Introduction

In the world of metalwork, precision cutting is nothing short of a marvel. The ability to achieve intricate designs and flawless finishes has revolutionized industries, making processes more efficient and products more appealing. With the advent of advanced technologies like the aluminum cutting laser, the magic of precision cutting has reached new heights.

The Magic of Precision Cutting

Precision cutting transforms raw materials into masterpieces with remarkable accuracy. Whether it's for industrial applications or artistic endeavors, laser cutting machines offer unparalleled control over the cutting process. This level of precision not only enhances aesthetic appeal but also optimizes functionality, ensuring every piece meets exact specifications.

Why Aluminum Matters in Metalwork

Aluminum stands out as a preferred material in metalwork due to its unique combination of lightweight properties and exceptional durability. Its corrosion resistance ensures longevity in various applications, making it an ideal choice for both structural and decorative purposes. Additionally, aluminum's versatility allows it to be easily manipulated by a cutting laser metal process, resulting in high-quality finished products.

Discovering the Benefits of Laser Technology

Laser technology has transformed traditional manufacturing methods by introducing speed and efficiency into the equation. Utilizing a laser machine for aluminum cutting not only enhances accuracy but also reduces material waste significantly—a win-win for any production line! Furthermore, metal laser cutting services have made this technology accessible to businesses of all sizes, enabling them to take advantage of these innovative tools without breaking the bank.

What is an Aluminum Cutting Laser?

In the world of modern manufacturing, the aluminum cutting laser stands out as a game changer. This high-tech tool utilizes focused light to slice through aluminum with unmatched precision, making it a favorite for various industries. Whether you're looking to create intricate designs or simply need efficient metal cutting, understanding this laser technology is essential.

An Overview of Laser Cutting

Laser cutting is a process that employs a concentrated beam of light to cut through materials with extreme accuracy. With advancements in technology, laser machines can now handle complex shapes and patterns that traditional methods struggle with.

The beauty of laser cutting lies in its versatility; it can be used for everything from industrial applications to artistic endeavors. This flexibility makes metal laser cutting services highly sought after across various sectors, including automotive and aerospace. As industries evolve, so does the demand for efficient and precise methods like aluminum cutting lasers.

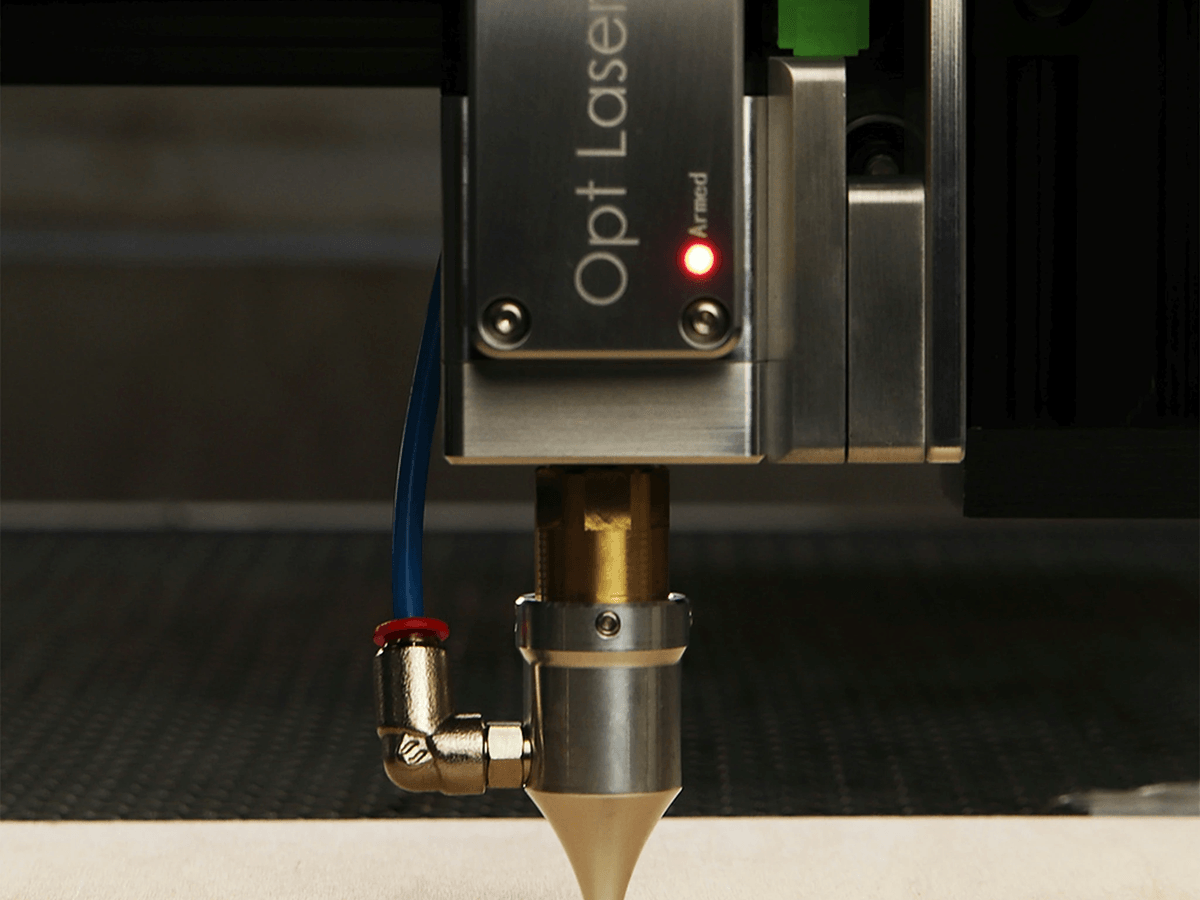

The Mechanics Behind the Laser Machine

At its core, a laser machine operates by generating a beam of light that is then focused through lenses or mirrors onto the workpiece—in this case, sheet metal for laser cutting. The concentrated energy from the beam melts or vaporizes the aluminum as it moves along predetermined paths guided by computer software. This method not only enhances speed but also ensures remarkable accuracy in every cut made.

Key components of these machines include a power source that generates the laser beam and motion systems that control its movement across the material surface. The integration of advanced software allows operators to design intricate patterns effortlessly while maintaining high production rates. Thus, choosing an effective laser machine becomes critical for businesses looking to optimize their operations.

Understanding Sheet Metal for Laser Cutting

Sheet metal serves as one of the primary materials used in conjunction with aluminum cutting lasers due to its favorable properties such as strength-to-weight ratio and ease of fabrication. When selecting sheet metal for laser cutting processes, thickness plays an important role—thinner sheets are easier to cut but may lack durability compared to thicker alternatives suitable for heavier applications.

Additionally, different grades of aluminum offer varying levels of machinability and finish quality when subjected to laser treatment; hence understanding these nuances can significantly impact project outcomes. Properly prepared sheet metal ensures smoother cuts and reduces overall waste during production—a key consideration when using any form of metal laser cutting service. Ultimately, knowing how best to utilize sheet metal will enhance efficiency while maximizing results with your aluminum cutting lasers.

Advantages of Using Aluminum for Cutting

This lightweight yet robust material offers a unique combination of attributes that make it ideal for various applications. From automotive to artistic designs, the benefits of using aluminum in conjunction with laser cutting technology are truly remarkable.

Lightweight Yet Durable Material

Aluminum is renowned for its impressive strength-to-weight ratio, making it an excellent choice for projects requiring both durability and lightness. This characteristic is particularly advantageous in industries such as aerospace and automotive, where every ounce counts. When utilizing a laser cutting machine, the precision achieved with aluminum allows for intricate designs without sacrificing structural integrity.

The ability to create lightweight components with an aluminum cutting laser means that manufacturers can enhance performance while reducing fuel consumption or improving maneuverability. Additionally, this material's malleability allows for easy shaping and forming during the cutting process, further expanding its versatility in production settings. Ultimately, choosing aluminum not only optimizes functionality but also elevates the quality of finished products.

Corrosion Resistance and Longevity

One of the standout features of aluminum is its natural corrosion resistance; this makes it a prime candidate for outdoor applications or environments prone to moisture exposure. When combined with advanced metal laser cutting services, manufacturers can create components that withstand harsh conditions without compromising on aesthetics or performance. The longevity afforded by using an aluminum cutting laser ensures that products maintain their integrity over time.

This durability translates into lower maintenance costs and fewer replacements over the lifespan of a product—an essential factor in any production line's bottom line. Moreover, since corrosion can lead to structural failure, employing aluminum not only enhances safety but also boosts overall reliability across various industries. Therefore, opting for aluminum in conjunction with precision laser technology is a smart investment for long-term success.

Cost-Effectiveness in Production

In today's competitive market, cost-efficiency is key—and this is where using aluminum shines brightly alongside innovative laser machines. The initial investment in high-quality sheet metal for laser cutting may seem daunting; however, the long-term savings from reduced waste and faster production times quickly offset these costs. Laser cutting technology allows manufacturers to make precise cuts that minimize scrap material while optimizing resource usage.

Additionally, because aluminum is easier to work with than many other metals due to its lightweight nature and superior machinability, production times are often shorter—leading to increased output rates without sacrificing quality. This efficiency not only lowers manufacturing costs but also enhances profit margins across various applications from prototyping to mass production runs. In essence, leveraging an aluminum cutting laser within your operations can yield significant financial benefits while maintaining high standards of excellence.

Precision and Accuracy with Laser Cutting

In the world of metal fabrication, precision is paramount, and aluminum cutting lasers are at the forefront of achieving that level of accuracy. Laser cutting technology allows for intricate designs and fine tolerances that are often unattainable with traditional cutting methods. By harnessing the power of a laser machine, manufacturers can ensure that every cut is exact, making it ideal for industries where precision is non-negotiable.

Achieving Fine Tolerances

One of the standout features of a laser cutting machine is its ability to achieve fine tolerances, often within ±0.1 mm or better. This level of precision is crucial when working with sheet metal for laser cutting, especially in applications like aerospace or automotive manufacturing where even minor discrepancies can lead to significant issues down the line. With an aluminum cutting laser, designers can confidently create components that fit together seamlessly, reducing the need for costly rework and enhancing overall project efficiency.

Reducing Material Waste

Another significant advantage of using a laser machine for aluminum cutting is its efficiency in material usage. Traditional methods often lead to excess scrap material due to inaccuracies or inefficient cuts; however, a well-calibrated laser cutting system minimizes waste by optimizing cut paths and maximizing sheet utilization. This not only saves money on raw materials but also supports sustainability efforts by reducing the environmental impact associated with metal fabrication.

Ideal for Complex Designs

The versatility of an aluminum cutting laser makes it particularly well-suited for complex designs that would challenge conventional machining techniques. Whether it's intricate patterns or detailed engravings, laser cutting technology excels at delivering high-quality results without compromising on accuracy or speed. This capability opens up new possibilities in artistic applications and innovative product designs that require both aesthetic appeal and functional integrity.

The Role of Equipment in Precision Work

In the world of metal fabrication, having the right equipment is crucial for achieving the finest results. When it comes to aluminum cutting lasers, selecting a suitable laser cutting machine can make all the difference between a mediocre cut and a masterpiece. With advancements in technology, modern laser machines offer unparalleled precision and efficiency, making them indispensable in various industries.

Choosing the Right Laser Cutting Machine

When it comes to selecting an aluminum cutting laser, there are several factors to consider that can significantly impact your projects. First and foremost, you’ll want to assess the thickness of the sheet metal for laser cutting you plan to work with; different machines have varying capabilities when it comes to material thickness. Additionally, consider features such as speed, power output, and ease of use—these elements will determine how effectively your laser cutting machine performs under pressure.

Another critical aspect is compatibility with software and design tools; a user-friendly interface can streamline your workflow and enhance productivity. For businesses looking for metal laser cutting service options, investing in a versatile machine that accommodates various designs can lead to increased profitability. Ultimately, choosing the right aluminum cutting laser means aligning your equipment with your specific needs for precision and quality.

Featured Brands: Kiant Machinery Innovations

When discussing top-tier equipment for precision work in aluminum cutting lasers, Kiant Machinery Innovations deserves special mention. Renowned for their state-of-the-art technology and commitment to quality, their range of laser machines sets industry standards high. Whether you're seeking compact models or large industrial-grade machines capable of heavy-duty tasks, Kiant offers something tailored for every requirement.

Their innovative features often include advanced cooling systems that prolong machine life and enhance performance during prolonged use—a crucial factor when engaging in extensive metal laser cutting service projects. Furthermore, Kiant's focus on customer support ensures that users have access to resources for maintenance and troubleshooting as needed—an invaluable asset when relying on sophisticated machinery like an aluminum cutting laser.

Importance of Regular Maintenance

Regular maintenance is not just an option; it's essential if you want your laser cutting machine to perform optimally over time. Just like any other sophisticated piece of equipment, neglecting routine care can lead to decreased efficiency or even costly breakdowns—especially critical when working with precise cuts on sheet metal for laser cutting applications. Implementing a regular maintenance schedule will help ensure that components like lenses remain clean and functional while keeping software updated.

Moreover, regular checks allow operators to spot potential issues before they escalate into major problems—saving both time and money in repairs or replacements down the line. By prioritizing maintenance on your aluminum cutting lasers from brands like Kiant Machinery Innovations, you'll not only extend their lifespan but also maintain peak performance levels essential for high-quality outputs.

Applications of Aluminum Cutting Lasers

Aluminum cutting lasers have revolutionized various industries by providing precision and efficiency that traditional cutting methods simply can't match. From automotive to artistic endeavors, the versatility of these laser machines is truly remarkable. Let’s dive into some of the most impactful applications where aluminum cutting lasers shine.

Automotive and Aerospace Industries

In the automotive and aerospace sectors, precision is not just a luxury; it's a necessity. Aluminum cutting lasers are essential for crafting lightweight yet strong components that meet rigorous safety standards while enhancing fuel efficiency. The ability to cut sheet metal for laser cutting with pinpoint accuracy allows manufacturers to produce intricate parts that contribute to overall performance and durability.

Moreover, using a laser machine ensures that components are made with minimal waste, which is crucial in industries where cost-effectiveness is key. With metal laser cutting services tailored specifically for these sectors, companies can streamline their production processes without sacrificing quality or safety. As vehicles become more advanced, the demand for high-precision aluminum parts will only continue to grow.

Artistic and Architectural Designs

The world of art and architecture has embraced aluminum cutting lasers as a means to push creative boundaries. Artists use these laser machines to create stunning sculptures and intricate designs that were previously impossible with conventional methods. The precision offered by an aluminum cutting laser allows for detailed patterns and shapes that elevate artistic expression.

In architecture, aluminum components cut with laser technology provide both aesthetic appeal and structural integrity. Whether it's ornate facades or unique interior elements, the versatility of aluminum makes it an ideal choice for architects looking to innovate while maintaining functionality. Additionally, using a metal laser cutting service can help artists and designers achieve their visions faster than ever before.

Manufacturing and Prototyping

The manufacturing sector benefits immensely from the speed and accuracy of aluminum cutting lasers during production runs and prototyping phases alike. Laser cutting enables manufacturers to produce prototypes rapidly without compromising on quality or detail—essential when testing new designs or products in competitive markets. This rapid turnaround can significantly reduce time-to-market for new innovations.

Furthermore, utilizing sheet metal for laser cutting in manufacturing processes helps optimize material usage while minimizing waste—an essential consideration in today's eco-conscious environment. Companies leveraging advanced laser machines can efficiently scale production while ensuring consistent results across batches, making them leaders in their fields. As industries continue to evolve, the role of aluminum cutting lasers will only expand further into manufacturing practices worldwide.

Conclusion

In the ever-evolving landscape of manufacturing, aluminum cutting technology stands at the forefront, promising precision and efficiency. As industries demand higher standards for accuracy and speed, advancements in laser cutting are paving the way for innovative solutions. The future of aluminum cutting lasers is bright, with continuous improvements in laser machine capabilities that cater to diverse applications.

The Future of Aluminum Cutting Technology

The future of aluminum cutting technology is set to revolutionize how we approach metalwork. With ongoing research and development, laser cutting machines are becoming faster and more efficient while maintaining their precision edge. As manufacturers increasingly adopt eco-friendly practices, innovations like fiber lasers are leading the charge by reducing energy consumption during metal laser cutting processes.

Elevate Your Production with Precision

To elevate your production capabilities, investing in a high-quality aluminum cutting laser can make all the difference. These machines not only offer unparalleled accuracy but also significantly reduce material waste during operations—an essential factor in cost-effective manufacturing. By utilizing advanced sheet metal for laser cutting techniques, businesses can tackle complex designs that were once deemed impossible.

Choosing Kiant Machinery for Your Needs

Known for their state-of-the-art equipment and exceptional customer support, they provide tailored solutions that meet specific production requirements. By choosing Kiant Machinery’s advanced laser machines, you’re not just investing in a tool; you’re securing a pathway to enhanced productivity and innovation.