Introduction

In the fast-paced world of manufacturing, square tube laser cutting machines have emerged as a game changer, revolutionizing how metal components are crafted. These advanced metal cutting machines utilize innovative laser cutting technology that enhances precision and efficiency, making them indispensable in various industries. As businesses strive for higher productivity and quality, investing in a reliable cutting machine laser is no longer just an option; it's a necessity.

Importance of Square Tube Laser Cutting Machines

The importance of square tube laser cutting machines cannot be overstated; they offer unmatched accuracy and speed when working with various materials. Unlike traditional metal cutting machines, these laser machines minimize waste and reduce the need for extensive post-processing, leading to significant cost savings. Moreover, their ability to handle complex designs with ease makes them vital for companies looking to stay competitive in today’s market.

Overview of Laser Cutting Technology

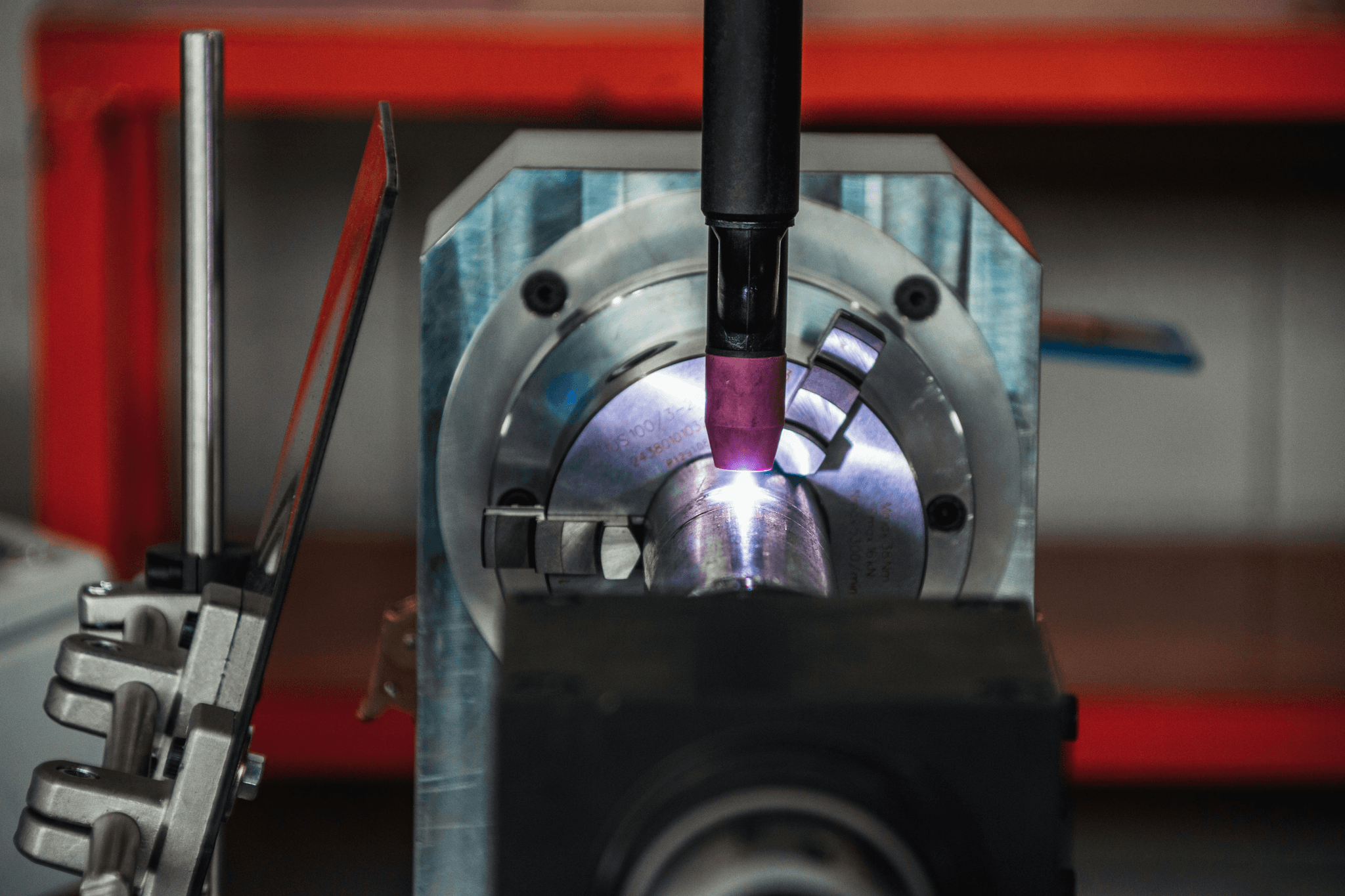

Laser cutting technology operates by focusing a high-powered beam of light onto the material surface, effectively melting or vaporizing it to create precise cuts. This method not only allows for intricate designs but also ensures clean edges without the need for additional finishing work—a major advantage over conventional methods. As advancements continue in this field, the capabilities of laser machinery are expanding rapidly, paving the way for even more efficient production processes.

Benefits of Advanced Metal Cutting Machines

Investing in advanced metal cutting machines like square tube laser cutting machines brings numerous benefits to manufacturers and fabricators alike. These include improved operational efficiency due to faster processing times and reduced labor costs as automation becomes more prevalent in modern manufacturing environments. Additionally, the versatility of these laser cutting machines enables businesses to expand their service offerings while maintaining high-quality standards across diverse applications.

Key Specifications of Laser Cutting Machines

These specifications not only influence the performance of the laser cutting machine but also determine its suitability for various applications. Let’s dive into the essential aspects that define a high-quality metal cutting machine.

Power Output and Efficiency

Power output is one of the most critical factors in any laser cutting machine, particularly when dealing with thicker materials or demanding projects. A higher wattage typically translates to faster cutting speeds and enhanced efficiency, allowing for quicker turnaround times on projects involving square tubes. Moreover, efficient power usage can lead to significant cost savings over time, making it an important consideration when investing in a metal cutting machine laser.

Efficiency also plays a vital role in determining how much energy is consumed during operation. Advanced laser machinery often incorporates features that optimize power usage without sacrificing performance, ensuring you get more done while using less energy. This balance between power output and efficiency can be a game-changer for businesses looking to enhance productivity while keeping operational costs low.

Cutting Speed and Precision

Cutting speed is another essential specification that defines how quickly a square tube laser cutting machine can operate without compromising quality. Faster cutting speeds increase productivity and allow manufacturers to meet tight deadlines more effectively, making this feature particularly appealing in competitive industries. It's important to note that while speed is vital, precision must not be overlooked; after all, accuracy ensures that your metal components fit seamlessly together.

Precision in laser cutting machines is achieved through advanced technology and engineering design that minimizes deviations from desired measurements. High-quality lasers can cut intricate designs with remarkable accuracy, which is especially beneficial when working with complex geometries found in various applications. The combination of speed and precision makes these machines indispensable tools for any serious fabricator or manufacturer.

Material Compatibility and Thickness

A versatile metal cutting machine should be capable of processing various metals such as steel, aluminum, brass, and even some plastics without breaking a sweat—ensuring you can tackle diverse projects without needing multiple machines.

The thickness of materials your chosen laser machinery can handle will directly impact your production capabilities as well; most advanced models offer varying capacities depending on their design and power output. Understanding these limits helps you select a system tailored specifically for your business's requirements—be it light gauge materials or heavy-duty applications requiring robust solutions from your laser cutting equipment.

In summary, choosing the right specifications regarding power output, efficiency, speed, precision, material compatibility, and thickness capacity will ensure you invest wisely in a square tube laser cutting machine that meets both current demands and future growth opportunities.

Advanced Features to Look For

When investing in a square tube laser cutting machine, it's crucial to consider advanced features that enhance performance and usability. These features not only improve efficiency but also ensure safety and ease of operation. Let's dive into the key aspects that make a laser cutting machine stand out in today's competitive market.

Automation and Smart Controls

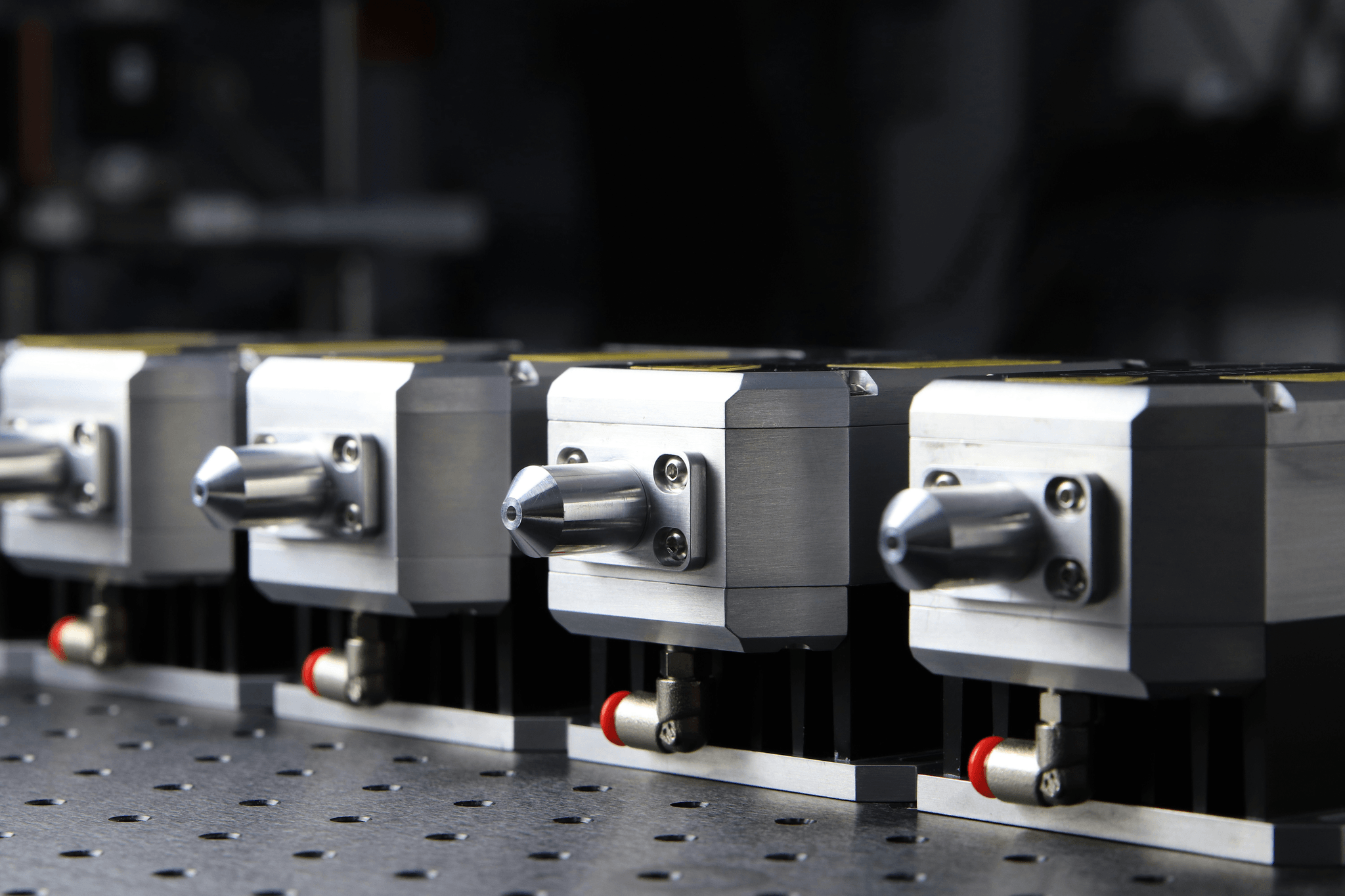

Automation is revolutionizing the realm of metal cutting machines, making processes faster and more efficient than ever before. A square tube laser cutting machine equipped with smart controls allows for real-time monitoring and adjustments, which significantly reduces human error. With features like automatic loading and unloading systems, operators can focus on other critical tasks while the cutting machine laser handles the heavy lifting.

Moreover, advanced software integration enables seamless communication between different components of the laser machinery, optimizing workflow from start to finish. This not only boosts productivity but also ensures consistent quality across all cuts. In an industry where precision is paramount, these automated systems are game-changers.

Safety Features and Compliance

Safety should always be a top priority when operating any metal cutting machine laser. A reliable square tube laser cutting machine comes equipped with multiple safety features designed to protect both operators and equipment. Look for machines with built-in safety enclosures, emergency stop buttons, and sensors that detect potential hazards.

Compliance with industry standards is essential as well; machines that meet OSHA regulations provide peace of mind while ensuring a safe working environment. Additionally, many modern laser machines come with advanced cooling systems that prevent overheating during prolonged use—a critical factor in maintaining both safety and performance over time.

User-friendly Interface and Software

A user-friendly interface can make all the difference when operating complex machinery like a laser cutting machine. The best square tube laser cutting machines feature intuitive touchscreens that simplify navigation through various settings and options. With easy-to-use software tailored for metal fabrication tasks, even less experienced operators can quickly learn how to maximize their machine's capabilities.

Moreover, many modern systems offer remote access capabilities through mobile apps or web interfaces, allowing users to monitor operations from anywhere in the facility—talk about convenience! Investing in a metal cutting machine laser with an accessible interface ultimately leads to reduced training time and increased overall productivity.

Applications of Square Tube Laser Cutting

Square tube laser cutting machines have revolutionized how various industries approach metal fabrication. With their precision and efficiency, these machines are essential in sectors ranging from automotive to aerospace. Understanding the applications of laser cutting technology can help businesses leverage its capabilities for enhanced productivity.

Industries Utilizing Laser Cutting Machines

The versatility of laser cutting machines makes them indispensable across numerous industries. The automotive sector relies heavily on square tube laser cutting for producing intricate parts with tight tolerances, ensuring safety and performance standards are met. Similarly, the construction industry utilizes metal cutting machines to create durable structural components that can withstand the test of time.

In addition to automotive and construction, the furniture industry has embraced laser machinery for crafting unique designs in metal furniture pieces. The ability to cut complex shapes quickly allows manufacturers to innovate while maintaining high-quality standards. Furthermore, the electronics sector benefits from precise laser cutting for creating intricate circuit boards and components that require exact specifications.

Case Studies and Success Stories

One notable success story involves a leading automotive manufacturer that integrated a square tube laser cutting machine into its production line, resulting in a 30% increase in efficiency. By utilizing advanced laser technology, this company reduced material waste significantly while improving part accuracy—a win-win situation! Another case study highlights a custom furniture maker who transformed their design process by adopting a metal cutting machine laser, enabling them to produce bespoke pieces faster than ever before.

These examples illustrate how companies can harness the power of laser machinery to not only streamline operations but also enhance product offerings. In both cases, customer satisfaction soared as businesses delivered high-quality products more rapidly than competitors relying on traditional methods. These success stories serve as inspiration for other industries looking to innovate through advanced technology.

Customization and Versatility in Applications

One of the standout features of square tube laser cutting is its remarkable customization capabilities. Businesses can easily adjust settings on their laser cutting machines to accommodate various materials and thicknesses, making it ideal for diverse applications—from signage creation to industrial equipment manufacturing. This versatility allows companies to pivot quickly based on market demands or client specifications without compromising quality or speed.

Moreover, the user-friendly interface found in many modern laser machines facilitates quick adjustments and programming changes—ideal for small batch runs or one-off projects requiring unique designs. The ability to seamlessly integrate with CAD software further enhances customization options, enabling designers and engineers alike to bring their visions to life effortlessly using advanced metal cutting technology.

In conclusion, whether it's streamlining production processes or crafting custom solutions tailored specifically for clients' needs, square tube laser cutting machines offer unparalleled advantages across multiple sectors—making them an essential investment for any forward-thinking business looking toward future growth.

Comparing Square Tube Laser Cutting Machines

When it comes to investing in a square tube laser cutting machine, understanding the landscape of available options is vital. The market is filled with various models, each boasting unique features and capabilities that cater to different needs. This section will help you navigate through leading brands, analyze price versus performance, and consider maintenance and operational costs.

Leading Brands in the Market

In the realm of laser cutting technology, several brands stand out for their innovation and reliability. Companies like Trumpf, Bystronic, and Amada have built strong reputations for their advanced metal cutting machines. These manufacturers offer cutting-edge laser machinery that not only enhances efficiency but also ensures precision in every cut made on square tubes.

Other notable players include Mitsubishi and Fiber Lasers, which specialize in high-performance laser cutting machines tailored for various industries. Each brand brings its own strengths to the table—whether it’s speed, power output, or user-friendly interfaces—making it essential to evaluate them based on your specific requirements. Ultimately, selecting a reputable brand can significantly impact your overall satisfaction with your metal cutting machine laser.

Price vs. Performance Analysis

When diving into the world of square tube laser cutting machines, price often plays a crucial role in decision-making. However, it's essential to remember that higher prices don’t always equate to better performance; sometimes you can find hidden gems that deliver exceptional quality without breaking the bank. Conducting a thorough analysis of price versus performance will help you identify which cutting machine laser offers the best value for your investment.

For instance, some mid-range models may provide impressive speed and precision while maintaining lower operational costs compared to premium options with extensive features that might go unused in smaller operations. It’s wise to weigh these factors carefully before making a decision; after all, an efficient metal cutting machine should not only fit within your budget but also meet your production demands effectively.

Maintenance and Operational Costs

Maintenance is another critical aspect when comparing square tube laser cutting machines; neglecting this can lead to costly downtime or repairs down the line. Regular upkeep ensures that your laser machinery operates at peak efficiency while minimizing unexpected expenses associated with breakdowns or subpar performance over time. Understanding both routine maintenance requirements and potential repair costs can save you significant headaches later.

Operational costs also play a vital role in determining the long-term viability of any metal cutting machine laser investment. Factors such as energy consumption, replacement parts availability, and labor requirements should be taken into account when evaluating different models on the market; these elements can vary widely between manufacturers and could impact your bottom line significantly.

Why Choose Kiant Machinery

When it comes to investing in a square tube laser cutting machine, Kiant Machinery stands out as a premier choice for metal cutting solutions. With years of experience in the field, they have built a reputation for delivering high-quality laser cutting machines that meet the diverse needs of various industries. Their commitment to innovation and customer satisfaction makes them a reliable partner in your metal fabrication journey.

Industry Expertise and Reputation

Kiant Machinery has established itself as a leader in the laser machinery sector, providing state-of-the-art metal cutting machines that are both efficient and reliable. Their extensive knowledge of laser cutting technology ensures that you receive equipment designed for optimal performance, tailored to specific applications like square tube laser cutting. This expertise not only enhances productivity but also minimizes downtime, making your investment worthwhile.

Comprehensive Support and Training

One of the standout features of choosing Kiant Machinery is their dedication to comprehensive support and training for all customers. They understand that operating a sophisticated laser cutting machine requires skill and knowledge, so they offer extensive training programs tailored to your team’s needs. From initial setup to ongoing maintenance of your metal cutting machine laser, Kiant ensures you have the resources necessary for success.

Tailored Solutions for Your Business Needs

Whether you’re looking for advanced automation features or specific material compatibility with your square tube laser cutting machine, they work closely with you to design systems that enhance efficiency and output. With their focus on flexibility and adaptability, you can be confident that you're investing in a metal cutting machine that's built just for you.

Conclusion

In the ever-evolving landscape of metal fabrication, choosing the right square tube laser cutting machine is crucial for maximizing efficiency and productivity. By investing in a high-quality laser cutting machine, businesses can streamline their operations, reduce waste, and enhance precision in their metal cutting processes. The right equipment not only boosts output but also contributes to overall operational excellence.

Maximizing Efficiency with the Right Machine

Selecting a square tube laser cutting machine tailored to your specific needs can dramatically enhance operational efficiency. Advanced features such as automation and smart controls allow for quicker setup times and reduced human error, making your metal cutting machine more effective than ever. Additionally, with improved power output and efficiency ratings, modern laser machinery ensures that you get the most out of every cut.

Future Trends in Laser Cutting Technology

The future of laser cutting technology is bright and filled with innovation that promises to revolutionize the industry. Expect advancements in artificial intelligence integration, which will enable smarter operations and predictive maintenance for your laser machine. Moreover, developments in material compatibility will allow metal cutting machines to handle an even wider range of materials with varying thicknesses—keeping pace with the demands of diverse industries.

Investing in Quality for Long-Term Returns

Investing in a high-quality square tube laser cutting machine may seem daunting at first glance but pays off significantly over time. A reliable metal cutting machine laser not only minimizes downtime but also reduces maintenance costs—ultimately leading to better return on investment (ROI). By choosing quality over quantity when it comes to your laser machinery, you’re setting up your business for long-term success and sustainability.