Introduction

In the fast-paced world of manufacturing, precision is paramount, and that's where the precision laser cutting machine shines. This advanced technology has revolutionized how materials are shaped and processed, offering unparalleled accuracy and efficiency. With the rise of laser cutting, industries are discovering new ways to enhance productivity while minimizing waste.

Understanding Precision Laser Cutting Machine

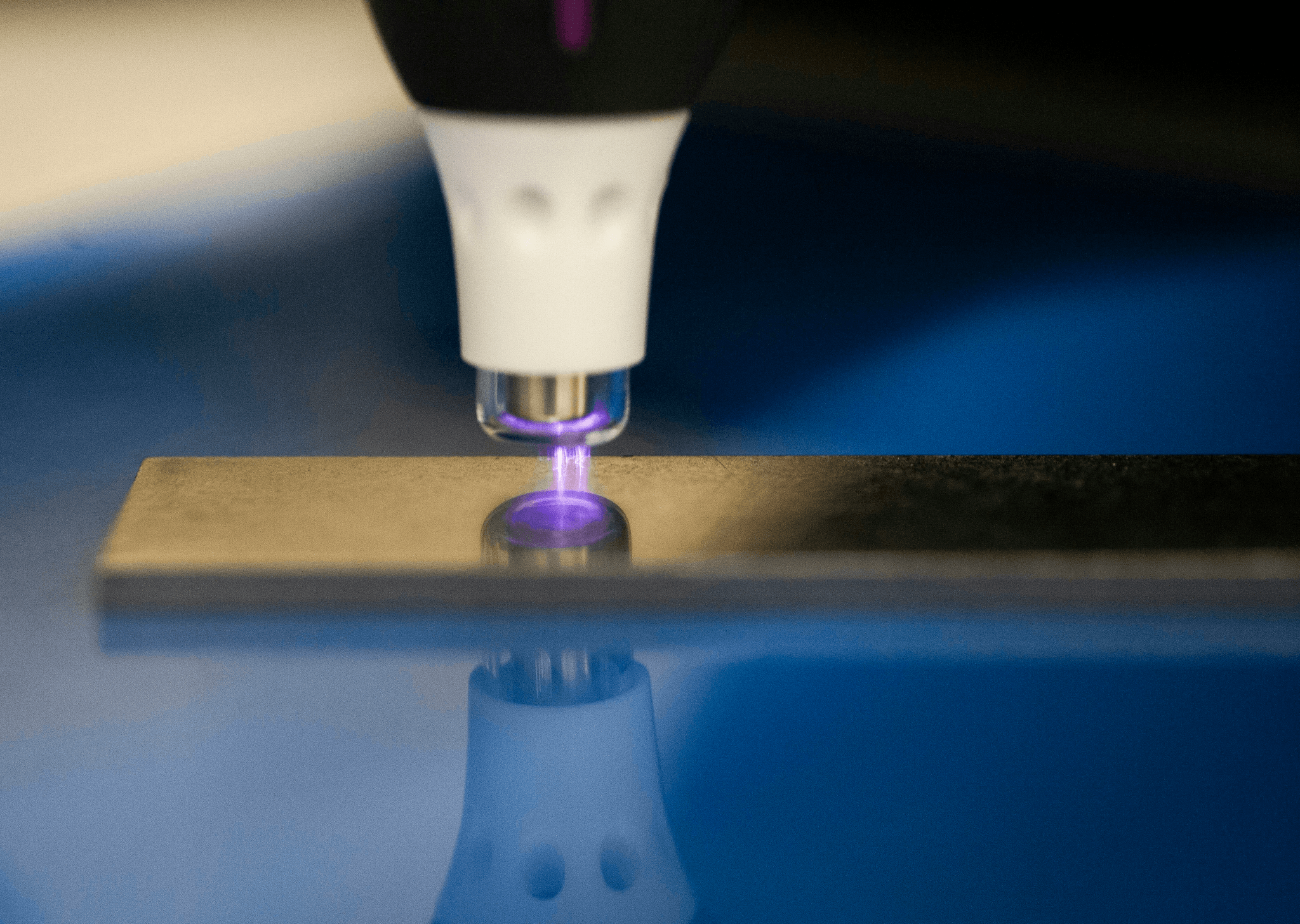

A precision laser cutting machine employs focused beams of light to slice through various materials with extreme accuracy. Unlike traditional cutting methods that can be imprecise and labor-intensive, laser machinery utilizes high-powered lasers to achieve clean cuts with minimal thermal distortion. This innovative approach not only improves the quality of finished products but also streamlines production processes across multiple sectors.

The Rise of Laser Cutting Technology

The adoption of laser cutting technology has surged in recent years due to its remarkable versatility and efficiency. From automotive to aerospace, businesses are increasingly turning to fiber laser cutting machines for their ability to handle complex designs with ease. As industries evolve, the demand for reliable and precise solutions continues to drive advancements in laser machinery.

Efficiency: The Key to Modern Manufacturing

Efficiency is at the heart of modern manufacturing practices, making it essential for companies looking to stay competitive in a global market. Precision laser cutting machines offer a unique combination of speed and accuracy that significantly enhances production capabilities while reducing operational costs. By investing in advanced laser technology, manufacturers can optimize their processes and achieve long-term success.

What is a Precision Laser Cutting Machine?

Precision laser cutting machines are advanced tools that utilize focused laser beams to cut through various materials with remarkable accuracy and speed. These machines have revolutionized the manufacturing landscape, providing solutions that traditional cutting methods simply cannot match. By employing high-powered lasers, they achieve intricate cuts and designs while minimizing material waste.

Basics of Laser Cutting Technology

At its core, laser cutting technology involves directing a high-intensity laser beam onto a material's surface to melt or vaporize it, creating precise cuts. This process can handle a wide range of materials, including metals, plastics, wood, and more. The precision offered by these machines ensures that even the most complex shapes can be achieved without compromising quality.

The fundamental components of a precision laser cutting machine include the laser source, focusing lens, and motion control system. Each part plays a critical role in determining the overall efficiency and effectiveness of the laser cutting operation. With advancements in technology, fiber lasers have become increasingly popular due to their superior performance and energy efficiency compared to traditional CO2 lasers.

Differences Between Laser Machinery Types

When exploring the realm of laser machinery, it's essential to understand the differences between various types of laser cutting machines available on the market today. The primary categories include CO2 lasers and fiber lasers; each type has unique characteristics suited for different applications. While CO2 lasers excel at cutting non-metal materials like wood or acrylics, fiber laser cutting machines shine when working with metals due to their higher power density and faster processing speeds.

Another distinction lies in the machine's configuration—some are designed for flat sheet metal while others cater to 3D objects or tubes. These variations allow businesses to select a precision laser cutting machine that aligns perfectly with their production needs. Additionally, advancements in automation have led to hybrid models that combine capabilities for even greater versatility.

Applications Across Various Industries

Precision laser cutting technology is employed across numerous industries due to its adaptability and efficiency in handling diverse materials. In automotive manufacturing, for instance, these machines are used for creating intricate parts with tight tolerances that ensure optimal performance on vehicles' assembly lines. Similarly, aerospace companies rely on precision lasers for lightweight components where every gram matters.

Beyond heavy industry applications, sectors like fashion design utilize precision laser cutters for fabric engraving or intricate pattern creation—demonstrating how versatile this technology can be across different fields. Even signage companies benefit from these machines’ ability to produce detailed designs quickly while maintaining high-quality finishes on various substrates such as metals or plastics.

How Precision Laser Cutting Machines Enhance Efficiency

In the fast-paced world of manufacturing, the efficiency of production processes is paramount. Precision laser cutting machines are at the forefront of this transformation, combining speed and accuracy to revolutionize how materials are processed. By harnessing advanced laser technology, businesses can streamline their operations, reduce turnaround times, and ultimately enhance their productivity.

Speed and Accuracy in Production

One of the standout features of a precision laser cutting machine is its unparalleled speed in processing materials. Unlike traditional cutting methods that may require multiple passes or setups, laser cutting machines operate with remarkable swiftness, allowing for rapid production cycles. This efficiency not only accelerates output but also ensures that each cut is executed with pinpoint accuracy, minimizing errors and rework.

Moreover, the precision offered by laser machinery means that intricate designs can be achieved without compromising on quality. Whether it’s metal or other materials being cut, the consistency in results enhances overall production reliability. As a result, manufacturers can meet tight deadlines while maintaining high standards—an essential aspect in today’s competitive market.

The Role of Fiber Laser Cutting Machines

Fiber laser cutting machines have emerged as game-changers within the realm of laser technology. These machines utilize fiber optics to generate high-intensity beams that penetrate materials with exceptional efficiency and speed. The unique properties of fiber lasers enable them to cut through thicker metals and complex shapes more effectively than traditional CO2 lasers.

The versatility of fiber lasers also allows them to adapt to various materials including stainless steel, aluminum, and even plastics—all while maintaining low operational costs. This adaptability makes fiber laser cutting machines an attractive option for businesses looking to diversify their offerings without investing heavily in multiple types of machinery. Consequently, they play a vital role in enhancing overall manufacturing efficiency across different sectors.

Reducing Waste with Cutting Laser Metal

Another significant advantage provided by precision laser cutting is its ability to minimize waste during production processes. Traditional cutting methods often result in excess material loss due to larger kerf widths or inefficient layouts on sheets; however, modern laser machinery addresses these issues head-on. By utilizing precise calculations and advanced software algorithms for nesting parts on raw material sheets, companies can significantly reduce scrap rates.

Moreover, when employing a cutting laser metal approach with high-precision settings, manufacturers can achieve cleaner cuts that require less finishing work afterward—further reducing waste generation over time. This eco-friendly aspect not only helps businesses save money but also aligns them with sustainability goals increasingly demanded by consumers today. In this way, precision laser cutting machines contribute significantly not just to efficiency but also environmental responsibility within modern manufacturing practices.

The Economic Advantages of Laser Cutting

In the fast-paced world of manufacturing, economic efficiency is paramount. Precision laser cutting machines have emerged as a game-changer, offering significant cost savings and productivity boosts. By integrating advanced laser machinery into production processes, businesses can streamline operations and enhance their bottom line.

Lower Operational Costs with Advanced Technology

One of the standout benefits of using a precision laser cutting machine is the reduction in operational costs. These machines are designed to consume less energy compared to traditional cutting methods, which translates to lower utility bills for manufacturers. Additionally, the high precision of laser cutting minimizes material waste, ensuring that every piece counts and further driving down costs.

Moreover, maintenance expenses are often lower with modern laser machinery due to their robust design and fewer moving parts. This reliability means less downtime and fewer repairs, allowing businesses to allocate resources more effectively. When it comes to operational efficiency, investing in a fiber laser cutting machine can pay off significantly over time.

Increased Productivity and Output

Precision laser cutting machines are not just about cost savings; they also ramp up productivity dramatically. With their ability to cut through various materials at high speeds without sacrificing accuracy, these machines enable manufacturers to meet tight deadlines effortlessly. As a result, companies can take on more projects simultaneously without compromising quality.

The versatility of laser cutting technology means it can be adapted for numerous applications across different industries—from automotive parts to intricate designs in metal fabrication—ensuring that output remains consistently high. Furthermore, automated features in modern laser machinery reduce manual labor needs while enhancing throughput rates even further. With increased productivity comes the potential for higher revenue generation.

Long-Term ROI with Laser Machinery

Investing in precision laser cutting technology is not just about immediate savings; it's also about long-term return on investment (ROI). While the initial purchase price of a high-quality laser machine might seem steep, the benefits over time make it worthwhile for many businesses. Reduced operational costs combined with increased output lead directly to improved profit margins.

Moreover, as industries continue evolving toward automation and precision engineering, having advanced equipment like fiber laser cutting machines positions companies favorably within competitive markets. The longevity of these machines also contributes to ROI; they are built for durability and often require less frequent replacement than older technologies. Ultimately, embracing advanced laser machinery today sets up manufacturers for sustained success tomorrow.

Kiant Machinery: Revolutionizing Laser Solutions

Kiant Machinery stands at the forefront of innovations in laser cutting technology, offering a diverse range of precision laser cutting machines tailored to meet the needs of various industries. Their commitment to advancing laser machinery ensures that customers receive state-of-the-art solutions that enhance efficiency and productivity. With a focus on quality and performance, Kiant Machinery is dedicated to providing top-notch laser cutting machines that redefine manufacturing standards.

Overview of Kiant Machinery’s Offerings

Kiant Machinery boasts an impressive lineup of precision laser cutting machines designed for speed, accuracy, and versatility. Their fiber laser cutting machines are particularly noteworthy, utilizing advanced technology to deliver exceptional results across multiple materials, including metal and composites. Whether you're in the automotive sector or engaged in artistic metalwork, Kiant’s range of laser machinery can be customized to suit your specific requirements, ensuring optimal performance every time.

Success Stories from Kiant Customers

The effectiveness of Kiant's precision laser cutting machine is reflected in the success stories shared by satisfied customers worldwide. For instance, a leading automotive manufacturer reported a significant reduction in production time after integrating Kiant's fiber laser cutting machine into their assembly line. Another customer in the aerospace industry highlighted how switching to a Kiant precision laser solution drastically minimized waste while improving overall output quality—demonstrating that investing in advanced laser machinery pays off.

The Future of Laser Cutting with Kiant

Looking ahead, the future of laser cutting technology with Kiant Machinery appears bright and promising. As they continue to innovate and refine their offerings, we can expect even more efficient designs that push the boundaries of what precision laser cutting machines can achieve. By embracing emerging technologies and customer feedback, Kiant aims not only to lead the market but also to set new benchmarks for sustainability and efficiency within the manufacturing landscape.

Choosing the Right Laser Machine for Your Needs

Selecting the perfect precision laser cutting machine can feel like finding a needle in a haystack, especially with so many options on the market. It’s essential to assess your specific requirements and understand what each laser cutting machine offers to make an informed decision. In this section, we’ll dive into evaluating machine specifications, factors to consider for your business, and how custom solutions can cater to various industries.

Evaluating Machine Specifications

When it comes to precision laser cutting machines, understanding the technical specifications is crucial. Look for key features such as cutting speed, power output, and material compatibility; these will dictate how well the laser machinery performs in your production environment. For instance, a fiber laser cutting machine typically offers superior speed and efficiency when working with metals compared to traditional CO2 lasers, making it an excellent choice for businesses focused on cutting laser metal.

Moreover, pay attention to the software capabilities of the laser machine; advanced systems can streamline operations by integrating with CAD programs and enhancing automation possibilities. The accuracy of a precision laser cutting machine also plays a pivotal role—higher precision means less rework and waste over time. Ultimately, carefully evaluating these specifications will ensure you choose a model that meets both your current needs and future growth potential.

Factors to Consider for Your Business

Choosing the right laser cutting machine goes beyond just technical specs; several business-related factors must be considered as well. First and foremost is your budget—while investing in advanced laser machinery may seem daunting initially, consider long-term savings from reduced operational costs and increased productivity. Additionally, think about your production volume; if you anticipate high demand or rapid scaling in operations, opting for a more robust fiber laser cutting machine could save you headaches down the line.

Another critical factor is staff training; ensure that your team is equipped with the necessary skills to operate sophisticated equipment effectively. Investing in training not only enhances safety but also maximizes efficiency during production runs. Lastly, consider customer support options from manufacturers like Kiant Machinery—having reliable assistance when issues arise can make all the difference in maintaining smooth operations.

Custom Solutions for Different Industries

Every industry has its unique challenges when it comes to precision laser cutting machines—what works wonders for one sector may not be suitable for another. For example, automotive manufacturers often require specialized machinery capable of high-speed processing while maintaining tight tolerances on metal parts; thus they benefit immensely from advanced fiber laser technology tailored specifically for their needs. On the other hand, industries like textiles may opt for versatile machines that handle different materials seamlessly without compromising quality.

Furthermore, customization doesn’t just stop at hardware; software solutions can also be tailored based on industry requirements—from intricate designs needed in jewelry-making to bulk processing demands in manufacturing environments involving heavy-duty applications of cutting laser metal techniques. By collaborating with experienced providers like Kiant Machinery who understand these nuances across sectors, businesses can adopt truly bespoke solutions that enhance productivity while meeting specific operational goals.

Conclusion

In the realm of modern manufacturing, the transformative power of laser cutting technology cannot be overstated. Precision laser cutting machines have redefined how industries approach production, allowing for intricate designs and flawless execution that were once unimaginable. As businesses strive for efficiency and innovation, embracing laser machinery is no longer a luxury but a necessity.

The Transformative Power of Laser Cutting

The capabilities of precision laser cutting machines extend far beyond simple cuts; they offer unparalleled speed and accuracy that revolutionize production lines. With advancements in fiber laser cutting machines, manufacturers can achieve cleaner cuts with less energy consumption, making operations not only faster but also more sustainable. This transformative technology enables businesses to meet customer demands with agility while maintaining high-quality standards across various applications.

Investing in the Future of Manufacturing

Investing in a laser cutting machine is investing in the future of your manufacturing processes. The economic advantages are clear: lower operational costs, increased productivity, and long-term returns on investment make these machines an attractive option for forward-thinking companies. As industries continue to evolve, those who harness the power of precision laser technology will undoubtedly stay ahead of the competition.

Kiant Machinery: Your Partner in Efficiency

Kiant Machinery stands at the forefront of this technological revolution, offering innovative solutions tailored to meet diverse industrial needs. Their range of advanced laser machinery ensures that businesses can find the perfect fit for their specific requirements while benefiting from exceptional support and expertise. By partnering with Kiant Machinery, you’re not just acquiring a tool; you’re gaining a trusted ally committed to enhancing your operational efficiency through state-of-the-art precision laser cutting solutions.