Introduction

In the world of modern manufacturing, fiber cutter machines have emerged as game-changers, revolutionizing the way industries approach precision cutting. These machines utilize advanced laser cutting technology to deliver unparalleled accuracy and efficiency in processing various materials. With applications spanning from automotive to aerospace, understanding fiber cutter machines is essential for anyone looking to enhance their production capabilities.

Understanding Fiber Cutter Machines

Fiber cutter machines are sophisticated tools that employ laser technology to cut through different materials with remarkable precision. Unlike traditional methods, these cutting machines utilize a focused beam of light that can slice through metal and other substances with ease. This innovative approach not only improves the quality of machine cut metal but also significantly reduces waste and operational costs.

Importance of Choosing the Right Equipment

Selecting the right equipment, particularly a laser cutting machine, is crucial for optimizing production processes and achieving desired outcomes. The wrong choice can lead to inefficiencies, increased costs, and subpar results in your projects. By investing in a suitable cutting machine laser tailored to your specific needs, you can ensure that your operations are both effective and economical.

Overview of Laser Cutting Technology

Laser cutting technology has transformed how industries handle material processing by providing high-speed solutions with exceptional accuracy. This technology harnesses focused light beams that melt or vaporize material at incredibly fast rates, making it ideal for applications requiring intricate designs or tight tolerances. As we explore fiber cutter machines further, it becomes clear that mastering this technology is vital for staying competitive in today’s fast-paced market.

Types of Fiber Cutter Machines

CO2 vs. Fiber Laser Technology

CO2 lasers have been a staple in the cutting industry for decades, utilizing gas to generate a high-powered beam that effectively cuts through various materials. In contrast, fiber laser technology employs a solid-state system that produces a more concentrated beam, making it particularly efficient for metal applications. While CO2 lasers excel at cutting non-metal materials like wood and acrylic, fiber lasers shine when it comes to machine cut metal, offering superior speed and precision.

Benefits of Each Technology

The benefits of CO2 lasers include their versatility; they can handle a wider range of materials beyond metals, making them ideal for businesses with diverse needs. However, fiber laser technology offers several advantages that make it increasingly popular in industrial settings: higher energy efficiency results in lower operational costs, faster cutting speeds lead to increased productivity, and reduced maintenance requirements mean less downtime for your laser machinery. Ultimately, choosing between these technologies boils down to your specific application requirements and budget constraints.

Applications in Various Industries

Fiber cutter machines find applications across numerous industries due to their adaptability and precision capabilities. For instance, they are extensively used in automotive manufacturing where high-quality machine cut metal parts are essential for vehicle safety and performance standards. Additionally, sectors such as aerospace and electronics benefit from the accuracy offered by cutting laser metal technologies—ensuring parts fit seamlessly into complex assemblies while minimizing material waste.

Key Features to Consider

When investing in a fiber cutter machine, understanding the key features is essential for maximizing performance and efficiency. The right laser cutting machine can significantly impact your production capabilities, allowing for precise and high-quality cuts in various materials. This section will explore critical aspects such as power and speed, size and material capacity, and advanced controls and software integration.

Power and Speed of the Cutting Machine

The power of a cutting machine laser is one of the most crucial specifications to consider when selecting a fiber cutter machine. Higher wattage typically translates to faster cutting speeds, enabling you to complete projects more quickly without compromising quality. Additionally, a powerful laser cutting machine will allow you to work with thicker materials—essential for industries that demand precision in machine cut metal applications.

Speed is equally important; after all, time is money in manufacturing! Machines that offer variable speed settings can cater to different material types and thicknesses, providing flexibility in operations. Therefore, it’s vital to evaluate both power ratings and speed capabilities when choosing a laser cutter for metal.

Size and Material Capacity

. A larger cutting area enables you to handle bigger sheets or multiple pieces simultaneously, saving time on setups and reducing waste from smaller cuts. Understanding your typical project sizes will help determine the ideal dimensions for your laser cutting machinery.

Material capacity also plays a pivotal role; some machines are designed specifically for certain types of materials or thickness ranges while others boast versatility across various substrates like stainless steel, aluminum, or even softer materials like acrylics. Ensuring that your selected laser machinery can accommodate the materials you frequently work with is vital for seamless operations.

Advanced Controls and Software Integration

In today’s fast-paced manufacturing environment, advanced controls are essential for optimizing productivity with any cutting laser metal technology. Many modern fiber cutter machines come equipped with intuitive interfaces that simplify operation while enhancing precision during complex cuts. Features like automatic height adjustment ensure consistent results across varying material thicknesses—making life easier for operators!

Moreover, software integration plays an increasingly important role in streamlining workflows by allowing designers to create intricate patterns directly linked to the cutting process through CAD/CAM systems. This level of automation not only reduces human error but also enhances overall efficiency by minimizing setup times between jobs on your laser cutter for metal tasks.

The Role of Laser Cutting Machines in Metalwork

Laser cutting machines have revolutionized the metalworking industry by offering unmatched precision and efficiency. The ability to cut various metals with a fiber cutter machine has made it an indispensable tool for manufacturers and fabricators alike. Whether it’s intricate designs or high-volume production, laser cutting technology delivers results that traditional methods simply cannot match.

Advantages of Cutting Laser Metal

One of the standout advantages of using a laser cutter for metal is its exceptional accuracy. Laser cutting allows for incredibly fine details and smooth edges, which are essential in applications requiring high precision. Additionally, cutting laser metal minimizes waste, as the narrow kerf width means less material is removed during the process, resulting in cost savings on raw materials.

Moreover, laser cutting machines can handle a wide range of metals, including stainless steel, aluminum, and brass with ease. This versatility makes them ideal for various industries such as automotive, aerospace, and artistic metal fabrication. With a fiber cutter machine, operators can achieve consistent results across different projects without compromising quality.

Comparing Laser Cutter for Metal Options

When evaluating options for laser machinery tailored to metal cutting needs, it's essential to consider factors like power output and speed capabilities. Different models offer varying wattages that impact the thickness of materials they can cut efficiently; higher wattage typically translates to faster processing times on thicker metals. Therefore, understanding your specific requirements will help you choose the right cutting machine laser that aligns with your production goals.

Another critical aspect to compare is the type of technology used—CO2 vs. fiber lasers—each having unique benefits depending on your application needs. Fiber lasers tend to be more efficient in energy consumption while providing superior performance on reflective materials compared to their CO2 counterparts. Evaluating these differences ensures you select a laser cutter for metal that not only fits your budget but also meets your operational demands.

Precision and Quality in Machine Cut Metal

Advanced software integration allows operators to design complex geometries easily while maintaining high-quality output throughout production runs. This level of control ensures that every piece meets stringent quality standards demanded by industries such as medical device manufacturing or aerospace engineering.

Furthermore, the quality achieved through laser cutting translates into reduced post-processing work like sanding or finishing since cuts are already clean and precise from the outset. Investing in a reliable laser cutting machine means investing in superior craftsmanship that enhances overall productivity and customer satisfaction rates over time. As companies continue embracing this technology, they position themselves at the forefront of innovation within their respective markets.

Leading Brands in Fiber Cutting

Choosing the right manufacturer can significantly impact your laser cutting experience, especially when you consider factors like reliability, customer support, and technological advancements. This section will highlight Kiant Machinery, along with other notable manufacturers, while also discussing how to evaluate brand reputation effectively.

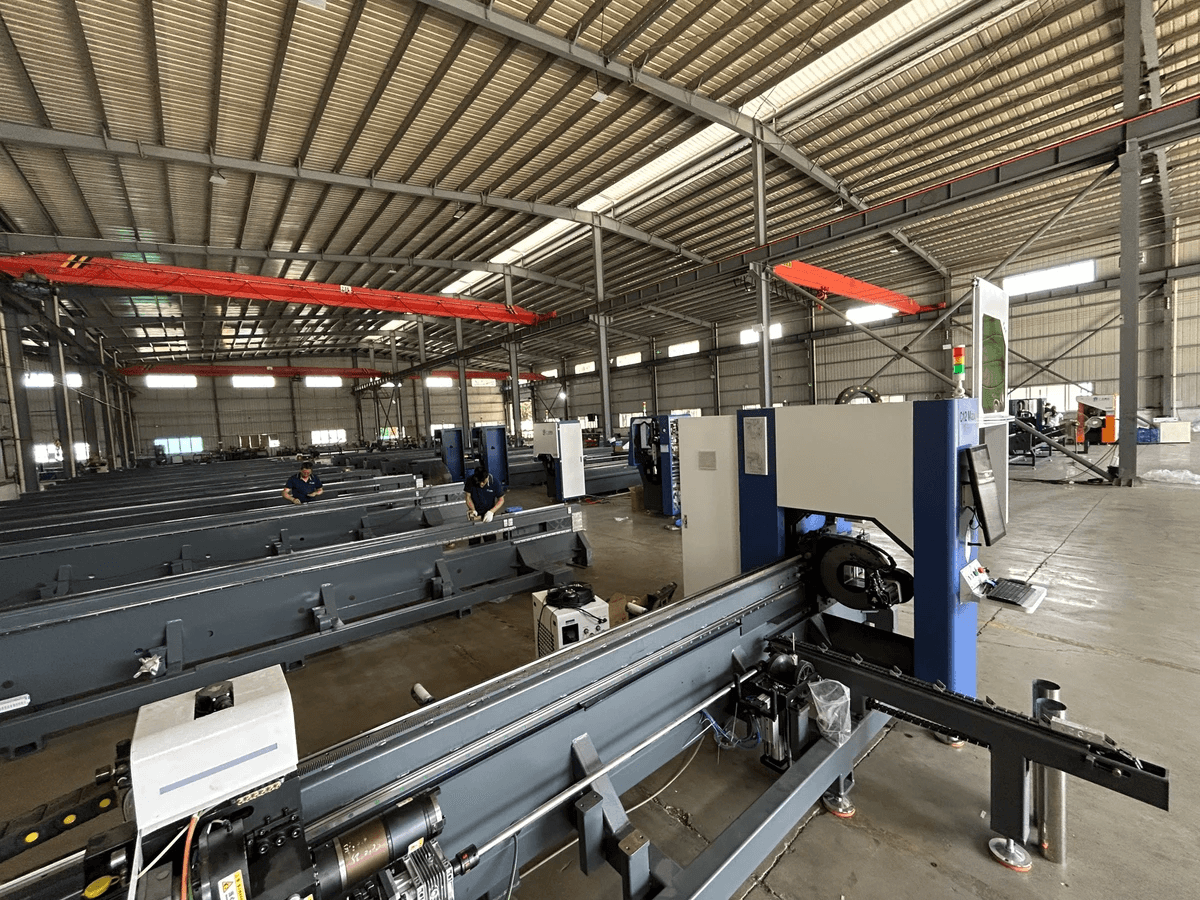

Overview of Kiant Machinery

Kiant Machinery stands out in the realm of fiber cutter machines for its commitment to innovation and quality. Known for their advanced laser cutting technology, they offer a range of cutting machines laser designed for different industrial applications. Their products are particularly recognized for delivering exceptional performance in machine cut metal tasks, ensuring high precision and minimal waste during the cutting process.

One of the key features of Kiant's laser cutting machines is their user-friendly interface combined with robust software integration capabilities. This allows operators to streamline their workflow while achieving optimal results in various materials. Furthermore, Kiant Machinery provides extensive training and support services to help customers maximize their investment in laser machinery.

Other Notable Manufacturers

While Kiant Machinery is a leader in fiber cutting technology, several other manufacturers deserve attention as well. Brands like Trumpf and Bystronic have built strong reputations for producing reliable laser cutters for metal that cater to both small businesses and large enterprises alike. These companies focus on continuous innovation and often lead the way in developing new features that enhance productivity and efficiency.

Another noteworthy player is Amada, which specializes in providing versatile solutions tailored to specific industry needs. Their fiber cutter machines are particularly effective at handling complex geometries while maintaining high-speed performance. Each manufacturer brings unique strengths to the table, making it essential for buyers to explore multiple options before making a decision.

Evaluating Brand Reputation and Support

When selecting a manufacturer for your fiber cutter machine needs, brand reputation should be a top consideration alongside product specifications. Researching customer reviews can provide valuable insights into how well a company supports its clients after purchase—something critical when investing in expensive laser machinery. Additionally, reputable brands often have established networks of service providers who can assist with maintenance or troubleshooting issues as they arise.

It's also beneficial to assess how long the company has been in business; longevity often indicates reliability and experience within the industry. Look for manufacturers who offer warranties or service agreements as these can significantly reduce long-term costs associated with maintenance or repairs on your cutting machine laser equipment. Ultimately, choosing a brand with solid backing ensures you're not just buying equipment but investing in ongoing support that helps you succeed over time.

Cost Considerations and Budgeting

When investing in a fiber cutter machine, understanding the financial implications is crucial. The initial investment can be substantial, but it’s essential to weigh that against potential long-term savings. By selecting the right laser cutting machine, businesses can optimize their production processes and reduce operational costs over time.

Initial Investment vs. Long-Term Savings

The upfront cost of a cutting machine laser can be daunting, especially for small businesses or startups. However, it's important to consider how a high-quality fiber cutter machine can lead to significant savings in materials and labor over its lifespan. Efficient laser cutting technology minimizes waste and maximizes precision, meaning that while you may pay more initially, the return on investment can be substantial as your production efficiencies improve.

Financing Options for Laser Machinery

For many companies, financing options make acquiring a laser cutter for metal much more manageable. Various lenders specialize in equipment financing tailored specifically for businesses looking to invest in advanced laser machinery. Many manufacturers also offer leasing programs or payment plans to ease the burden of an upfront payment while allowing immediate access to cutting-edge technology.

Understanding Maintenance Costs

Owning a fiber cutter machine comes with ongoing maintenance costs that should not be overlooked when budgeting. Regular upkeep is essential to ensure optimal performance and longevity of your cutting machine laser; this includes routine inspections and part replacements as needed. Understanding these costs upfront will help you make informed decisions about which model best fits your budget without sacrificing quality or performance.

Conclusion

In wrapping up our exploration of fiber cutter machines, it's essential to recognize the pivotal role they play in modern manufacturing. The right choice of a cutting machine laser can significantly impact efficiency, precision, and overall production quality. By understanding the nuances of laser cutting technology and its various applications, you can make informed decisions that align with your business goals.

Making an Informed Decision

When selecting a fiber cutter machine, consider factors like power, speed, and compatibility with materials you frequently work with. Each laser cutting machine has its unique strengths; therefore, evaluating your specific needs is crucial. Remember that investing in high-quality laser machinery today can lead to long-term savings and enhanced productivity tomorrow.

The Future of Fiber Cutter Technology

The landscape of fiber cutter technology is rapidly evolving, with advancements promising even greater precision and efficiency in cutting laser metal. Innovations such as AI integration and improved software controls are set to transform how industries approach metalwork. As these technologies develop, businesses that embrace them will likely gain a competitive edge in their respective markets.

Choosing the Right Partner for Success

Finding the right partner for your fiber cutter machine needs goes beyond just choosing a manufacturer; it involves selecting someone who understands your industry challenges and goals. Look for brands that not only offer reliable equipment but also provide exceptional support and service after the sale. By establishing a strong partnership with reputable manufacturers or suppliers, you can ensure that your investment in laser cutting technology pays off handsomely.