Introduction

In the world of fabrication and manufacturing, discovering affordable laser cutting options can feel like finding a needle in a haystack. With the rise of technology, many businesses are now able to invest in laser cutting equipment that doesn’t break the bank while still delivering high-quality results. Whether you’re a small workshop or a larger industrial operation, understanding the nuances of cutting machine lasers can make all the difference in your production efficiency and cost-effectiveness.

Discover Affordable Laser Cutting Options

Fortunately, there are numerous budget-friendly models available that offer impressive capabilities without sacrificing quality. By exploring various options for metal cutting machines, you can find solutions that fit your financial constraints while meeting your operational needs.

Why Precision Matters in Cutting Equipment

An industrial laser cutter must provide not just power but also accuracy to ensure tight tolerances and clean finishes on materials. Investing in precision-engineered machines ensures that your projects meet high standards and minimizes waste—saving both time and money.

Overview of Cost-Effective Laser Tools

The market today boasts an array of cost-effective laser tools designed for various applications—from intricate designs to robust industrial tasks. These machines vary widely in features and capabilities, making it essential to assess them based on your specific requirements before making a purchase decision regarding an industrial laser cutting machine. Understanding these differences will empower you to choose wisely while keeping an eye on the all-important laser cutting machine price tag.

Understanding Laser Cutting Technology

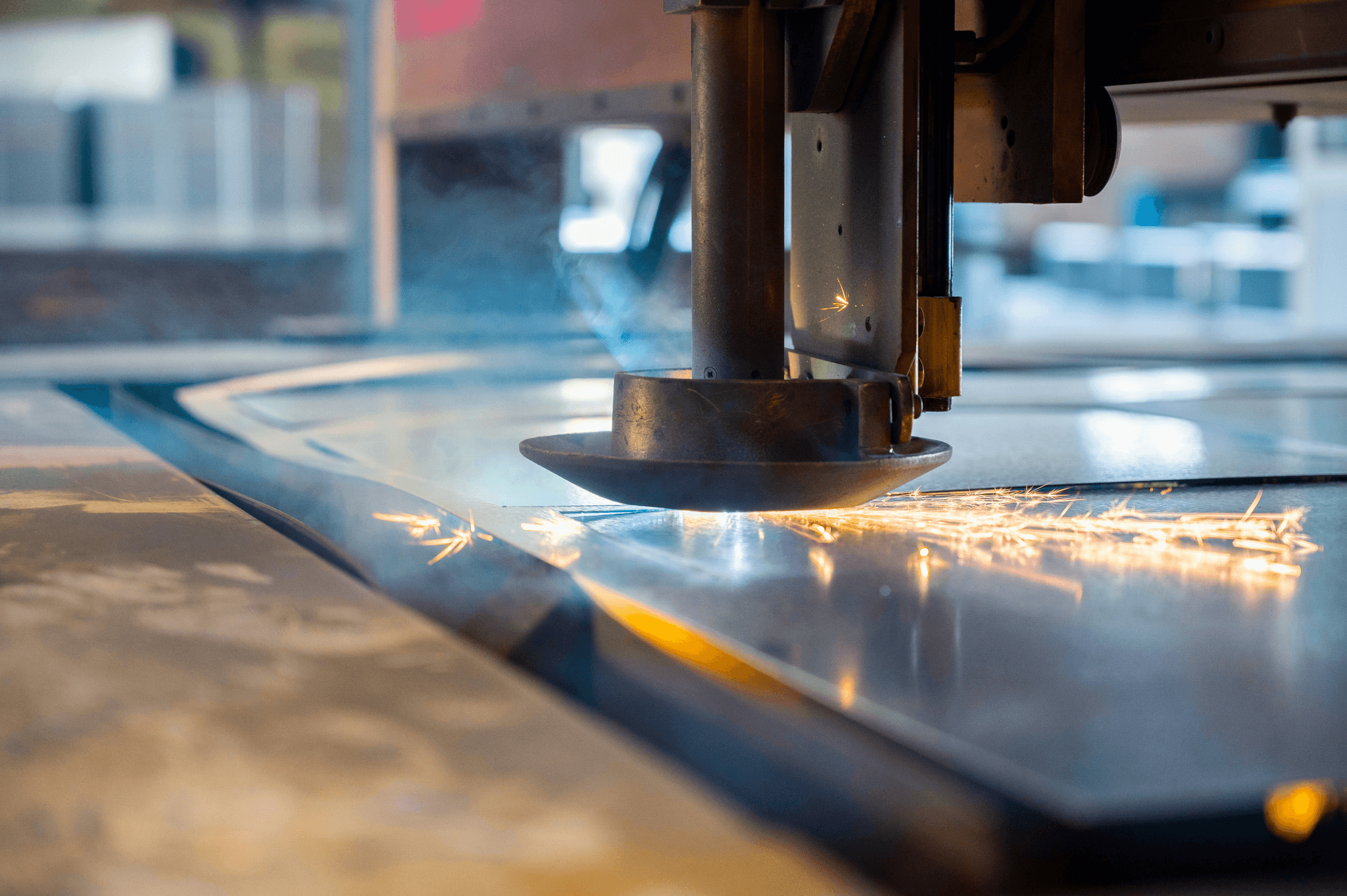

Laser cutting technology has revolutionized the manufacturing landscape, offering precision and efficiency that traditional methods often struggle to match. At its core, laser cutting equipment utilizes focused beams of light to slice through materials with remarkable accuracy. This sophisticated process allows for intricate designs and clean edges, making it a go-to choice for various applications.

How Laser Cutting Works

The operation of a cutting machine laser is both fascinating and complex. It starts with a high-powered laser beam generated by a laser source, usually CO2 or fiber lasers, which is then directed through optics to focus the beam onto the material's surface. As the focused light hits the material, it melts, burns, or vaporizes away in a controlled manner, creating precise cuts with minimal kerf width.

This process can be adjusted based on the thickness and type of material being cut—particularly advantageous for metal cutting laser cutters used in industrial applications. The ability to fine-tune parameters like speed and power ensures that users can achieve optimal results across various materials while maintaining cost-effectiveness in their operations.

Benefits of Using A Laser Cutting Machine

Investing in a metal cutting machine laser offers numerous benefits that can enhance productivity and reduce waste in manufacturing processes. One major advantage is precision; these machines can create intricate patterns without compromising on quality or speed. Additionally, they minimize material wastage by utilizing advanced software that optimizes cut paths and layouts.

Moreover, industrial laser cutters are known for their versatility; they can handle different materials such as metals, plastics, wood, and more without significant adjustments to the setup. This adaptability makes them ideal for businesses looking to diversify their product offerings while keeping costs manageable—especially important when considering laser cutting machine prices.

Different Types of Laser Cutting Machines

The main categories include CO2 lasers typically used for non-metal materials like acrylics or wood and fiber lasers designed specifically for metal applications due to their efficiency and speed in processing various metals.

Industrial laser cutting machines also vary based on power levels; low-power models are great for thin sheets while high-power systems excel at heavy-duty tasks involving thick plates or complex geometries. Each type serves distinct purposes within industries ranging from automotive to aerospace—ensuring there's always an appropriate solution available regardless of specific requirements or budget constraints associated with purchasing new equipment.

Top Affordable Laser Cutting Equipment

Best Budget-Friendly Laser Cutters

For those looking to dive into the world of laser cutting without draining their wallets, several budget-friendly laser cutters stand out. Models like the Glowforge Basic and the Orion Motor Tech 40W are popular choices, offering reliable performance for hobbyists and small businesses alike. These cutting machine lasers provide impressive capabilities for materials ranging from wood to acrylic, making them versatile tools for various projects.

Another noteworthy mention is the Ten-High CO2 Laser Cutter, which brings industrial-grade features at a fraction of the price of traditional metal cutting machines. With its user-friendly interface and solid build quality, it’s perfect for anyone wanting to explore metal cutting with a laser cutter without breaking the bank. These affordable options ensure you get exceptional value while maintaining precision in your cuts.

Comparing Features of Cost-Effective Models

When evaluating cost-effective models of laser cutting equipment, it's essential to consider key features that differentiate them from one another. Look for specifications such as wattage; higher wattage typically means faster cuts and better performance on thicker materials with your metal cutting laser cutter. Additionally, bed size plays a crucial role in determining what projects you can tackle; larger beds allow for bigger pieces or multiple items cut simultaneously.

Another feature worth comparing is software compatibility; some industrial laser cutters come with proprietary software that may limit your creativity if you prefer using other design programs. Connectivity options also vary across models—USB ports or Wi-Fi capabilities can significantly enhance workflow efficiency when working with an industrial laser cutting machine or any other type of cutter. By weighing these features carefully, you can choose a model that fits both your needs and budget.

Notable Brands: Kiant Machinery and Others

Kiant Machinery has made quite an impression in the realm of affordable laser cutting equipment thanks to its commitment to quality and innovation at reasonable prices. Their line-up includes both entry-level models perfect for beginners as well as more advanced machines suitable for professionals looking to invest in reliable tools without overspending on their budget. Other notable brands like Epilog Laser and Full Spectrum Laser also offer excellent alternatives catering to different budgets and requirements.

These manufacturers are known not just for their competitive pricing but also for providing robust customer support—a must-have when investing in an industrial laser cutter or any type of metal cutting machine laser equipment. Whether you're starting out or upgrading your existing setup, exploring these brands will help you find just what you need without compromising on quality or functionality.

The Metal Cutting Laser Cutter Advantage

When it comes to precision and efficiency, metal cutting laser cutters are a game-changer in the world of manufacturing. These cutting machines utilize focused laser beams to slice through various types of metal with unparalleled accuracy, making them indispensable for both small workshops and large industrial settings. The speed at which these machines operate allows businesses to streamline their production processes, ultimately saving time and reducing costs associated with traditional cutting methods.

Precision and Speed in Metal Cutting

One of the standout features of metal cutting laser cutters is their remarkable precision. Unlike conventional cutting tools, which can leave rough edges or require extensive finishing work, a laser cutting machine delivers clean cuts with minimal kerf width. This level of accuracy not only enhances the quality of the finished product but also reduces material waste significantly.

Speed is another compelling advantage offered by industrial laser cutters. These machines can cut through thick sheets of metal faster than you can say laser cutting equipment, allowing manufacturers to meet tight deadlines without compromising quality. With advancements in technology, modern metal cutting machines have become even more efficient, enabling businesses to increase their output while maintaining high standards.

Applications of Metal Cutting Laser Machines

The versatility of metal cutting laser machines makes them suitable for a wide array of applications across different industries. From automotive parts manufacturing to intricate jewelry design, these machines excel in producing complex shapes and designs that traditional methods simply cannot match. Additionally, they are widely used in aerospace engineering for crafting components that require extreme precision and reliability.

Moreover, industries such as construction often rely on metal cutting equipment for fabricating structural components like beams and frames that must withstand rigorous conditions. The adaptability of these machines means they can handle various metals—be it aluminum, steel, or copper—making them essential tools for any workshop or factory setting looking to optimize their production capabilities.

How to Choose the Right Metal Cutting Equipment

Selecting the right metal cutting machine laser involves several factors that should align with your specific needs and budget constraints. First and foremost, consider the types of materials you'll be working with; some industrial laser cutters are better suited for thicker metals while others excel at delicate tasks involving thin sheets. Understanding your project requirements will help narrow down your options effectively.

Next up is evaluating the features offered by different models on the market today—look out for power output specifications since this directly influences cut speed and quality. Also take into account user-friendliness; a good interface ensures that even those new to using a laser cutter can quickly get up to speed without unnecessary complications.

Lastly, don't forget about maintenance costs associated with each model you consider; investing in high-quality equipment may come with higher initial expenses but could save you money long-term through reduced downtime and fewer repairs needed over time when compared against lower-end options available at cheaper prices.

Evaluating Industrial Laser Cutting Machines

When it comes to selecting an industrial laser cutting machine, the right features can make all the difference in efficiency and output quality. Understanding what to look for will help you make an informed decision that aligns with your business needs. From power capabilities to software compatibility, each feature plays a vital role in determining the overall performance of your laser cutting equipment.

Features to Look for in Industrial Models

First and foremost, consider the power output of your metal cutting laser cutter; higher wattage often translates to faster cutting speeds and the ability to handle thicker materials. Additionally, look for advanced features such as automated focusing systems and programmable settings that enhance precision and ease of use. Don't forget about the importance of safety features—an industrial laser cutter should come equipped with protective enclosures and emergency shut-off mechanisms.

Another critical aspect is the type of cutting head used in these machines. A high-quality cutting head can improve efficiency while reducing wear on components, leading to lower maintenance costs over time. Also, ensure that your chosen metal cutting machine laser is compatible with various materials; versatility can be a game-changer for businesses looking to expand their offerings.

Cost vs. Performance: What to Consider

When evaluating industrial laser cutting machines, it's essential to strike a balance between cost and performance. While it might be tempting to go for budget-friendly options, remember that investing in quality often pays off in terms of reliability and longevity—especially when it comes to laser cutting equipment designed for heavy-duty applications. Analyze not only the initial purchase price but also long-term operational costs like energy consumption and maintenance.

Consider how much production volume you'll need from your industrial laser cutter; higher-performing models may have a steeper upfront cost but could save you money by increasing throughput over time. Additionally, scrutinize warranty options—reputable manufacturers typically offer extensive warranties on their equipment as a sign of confidence in their product's durability.

Customer Reviews on Popular Industrial Cutters

Customer feedback can provide invaluable insights into which industrial laser cutting machines stand out from the rest. Look for reviews that highlight both positive experiences and potential drawbacks; this well-rounded perspective will help you gauge whether a specific model meets your needs effectively. Pay attention not only to performance ratings but also comments regarding customer service from manufacturers—support after purchase is just as important as initial sales promises.

Many users emphasize how certain models excel at precision cuts while others may struggle with speed or material versatility—this information can guide you toward making an informed choice tailored specifically for your operations. Lastly, don’t ignore online forums or industry groups where professionals share real-world experiences with different metal cutting machines; these platforms are treasure troves of practical advice!

Budgeting for Your Laser Cutting Machine

Navigating the financial landscape of acquiring laser cutting equipment can feel like a daunting task, but it doesn't have to be. Understanding the costs associated with different types of cutting machine lasers is crucial for making an informed decision. From entry-level models to industrial laser cutters, prices can vary significantly based on features and capabilities.

Understanding Laser Cutting Machine Prices

The type of machine—whether it's a metal cutting laser cutter or a more versatile model—will largely dictate costs. Additionally, features such as power output, bed size, and brand reputation can also influence the final price tag.

For instance, budget-friendly options may start around a few thousand dollars for basic models but can escalate into tens of thousands for high-performance industrial laser cutting machines with advanced capabilities. It's essential to weigh your needs against your budget; investing in quality laser cutting equipment may save you money in the long run through increased efficiency and reduced operational costs.

Financing Options for Small Businesses

For small businesses looking to invest in a metal cutting machine laser without breaking the bank, financing options are plentiful and often flexible. Many manufacturers and distributors offer financing plans that allow you to spread payments over time while still enjoying immediate access to your new industrial laser cutter. This approach can help ease cash flow concerns while ensuring you have the latest technology at your fingertips.

Additionally, consider exploring grants or loans specifically aimed at supporting small businesses in purchasing advanced manufacturing equipment like laser cutters. Researching local programs or federal assistance could open doors to funding opportunities that make acquiring high-quality laser cutting equipment more attainable.

Maintenance Costs: What to Expect

Once you've secured your metal cutting machine laser, it's vital to factor maintenance costs into your budgeting equation. Regular upkeep is essential for ensuring optimal performance from your industrial laser cutting machine; neglecting this aspect can lead to costly repairs down the line. Expect routine expenses such as lens replacements, coolant refills, and occasional servicing by professionals who specialize in maintaining these sophisticated machines.

Understanding that maintenance is an ongoing cost will help you plan better financially; setting aside a portion of your budget specifically for this purpose will keep surprises at bay. In the end, investing in proper care not only extends the lifespan of your equipment but also enhances its performance—saving you time and money while boosting productivity.

Conclusion

As we wrap up our exploration of laser cutting equipment, it's clear that investing in the right cutting machine laser can significantly enhance your production capabilities. From understanding the intricate workings of laser technology to evaluating budget-friendly options, this guide has equipped you with essential insights. Remember, whether you're eyeing a metal cutting machine laser or an industrial laser cutter, precision and affordability can go hand in hand.

Key Takeaways on Laser Cutting Equipment

First, always consider your specific needs—whether you're focusing on intricate designs or heavy-duty metal cutting tasks will dictate your choice of a metal cutting laser cutter. Additionally, comparing features across different models will help you find the best fit without breaking the bank.

Investing in Quality for Long-term Savings

While it may be tempting to opt for the cheapest option available, investing in quality industrial laser cutting machines often pays off in the long run. Higher-quality machines tend to offer better performance and durability, reducing maintenance costs and downtime associated with cheaper alternatives. By choosing a reliable model from reputable brands like Kiant Machinery, you ensure that your investment translates into consistent output and efficiency.

Future Trends in Affordable Laser Cutting Technology

The landscape of affordable laser cutting technology is ever-evolving, with innovations continuously emerging to enhance efficiency and reduce costs. Expect advancements such as AI integration for improved precision and automation capabilities that streamline operations further in upcoming years. As these trends unfold, staying informed will help you make smarter choices regarding your metal cutting machine laser investments.