Introduction

In today’s fast-paced manufacturing landscape, understanding precision cutting machines is crucial for businesses aiming to enhance their production capabilities. These machines, including the highly sought-after laser cutting and metal cutting machines, offer unparalleled accuracy and efficiency in creating intricate designs and shapes from various materials. Whether you're looking to machine cut metal or explore the latest in laser technology, knowing your options can significantly impact your operations.

Understanding Precision Cutting Machines

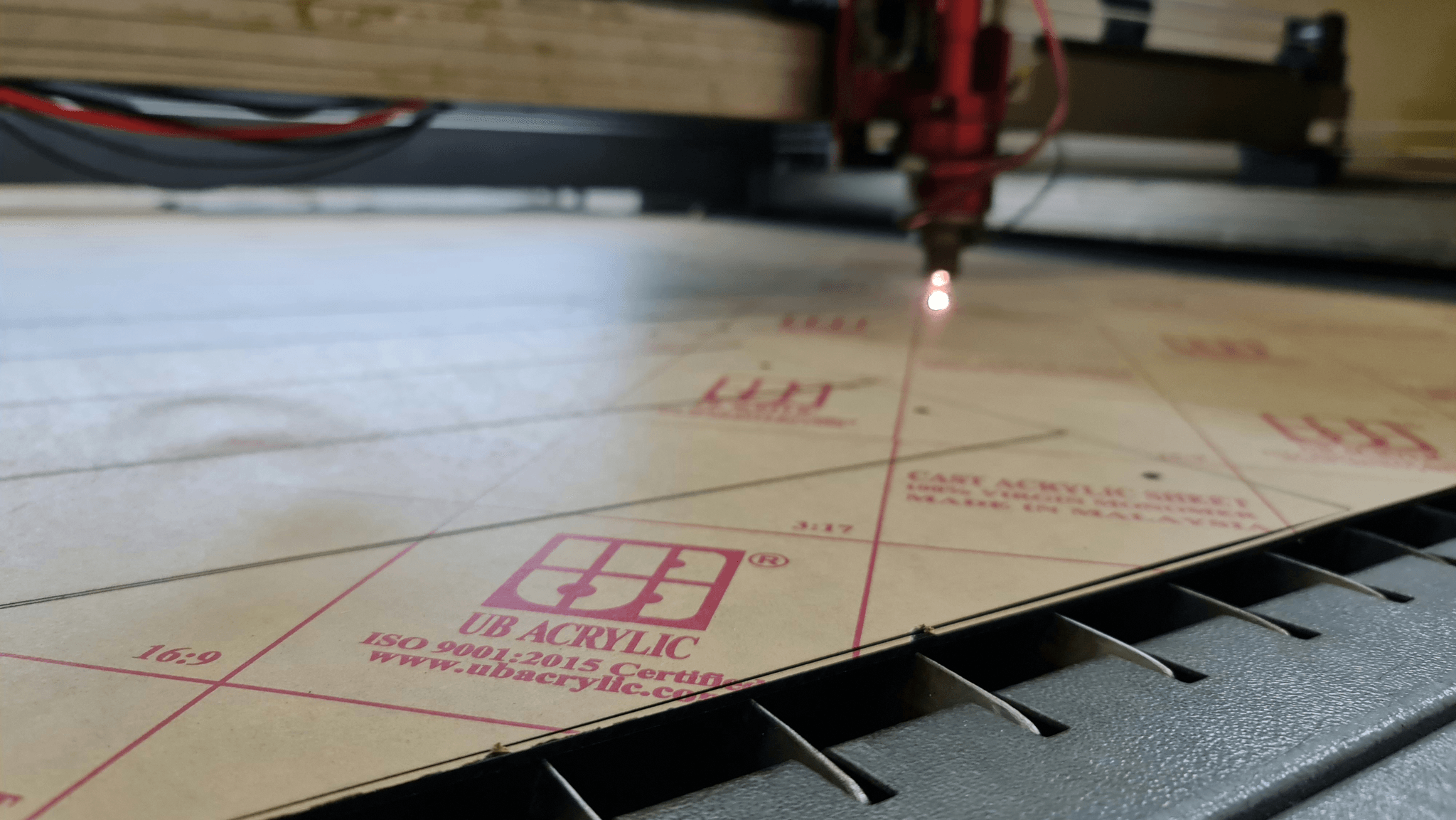

Precision cutting machines are designed to deliver exact cuts with minimal waste, making them a vital component in industries ranging from automotive to aerospace. The technology behind these machines varies widely; however, laser cutting has emerged as a leader due to its remarkable precision and versatility. With options like industrial laser cutting machines available on the market, businesses can achieve high-quality results that were once thought unattainable.

The Importance of Choosing Wisely

Choosing the right cutter machine isn't just about picking one that looks good on paper; it's about understanding your specific needs and how different technologies can meet them. A well-informed decision regarding a laser cutting machine or a traditional metal cutting machine can save time, reduce costs, and improve overall efficiency in production processes. Therefore, taking the time to evaluate all aspects of these precision tools is essential for long-term success.

Overview of Cutting Technologies

The world of cutting technologies is vast and varied, encompassing everything from traditional methods like sawing and shearing to advanced techniques such as laser cutting and waterjet machining. Each technology has its unique advantages; for instance, while traditional methods may excel in certain applications, modern innovations like the laser machine offer unmatched speed and precision for complex designs. Understanding these differences will empower businesses to select the most suitable option for their specific applications.

Assess Your Cutting Needs

Before diving into the world of precision cutting machines, it's essential to assess your specific cutting needs. This evaluation will help you identify the right technology and machine that suits your operations best. Whether you're in metal fabrication or crafting intricate designs, understanding your requirements is crucial for making an informed decision.

Different Materials for Precision Cutting

Precision cutting machines are designed to handle a variety of materials, ranging from metals to plastics and composites. Each material has unique properties that affect how it can be cut; for instance, laser cutting is particularly effective for thin metals and intricate patterns, while a metal cutting machine might excel in thicker materials. Knowing what materials you'll be working with allows you to choose a cutter machine that delivers optimal results without compromising quality.

Understanding Thickness Requirements

Thickness plays a significant role in determining which precision cutting machine is best suited for your needs. By assessing the thickness requirements of your projects, you can ensure that your chosen laser cutting machine will perform effectively without unnecessary strain or wear.

Evaluating Production Volume

Production volume is another critical factor when selecting a precision cutting machine. If you're operating on a large scale, investing in a high-speed laser machine could significantly enhance efficiency and output quality compared to traditional methods. Conversely, if you're working on smaller batches or custom projects, a more versatile cutter machine might be the way to go—allowing you flexibility without sacrificing precision.

Explore Different Technologies

When it comes to precision cutting machines, understanding the various technologies available is crucial for making an informed decision. The right choice can significantly impact efficiency, quality, and overall production costs. In this section, we will explore the differences between laser cutting and traditional methods, delve into the role of metal cutting machines, and highlight what makes laser machines stand out in today's industrial landscape.

Comparing Laser Cutting vs. Traditional Methods

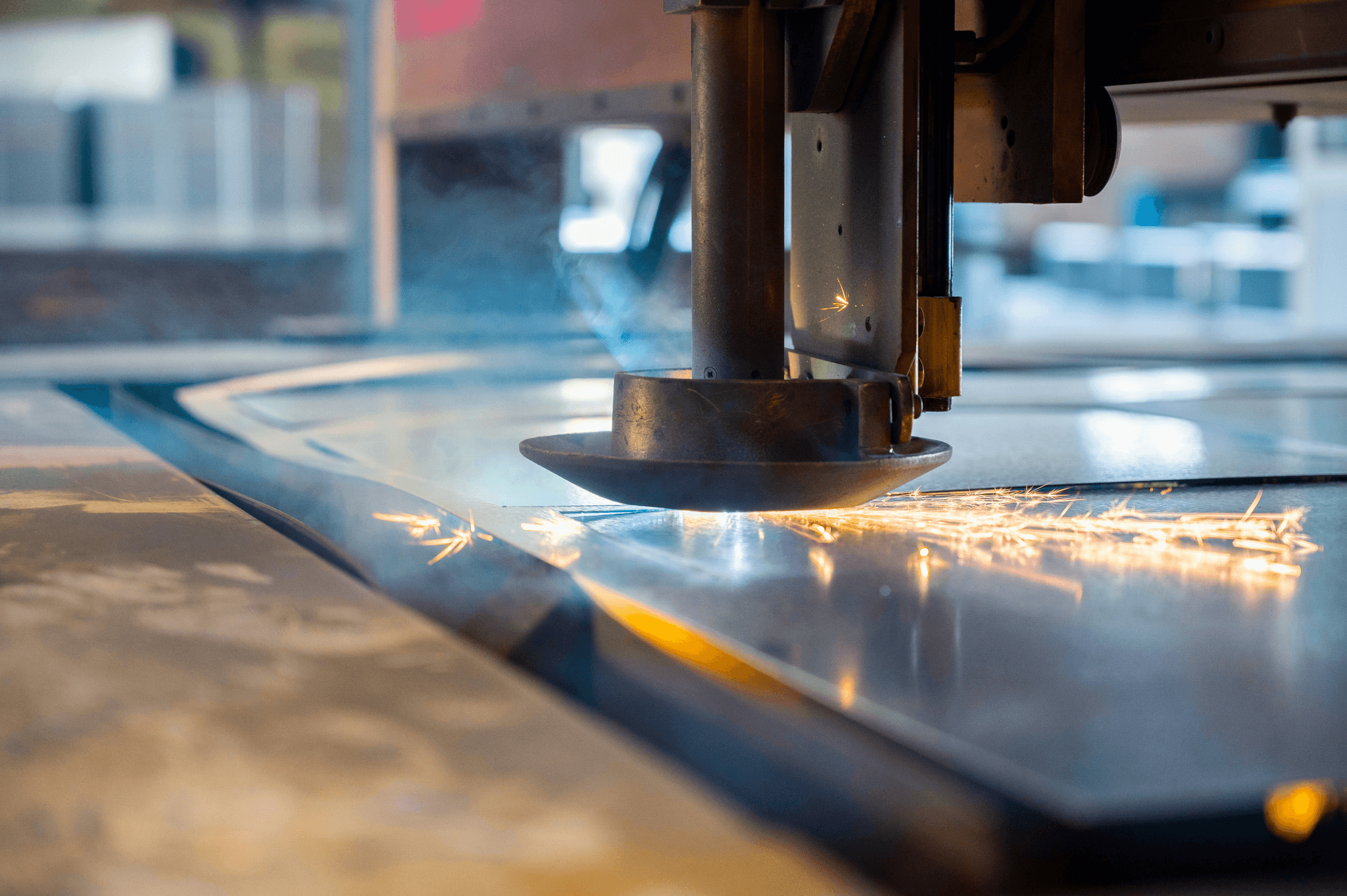

Laser cutting has revolutionized how industries approach precision cutting tasks compared to traditional methods like plasma or mechanical cutting. While traditional techniques often struggle with intricate designs and fine details, a laser cutting machine excels at delivering clean edges and precise cuts even in complex geometries. This capability not only enhances the aesthetic quality of machine cut metal but also reduces waste, making laser technology a more sustainable option for manufacturers.

Moreover, speed is another area where laser cutting triumphs over its traditional counterparts. Industrial laser cutting machines can operate at remarkable speeds without compromising on accuracy or material integrity. This efficiency translates into higher productivity levels for businesses that rely on precision cutting machines to meet demanding production schedules.

The Role of a Metal Cutting Machine

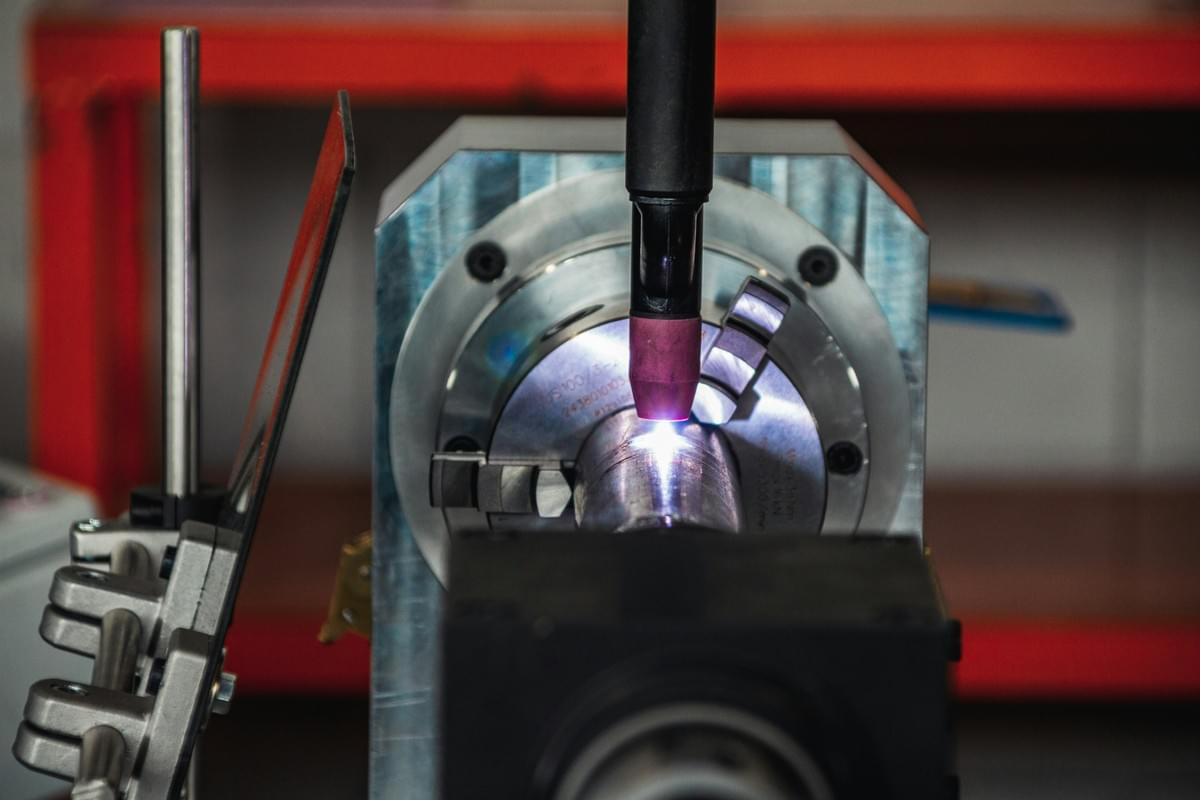

Metal cutting machines play an essential role in various industries such as automotive, aerospace, and manufacturing by enabling precise fabrication of components. These machines are designed to handle different types of metals with varying thicknesses while ensuring minimal distortion during the process. With advancements in technology, modern metal cutting machines now incorporate features that enhance their versatility and performance.

A well-designed cutter machine not only streamlines production but also improves safety standards within the workspace by minimizing operator exposure to hazardous conditions associated with traditional methods. Additionally, these machines help reduce operational costs by optimizing material usage through precise cuts that leave little scrap behind. As industries continue to evolve toward automation and smart manufacturing practices, investing in advanced metal cutting technologies becomes increasingly vital.

How a Laser Machine Stands Out

What truly sets a laser machine apart from other precision cutting options is its unparalleled accuracy combined with flexibility across various materials beyond just metals—think plastics and wood too! With adjustable settings for power intensity and speed control, users can fine-tune their operations based on specific project requirements without needing extensive reconfiguration or downtime typical of other cutter machines.

Furthermore, many industrial laser cutting machines come equipped with advanced software solutions that allow operators to design intricate patterns directly from CAD files seamlessly integrated into the machine's workflow—making it easier than ever to produce high-quality results quickly! This level of adaptability not only enhances creativity but also empowers businesses to respond swiftly to market demands while maintaining competitive pricing structures.

Evaluate Machine Specifications

When diving into the world of precision cutting machines, understanding machine specifications is crucial for making an informed decision. The right specifications can mean the difference between a smooth operation and a frustrating experience, especially when it comes to laser cutting and metal cutting machines. Here, we’ll break down essential features that will help you choose the best cutter machine for your needs.

Key Features of a Laser Cutting Machine

A laser cutting machine boasts several key features that set it apart from traditional cutter machines. One prominent feature is its ability to cut intricate designs with high precision, making it ideal for various applications in industries like automotive and aerospace. Additionally, many industrial laser cutting machines come equipped with advanced software integration, allowing for seamless design transfers and modifications on-the-fly.

Another important aspect is the type of laser used; CO2 lasers are commonly found in metal cutting machines due to their versatility and effectiveness on different materials. Furthermore, look for automated features such as auto-focus systems that enhance cutting quality by adjusting the laser's focus based on material thickness. These features not only improve operational efficiency but also ensure consistent results across multiple production runs.

Importance of Precision and Speed

In the realm of precision cutting, speed and accuracy go hand in hand; after all, no one wants a slow cutter machine that compromises quality! A high-speed laser cutting machine can drastically reduce production times while maintaining exceptional levels of precision—think sharp corners and clean edges without any burrs left behind. This balance is particularly critical in industries where time-to-market can make or break a business.

Moreover, advancements in technology have led to faster processing speeds without sacrificing detail or quality—an absolute game-changer for manufacturers looking to scale operations efficiently. A reliable industrial laser cutting machine should deliver consistent performance over extended periods without overheating or requiring frequent maintenance breaks, ensuring your workflow remains uninterrupted.

Power and Efficiency Ratings

When evaluating power ratings for a precision cutting machine, consider both wattage and efficiency as they play pivotal roles in performance outcomes. Higher wattage typically means faster cuts through thicker materials; however, it's essential to balance this with energy consumption to avoid skyrocketing operational costs. An efficient laser machine not only saves energy but also extends the lifespan of its components by minimizing wear during operation.

Efficiency ratings often reflect how well a machine utilizes its power—look out for models that boast lower energy usage while delivering high output performance levels. This combination translates into cost savings over time as you manage both your electricity bills and maintenance expenses effectively while enjoying superior machining capabilities from your metal cutting machine.

Consider the Brand Reputation

When investing in a precision cutting machine, brand reputation plays a pivotal role in determining the reliability and performance of your equipment. Trusted manufacturers often have a proven track record for quality, innovation, and customer support, which can significantly impact your operational efficiency. Opting for well-established brands not only ensures you receive a high-quality laser cutting machine but also provides peace of mind knowing that you are supported by their expertise.

Importance of Trusted Manufacturers

Choosing a trusted manufacturer is essential when selecting a laser cutting or metal cutting machine, as their reputation often reflects the durability and effectiveness of their products. Reputable companies invest in research and development to improve their technologies constantly, ensuring that you're getting the latest advancements in industrial laser cutting machines. Moreover, established brands typically offer robust customer service and support options that can be invaluable when troubleshooting issues or seeking maintenance advice.

Spotlight on Kiant Machinery

Kiant Machinery stands out as a leading name in the precision cutting machine industry, known for its commitment to quality and innovation. Their range of cutter machines includes state-of-the-art laser machines designed to handle various materials with unparalleled precision. With years of experience under their belt, Kiant Machinery has built a solid reputation among users who rely on efficient metal cutting solutions for diverse applications.

Customer Testimonials and Reviews

Customer testimonials serve as powerful endorsements for any brand, particularly when it comes to investing in equipment like a laser cutting machine. Many users rave about Kiant Machinery's products, highlighting how their industrial laser cutting machines have transformed production processes by enhancing speed and accuracy while minimizing waste. These reviews not only reflect satisfaction with the performance but also emphasize excellent after-sales support—an essential factor when choosing your next precision cutting machine.

Analyze Support and Training Options

When investing in a precision cutting machine, understanding the support and training options available is crucial. After all, even the most advanced laser cutting technology can fall short without proper guidance. A well-rounded support system ensures that your industrial laser cutting machine operates at peak efficiency and longevity.

The Value of After-Sales Support

After-sales support can make or break your experience with a metal cutting machine. It’s not just about selling a cutter machine; it’s about ensuring you have access to technical assistance when things go awry. Reliable after-sales service means you have experts on hand who understand your specific laser cutting needs, helping you troubleshoot issues quickly and effectively.

Investing in a precision cutting machine often comes with unforeseen challenges, whether it's software updates or mechanical hiccups. Quality after-sales support provides peace of mind, knowing that you're not alone in navigating these complexities. This ongoing partnership can extend the lifespan of your laser machine and enhance its overall performance.

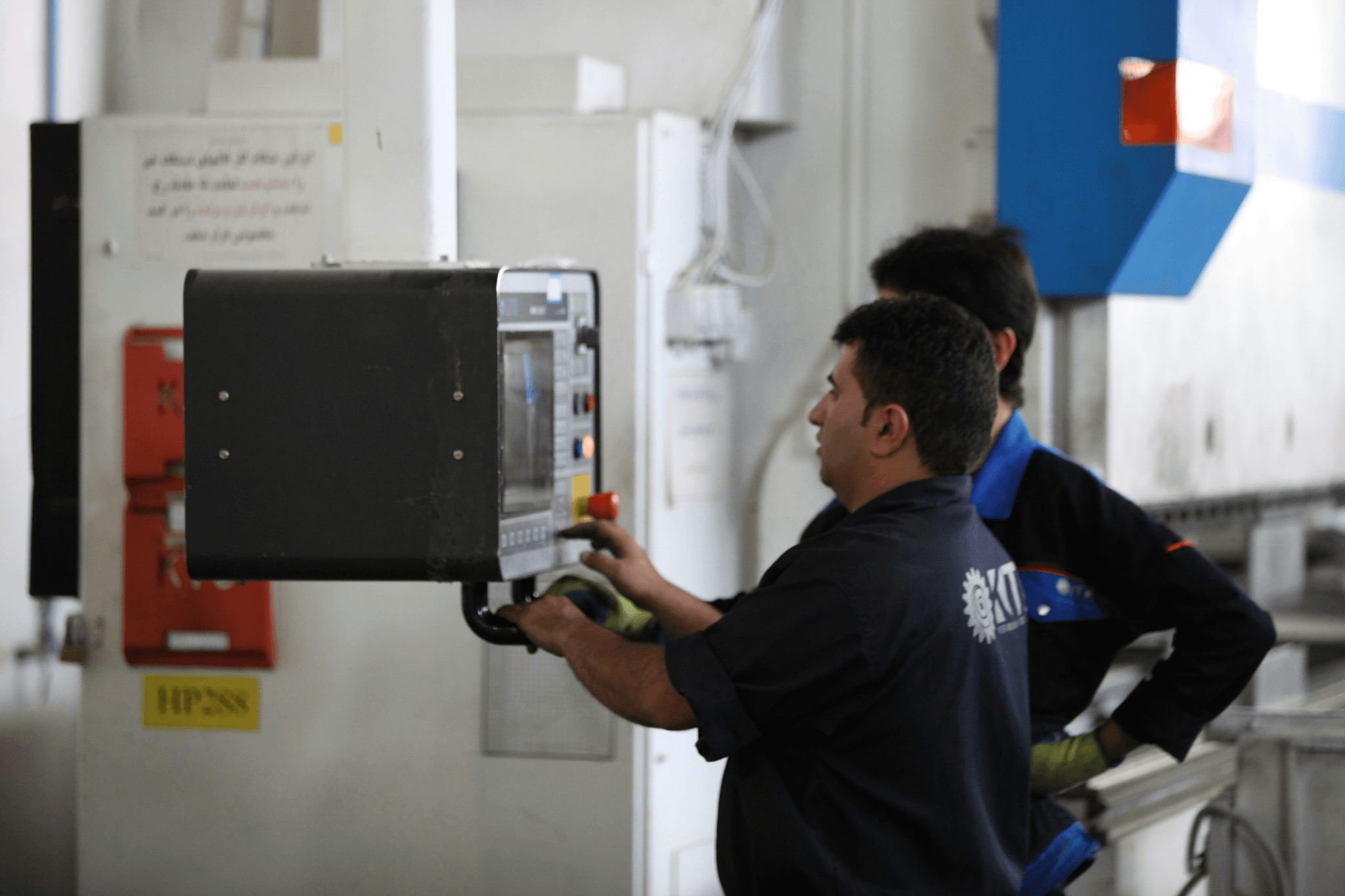

Training for Operators and Maintenance

Training is an essential component when it comes to maximizing the potential of your laser cutting machine. Proper operator training ensures that staff are well-versed in utilizing the features of the industrial laser cutting machine efficiently and safely. This knowledge not only enhances productivity but also minimizes risks associated with operating complex machinery.

Maintenance training for operators is equally important, as it empowers them to perform routine checks and minor repairs on their own. Understanding how to maintain a metal cutting machine prolongs its lifespan and reduces downtime caused by unexpected failures. With a well-trained team, you can ensure that your cutter machine remains in optimal condition for years to come.

Long-Term Service Agreements

Long-term service agreements offer an added layer of security when investing in precision cutting machines like laser cutters or metal cutters. These agreements typically include regular maintenance checks, which help identify potential issues before they escalate into costly repairs or replacements. By securing such an agreement, businesses can budget more effectively while ensuring their equipment remains operational without surprise expenses.

Moreover, long-term agreements often come with prioritized customer support services, giving you quicker access to expert advice when needed most—especially during critical production times involving intricate cuts on materials like metal or plastics. This proactive approach allows businesses to focus on what they do best: producing high-quality products using their advanced machinery without worrying about unexpected breakdowns.

In summary, analyzing support and training options is vital for anyone considering a precision cutting machine investment like an industrial laser cutting machine or any cutter machines designed for specific applications.

Budgeting for Your Investment

Investing in a precision cutting machine is no small feat, and understanding the financial landscape is crucial. With various technologies available, including laser cutting and traditional methods, the cost can vary significantly based on performance and capabilities. A thorough cost analysis will help you gauge what fits your budget while meeting your production needs.

Cost Analysis of Precision Cutting Machines

When diving into the cost analysis of precision cutting machines, you'll find that prices can range from a few thousand to several hundred thousand dollars depending on the technology and features. For instance, a basic metal cutting machine might be more affordable upfront but could lack the efficiency of an industrial laser cutting machine over time. Evaluating both initial costs and potential long-term savings—like reduced material waste and faster production times—will provide a clearer picture of your investment's value.

Moreover, consider additional expenses such as maintenance, replacement parts, and energy consumption when calculating total ownership costs for your laser machine or cutter machine. It's also wise to factor in any necessary software or training that may accompany advanced models like a laser cutting machine. By understanding these variables, you can make an informed decision about which option aligns best with your budgetary constraints.

Balancing Quality and Affordability

Finding the sweet spot between quality and affordability is essential when selecting a precision cutting machine. While it may be tempting to go for the lowest-priced option available, remember that cheaper machines often compromise on performance, leading to higher operational costs down the line. High-quality machines—especially those designed for industrial applications—tend to deliver better results in terms of speed and accuracy in tasks like machine cut metal.

Investing in a reliable laser cutting or metal cutting machine may seem daunting initially but will pay off through enhanced productivity and lower maintenance needs over time. Look for brands known for their durability and support services; this can save you money on repairs or replacements later on. Ultimately, balancing quality with affordability ensures you're not just buying equipment but investing in your business's future success.

Exploring Financing Options

Financing options are often overlooked yet play a pivotal role in budgeting for your investment in a precision cutting machine. Many manufacturers offer flexible payment plans tailored to fit various financial situations; this can ease the burden of upfront costs associated with high-end models like an industrial laser cutting machine or advanced cutter machines. Additionally, exploring third-party financing solutions could provide competitive rates that make acquiring top-tier technology more attainable.

Consider leasing options as well; they allow you to use state-of-the-art equipment without committing significant capital upfront while maintaining cash flow flexibility for other business needs. Don't forget to investigate any available grants or incentives aimed at businesses adopting advanced manufacturing technologies—these can significantly reduce overall expenses related to purchasing a laser cutting machine or similar equipment. By thoroughly exploring all financing avenues available, you'll ensure that your investment remains manageable while still securing high-quality machinery essential for growth.

Conclusion

In the world of manufacturing and fabrication, making an informed decision about your precision cutting machine can significantly impact your operations. With a variety of options available, from laser cutting machines to traditional methods, understanding your specific needs is crucial. When you take the time to evaluate technologies, specifications, and support options, you're setting yourself up for success.

Making an Informed Decision

Choosing the right machine cut metal solution requires careful consideration of various factors. Whether you opt for a high-performance industrial laser cutting machine or a more traditional cutter machine, it's essential to weigh the benefits against your production requirements. By analyzing all aspects—from material compatibility to budget constraints—you'll ensure that your investment in a precision cutting machine pays off in both efficiency and quality.

The Role of Innovation in Cutting Technology

Innovation plays a pivotal role in shaping the future of metal cutting machines. Modern advancements in laser cutting technology have revolutionized how industries approach precision tasks, offering unparalleled speed and accuracy compared to older methods. As new features continue to emerge in laser machines—like enhanced software capabilities and improved energy efficiency—staying updated on these trends will help you make smarter choices for your business.

Taking the Next Steps with Kiant Machinery

Now that you've gathered valuable insights into selecting the right equipment, it’s time to consider Kiant Machinery as your partner in this journey. With a reputation for quality and innovation in laser cutting solutions, they offer an impressive range of machines tailored to meet diverse needs. By reaching out for consultations or demonstrations, you can explore firsthand how their advanced precision cutting machines can elevate your production capabilities.