Introduction

In the realm of modern manufacturing, laser tube cutting has emerged as a revolutionary technique that combines precision with efficiency. This technology utilizes advanced laser cutting machines to slice through various materials, particularly metal tubes and pipes, with remarkable accuracy. As industries demand higher standards of quality and speed, understanding the nuances of laser tube cutting becomes essential for staying competitive.

Understanding Laser Tube Cutting

Laser tube cutting is a specialized process that employs focused laser beams to cut intricate shapes and designs in tubular materials. These laser machines are engineered to handle various types of metals, including steel, aluminum, and stainless steel, making them versatile tools for manufacturers. By harnessing the power of light, the process offers unparalleled control over cuts, allowing for complex geometries that traditional methods simply cannot achieve.

Benefits of Laser Cutting Technology

The benefits of laser cutting technology are numerous and compelling for businesses across different sectors. First and foremost is the precision it offers; even the most delicate designs can be executed flawlessly without compromising material integrity. Additionally, using a metal tube laser cutter significantly reduces waste compared to conventional cutting methods—this not only saves costs but also promotes sustainability in manufacturing practices.

Applications of Laser Tube Cutting

Laser tube cutting finds its place in a wide array of applications across multiple industries. From automotive manufacturing where lightweight components are crucial for performance to aerospace component production requiring stringent quality standards, this technology is indispensable. Furthermore, furniture makers utilize pipe cutting lasers to craft unique designs that enhance aesthetic appeal while maintaining structural strength—demonstrating just how versatile this machine for cutting steel can be.

What is Laser Tube Cutting?

Laser tube cutting is a cutting-edge technology that employs focused laser beams to slice through various materials with exceptional precision. This method is particularly effective for creating intricate shapes and designs in metal tubes and pipes, making it a popular choice in industries ranging from automotive to furniture design. By harnessing the power of laser cutting, manufacturers can achieve superior results while significantly reducing production time and costs.

Overview of the Technology

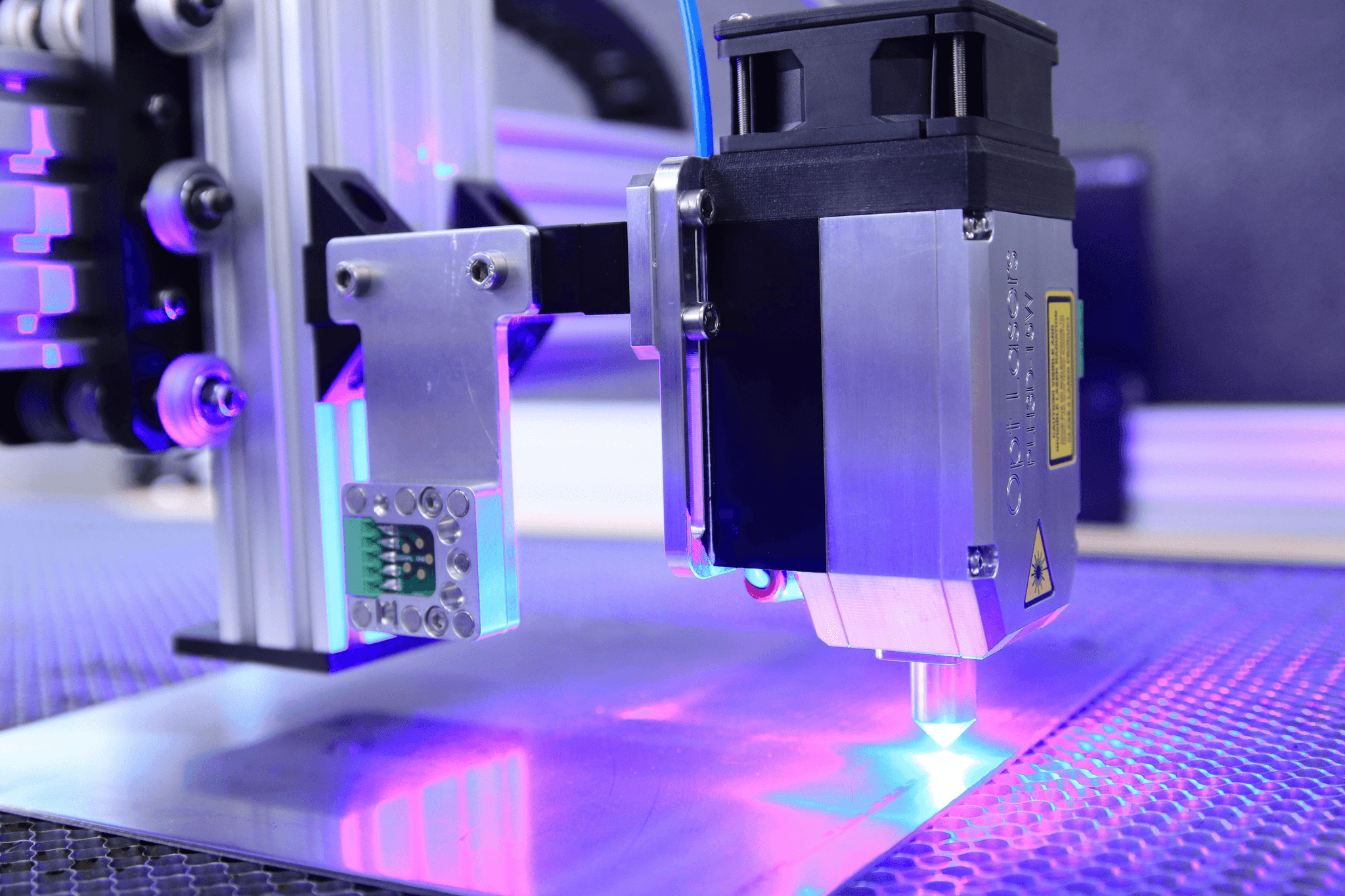

At its core, laser tube cutting utilizes high-powered lasers to melt or vaporize material along a predetermined path. The process begins with a computer-controlled system that directs the laser beam with pinpoint accuracy, allowing for complex geometries and clean edges. This technology not only enhances the quality of cuts but also minimizes the need for secondary finishing processes, making it an efficient solution for metal tube fabrication.

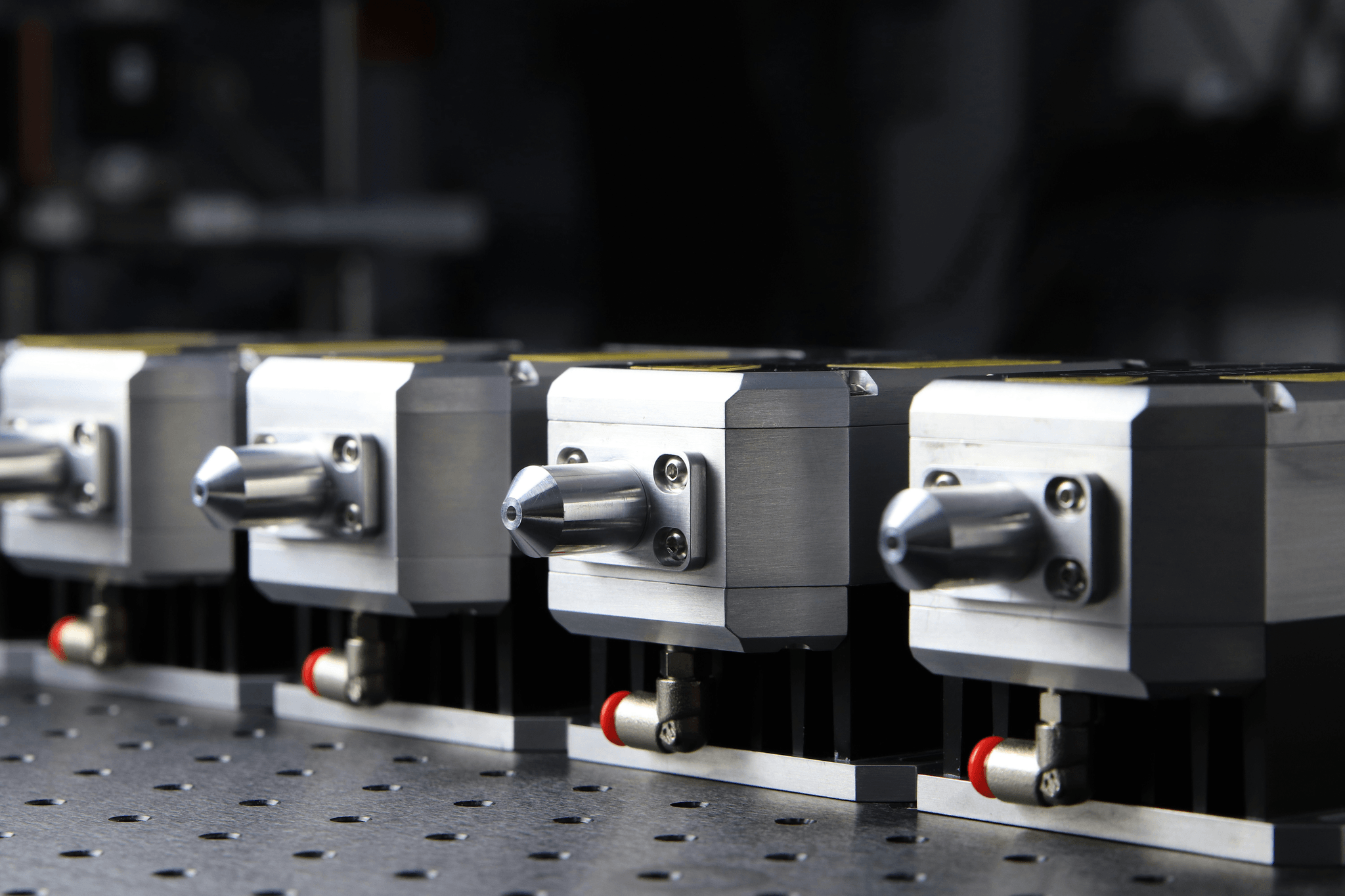

Components of a Laser Cutting Machine

A typical laser cutting machine consists of several key components that work harmoniously to deliver high-quality results. The primary elements include the laser source—either CO2 or fiber—optics that focus the beam, and a motion system that guides the material under the laser. Additionally, cooling systems are vital for maintaining optimal operating temperatures, ensuring longevity and reliability in steel tube laser cutting operations.

How Laser Machines Work

Understanding how a laser machine operates involves grasping its intricate mechanics and sophisticated software systems. Initially, raw materials such as steel tubes are loaded into the machine, where sensors detect their dimensions to ensure accurate cuts. As the machine begins its operation, it emits a concentrated beam of light that interacts with the material at high speeds; this interaction enables precise pipe cutting by either melting or burning away unwanted sections while leaving clean edges behind.

Advantages of Using Laser Cutting

Laser cutting technology has revolutionized the way industries approach manufacturing and fabrication. The advantages of laser tube cutting extend beyond mere efficiency; they encompass precision, versatility, and sustainability. With a laser machine, businesses can achieve high-quality results while minimizing waste, making it a game-changer in modern production.

Precision and Accuracy in Cutting

One of the standout features of laser tube cutting is its exceptional precision and accuracy. Laser machines utilize focused beams to cut through materials with remarkable detail, allowing for intricate designs that traditional methods struggle to replicate. This level of precision is especially critical in industries like aerospace and automotive manufacturing, where even the slightest error can lead to significant safety concerns or costly reworks.

Moreover, steel tube laser cutting ensures that each cut is clean and precise, reducing the need for additional finishing processes. This not only saves time but also enhances the overall quality of the final product. When you invest in a metal tube laser cutter, you’re investing in reliability and excellence—attributes every manufacturer strives for.

Versatility in Material Types

Another compelling advantage of using a laser cutting machine is its versatility across various material types. From metals like steel and aluminum to plastics and wood, these machines can handle an impressive range of materials without compromising on quality or performance. This flexibility makes pipe cutting lasers an invaluable asset for businesses looking to diversify their product offerings.

Additionally, different types of laser technologies cater to specific material needs; for instance, fiber lasers excel at cutting reflective metals while CO2 lasers are ideal for non-metallic materials. This adaptability allows manufacturers to switch between projects seamlessly without needing separate machinery for each material type. By incorporating a machine for cutting steel along with other materials into your production line, you can optimize your operations significantly.

Reduced Waste and Enhanced Efficiency

Laser tube cutting stands out not only because it maximizes productivity but also because it minimizes waste during the manufacturing process. The high precision associated with laser machines means that cuts are made accurately on the first attempt—eliminating excess scrap material often generated by traditional methods. As businesses strive to become more eco-friendly, this reduction in waste aligns perfectly with sustainability goals.

Furthermore, enhanced efficiency comes from faster processing times compared to conventional techniques; this means quicker turnaround on projects without sacrificing quality or accuracy. For companies looking to improve their bottom line while being environmentally conscious, investing in a metal tube laser cutter may prove pivotal in achieving those objectives efficiently.

Different Types of Laser Cutting Machines

In the realm of laser tube cutting, two primary types of laser machines dominate the landscape: CO2 laser machines and fiber laser cutting technology. Each type has its unique features and advantages, making them suitable for various applications in metal tube laser cutting and beyond. Understanding these differences is crucial for industries looking to invest in a machine for cutting steel or other materials.

CO2 Laser Machines

CO2 laser machines have been around for quite some time and are known for their versatility in cutting various materials, including plastics, wood, and metals. These machines use a gas mixture of carbon dioxide to generate a high-powered beam capable of precise cuts through thick steel tubes or intricate designs on lighter materials. With their proven track record in industries like automotive manufacturing, CO2 lasers remain a popular choice among businesses seeking reliable solutions for pipe cutting lasers.

One significant advantage of CO2 lasers is their ability to produce high-quality cuts with smooth edges, minimizing the need for post-processing work on metal tube laser cutters. However, they tend to be less efficient than fiber lasers when it comes to speed and energy consumption, which can impact overall production costs over time. Still, when it comes to versatility across diverse materials, CO2 laser machines hold their ground firmly in the market.

Fiber Laser Cutting Technology

On the other hand, fiber laser cutting technology has gained immense popularity due to its efficiency and speed in processing metals like aluminum and stainless steel. Utilizing solid-state lasers that emit light through optical fibers, these machines deliver higher energy density beams that cut through materials faster than traditional methods or even CO2 lasers. This makes them an ideal choice for those looking to invest in a high-performance machine for cutting steel tubes with precision.

Fiber lasers also boast lower operational costs as they consume less power while providing superior performance compared to their counterparts. Additionally, they require minimal maintenance since there are no mirrors involved that need regular alignment or cleaning—an attractive feature for busy manufacturing environments focused on productivity. As industries continue seeking innovative solutions like pipe cutting lasers that enhance efficiency without compromising quality, fiber technology stands out as a frontrunner.

Comparisons between Laser Types

When comparing CO2 laser machines with fiber laser cutting technology, several factors come into play that can influence your decision based on specific needs and applications involving metal tube laser cutters or general sheet metal fabrication tasks. For instance, while CO2 lasers excel at handling non-metallic materials alongside metals effectively—making them versatile—they may lag behind fiber systems when it comes to speed and energy efficiency during heavy-duty operations.

Moreover, the thickness of the material being cut often dictates which type would be more advantageous; fiber lasers generally outperform CO2 models on thicker metals due largely to their concentrated beam strength allowing deeper penetrations without sacrificing quality cuts—essentially speeding up production cycles significantly! Ultimately though both technologies have proven benefits depending upon individual requirements—be it versatility from CO2 options or sheer power from fibers—the choice boils down primarily towards specific applications within each industry sector utilizing advanced machinery designed explicitly around tailored needs!

Key Industries Utilizing Laser Tube Cutting

Laser tube cutting technology is revolutionizing various industries by providing precision, efficiency, and versatility in manufacturing processes. From automotive to aerospace and even furniture design, the laser cutting machine has become an indispensable tool for creating high-quality components. Let’s dive into how different sectors are leveraging this innovative technology.

Automotive Manufacturing Applications

In the automotive industry, laser tube cutting is a game changer, allowing manufacturers to produce intricate parts with remarkable accuracy. The ability of metal tube laser cutters to handle complex geometries means that components like exhaust systems and chassis parts can be designed with optimal performance in mind. Moreover, the speed of steel tube laser cutting reduces production time significantly, enabling manufacturers to meet tight deadlines without compromising on quality.

Automakers are increasingly turning to pipe cutting lasers for their ability to cut through various materials such as aluminum and stainless steel efficiently. This technology not only enhances the overall design but also contributes to lighter vehicle structures, improving fuel efficiency. With advancements in laser machine capabilities, automotive manufacturers can now innovate faster while maintaining high standards of safety and durability.

The integration of laser cutting into automotive production lines exemplifies how modern manufacturing practices can evolve through technology. By adopting these machines for cutting steel and other materials, companies can ensure they stay competitive in a rapidly changing market landscape.

Aerospace Component Production

The aerospace sector demands unparalleled precision and reliability in its components—qualities that laser tube cutting readily provides. Aerospace manufacturers utilize advanced laser machines for producing intricate parts such as brackets, frames, and engine components that must meet stringent safety regulations. The accuracy achieved through metal tube laser cutters ensures that every piece fits perfectly within larger assemblies.

Additionally, the versatility of laser cutting allows for the use of a wide range of materials including titanium and composite materials commonly found in aircraft construction. This adaptability not only streamlines production processes but also leads to significant weight savings essential for flight efficiency. As aerospace technologies continue to evolve, so too does the reliance on sophisticated pipe cutting lasers that push the boundaries of what’s possible.

With rigorous testing standards in place within aerospace manufacturing, choosing a reliable machine for cutting steel is crucial—this is where advanced laser systems shine bright! They offer consistent quality while minimizing waste during production runs.

Furniture and Interior Design Solutions

In furniture design and interior architecture, creativity meets functionality with the help of innovative technologies like laser tube cutting. Designers are embracing this technique to craft unique pieces from various materials—be it wood or metal—that stand out while remaining structurally sound. The precision offered by a laser machine enables intricate designs that would be nearly impossible with traditional methods.

Moreover, using a metal tube laser cutter allows artisans to explore new shapes and forms that enhance aesthetic appeal without sacrificing durability or cost-effectiveness. As sustainability becomes increasingly important in design choices, reduced waste from efficient steel tube laser cutting processes aligns perfectly with eco-friendly practices favored by modern consumers.

Laser-cut furniture pieces often feature striking patterns or custom engravings which add character to any space; it’s this blend of art and engineering that makes them highly sought after today! By integrating advanced technology into their workflows, designers can bring their visions to life while ensuring they deliver quality products consistently.

Choosing the Right Laser Machine

Selecting the right laser machine for your needs can feel like navigating a maze, but it doesn’t have to be overwhelming. Whether you’re in the market for a metal tube laser cutter or a pipe cutting laser, understanding your specific requirements will set you on the path to success. Let’s explore how to assess your material needs, understand production requirements, and discover tailored solutions from Kiant Machinery.

Assessing Your Material Needs

Different materials—be it steel tubes or aluminum profiles—require distinct approaches and settings on your laser cutting machine. For instance, if you're primarily focusing on steel tube laser cutting, you'll want a machine that can handle thicker gauges efficiently without compromising precision.

In addition to material type, consider factors such as thickness and surface finish. A robust metal tube laser cutter should accommodate various thicknesses while delivering clean edges and minimal burrs. By evaluating these aspects upfront, you can ensure that your chosen machine meets both current and future project demands.

Lastly, don’t forget about any special features you might need for unique applications! If you're looking to expand into more complex designs or intricate cuts in the future, opting for a versatile laser machine now could save you time and money later.

Understanding Production Requirements

Production efficiency is key when selecting a laser cutting machine; after all, time is money! Start by analyzing your output goals—how many pieces do you need per day? Knowing this will help determine whether you require a high-speed model or if a standard unit will suffice for your operations.

Another vital consideration is automation capabilities. Some machines offer advanced features like automatic loading systems or integrated software that streamlines workflow from design to production. This added efficiency can significantly reduce labor costs while enhancing overall productivity in metal tube laser cutting processes.

Finally, think about maintenance and support services offered by manufacturers like Kiant Machinery. Ensuring that you have access to timely assistance can prevent downtime due to unforeseen issues with your pipe cutting laser or other equipment.

Kiant Machinery’s Tailored Solutions

Kiant Machinery prides itself on providing tailored solutions that cater specifically to individual customer needs in the realm of laser tube cutting technology. With an array of customizable options available across their range of machines for cutting steel and other metals, they ensure each client gets precisely what they need without unnecessary bells and whistles.

Their team of experts works closely with customers during the selection process—offering insights based on years of experience in various industries including automotive and aerospace manufacturing applications. This personalized approach means you're not just getting another piece of machinery; you're investing in a solution designed specifically for your operational challenges.

Moreover, Kiant Machinery stands out with its comprehensive after-sales support service ensuring longevity and optimal performance of every metal tube laser cutter sold. With them by your side, rest assured that choosing the right equipment will elevate both quality and efficiency in all your projects!

Conclusion

In the ever-evolving landscape of manufacturing, laser tube cutting stands out as a pivotal technology that continues to shape the future of precision fabrication. With advancements in laser cutting machines, industries are witnessing enhanced capabilities that allow for intricate designs and efficient production processes. As we look ahead, the potential applications for laser technology seem boundless, promising a new era of innovation in metalworking and beyond.

Future of Laser Cutting Technology

The future of laser cutting technology is bright, with ongoing research and development paving the way for even more sophisticated machines. Innovations such as AI integration and automation are set to revolutionize how we approach laser tube cutting, making processes faster and more efficient than ever before. Additionally, as industries demand greater sustainability practices, laser cutting’s reduced waste output positions it as a leading choice for environmentally conscious manufacturers.

Common Myths about Laser Cutting

Despite its widespread use, several myths about laser cutting persist in the industry. One common misconception is that all laser machines are overly complex and difficult to operate; however, modern systems are designed with user-friendliness in mind. Another myth suggests that laser tube cutting is only suitable for thin materials; on the contrary, advanced metal tube laser cutters can handle a variety of thicknesses with remarkable precision.

How Kiant Machinery Supports Your Success

Kiant Machinery stands ready to support your success by offering tailored solutions specifically designed for your needs in steel tube laser cutting and other applications. Our team provides comprehensive assessments to ensure you choose the right machine for cutting steel based on your unique material requirements and production goals. With our commitment to customer satisfaction and ongoing support, you can confidently harness the power of advanced laser technology in your operations.