Introduction

In today's fast-paced industrial landscape, the evolution of pipe cutting machines has become a game changer. With advancements in technology, these machines are no longer just tools; they are integral components that enhance productivity and precision in tube cutting processes. As industries embrace these innovations, the focus shifts toward maximizing efficiency and adapting to diverse material needs.

Embracing Technology in Pipe Cutting Machines

The integration of smart technology into pipe cutting machines has revolutionized how we approach tube cutting. Modern equipment now boasts features like automation and real-time monitoring, allowing operators to achieve unparalleled accuracy with minimal human intervention. This technological embrace not only streamlines operations but also ensures that businesses remain competitive in a rapidly evolving market.

Key Features to Enhance Efficiency

Key features such as advanced robotics and software solutions have significantly enhanced the efficiency of industrial laser cutting machines. These innovations enable precision cutting that reduces waste while improving overall output quality—crucial factors for any manufacturing operation. With fiber laser tube cutting machines leading the charge, companies can now tackle complex designs with ease and speed.

The Future of Tube Cutting Technologies

Looking ahead, the future of tube cutting technologies is bright, driven by continuous innovation and demand for higher performance standards. As manufacturers seek out more versatile and adaptable solutions, we can expect to see even more sophisticated laser cutting equipment emerge on the market. The journey towards greater efficiency and precision is just beginning; it's an exciting time for those involved in the world of pipe cutting machines.

Advanced Automation and Control

In today's fast-paced manufacturing landscape, advanced automation and control systems are revolutionizing the way we approach pipe cutting. The integration of smart technology not only enhances efficiency but also ensures precision in every cut made by a pipe cutting machine. As industries evolve, embracing these innovations is essential for staying competitive.

Benefits of Smart Technology Integration

Smart technology integration in pipe cutting machines brings a myriad of benefits that significantly improve operational efficiency. With real-time monitoring and data analytics, manufacturers can optimize their tube cutting processes, reducing downtime and increasing productivity. Furthermore, these systems enable predictive maintenance, which minimizes unexpected machine failures and extends the lifespan of laser cutting equipment.

The ability to connect various components through IoT (Internet of Things) allows for seamless communication between machines and operators. This connectivity ensures that adjustments can be made on-the-fly, improving the overall adaptability of industrial laser cutting machines to different production environments. Ultimately, smart technology transforms traditional practices into streamlined operations that drive success.

Role of Robotics in Pipe Cutting

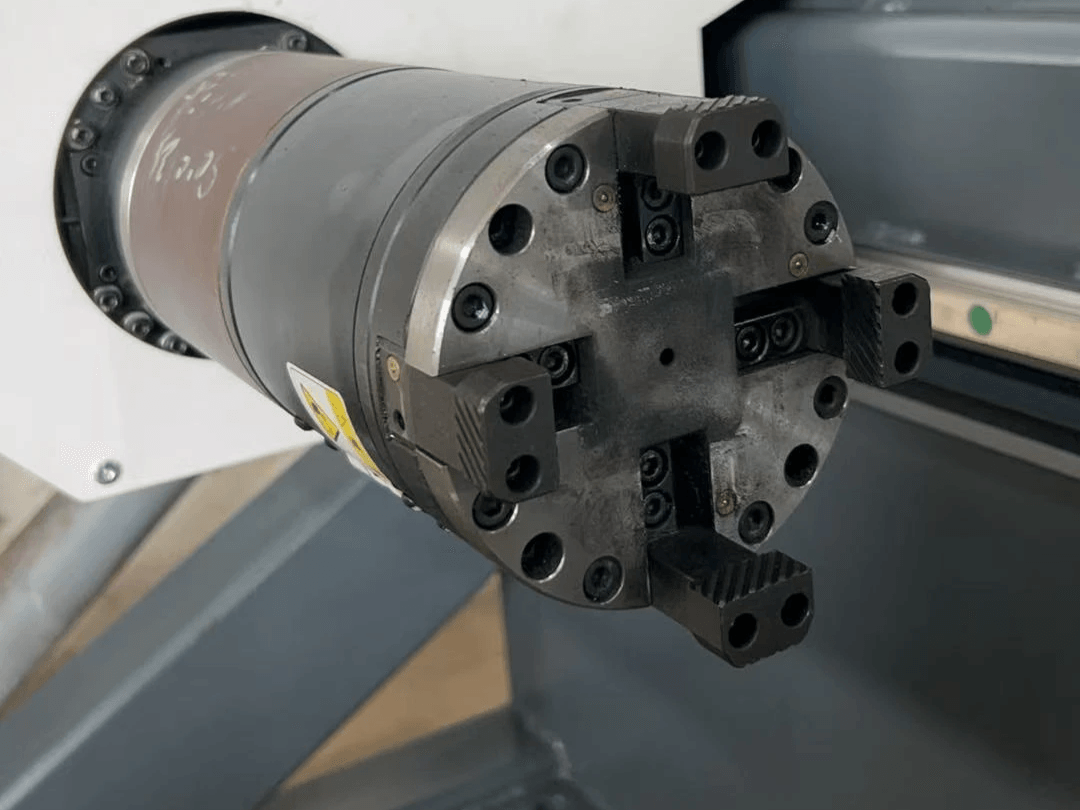

Robotics play an increasingly vital role in modern pipe cutting operations by enhancing precision and speed in the manufacturing process. Robotic arms equipped with advanced sensors can maneuver around complex geometries with ease, ensuring that each cut made by a fiber laser tube cutting machine is flawless. This level of accuracy not only boosts product quality but also reduces material waste—an essential factor for cost-effective production.

Moreover, the use of robotics allows for automation in tasks that were once labor-intensive, freeing up skilled workers to focus on more strategic aspects of production. By implementing robotic solutions alongside precision cutting machines, companies can achieve higher throughput without compromising on quality or safety standards. As a result, businesses are better positioned to meet market demands while maintaining competitive pricing.

Software Solutions for Precision Cutting

To fully harness the capabilities of modern pipe cutting machines, robust software solutions are essential for precision cutting tasks. Advanced CAD/CAM software enables designers to create intricate designs that can be seamlessly translated into actionable instructions for industrial laser cutting machines. This synergy between design software and machinery ensures that every aspect—from initial concept to final product—is executed with impeccable accuracy.

Additionally, software tools often come equipped with features like nesting optimization which maximizes material usage during tube cutting processes—further enhancing efficiency and reducing costs associated with waste management. With user-friendly interfaces designed specifically for operators' needs, these solutions empower teams to execute complex cuts effortlessly while maintaining high standards of safety compliance. Investing in sophisticated software is not just about keeping up; it's about leading the charge toward innovation in manufacturing.

Precision Cutting Capabilities

In the world of manufacturing, precision cutting capabilities are not just a luxury; they are a necessity. A pipe cutting machine that offers high accuracy can significantly enhance production quality and efficiency, ensuring that every cut is exact and meets stringent specifications. This level of precision is crucial for industries where even the slightest deviation can lead to costly errors or safety hazards.

Importance of Accuracy in Pipe Cutting

Accuracy in pipe cutting cannot be overstated; it directly impacts both product quality and operational costs. When using a precision cutting machine, manufacturers can achieve tighter tolerances, which minimizes waste and optimizes material usage. Furthermore, precise cuts reduce the need for rework or adjustments during assembly, streamlining the entire manufacturing process.

Exploring Fiber Laser Tube Cutting Machines

Fiber laser tube cutting machines represent a groundbreaking advancement in tube cutting technology. These machines utilize high-powered lasers to cut through various materials with unparalleled speed and accuracy, making them ideal for complex shapes and designs. The efficiency of fiber laser technology not only enhances productivity but also ensures that each piece produced meets high-quality standards without compromising on performance.

Enhancing Production with Industrial Laser Cutting Machines

Industrial laser cutting machines have revolutionized the way manufacturers approach production processes by offering versatility and speed unmatched by traditional methods. With advanced features like automated loading systems and real-time monitoring, these machines maximize throughput while maintaining exceptional precision in every cut. By integrating industrial laser cutting equipment into their operations, businesses can elevate their output levels while reducing operational costs associated with less efficient technologies.

Versatility and Adaptability

In the ever-evolving landscape of manufacturing, versatility and adaptability have become essential traits for any pipe cutting machine. The ability to handle various materials and adapt to diverse applications not only enhances productivity but also positions companies to meet the dynamic demands of their clients. With advancements in technology, modern tube cutting solutions are more flexible than ever, allowing businesses to scale operations efficiently.

Multi-Material Cutting Options

One of the standout features of contemporary industrial laser cutting machines is their capability to cut through multiple materials with precision. Whether it’s stainless steel, aluminum, or even plastics, a fiber laser tube cutting machine can handle it all with ease. This multi-material cutting capability enables manufacturers to diversify their product offerings and respond swiftly to market changes without investing in additional machinery.

Moreover, the integration of advanced sensors and software in these precision cutting machines ensures that material properties are accurately assessed during the cutting process. This leads not only to improved quality but also minimizes waste—a crucial factor for cost-effectiveness in production environments. Ultimately, having a pipe cutting machine that can adapt to various materials allows businesses to maximize their operational efficiency while minimizing downtime associated with changing setups.

Customization Features for Different Applications

Customization is another key aspect that enhances the versatility of modern tube cutting technologies. Many manufacturers now offer pipe cutting machines equipped with features tailored for specific applications—be it intricate designs or large-scale production runs. These customization options can range from adjustable speed settings to specialized tooling that caters specifically to unique project requirements.

For instance, some industrial laser cutting machines allow operators to modify parameters on-the-fly based on material thickness or desired cut quality, ensuring optimal results every time. This level of adaptability not only streamlines workflows but also empowers companies to take on a wider variety of projects without compromising quality or efficiency. In an industry where time is money, having a customizable solution like this can make all the difference.

Case Studies of Innovative Uses

The real-world application of versatile pipe cutting machines showcases their potential across different sectors—from automotive manufacturing to aerospace engineering. For example, one leading automotive manufacturer utilized a fiber laser tube cutting machine for producing complex exhaust systems that required precise cuts at various angles and lengths—demonstrating how flexibility can lead directly to enhanced performance and reduced assembly times.

Another remarkable case involved an aerospace company that adopted an industrial laser cutting machine capable of handling lightweight composites alongside traditional metals for aircraft components. This innovative approach not only expedited production but also contributed significantly towards achieving weight reduction targets critical in aviation design standards. Such case studies highlight how embracing adaptable technologies allows industries not just to keep pace but thrive amidst increasing competition.

Safety Features and Compliance

When it comes to operating a pipe cutting machine, safety is paramount. The integration of advanced technology in tube cutting processes not only enhances efficiency but also ensures compliance with essential safety standards. By adhering to these regulations, manufacturers can create a safer working environment while optimizing the performance of their industrial laser cutting machines.

Essential Safety Standards for Machinery

Safety standards are designed to protect both operators and equipment when using precision cutting machines like fiber laser tube cutting machines. These regulations outline necessary features such as emergency shut-off systems, protective barriers, and proper ventilation to mitigate hazards associated with laser cutting equipment. Compliance with these standards not only safeguards workers but also enhances the credibility of manufacturers within the industry.

User-Friendly Controls and Emergency Systems

User-friendly controls are a game-changer for anyone operating a pipe cutting machine or an industrial laser cutting machine. Intuitive interfaces allow operators to navigate complex functions easily, reducing the likelihood of errors during operation. Moreover, emergency systems must be readily accessible; they should include clearly marked buttons that immediately halt operations if any unsafe conditions arise, ensuring that safety remains at the forefront during tube cutting activities.

Ensuring Operator Safety with Advanced Technology

Advanced technology plays a crucial role in ensuring operator safety in environments where precision cutting machines are used extensively. Features like automated monitoring systems can detect anomalies or malfunctions in real-time, providing alerts before issues escalate into dangerous situations. Additionally, incorporating ergonomic designs into machinery helps reduce physical strain on operators while enhancing overall productivity during pipe cutting tasks.

Cost-Effectiveness and Efficiency

In today's fast-paced manufacturing environment, cost-effectiveness is paramount. Investing in a high-quality pipe cutting machine can significantly reduce operational costs while enhancing productivity. By leveraging advanced technologies, businesses can streamline their processes and maximize efficiency.

Reducing Waste with Precision Cutting Machines

Precision cutting machines are designed to minimize material waste during the cutting process. With laser cutting equipment, manufacturers can achieve intricate cuts that utilize the entire length of the material, leaving little to no scrap behind. This not only conserves resources but also contributes to a more sustainable production model, proving that smart investments in technology pay off.

Moreover, fiber laser tube cutting machines offer unmatched accuracy, ensuring that every cut is precise and tailored to specifications. This level of precision means fewer reworks and less wasted time on correcting mistakes—an essential factor for any business aiming to boost profitability. Ultimately, reducing waste through effective tube cutting translates into lower material costs and improved bottom lines.

Long-Term Savings with Laser Cutting Equipment

Investing in industrial laser cutting machines might seem like a hefty upfront cost; however, the long-term savings are undeniable. These machines boast durability and require less maintenance compared to traditional cutting methods, translating into lower operational expenses over time. Additionally, efficient energy use in laser cutting equipment results in reduced utility bills—a win-win for both the environment and your budget.

Furthermore, as companies adopt these advanced technologies, they often find themselves completing projects faster than before due to increased speed and accuracy of laser systems. This boosts overall productivity while allowing businesses to take on more jobs without sacrificing quality or timelines. In essence, choosing quality over quantity with precision tools leads to substantial financial benefits down the line.

Kiant Machinery’s Competitive Edge in the Market

Kiant Machinery stands out among competitors by offering top-of-the-line pipe cutting machines that prioritize both efficiency and cost-effectiveness. Their innovative designs incorporate state-of-the-art technology that not only enhances performance but also reduces operational costs for users across various industries. With a focus on delivering high-quality solutions like fiber laser tube cutting machines at competitive prices, Kiant Machinery helps clients achieve remarkable savings.

Additionally, Kiant's commitment to customer satisfaction ensures that users receive ongoing support and training for their industrial laser cutting machines—maximizing return on investment from day one. By choosing Kiant Machinery's products, businesses gain access to superior technology that fosters growth while keeping an eye on their budgets. Ultimately, this competitive edge positions Kiant as a leader in providing efficient solutions for modern manufacturing challenges.

Conclusion

In the ever-evolving landscape of manufacturing, innovations in pipe cutting technology are paving the way for smarter, more efficient processes. The integration of advanced features in tube cutting machines is not just a trend; it's a necessity for businesses aiming to stay competitive. With the rise of industrial laser cutting machines and fiber laser tube cutting machines, precision and versatility have never been more accessible.

Innovations Driving the Future of Tube Cutting

The future of tube cutting is being shaped by groundbreaking advancements in automation and smart technology integration. These innovations allow for enhanced precision cutting capabilities that significantly reduce waste and increase production efficiency. As industries continue to demand higher quality and faster turnaround times, the role of laser cutting equipment will only become more critical.

Choosing the Right Pipe Cutting Machine

Selecting the right pipe cutting machine involves understanding your specific needs, including material types, thicknesses, and desired cut quality. It's essential to evaluate features like versatility, adaptability, and cost-effectiveness when making your choice. Investing in a high-quality precision cutting machine can lead to long-term savings while ensuring that your operations remain efficient.

How Kiant Machinery Elevates Cutting Performance

Kiant Machinery stands out in the market by offering state-of-the-art solutions that elevate cutting performance across various applications. Their commitment to innovation ensures that each pipe cutting machine is equipped with advanced safety features and user-friendly controls for optimal operator experience. By choosing Kiant Machinery's industrial laser cutting machines or fiber laser tube cutting machines, you’re not just investing in equipment; you’re investing in your future success.