Introduction

In the world of manufacturing and fabrication, laser cutting machines have emerged as game-changers, revolutionizing the way we approach precision metal cutting. These advanced tools utilize high-powered lasers to slice through materials with remarkable accuracy and speed, making them essential for various industries. As businesses seek to enhance their production capabilities, understanding the nuances of laser cutting technology becomes paramount.

Understanding Laser Cutting Machines

Laser cutting machines come in various types, each designed to cater to specific needs and applications. From fiber laser cutting machines that excel in speed and efficiency to tube laser cutting machines that offer versatility in handling different shapes and sizes, there's a solution for every requirement. With the ability to cut through metals with minimal heat-affected zones, these machines ensure clean edges and high-quality finishes.

Why Choose China for Laser Cutting SolutionsChinese manufacturers produce a wide range of laser cutting machines that meet international standards while offering cost-effective options for buyers worldwide. Additionally, the rapid advancements in technology within China's industrial sector mean that businesses can access some of the latest innovations in metal cutting machine technology.

Key Considerations for Buyers

As you embark on your journey to purchase a laser machine from China, several key considerations should guide your decision-making process. Assessing the quality and reliability of suppliers is crucial; after all, investing in a metal cutting machine is no small feat! Furthermore, understanding customer support options can make or break your experience post-purchase—ensuring you're not left stranded without assistance when you need it most.

Overview of Laser Cutting Technology

Laser cutting technology has revolutionized the manufacturing landscape, offering precision and efficiency that traditional methods simply cannot match. By utilizing focused laser beams to cut through various materials, laser cutting machines have become a staple in industries ranging from automotive to aerospace. In this section, we will explore the different types of laser cutting machines, the advantages of fiber laser cutting machines, and their applications across various sectors.

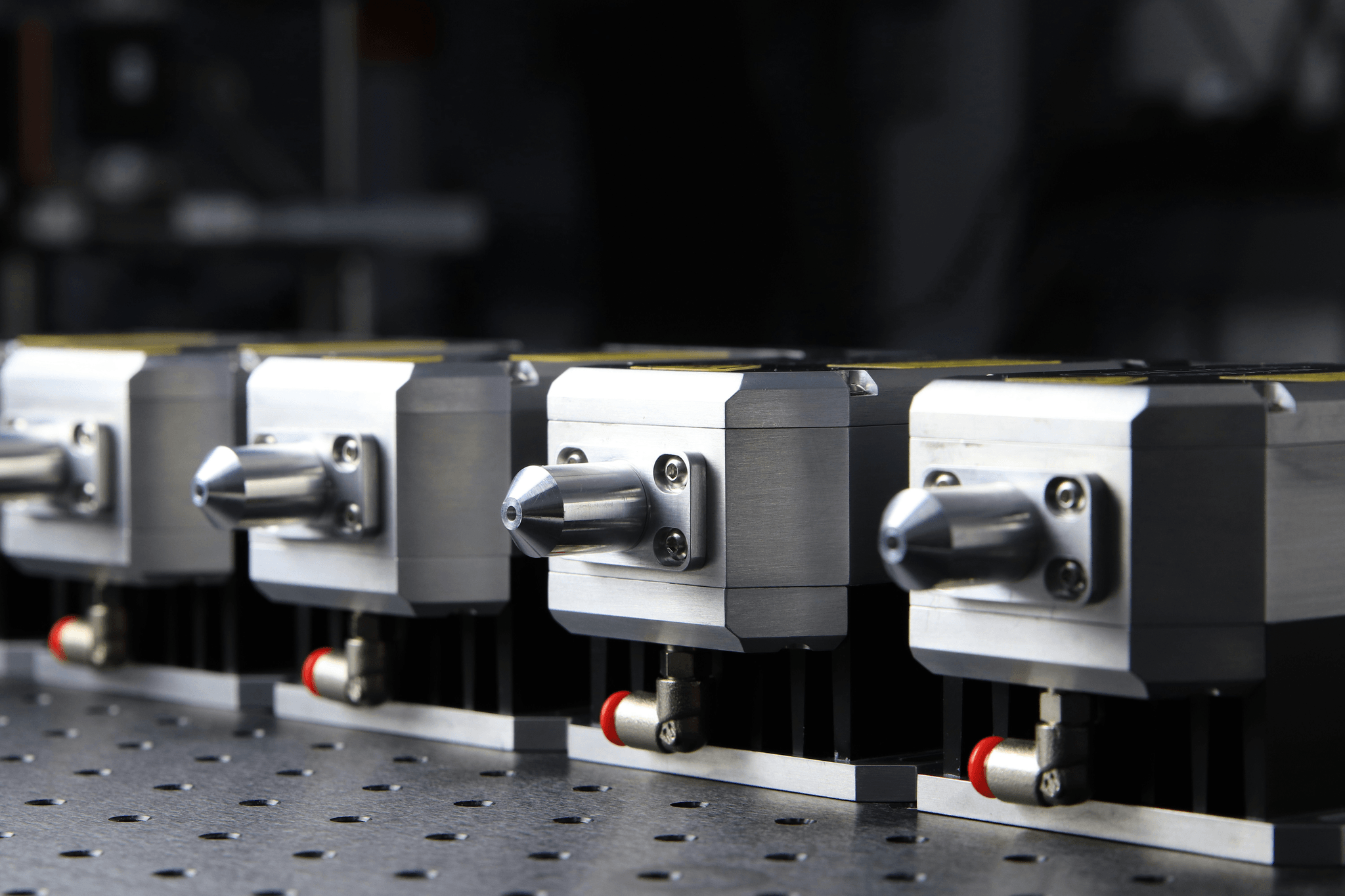

Types of Laser Cutting Machines

The most common types include CO2 laser cutting machines and fiber laser cutting machines, each with unique strengths suited for different tasks. For instance, while CO2 lasers excel in cutting non-metal materials like wood and acrylic, fiber lasers are often preferred for metal cutting due to their efficiency and precision.

Additionally, there are specialized systems such as tube laser cutting machines designed specifically for processing tubular materials. These metal cutting machine lasers can create intricate designs with high accuracy on pipes and tubes. Understanding these types is crucial when considering a purchase from a reputable manufacturer in China.

Advantages of Fiber Laser Cutting Machines

Fiber laser cutting machines have gained immense popularity due to their numerous advantages over traditional technologies. One significant benefit is their ability to cut through thick metals with remarkable speed while maintaining exceptional quality—perfect for those demanding fabrication jobs! Moreover, these metal cutting machine lasers require less maintenance than other types because they have fewer moving parts.

Another advantage lies in energy efficiency; fiber lasers consume less power than CO2 counterparts without compromising performance levels. This makes them an attractive option for businesses looking to optimize costs while still achieving high-quality results in their operations. With all these benefits combined, it's no wonder that many companies are turning towards fiber laser technology sourced from reliable suppliers in China.

Applications in Various Industries

The versatility of laser cutting technology allows it to be utilized across a multitude of industries effectively. In manufacturing sectors such as automotive and aerospace, precision cuts made by metal cutting machine lasers ensure that components fit together seamlessly—crucial for safety and performance standards! Additionally, industries like signage production benefit from the aesthetic appeal achieved through intricate designs created by advanced laser machines.

Moreover, the medical field has also seen increased adoption of laser technology; surgical instruments often require precise cuts that only advanced systems can deliver reliably over time. From creating custom parts for machinery to producing artistic sculptures or functional items like furniture—laser cutting is truly transforming how products are made today! As we continue exploring this innovative technology sourced from leading manufacturers in China, it's clear its applications are only limited by our imagination.

Evaluating Suppliers in China

The sheer variety and volume of laser cutting solutions available can be overwhelming, but understanding how to evaluate suppliers is key to making the right choice. This section will guide you through identifying top manufacturers, assessing their quality and reliability, and recognizing the importance of customer support.

Top Manufacturers of Laser Cutting Machines

China is home to some of the world's leading manufacturers of laser cutting machines. Companies like Han’s Laser, Trumpf China, and Bystronic have built solid reputations for producing high-quality metal cutting machines that cater to various industries. Additionally, emerging brands like Kiant Machinery are gaining traction due to their innovative designs and competitive pricing in the fiber laser cutting machine market.

These manufacturers offer a wide range of products including tube laser cutting machines and advanced fiber laser systems that enhance efficiency and precision in metal fabrication. When selecting a supplier, consider their production capacity, technological advancements, and industry certifications which can significantly impact your business operations. Remember that reputable manufacturers usually have a robust online presence showcasing their product lines and client testimonials.

Assessing Quality and Reliability

Quality should be your top priority when evaluating suppliers for laser cutting machines in China. Look for companies that adhere to international standards such as ISO certifications; this indicates they maintain rigorous quality control processes throughout production. Additionally, examine user reviews or case studies from other businesses that have purchased similar metal cutting machines; these insights can reveal potential reliability issues or highlight exceptional performance.

It's also wise to request samples or demonstrations before committing to a purchase; this will give you firsthand experience with the machine's capabilities—especially important for high-stakes applications like tube laser cutting where precision is crucial. Investing time in quality assessment not only ensures you receive a dependable product but also saves money by avoiding costly repairs or replacements down the line.

Importance of Customer Support

Customer support is an often-overlooked aspect when purchasing a laser machine from China but can make all the difference post-sale. A supplier with excellent customer service will provide timely assistance during installation, training sessions on using complex software systems, and ongoing maintenance support for your metal cutting machine laser. This level of engagement helps ensure your equipment runs smoothly over its lifespan.

Furthermore, consider suppliers who offer comprehensive warranties or service packages; these can safeguard your investment against unforeseen issues while providing peace of mind as you navigate through any operational challenges that may arise later on. Ultimately, strong customer support reflects a manufacturer's commitment to building lasting relationships with clients—a vital factor when choosing your ideal supplier.

Key Features of a Metal Cutting Machine

A laser cutting machine designed for precision and speed is essential, especially in industries that require intricate designs and quick turnaround times. Understanding these features will help you make an informed decision when sourcing from suppliers, particularly those offering laser cutting machines in China.

Precision and Speed in Metal Cutting

Precision is the hallmark of any effective metal cutting machine, especially when utilizing advanced technologies like fiber laser cutting machines. These machines can achieve tolerances as tight as a few microns, ensuring that every cut is clean and accurate. Coupled with high-speed operations, a metal cutting machine laser can dramatically reduce production time while maintaining quality—a vital aspect for manufacturers aiming to meet tight deadlines.

Moreover, the ability to cut various materials—from steel to aluminum—without compromising speed or quality makes these machines indispensable in modern manufacturing environments. The combination of precision and speed not only boosts productivity but also enhances overall operational efficiency. When looking at options like tube laser cutting machines, it's crucial to assess their capabilities in both areas to ensure they meet your specific needs.

Software and Control Systems

The software integrated into a laser cutting machine plays a pivotal role in its functionality and ease of use. Advanced control systems allow operators to program intricate designs with minimal effort, making the process more intuitive than ever before. Many modern metal cutting machines come equipped with user-friendly interfaces that simplify the design-to-cut process through CAD/CAM compatibility.

Additionally, robust software solutions enable real-time monitoring of operations, allowing users to adjust settings on-the-fly for optimal results. This adaptability ensures that your laser machine can handle various projects without requiring extensive downtime for recalibration or adjustments. When sourcing from manufacturers in China, it's wise to inquire about the software capabilities included with their laser cutting solutions.

Safety Features and Compliance

Safety should never be an afterthought when investing in a metal cutting machine; it’s paramount for protecting both operators and equipment alike. Many state-of-the-art laser cutting machines incorporate advanced safety features such as automatic shut-off systems, protective enclosures, and emergency stop buttons that comply with international safety standards. Ensuring compliance not only protects workers but also mitigates liability risks associated with workplace accidents.

Moreover, many suppliers now offer additional safety training resources or packages alongside their equipment purchases—an excellent way to foster a culture of safety within your organization while maximizing the benefits of your new machinery. When considering options from Chinese manufacturers specializing in laser technology, prioritize those who demonstrate commitment to safety compliance as well as product reliability.

Best Practices for Sourcing from China

Sourcing a laser cutting machine from China can be a rewarding experience, but it requires careful planning and execution. By following best practices, you can ensure that you obtain a quality metal cutting machine that meets your needs while avoiding common pitfalls. This section will guide you through establishing communication with suppliers, negotiating prices and terms, and ensuring reliable after-sales service.

Establishing Communication with Suppliers

Effective communication is the cornerstone of successful sourcing in the laser cutting industry. When dealing with suppliers of laser cutting machines in China, it's crucial to be clear about your requirements and expectations. Utilize multiple channels such as email, video calls, and instant messaging apps to establish rapport; this helps build trust and facilitates smoother transactions.

In addition to language considerations—where using simple English or translation tools can help—understanding cultural nuances plays an important role in negotiations. Many Chinese suppliers appreciate directness but also value politeness; striking this balance can lead to more fruitful discussions about your desired fiber laser cutting machine or tube laser cutting machine. Regular updates on production timelines and shipping processes are also vital for keeping you informed throughout the sourcing journey.

Negotiating Prices and Terms

Negotiating prices for a metal cutting machine is not just about haggling; it's an art form that requires strategy and finesse. Start by researching market prices for various types of laser machines so you have a solid baseline during negotiations. When discussing costs, consider asking for bulk purchase discounts or exploring financing options that might make your investment more manageable.

Transparency is key during negotiations; both parties should feel comfortable discussing payment terms, delivery schedules, and warranty conditions upfront. Keep in mind that while price is essential, factors like the quality of the laser cutting machine should not be sacrificed for a lower cost—after all, investing in a reliable fiber laser cutting machine can save you money in the long run through efficiency gains and reduced maintenance costs.

Ensuring After-Sales Service and Support

After-sales service is often overlooked but is crucial when purchasing a metal cutting machine from China. Make sure your supplier offers robust support options including installation assistance, training programs for operators on how to use the laser machine effectively, and access to spare parts when needed. A supplier's commitment to customer support can significantly impact your operational efficiency down the line.

Inquire about warranty terms as well; reputable manufacturers typically offer warranties that cover defects or malfunctions within specified timeframes—this provides peace of mind knowing you're protected against unforeseen issues with your new tube laser cutting machine or other equipment purchased from them. Additionally, having access to technical support ensures any potential problems are resolved quickly without disrupting production schedules.

Kiant Machinery: A Leading Choice

Products Offered by Kiant Machinery

Kiant Machinery boasts an impressive lineup of products designed for efficient metal cutting. Their offerings include various models of fiber laser cutting machines that excel in precision and speed, making them ideal for intricate designs and large-scale production alike. Additionally, they provide specialized equipment such as tube laser cutting machines that cater to the unique requirements of tubular materials.

Each metal cutting machine is engineered with the latest technology to ensure optimal performance and durability. This commitment to quality means that users can expect high reliability and minimal downtime, which is crucial in today's fast-paced manufacturing environment. By choosing Kiant Machinery's products, customers gain access to state-of-the-art solutions that enhance productivity and reduce operational costs.

Benefits of Choosing Kiant Machinery

Opting for Kiant Machinery as your supplier means investing in quality assurance and customer satisfaction. Their laser cutting machines are not only competitively priced but also come with comprehensive warranties that ensure peace of mind for buyers. Furthermore, their commitment to after-sales service sets them apart from other manufacturers in the market.

Another significant advantage is their ability to customize solutions based on specific client needs—whether it’s adjusting machine configurations or integrating advanced software systems into existing setups. This flexibility allows businesses to scale operations without compromising on performance or efficiency when using their metal cutting machines. Ultimately, choosing Kiant Machinery translates into better investment returns through enhanced productivity and lower maintenance costs.

Customer Testimonials and Success Stories

Customers rave about their experiences with Kiant Machinery's products, often highlighting the exceptional performance of their fiber laser cutting machines in various applications. Many clients report increased efficiency in their production lines after switching to these advanced laser systems, noting how they have dramatically reduced waste during the metal cutting process. Success stories abound where businesses have scaled up operations thanks to the reliability and precision offered by Kiant's machinery.

Moreover, numerous testimonials emphasize the responsive customer support team at Kiant Machinery who assist throughout the entire purchasing process—from initial inquiry through installation and beyond. Users appreciate this level of engagement which fosters long-term relationships built on trust and satisfaction with their chosen laser cutting machine from China. With such positive feedback circulating among industry peers, it's no wonder that more companies are turning toward Kiant Machinery for their metal fabrication needs.

Conclusion

In the ever-evolving world of manufacturing, laser cutting machines stand out for their precision and efficiency. With innovations constantly emerging, particularly from manufacturers in China, the landscape of metal cutting is being transformed. Understanding these advancements is crucial for businesses looking to enhance their production capabilities.

Laser Cutting Machine Innovations

Recent innovations in laser cutting technology have revolutionized how industries approach metal fabrication. The introduction of fiber laser cutting machines has significantly improved speed and efficiency, making it easier to handle various materials with unmatched precision. Additionally, tube laser cutting machines are gaining traction for their ability to cut complex shapes and designs, further expanding the possibilities in metal processing.

Making an Informed Purchase Decision

When considering a purchase of a laser cutting machine from China, it's essential to weigh your options thoughtfully. Look beyond just price; consider factors such as machine reliability, supplier reputation, and after-sales support to ensure you’re making a wise investment. By doing thorough research and asking the right questions about features and capabilities—especially regarding fiber laser cutting machines—you can confidently select a metal cutting machine that meets your needs.

Future Trends in Laser Cutting Technology

The future of laser cutting technology looks promising with trends indicating enhanced automation and integration with Industry 4.0 principles. As artificial intelligence continues to influence manufacturing processes, expect smarter laser machines that optimize performance based on real-time data analysis. This shift will not only streamline operations but also lead to even more innovative applications across various industries relying on advanced metal cutting solutions.