Introduction

In the world of metal fabrication, steel laser cutting stands out as a game-changer, offering unparalleled precision and efficiency. Understanding the quality of steel laser cutting is essential for anyone involved in metal work, from engineers to hobbyists. The ability to produce clean, accurate cuts not only enhances the final product but also optimizes material usage, making it an invaluable process in today’s manufacturing landscape.

Understanding Steel Laser Cutting Quality

The quality of steel laser cutting is influenced by a myriad of factors that can make or break the final output. When using a laser cutting machine, the interaction between the laser beam and the material determines everything from edge smoothness to cut depth. By grasping these intricacies, one can better appreciate why investing in high-quality metal laser cutting services pays off in durability and aesthetics.

Importance of Precision in Metal Cutting

In applications where tolerances are tight, such as aerospace or automotive industries, even minor deviations can lead to significant issues down the line. Thus, mastering precision in processes like cutting laser metal ensures that each piece meets stringent industry standards while maintaining structural integrity.

Overview of Key Influencing Factors

Several key factors influence the quality of steel laser cutting—ranging from material type and thickness to operator skill and technology used. For instance, different metals respond uniquely to various settings on a laser machine; knowing how these variables interact is crucial for achieving optimal results. Additionally, advancements in technology continue to reshape what’s possible with metal laser cutting services, making it essential for professionals to stay updated on best practices and innovations.

Material Type and Thickness

Different materials respond uniquely to laser cutting techniques, which is crucial for achieving precise results. Understanding these variations helps in selecting the right laser cutting machine for your specific project needs.

How Material Affects Laser Cutting

The composition of the material being cut plays a pivotal role in determining how effective and efficient the laser cutting process will be. For instance, different grades of steel have varying levels of reflectivity and thermal conductivity, which can affect how well a metal cutting laser cutter performs. Additionally, some materials may require different gas assist technologies or settings on the laser machine to achieve optimal results.

Moreover, factors such as surface finish and coating can also impact how cleanly a material cuts during the laser process. Materials with rough surfaces may produce more dross or slag after cutting, necessitating additional post-processing work. Therefore, understanding your material's characteristics is essential for ensuring high-quality cuts when utilizing metal laser cutting services.

Optimal Thickness for Cutting Steel

Determining the optimal thickness for cutting steel is vital when using a laser machine; it directly influences both cut quality and speed. Generally speaking, thinner sheets are easier to cut with high precision compared to thicker ones due to reduced heat input and faster processing times. For most industrial applications, sheets ranging from 1mm to 20mm are ideal candidates for steel laser cutting.

However, while thicker materials can still be processed effectively with advanced lasers that offer higher power settings, they often require slower speeds to maintain quality cuts without warping or excessive heat distortion. This balance between thickness and speed becomes crucial as you increase material size; otherwise, you risk compromising on precision—something that no one wants in their final product!

Impact of Material Quality

The quality of steel used in metal laser cutting significantly affects both performance and end results during processing. High-quality steel typically has fewer impurities and consistent composition throughout its structure, allowing for cleaner cuts with minimal post-processing required on finished parts like a laser-cut steel sheet. Conversely, lower-quality materials may lead to issues such as inconsistent cuts or increased wear on your equipment.

Moreover, investing in high-quality raw materials not only enhances cut quality but also contributes positively toward operational efficiency by reducing downtime caused by maintenance or rework needed due to poor initial outcomes from lower-grade materials. In an industry where precision matters immensely—especially when dealing with intricate designs—the importance of using superior materials cannot be overstated.

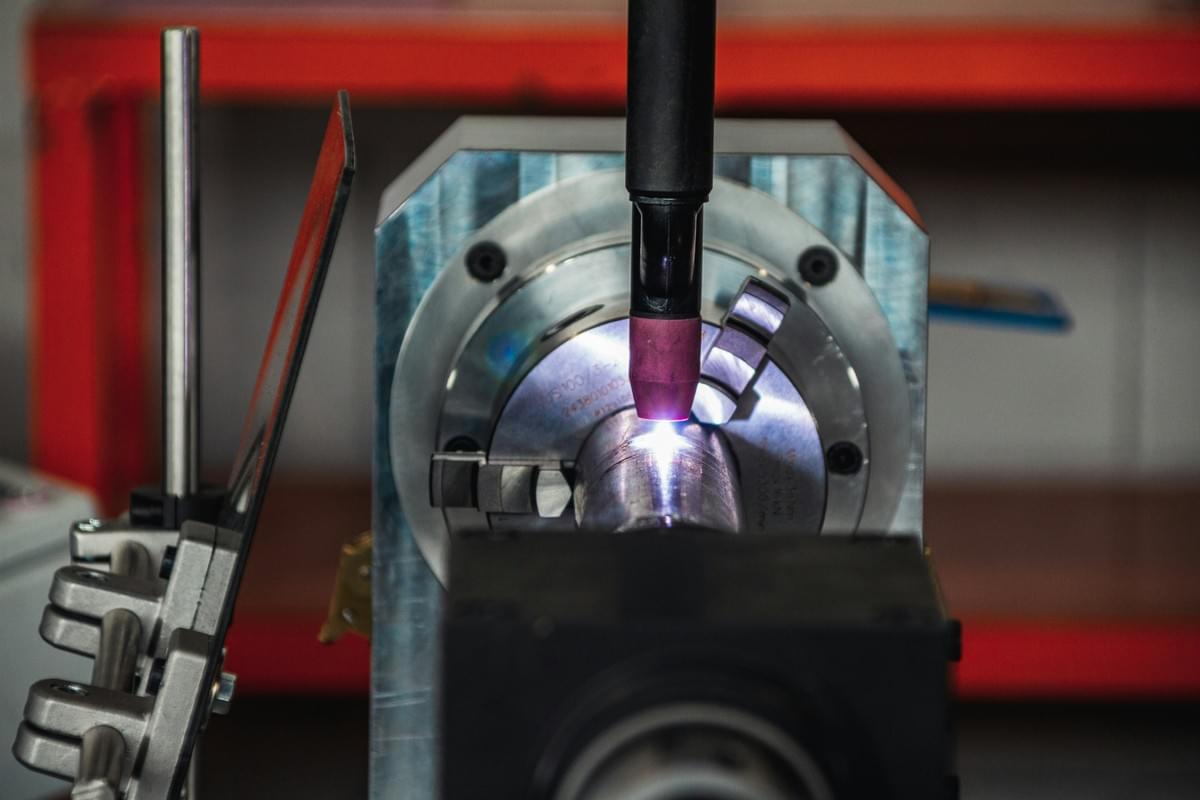

Laser Cutting Technology

In the realm of steel laser cutting, technology plays a pivotal role in achieving high-quality results. The evolution of laser cutting machines has transformed the metal fabrication industry, enabling precision and efficiency that were once deemed unattainable. Understanding the various types of laser cutting systems available is essential for anyone looking to optimize their metal cutting processes.

Different Types of Laser Cutting Machines

There are several types of laser cutting machines, including CO2 lasers, fiber lasers, and solid-state lasers, each with its unique advantages. CO2 lasers are renowned for their versatility and effectiveness in cutting thick materials like steel; fiber lasers shine when it comes to speed and efficiency in thin sheet metal applications; while solid-state lasers offer impressive power for specific tasks.

Choosing the right laser machine can significantly impact your project outcomes. For instance, if you’re focused on high-speed production with minimal waste, investing in a fiber laser could be your best bet for metal laser cutting service. Conversely, if your projects involve diverse materials and thicknesses, a CO2 machine might provide the flexibility you need.

Importance of Laser Technology in Precision

Precision is the name of the game in steel laser cutting, and advanced technology is what enables that precision. Modern laser machines utilize sophisticated optics and control systems that allow for incredibly fine adjustments during the cutting process. This level of control translates into cleaner edges and more accurate cuts—essential qualities when dealing with intricate designs or tight tolerances.

Moreover, advancements in software have made it easier than ever to program complex cuts into a single pass without sacrificing quality. This means less time spent on setup and more time producing high-quality products—whether you're working on a simple project or a detailed design involving multiple layers of cut steel sheet material. The ability to achieve consistent results across various jobs makes modern laser technology an invaluable asset.

Advancements in Metal Laser Cutting

The world of metal laser cutting is continuously evolving thanks to ongoing research and development efforts aimed at enhancing performance and efficiency. Recent advancements include improved beam quality from fiber lasers that lead to faster cut speeds without compromising edge quality or accuracy—a game-changer for industries relying heavily on precision cuts like automotive or aerospace manufacturing.

Additionally, innovations such as automated loading systems are streamlining workflows by reducing manual handling time while increasing safety during operations involving heavy materials like steel sheets. These advancements not only boost productivity but also lower operational costs over time—benefits that every business owner can appreciate.

As we look toward future developments in this field, it’s clear that staying updated with technological trends will be crucial for anyone involved in steel laser cutting or related services. Embracing these innovations ensures you remain competitive while delivering top-notch quality products to your customers.

Cutting Speed and Power Settings

The interplay between these two factors can significantly affect the precision and overall quality of the cut. A well-calibrated laser machine can make all the difference in delivering clean, accurate cuts that meet industry standards.

Finding the Right Speed for Steel Cutting

Finding the optimal speed for steel cutting involves understanding how different materials respond to various laser settings. A faster cutting speed may seem appealing, but it can lead to incomplete cuts or excessive burrs on the edges of a laser cut steel sheet. Conversely, moving too slowly can cause overheating, resulting in warping or melting of the material—definitely not what you want when utilizing a metal cutting laser cutter.

To achieve precision in your cuts, it's essential to experiment with different speeds based on material thickness and type. For instance, thinner sheets of steel might require a quicker pace compared to thicker materials that need slower speeds for deeper penetration and cleaner edges. This balancing act is where skilled operators come into play; their experience can guide adjustments that enhance both efficiency and output quality.

Power Settings Impact on Cut Quality

Power settings are another critical aspect of effective metal laser cutting that directly influences cut quality. Higher power levels generally enable deeper cuts but can also lead to excessive heat buildup if not managed properly. This heat can create a rough edge finish or even damage sensitive components within your laser machine.

On the flip side, lower power settings might be more suitable for thinner materials or intricate designs where precision is paramount. However, insufficient power could result in incomplete cuts or poor edge quality—defeating the purpose of using a high-tech laser machine in the first place! Therefore, striking a balance between power output and material characteristics is vital for achieving optimal results during metal cutting operations.

Balancing Speed and Precision

Balancing speed and precision is like walking a tightrope; one misstep could lead to undesirable outcomes in your steel laser cutting projects. Operators must constantly adjust both parameters based on real-time feedback from their machines as they work through various types of metal sheets. This delicate dance ensures that each cut maintains its integrity while still being produced efficiently.

Moreover, advancements in technology have introduced features like automatic adjustments based on material detection, making this balancing act easier than ever before! By leveraging these innovations alongside operator expertise, companies offering metal laser cutting services can ensure they deliver top-notch results consistently while maximizing productivity levels across their operations.

In summary, mastering cutting speed and power settings is essential for anyone involved with steel laser cutting processes today—whether you're running a small shop or managing large-scale production lines with advanced machinery at your fingertips!

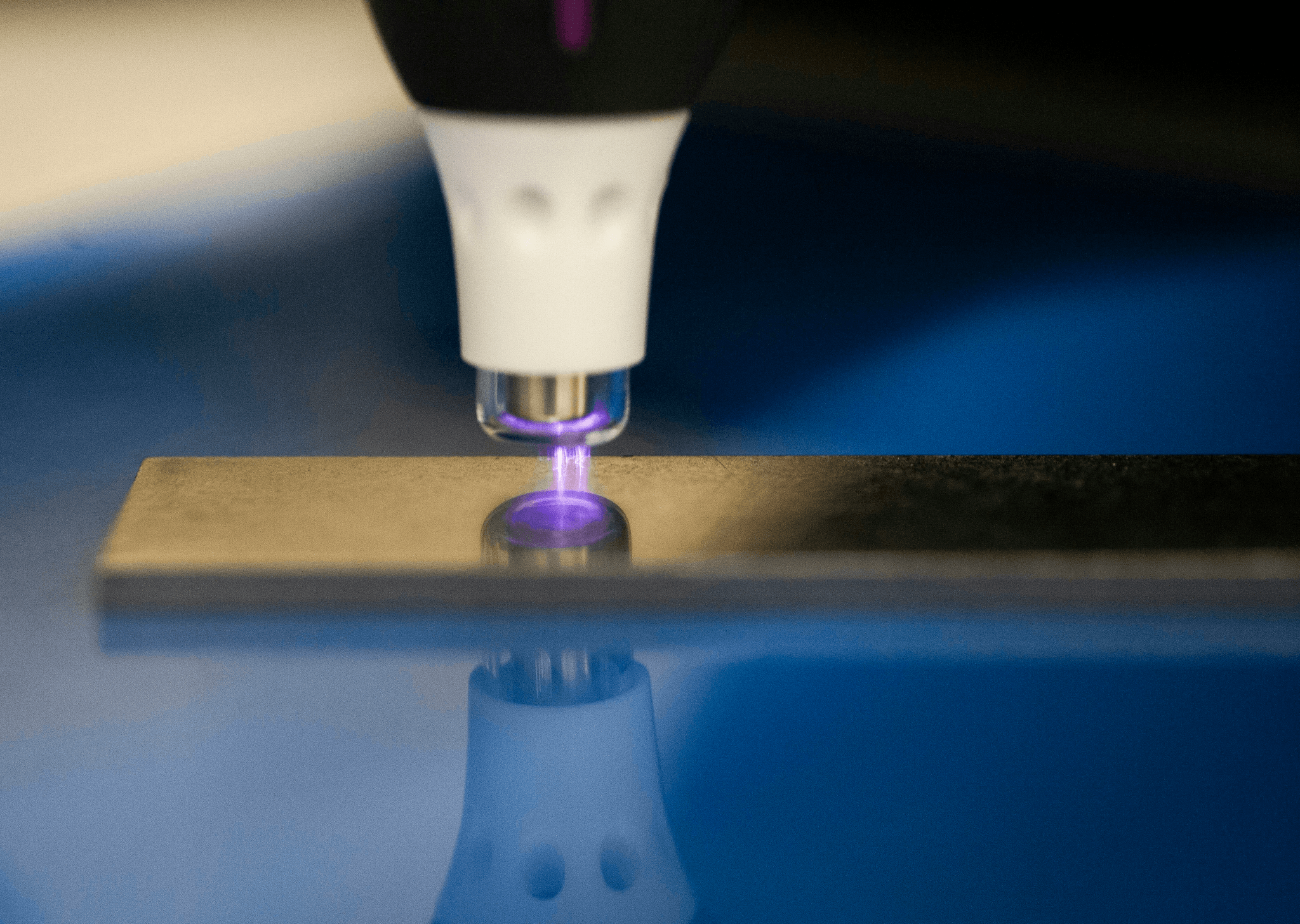

Focus and Spot Size

When it comes to steel laser cutting, focus and spot size are crucial elements that can make or break the quality of a cut. The precise alignment of the laser beam affects not only the depth of penetration but also the overall finish of the cut surface. A well-focused beam ensures that energy is concentrated on a small area, allowing for cleaner cuts and reduced thermal distortion.

Role of Focus in Laser Cutting

The focus point in laser cutting refers to where the laser beam converges to its smallest diameter, which is essential for achieving optimal results in metal cutting. A properly focused laser beam allows for maximum energy concentration, resulting in precise cuts with minimal kerf width. When using a laser machine for steel cutting, maintaining this focus is vital; even slight deviations can lead to uneven edges or excessive heat-affected zones.

Moreover, focusing techniques vary based on material thickness and type; thicker materials may require adjustments to ensure that the energy penetrates effectively without compromising quality. Regular calibration and maintenance of the focusing lens are necessary to keep your metal cutting laser cutter performing at its best. Ultimately, understanding how focus impacts steel laser cutting can elevate your project from mediocre to exceptional.

Adjusting Spot Size for Different Metals

Spot size plays a significant role in determining how efficiently a metal laser cutting service can operate across various materials. Different metals have unique thermal properties that influence how they respond to focused lasers; thus, adjusting spot size becomes essential for different applications. For instance, when working with thinner materials like aluminum versus thicker steel sheets, varying the spot size allows operators to optimize energy delivery and minimize waste.

A smaller spot size typically enhances precision but may slow down production speed; conversely, a larger spot size increases speed but could compromise cut quality if not managed correctly. Understanding these nuances helps operators make informed decisions about their settings on the laser machine while ensuring they achieve desired outcomes without sacrificing accuracy or efficiency during metal cutting processes. This adaptability is key when working with diverse projects requiring tailored solutions.

Ensuring Consistency in Cut Quality

Consistency is paramount in any manufacturing process involving steel laser cutting; after all, clients expect uniformity across all pieces produced by a metal cutting service provider. Achieving consistent cut quality hinges on several factors: maintaining proper focus and optimizing spot size are just two critical components among many others like power settings and material handling practices. By establishing clear operational protocols around these aspects, businesses can enhance their reputation while minimizing costly rework due to poor cuts.

Regularly monitoring equipment performance ensures that adjustments can be made proactively rather than reactively—this includes checking lens cleanliness as well as verifying alignment accuracy before commencing any job involving complex designs or intricate patterns on a laser cut steel sheet. Through diligent attention-to-detail practices combined with skilled operator training programs aimed at refining techniques around focus and spot size adjustments will undoubtedly result in consistently high-quality outputs every time you engage your metal laser cutting services.

Operator Skill and Experience

The role of skilled operators in the realm of steel laser cutting cannot be overstated. A proficient operator not only understands the intricacies of the laser cutting machine but also knows how to adapt settings based on material type, thickness, and desired outcomes. Their expertise ensures that every cut is precise, reducing waste and enhancing overall productivity in metal cutting processes.

Importance of Skilled Operators in Laser Cutting

When it comes to laser cutting, human skill is often the unsung hero behind high-quality results. Skilled operators bring a wealth of knowledge about various materials and their behaviors under laser applications, which can significantly affect the quality of the final product. Without their expertise, even the most advanced laser machine may struggle to achieve optimal performance during metal laser cutting tasks.

Operators are responsible for monitoring real-time feedback from the laser cutter, adjusting parameters as needed to maintain precision throughout the process. Their ability to troubleshoot issues on-the-fly can prevent costly mistakes and ensure that each steel cut sheet meets rigorous standards. Ultimately, a well-trained operator transforms a standard metal cutting laser cutter into a powerhouse of efficiency and accuracy.

Training for Effective Use of Laser Machines

To harness the full potential of a laser machine, comprehensive training programs are essential for operators. These programs should cover everything from basic machine operation to advanced troubleshooting techniques specific to steel laser cutting applications. By investing in thorough training, companies can ensure that their workforce is equipped with both theoretical knowledge and practical skills necessary for effective use.

Hands-on training sessions allow operators to familiarize themselves with different types of materials and settings tailored for various applications in metal laser cutting services. Understanding how factors like speed and power settings interact with material characteristics is crucial for achieving superior cut quality in every project undertaken with a metal cutting laser cutter. Moreover, ongoing education keeps operators updated on advancements in technology that could further enhance their capabilities.

Real-world Examples of Operator Impact

The difference between an average cut and an exceptional one often boils down to operator skill—real-world examples abound illustrating this point vividly within the industry. For instance, one company experienced significant improvements in production efficiency after investing in specialized training for its team operating steel laser cutters; they reported reduced scrap rates by nearly 30%. This not only saved costs but also improved turnaround times for clients seeking high-quality finished products like precision-cut steel sheets.

Another example highlights how an untrained operator misjudged power settings while working on intricate designs; this led to uneven cuts that required rework—a costly mistake that could have been easily avoided with proper training on their metal laser cutting service equipment. Such instances underline why organizations must prioritize operator development as part of their operational strategy; skilled personnel directly influence both quality outcomes and customer satisfaction levels.

Conclusion

In the world of steel laser cutting, understanding the nuances that shape cutting quality is paramount. Factors such as material type, thickness, and operator skill all play crucial roles in determining the outcome of a laser cut. By recognizing these elements, businesses can enhance their metal cutting processes and achieve superior results.

Key Factors Shaping Cutting Laser Metal Quality

The quality of cutting laser metal hinges on several key factors, including the material used and the technology employed. Different metals respond uniquely to laser cutting; for instance, steel requires specific settings for optimal results. Additionally, maintaining high standards in both material quality and machine calibration ensures that every cut meets industry expectations.

Role of Technology in Steel Laser Cutting

Advancements in technology have revolutionized steel laser cutting practices, allowing for unprecedented precision and efficiency. Modern laser machines are equipped with sophisticated features that enhance their capabilities, enabling faster production times without sacrificing quality. As a result, businesses utilizing advanced metal laser cutting services can remain competitive while delivering superior products to their clients.

Kiant Machinery's Contribution to Quality Solutions

Kiant Machinery stands at the forefront of innovation in the field of steel laser cutting, providing state-of-the-art equipment designed to meet diverse industrial needs. Their commitment to quality solutions ensures that users can maximize the potential of their laser machines while achieving exceptional cut quality consistently. With Kiant’s expertise and advanced technology backing them up, companies can confidently navigate the complex landscape of metal cutting with ease.