensure that your investment meets both current needs and future growth potential.

Types of Laser Cutting Machines

Each type offers unique benefits and drawbacks that cater to different applications and materials. Understanding these differences is essential for selecting the right cutting machine laser for your specific needs.

CO2 vs. Fiber Lasers

CO2 lasers have long been a staple in the world of industrial laser cutting machines, known for their versatility in handling non-metals like wood, acrylic, and fabric. On the other hand, fiber lasers utilize a wavelength of about 1.06 micrometers, making them more suitable for metal cutting laser cutter applications due to their efficiency and speed with metallic substrates.

Fiber lasers also boast a longer lifespan than CO2 lasers and require less maintenance, which can save both time and money in the long run. However, CO2 lasers typically have lower initial costs compared to fiber options, making them an attractive choice for businesses just starting out in laser machinery investments. Ultimately, your selection should depend on the types of materials you plan to cut regularly.

Pros and Cons of Each Type

Each type of industrial laser cutter has its advantages and disadvantages that can influence your decision-making process. For instance, while CO2 lasers excel at cutting non-metallic materials with intricate designs due to their flexibility, they may struggle with thicker metals or high-speed operations compared to fiber lasers.

Additionally, consider factors such as initial investment costs versus operational efficiency over time when weighing your options between these two types of laser cutting machines. While CO2 models are generally cheaper upfront, fiber systems provide greater longevity and lower energy consumption rates—an important consideration for companies focused on sustainability as well as profitability.

Applications in Various Industries

The applications of CO2 and fiber laser technology span numerous industries—from automotive manufacturing to fashion design—showcasing their versatility as industrial laser machines. In automotive sectors where precision is paramount, metal cutting laser cutters using fiber technology dominate because they can quickly process various metals while maintaining high-quality cuts without excessive heat distortion.

Meanwhile, industries like woodworking or textiles benefit from CO2 lasers due to their ability to create intricate patterns on non-metal surfaces effortlessly; think decorative engravings or custom signage! As you explore potential uses within your own business context or industry niche—be sure also consider how each type aligns with both current demands and future growth opportunities within this rapidly evolving technological landscape.

Evaluating Power and Speed

Understanding how these elements interact can help you select the right industrial laser cutter for your needs, ensuring precise cuts and optimal performance. Let's dive into how power affects performance, the importance of speed for efficiency, and how to match power with material types.

How Power Affects Performance

Power is a key player in the world of laser machinery; it directly influences the cutting capabilities of your industrial laser cutting machine. Higher wattage typically translates to faster cutting speeds and the ability to work with thicker materials, making a metal cutting laser cutter more effective in demanding applications. Conversely, lower-powered machines may struggle with tougher materials or take longer to achieve clean cuts, which can lead to inefficiencies in production.

Selecting a suitable power level is essential for maximizing the performance of your cutting machine laser. If you’re working primarily with thin sheets or softer materials, a lower-powered machine may suffice; however, if you're tackling robust metals or intricate designs, investing in a high-powered industrial laser cutter will pay off in spades. Remember that finding the right balance between power and precision is crucial for achieving high-quality results.

Speed Considerations for Efficiency

Speed is another vital aspect when evaluating industrial laser machines; after all, time is money in any manufacturing setting! The speed at which your laser cutting machines operate can significantly impact overall productivity rates and turnaround times on projects. Faster speeds allow for more parts to be cut within a given timeframe but must be balanced against quality—too much speed can lead to rough edges or incomplete cuts.

When considering an industrial laser cutting machine's speed capabilities, it's essential to evaluate both acceleration rates and maximum feed rates. A machine that accelerates quickly while maintaining consistent speeds will enhance workflow efficiency without sacrificing cut quality. Ultimately, finding an ideal combination of speed and precision will ensure that you get the most out of your investment in laser machinery.

Matching Power to Material Types

Not all materials are created equal when it comes to their compatibility with various types of lasers; thus matching power levels with material types is crucial for optimal performance from your metal cutting laser cutter. Different materials absorb lasers differently—while some metals may require higher wattages due to their density and thickness, non-metals like wood or acrylic might perform best at lower settings.

Understanding these nuances allows operators of industrial laser cutters to tailor their approach based on specific projects effectively. For instance, thicker metals often necessitate higher-powered lasers operating at slower speeds for clean cuts without warping or burn marks—a key consideration when selecting equipment for diverse applications across industries. By aligning power levels with material characteristics, users can maximize both efficiency and output quality from their chosen equipment.

Assessing Material Compatibility

When it comes to laser cutting machines, understanding material compatibility is crucial for achieving optimal results. Different materials react differently to laser technology, making it essential to choose the right cutting machine laser for your specific needs. This section will delve into the distinctions between metals and non-metals, explore how thickness and density influence cutting performance, and guide you in selecting the ideal industrial laser cutter for your projects.

Metals vs. Non-Metals in Laser Cutting

Laser cutting machines are versatile tools that can handle a variety of materials, but metals and non-metals require different approaches. Industrial laser cutting machines equipped with fiber lasers excel at cutting through metals like steel, aluminum, and brass due to their ability to focus energy effectively on denser materials. On the other hand, CO2 lasers are typically better suited for non-metal materials such as wood, plastics, and fabrics because they can produce cleaner cuts without excessive heat buildup.

Understanding these differences helps ensure that you select the right metal cutting laser cutter or industrial laser cutter based on your material requirements. For instance, if you're primarily working with thicker metals, a high-powered fiber laser would be more efficient than a CO2 option. Conversely, if you're focusing on intricate designs in acrylic or wood, a CO2 laser would be your best bet.

The choice between metal and non-metal applications also affects operational costs and maintenance needs associated with different types of industrial laser machines. Therefore, knowing your primary materials beforehand can save time and money while enhancing productivity.

The Role of Thickness and Density

Thickness and density play pivotal roles in determining which type of industrial laser cutting machine is appropriate for your projects. Generally speaking, thicker materials necessitate more powerful lasers; thus understanding power ratings is essential when evaluating options like metal cutting laser cutters or other industrial models. When dealing with dense materials such as stainless steel or titanium that require high precision cuts at greater depths, investing in an advanced industrial laser cutter becomes imperative.

Moreover, varying thicknesses can impact not only cut quality but also speed during the operation process; thicker sections might slow down production rates compared to thinner ones due to increased energy requirements from the machine's power settings. In this context, finding balance between speed and quality is key—selecting an appropriate machine ensures efficiency without compromising on precision.

Additionally, density affects how well a material absorbs the focused light from a laser beam; denser materials may require adjustments in settings such as speed or power output to achieve clean cuts without causing burn marks or warping effects around edges of finished products.

Choosing the Right Cutting Machine Laser

Selecting the right cutting machine laser involves careful consideration of various factors including intended applications and material types involved in production processes. Start by assessing what kind of projects you’ll undertake most frequently—will they primarily involve metals or non-metals? This initial evaluation will help narrow down choices between fiber lasers suited for heavy-duty metal work versus CO2 lasers ideal for softer substrates.

Another critical aspect is evaluating brand reputation alongside features offered by different models within each category; some manufacturers may specialize more prominently in one type over another which could greatly influence overall performance outcomes when using their equipment regularly over time! Look into after-sales support options too—having reliable assistance available during maintenance periods can significantly extend lifespan while ensuring consistent output quality throughout operations involving these advanced pieces of equipment.

Lastly but importantly: budget considerations cannot be neglected! Depending on whether you lean towards high-end industrial setups capable of tackling diverse workloads versus entry-level options designed specifically around smaller tasks will ultimately determine both initial investment costs along with long-term value derived from owning such specialized machinery!

Brand Reputation and Support

When investing in laser cutting machines, brand reputation plays a pivotal role in ensuring you receive a reliable and effective product. Established brands often have a track record of quality, performance, and innovation that can significantly influence your decision-making process. Opting for a reputable brand means you're more likely to benefit from advanced technology and superior customer service, which can be crucial for the longevity of your industrial laser cutter.

Why Brand Matters in Industrial Laser Machines

Choosing the right brand for your cutting machine laser is essential because it reflects the manufacturer's commitment to excellence. A strong brand typically offers rigorous testing, quality assurance, and robust research and development efforts that enhance their products' reliability. Moreover, well-known brands often provide extensive resources for training and support that can help you maximize the efficiency of your metal cutting laser cutter.

Kiant Machinery: A Leader in Laser Technology

Kiant Machinery has emerged as a frontrunner in the realm of industrial laser machines by continually pushing boundaries in innovation and design. Their range of industrial laser cutting machines is celebrated for precision, speed, and durability—qualities that any serious manufacturer would prioritize. By choosing Kiant Machinery, you're aligning with a leader dedicated to advancing laser technology while ensuring their systems are user-friendly and efficient.

Importance of After-Sales Support

After-sales support is an often-overlooked aspect when selecting an industrial laser cutting machine but is critical for long-term satisfaction. A dependable support system ensures that any issues you encounter are swiftly resolved, minimizing downtime in your operations. Brands like Kiant Machinery prioritize after-sales service by offering comprehensive maintenance programs and readily available technical assistance to keep your laser machinery running smoothly.

Budgeting for Your Laser Cutter

When it comes to acquiring laser cutting machines, budgeting is a critical aspect that can’t be overlooked. The initial costs of an industrial laser cutter may seem daunting, but understanding the long-term investment can help ease some of the financial burden. A well-chosen cutting machine laser can lead to increased efficiency and reduced operational costs over time, making it a savvy investment for any business aiming to thrive in a competitive market.

Initial Costs vs. Long-Term Investment

The initial cost of industrial laser machines varies widely based on their capabilities and features. While you might find cheaper options, investing in a high-quality metal cutting laser cutter often pays off through durability and superior performance. Additionally, consider factors like maintenance costs and energy efficiency; these aspects will influence your total expenditure in the long run.

Many businesses underestimate the total cost of ownership when selecting an industrial laser cutting machine. It's essential to factor in not just the purchase price but also potential savings from faster production times and lower material waste. Ultimately, a more expensive yet efficient cutting machine laser may save you money over years of use compared to opting for a budget model with limited capabilities.

Financing Options for Industrial Laser Cutting Machines

Many manufacturers offer financing plans that allow you to spread payments over time while still enjoying the benefits of advanced laser machinery right away. Exploring leasing options can also be beneficial; this enables companies to upgrade their equipment without committing significant capital upfront.

Additionally, some financial institutions specialize in equipment financing tailored specifically for industries using advanced technology like laser cutting machines. These lenders understand the unique needs of businesses and often provide favorable terms that align with your cash flow situation. By taking advantage of these financing options, you can invest in high-quality industrial laser cutting machines that enhance productivity without straining your budget.

Understanding Cost-Effectiveness of Metal Cutting Laser Cutter

When evaluating cost-effectiveness, it's crucial to analyze how well your chosen metal cutting laser cutter performs relative to its operating costs and productivity levels. A high-performing industrial laser cutter may have a higher upfront price but could result in lower per-part costs due to faster processing speeds and less material waste during operations. This efficiency translates directly into improved profit margins over time.

Moreover, consider the versatility offered by modern industrial laser machines; they often handle various materials beyond metals, which can expand your service offerings without significant additional investment in equipment. By maximizing the utility of one machine across different applications, you effectively reduce overall operational costs while increasing revenue potential from diverse projects or client demands.

In summary, understanding budgeting intricacies surrounding your choice of cutting machine lasers is vital for success in today's competitive landscape—balancing initial investments with long-term gains will set your business on a path toward sustained growth.

Conclusion

In the rapidly evolving world of manufacturing, selecting the right laser cutting machines is paramount for ensuring efficiency and precision. With numerous options available, it’s essential to consider factors like power, speed, and material compatibility when making your choice. Remember that investing in a quality cutting machine laser can significantly enhance your production capabilities and overall output.

Final Thoughts on Machine Selection

Each type of laser machinery offers unique benefits that can cater to various applications across industries. By carefully evaluating your requirements and aligning them with the features of different industrial laser cutting machines, you can make an informed decision that will serve your business well for years to come.

Future Trends in Laser Machinery

The landscape of laser technology is continually advancing, with innovations aimed at improving performance and reducing costs on the horizon. Future trends suggest a growing emphasis on automation and integration with digital technologies in industrial laser machines, which will enhance productivity further. As these advancements unfold, staying informed about new developments will help you maintain a competitive edge in your industry.

Maximizing Performance with the Right Equipment

To truly maximize the performance of your metal cutting laser cutter or any other cutting machine laser, regular maintenance and updates are essential. Ensuring that you have access to reliable after-sales support from reputable brands can make all the difference in keeping your equipment running at peak efficiency. Ultimately, investing time and resources into selecting the right industrial laser cutting machine will pay dividends in productivity and quality.