Introduction

In the world of modern manufacturing, laser cutting has emerged as a revolutionary technique for processing various metals. The evolution of laser metal cutting technology has transformed industries, enabling precision and efficiency previously thought unattainable. Today, businesses are increasingly asking, Can aluminum be laser cut? and discovering that the answer is a resounding yes.

The Evolution of Laser Metal Cutting

Laser cutting technology traces its roots back to the late 1960s when scientists first harnessed lasers for industrial applications. Over the decades, advancements in laser cutting machines have led to enhanced capabilities, allowing for intricate designs and faster production times in metal fabrication. As industries continue to evolve, so too does the technology behind cutting laser metal; innovations are constantly reshaping how we think about metalworking.

Why Precision Matters in Metal Fabrication

Precision is paramount in metal fabrication as even the slightest deviation can lead to costly errors or wasted materials. Laser cutting offers unparalleled accuracy, making it an ideal choice for projects requiring meticulous detail and clean edges. Whether working with sheet metal for laser cutting or heavier gauges, achieving precise cuts ensures that components fit together seamlessly during assembly.

Exploring Laser Cutting Technology

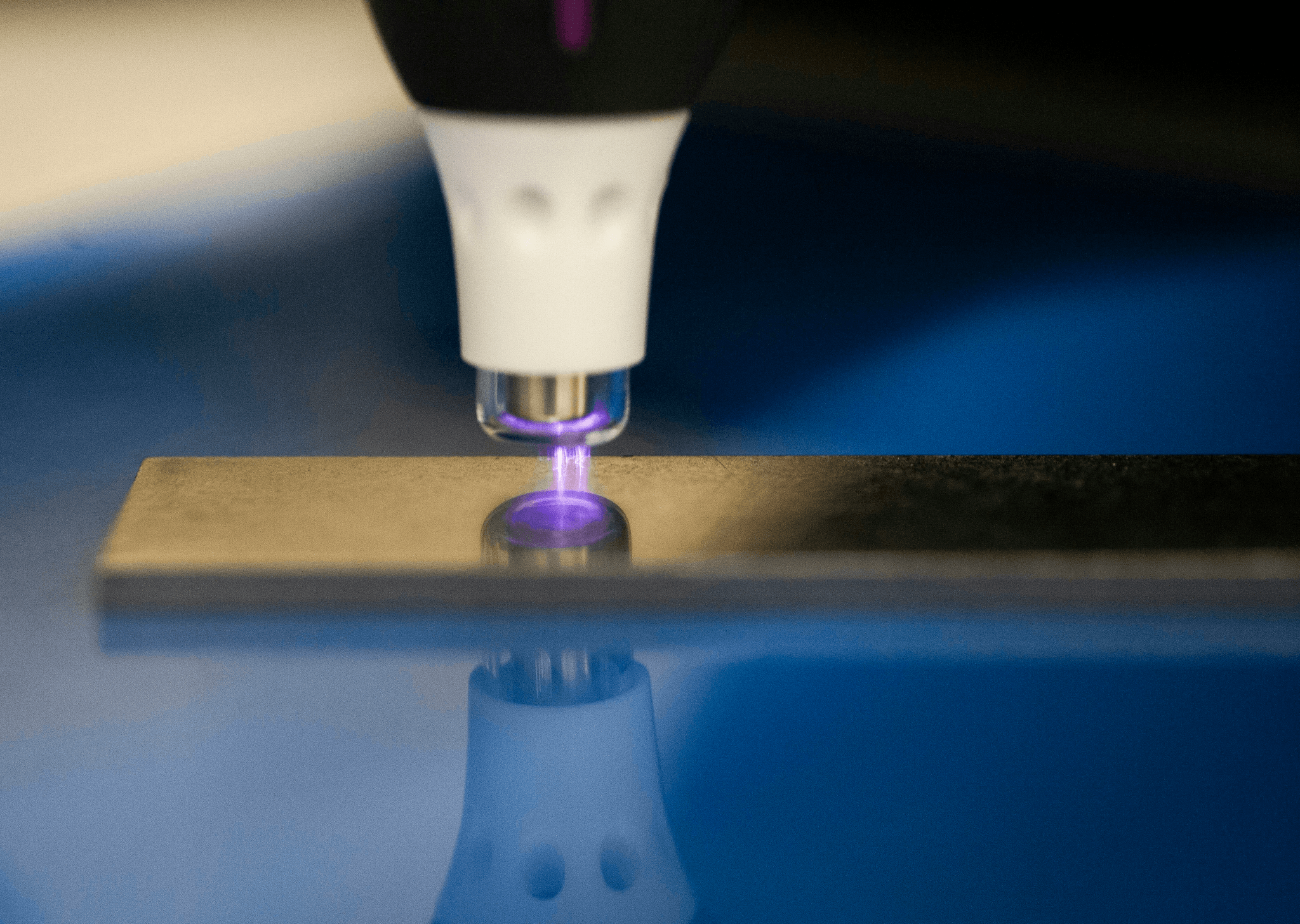

At its core, laser cutting utilizes focused beams of light to melt or vaporize metals with exceptional precision. The versatility of different types of lasers allows manufacturers to tailor their processes according to specific material requirements—whether it's aluminum or steel being processed by a state-of-the-art laser cutting machine for metal. As we delve deeper into this topic throughout our discussion, we'll uncover not only how these machines work but also their significant impact on various applications across industries.

Understanding Laser Cutting Principles

Laser cutting technology has revolutionized the way we approach metal fabrication, offering precision and efficiency that traditional methods simply can't match. Understanding how laser cutting works is essential for anyone looking to delve into the world of metal processing. From the mechanics behind a laser cutting machine to the types of lasers used for cutting metal, each element plays a crucial role in achieving high-quality results.

How Laser Cutting Works

At its core, laser cutting involves focusing a high-powered beam of light onto a material, creating intense heat that melts or vaporizes the metal. This process allows for intricate designs and clean edges, making it particularly appealing for applications where precision matters—like when asking, can aluminum be laser cut? The energy from the laser is precisely controlled, allowing operators to adjust settings based on material type and thickness for optimal performance.

The process begins with a computer-aided design (CAD) file that guides the laser cutting machine in executing complex shapes with extreme accuracy. As the cutting laser moves along predefined paths, it can handle various materials—including metals like steel and aluminum—making it versatile in industrial applications. This precision not only enhances productivity but also minimizes waste, an important consideration in any manufacturing environment.

Key Components of a Laser Cutting Machine

A typical laser cutting machine comprises several key components that work together seamlessly to deliver outstanding results. The primary element is the laser source itself, which generates the beam needed for cutting; this can be CO2 or fiber lasers depending on specific requirements. Other essential parts include optics systems that focus and direct the beam onto the workpiece and motion control systems that ensure accurate positioning.

Additionally, there are cooling systems designed to manage heat generated during operation—the last thing you want is overheating affecting performance! A user-friendly interface allows operators to easily input designs and monitor progress throughout the process. When selecting a machine for your needs, understanding these components will help you choose one that's best suited for your metal fabrication tasks.

Types of Lasers Used in Metal Cutting

When it comes to choosing a suitable type of laser for metal cutting, several options are available—each with its unique advantages and applications. CO2 lasers are popular due to their ability to cut through various materials efficiently; they excel at thicker metals but may require more maintenance compared to other types. On the other hand, fiber lasers have gained traction thanks to their speed and efficiency when working with reflective metals like aluminum.

In addition to CO2 and fiber lasers, there are also solid-state lasers used primarily in specialized applications requiring extreme precision or specific wavelengths tailored for unique materials. Each type offers distinct benefits depending on factors such as material thickness or desired finish quality when using sheet metal for laser cutting projects. Understanding these differences will empower you to make informed decisions about which cutting technology aligns best with your production goals.

Can Aluminum Be Laser Cut?

Aluminum is a versatile metal that can indeed be laser cut, a process that has gained popularity in various industries. The ability to use a cutting laser metal technique on aluminum allows for precise and intricate designs that would be challenging with traditional cutting methods. This capability makes aluminum an excellent candidate for applications requiring high accuracy and clean edges.

Advantages of Laser Cutting Aluminum

One of the primary advantages of using a laser cutting machine for aluminum is its precision. Laser cutting ensures clean cuts with minimal kerf, which is particularly beneficial when working with thin sheet metal for laser cutting. Additionally, the heat-affected zone (HAZ) is significantly reduced, minimizing thermal distortion and preserving the material's integrity.

Another notable benefit is the speed at which a laser cutting machine can operate. With advanced technology, these machines can quickly process large volumes of aluminum sheets, making them ideal for high-demand production environments. Furthermore, the flexibility of laser cutting allows manufacturers to create complex shapes and designs without needing extensive tooling changes.

Lastly, laser cutting reduces waste material compared to traditional methods since it can achieve tighter tolerances and more efficient nesting of parts on sheets. This efficiency not only saves money but also contributes to environmentally friendly practices by minimizing scrap material generated during production.

Common Applications for Aluminum Laser Cutting

Laser cutting technology has found its way into numerous applications involving aluminum due to its unique properties and advantages. Industries such as automotive manufacturing utilize this method to create lightweight components that enhance fuel efficiency while maintaining strength and durability. From brackets to intricate body panels, the precision of laser-cut aluminum parts plays a crucial role in overall performance.

Another common application is in aerospace engineering where weight reduction is critical without compromising safety or functionality. Components like aircraft skins or structural elements are often produced using aluminum laser cutting techniques due to their ability to handle complex geometries with remarkable accuracy. The aerospace sector benefits from both the lightweight nature of aluminum and the precision offered by modern laser technologies.

In addition to automotive and aerospace industries, architectural applications frequently employ aluminum laser-cut elements for aesthetic purposes as well as functional ones. Decorative facades, custom signage, and interior design features often leverage this technology to produce eye-catching designs that stand out while maintaining structural integrity.

Limitations and Considerations

While there are numerous advantages associated with using a laser cutting machine for metal like aluminum, some limitations exist that manufacturers need to consider before diving in headfirst. One significant factor is cost; while initial investments in high-quality lasers may seem steep, they pay off over time through efficiency gains—though smaller operations might find it challenging initially.

Another consideration revolves around thickness limitations; although lasers can cut through various thicknesses of aluminum effectively, there are optimal ranges where performance peaks—typically between 1mm and 10mm depending on the specific type of alloy being used. Beyond these limits may require adjustments in settings or even transitioning to different methods altogether if thicker materials are needed.

Finally, it's important to note that not all types of lasers are suitable for every application involving aluminum—certain wavelengths work better than others depending on factors like alloy composition or desired finish quality when using a metal laser cutter system. Understanding these nuances will help ensure successful outcomes when venturing into projects involving this versatile material.

Steel Cutting with Precision Lasers

Steel cutting has undergone a significant transformation thanks to advancements in laser technology. Precision lasers have become the go-to method for cutting steel, offering unparalleled accuracy and efficiency. As industries evolve, understanding the benefits and best practices of using a laser cutting machine for metal is essential.

Benefits of Laser Cutting Steel

One of the primary benefits of laser cutting steel is its remarkable precision, allowing for intricate designs that traditional cutting methods struggle to achieve. This precision not only enhances the aesthetic appeal but also minimizes waste, making it an environmentally friendly option in metal fabrication. Additionally, laser cutting machines can operate at high speeds, significantly improving production rates while maintaining quality.

Another advantage of using a cutting laser metal is its ability to handle various thicknesses with ease. Whether you’re working with thin sheets or thicker plates, a well-calibrated laser can adapt to your needs without compromising on performance. This versatility makes it an ideal choice for diverse applications across multiple industries.

Moreover, the cleanliness of cuts produced by laser technology reduces or eliminates the need for further finishing processes, saving time and resources. The minimized heat-affected zone (HAZ) means less distortion and better material integrity post-cutting. All these factors contribute to making steel laser cutting a preferred choice among manufacturers looking for efficient solutions.

Common Steel Grades for Laser Cutting

Commonly used grades include carbon steels like A36 and A572 due to their excellent machinability and weldability when processed with a laser cutting machine for metal. Stainless steels such as 304 and 316 are also popular choices due to their corrosion resistance and strength.

Each grade has unique characteristics that affect how well it can be cut by lasers; thus understanding these properties is crucial in achieving optimal results during manufacturing processes. For instance, high-carbon steels may require different settings compared to mild steels when utilizing a metal laser cutter due to their varying hardness levels.

In addition to carbon and stainless steels, specialized alloys like tool steels or high-strength low-alloy (HSLA) steels are increasingly being utilized in advanced applications where durability is paramount. Selecting the right grade not only impacts cut quality but also influences overall project costs.

Best Practices in Steel Laser Cutting

To maximize efficiency when employing a laser cutting machine for metal, adhering to best practices is key! First off, ensure that your sheet metal for laser cutting is clean and free from contaminants; this helps maintain beam integrity during operation and results in cleaner cuts overall.

Next up: optimizing your machine settings based on material type and thickness can make all the difference! Adjusting parameters such as power levels, speed settings, and focal length ensures that you’re getting the most out of your equipment while minimizing wear on components over time.

Lastly, regular maintenance checks on your equipment will keep everything running smoothly—think of it as giving your trusty laser cutter some TLC! Keeping lenses clean and ensuring proper alignment will help maintain accuracy over time while extending the lifespan of your investment into this advanced technology.

The Role of Sheet Metal in Laser Cutting

In the realm of laser cutting, sheet metal plays a pivotal role, acting as the canvas upon which intricate designs and precision cuts are created. Selecting the right sheet metal for laser cutting is crucial, as it determines not only the quality of the finished product but also the efficiency of the cutting process itself. Factors such as material type, thickness, and surface finish must be considered to achieve optimal results when using a laser cutting machine for metal.

Selecting Sheet Metal for Laser Cutting

Common choices include aluminum and steel; both materials possess unique characteristics that affect how they interact with a cutting laser metal. For instance, while aluminum is lightweight and corrosion-resistant, steel offers strength and durability—each requiring specific settings on your laser cutting machine to ensure precision.

Moreover, evaluating surface finishes can significantly impact cut quality; smoother surfaces typically yield cleaner cuts with less dross. It’s vital to consider whether you need pre-treated or raw sheets based on your project's requirements. Ultimately, choosing the right sheet metal not only enhances aesthetic appeal but also optimizes performance during the laser cutting process.

Thickness Considerations for Optimal Results

Thickness is another critical factor when it comes to achieving optimal results in laser cutting applications. Different materials respond differently to varying thickness levels; thus understanding these nuances can make or break your project. For example, thinner sheets can be cut quickly and efficiently with high-speed lasers while thicker sheets may require slower speeds and higher power settings.

When asking yourself can aluminum be laser cut?, remember that aluminum typically ranges from 0.5 mm to 25 mm in thickness for effective processing with a laser cutting machine for metal. On the other hand, steel might require more robust machinery capable of handling greater thicknesses without compromising precision or quality during cuts. Therefore, assessing material thickness ensures you select appropriate machinery settings that maximize efficiency while minimizing waste.

Innovations in Sheet Metal for Laser Cutting

The landscape of sheet metal used in laser cutting is continually evolving thanks to advancements in technology and material science. Innovations such as high-strength alloys and composite materials are now making their way into fabrication shops worldwide—these materials often provide enhanced performance characteristics suited for modern applications involving intricate designs or demanding environments.

Additionally, developments in surface treatments are paving new paths toward improved cut quality; coatings that enhance reflectivity can optimize interactions between the beam from a cutting laser metal and various substrates like stainless steel or titanium alloys used widely today. As manufacturers push boundaries with innovative materials tailored specifically for use with advanced laser cutting machines, we can expect even greater efficiencies and capabilities across industries.

Choosing the Right Laser Cutting Machine

Selecting the right laser cutting machine can feel like navigating a maze, especially with so many options available. The perfect machine should align with your specific needs, whether you're cutting aluminum or steel, and it should enhance your overall metal fabrication process. Understanding the critical factors at play will help you make an informed decision that boosts productivity and precision.

Factors to Consider When Selecting a Machine

When choosing a laser cutting machine for metal, several factors come into play. First, consider the type of materials you'll be working with; different machines are optimized for various metals, including aluminum and steel. Additionally, think about the thickness of sheet metal for laser cutting—some machines handle thicker materials better than others.

Next up is power and speed; higher wattage typically means faster cutting speeds and the ability to handle thicker materials efficiently. Don't forget about precision—look for machines known for their accuracy if you want clean edges without excessive post-processing work. Finally, consider your budget; while top-tier machines offer superior performance, there are plenty of cost-effective options that still deliver quality results.

Comparing Different Laser Cutting Technologies

The world of laser cutting technology is diverse, featuring various types of lasers suited for different applications in metal fabrication. CO2 lasers are popular due to their versatility and ability to cut non-metal materials as well as metals like aluminum and steel.

Another technology worth mentioning is solid-state lasers; these machines excel in precision but may come at a higher price point compared to CO2 or fiber options. Each type has its pros and cons depending on your specific needs—whether it's speed, material compatibility (like can aluminum be laser cut), or operational costs. When comparing technologies, don’t overlook after-sales support and maintenance services offered by manufacturers.

Kiant Machinery: Your Partner in Laser Cutting Solutions

When it comes to finding reliable laser cutting solutions tailored to your needs, Kiant Machinery stands out as a trusted partner in the industry. They offer an impressive range of high-performance laser cutting machines designed specifically for various applications—from thin sheet metal for laser cutting to thicker plates requiring robust machinery capabilities. With their expertise in both CO2 and fiber technologies, Kiant ensures that you’ll find exactly what you need.

Moreover, they provide comprehensive support throughout your purchasing journey—from helping you choose the right machine based on your requirements to offering training on how best to operate it efficiently. Their commitment doesn't end there; Kiant Machinery also offers ongoing maintenance services that keep your equipment running smoothly long after installation.

In conclusion, investing in a top-notch laser cutting machine can significantly enhance your fabrication processes while ensuring precision in every cut made—whether you're working with aluminum or steel sheets! As technology continues evolving at breakneck speed within this field (and yes—can aluminum be laser cut?), having a reliable partner like Kiant Machinery will keep you ahead of the curve.

Conclusion

In the ever-evolving landscape of manufacturing, laser cutting technology stands out as a game-changer, with its efficiency and precision redefining metal fabrication. As we look to the future, advancements in laser cutting machines promise to enhance capabilities and broaden applications across various industries. The question can aluminum be laser cut? is just one of many that highlights the ongoing exploration of materials suitable for this innovative process.

The Future of Laser Cutting Technology

The future of laser cutting technology appears bright, with continuous improvements in both machine design and operational efficiency. Innovations such as fiber lasers and advanced optics are paving the way for faster cutting speeds and higher quality finishes in metal laser applications. As manufacturers increasingly adopt these technologies, they will find new ways to optimize their processes, making it easier than ever to explore whether aluminum can be laser cut alongside other metals.

Enhancing Efficiency with Precision Cutting

Precision is crucial in metal fabrication, especially when working with materials like sheet metal for laser cutting. By utilizing high-quality laser cutting machines, manufacturers can achieve intricate designs while minimizing waste and maximizing productivity. The ability to quickly switch between different types of metals without sacrificing quality allows businesses to respond swiftly to market demands while maintaining a competitive edge.

Final Thoughts on Laser Metal Cutting

In conclusion, the realm of laser metal cutting offers vast potential for innovation and efficiency in manufacturing processes. With numerous advantages such as reduced lead times and improved accuracy, companies are increasingly turning to this technology for their fabrication needs. Whether it's about understanding how aluminum can be laser cut or exploring new applications in steel or sheet metal for laser cutting, embracing these advancements will undoubtedly shape the future of metalworking.