Introduction

In the world of manufacturing and fabrication, the choice of a large laser cutting machine can significantly influence productivity, precision, and overall operational efficiency. Whether you are involved in metalworking or other industries requiring intricate designs, selecting the right laser cutting welding machine is crucial for achieving optimal results. With various options available, understanding your specific needs and the features of different machines can make all the difference in your cutting endeavors.

Importance of Choosing the Right Machine

Choosing the right large laser cutting machine is not just about making a purchase; it’s an investment that impacts your business's bottom line. The appropriate machine will enhance your production capabilities while minimizing waste and operational downtime. Moreover, with advancements in technology, selecting a modern laser cutting welding machine can provide superior performance and versatility compared to older models.

Types of Large Laser Cutting Machines

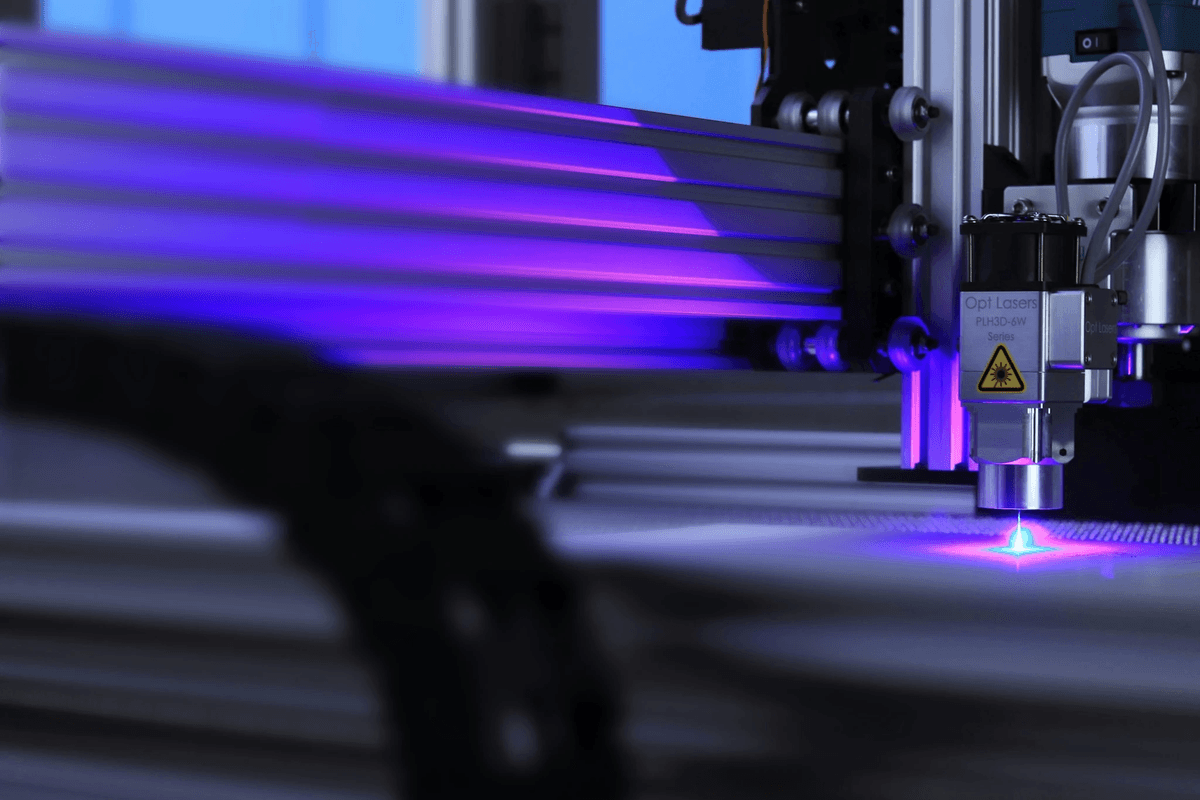

When exploring options for a metal cutting machine laser or other types of large laser cutting machines, you'll encounter various technologies tailored for specific applications. CO2 lasers are popular for their ability to cut through non-metal materials effectively, while fiber lasers excel at high-speed metal processing. Understanding these distinctions is essential for determining which type will best suit your operational needs.

Key Features to Consider

As you evaluate different large laser cutting machines, several key features should be at the forefront of your decision-making process. Look for capabilities such as adjustable power settings, advanced cooling systems, and user-friendly interfaces that enhance both performance and ease of use. Additionally, consider factors like automation options and software compatibility that can streamline workflows in conjunction with your new laser cutting welding machine.

Understanding Your Cutting Needs

Each application requires specific considerations that can significantly impact the efficacy and efficiency of your operations. By assessing material types, determining thickness and size, and evaluating production volume, you can make an informed decision that aligns with your business goals.

Assessing Material Types

The first step in understanding your cutting needs is to assess the types of materials you will be working with. Large laser cutting machines are versatile but excel at different materials such as metals, plastics, and wood. For instance, a metal cutting machine laser may be ideal for steel or aluminum, while a laser welding and cutting machine might better suit softer materials like acrylic or wood.

Each material type has unique properties that affect how the laser interacts with it; some may require higher power settings or different wavelengths for optimal results. Therefore, knowing whether you’ll primarily cut metals or softer substrates will guide you toward the right technology—whether that’s a CO2 system for organic materials or a fiber laser system for metals. In short, assessing material types is not just about what you want to cut; it's about ensuring compatibility with your chosen large laser cutting machine.

Determining Thickness and Size

This factor influences not only the choice of equipment but also how efficiently you can process multiple pieces at once—crucial for high-volume jobs where time is money! Thus, accurately measuring both thickness and size will help streamline operations in any manufacturing setting.

Evaluating Production Volume

Finally, evaluating production volume is essential when selecting a large laser cutting machine tailored to your needs. If you're operating in an environment where high throughput is necessary—think automotive parts or electronics manufacturing—you'll need machinery designed for speed without sacrificing precision. Conversely, if you're focusing on smaller batches or custom projects like signage or artistic applications, flexibility might take precedence over sheer volume.

Understanding production volume also helps gauge how often you'll need maintenance and support services down the line—a critical factor when considering operational costs associated with running a metal cutting machine laser effectively over time! Ultimately, aligning production expectations with equipment capabilities will lead to smoother workflows and higher customer satisfaction rates.

Comparing Different Technologies

CO2 vs. Fiber Laser Systems

CO2 lasers have been around longer and are known for their versatility, particularly in cutting non-metal materials like wood, plastic, and fabrics with precision. They utilize a gas mixture to produce a coherent beam of light, which can be focused to achieve intricate designs on various surfaces. On the other hand, fiber laser systems are gaining traction due to their efficiency in metal cutting; they use solid-state technology that provides higher power density and faster processing speeds.

When comparing these two technologies, consider your specific needs—CO2 lasers excel in diverse materials but may struggle with thicker metals compared to fiber lasers. The latter shines with metals such as stainless steel and aluminum, making it an ideal choice for industries focusing on metal fabrication. Ultimately, the decision hinges on whether your projects lean more towards versatile material usage or specialized metal cutting capabilities.

Advantages of Each Technology

The advantages of CO2 lasers lie primarily in their adaptability; they can handle a wider range of materials including plastics and textiles while still delivering excellent quality cuts. This makes them perfect for businesses involved in varied production lines or custom design work where flexibility is key. Additionally, CO2 lasers often come at a lower initial investment cost compared to fiber systems.

Conversely, fiber laser systems boast remarkable speed and efficiency when it comes to metal cutting applications; they require less maintenance due to fewer moving parts and offer lower operating costs over time. Their ability to cut through thick metals quickly without compromising quality makes them highly sought after by manufacturers looking for productivity gains. Furthermore, fiber lasers generally consume less energy than their CO2 counterparts—great news for eco-conscious businesses aiming for sustainability.

Cost Implications

When considering cost implications between these two types of machines, it's essential to look beyond just the purchase price of the large laser cutting machine itself. While CO2 machines might seem more affordable upfront, their operational costs can add up due to higher energy consumption and greater maintenance needs over time—a factor that could impact your bottom line significantly if you’re running high-volume production.

Fiber laser systems may require a larger initial investment but often prove more economical in the long run due to their efficiency and lower maintenance requirements—this is especially true if you're primarily focused on metal cutting processes like those used in welding machine laser applications or heavy-duty manufacturing tasks involving metal sheets or tubes. Carefully evaluating both short-term purchase costs alongside long-term operational expenses will ensure you make an informed decision that aligns with your business goals.

Evaluating a Brand's Reputation

When it comes to investing in a large laser cutting machine, the reputation of the brand is pivotal. A reputable brand not only assures quality but also provides peace of mind regarding performance and reliability. In this section, we’ll delve into why Kiant Machinery stands out in the crowded field of laser cutting solutions.

The Case for Kiant Machinery

Kiant Machinery has established itself as a leader in the domain of laser cutting technologies, particularly with its innovative large laser cutting machines. Known for their precision and durability, these machines are designed to meet various industrial needs, from metal fabrication to intricate designs. Their extensive range includes advanced models that integrate both laser cutting and welding capabilities, making them versatile tools for any workshop.

Moreover, Kiant Machinery’s commitment to quality is evident through rigorous testing and customer feedback loops that ensure their products continually evolve to meet market demands. The company prides itself on using top-tier components that enhance the longevity and efficiency of their cutting machines, including specialized systems for metal cutting machine lasers. This focus on excellence positions Kiant as a go-to option for businesses looking to optimize their production processes.

Customer Reviews and Case Studies

Customer reviews provide invaluable insights into how well a large laser cutting machine performs in real-world scenarios. Many users rave about Kiant’s machines for their speed and accuracy in both laser welding and cutting applications, often citing specific projects where these machines saved time and reduced waste significantly. Case studies highlight successful implementations across various industries—showcasing how businesses have transformed their operations by integrating Kiant's technology into their workflows.

Additionally, customers appreciate the user-friendly interfaces of Kiant's machines which make training easier for operators new to laser cutting technologies. This ease-of-use contributes to quicker adoption rates within companies looking to scale up production without sacrificing quality or efficiency. The positive testimonials underscore not just satisfaction but also trust in Kiant Machinery as a reliable partner in achieving operational goals.

Industry Certifications and Awards

A strong indicator of a brand's credibility is its collection of industry certifications and awards—something that Kiant Machinery boasts proudly. These accolades are not merely decorative; they reflect adherence to rigorous standards that govern safety, performance, and environmental responsibility within the manufacturing sector of large laser cutting machines. Such certifications assure potential buyers that they are investing in equipment that meets or exceeds industry benchmarks.

Furthermore, awards received by Kiant serve as an endorsement from peers within the industry—recognizing innovation in design and functionality among competitors in metal cutting machine lasers market space. By choosing a brand with such accolades under its belt, you're likely making an investment backed by proven excellence rather than taking a gamble on lesser-known manufacturers.

In conclusion, evaluating a brand’s reputation is essential when selecting your next laser welding and cutting machine; it can make all the difference between success and frustration down the line.

Considering Operational Costs

When investing in a large laser cutting machine, understanding the operational costs is crucial for long-term success. This section delves into maintenance and repair expenses, energy efficiency, and the overall total cost of ownership. By evaluating these factors, you can ensure that your investment in laser cutting technology pays off.

Maintenance and Repair Expenses

Maintenance and repair expenses are key considerations when selecting a metal cutting machine laser. Regular upkeep ensures optimal performance and longevity of the equipment, preventing costly downtime due to unexpected failures. It's essential to factor in not just the routine maintenance costs but also potential repairs that may arise from wear and tear over time.

Moreover, some brands offer better support for their laser welding and cutting machines than others. Choosing a reputable manufacturer can reduce your maintenance burden significantly by providing readily available replacement parts and efficient service options. In contrast, opting for a less-known brand may lead to higher repair costs due to limited support or parts availability.

Lastly, consider the complexity of the large laser cutting machine when assessing maintenance needs. Advanced models with intricate systems might require specialized technicians for repairs, which could further inflate your operational costs compared to simpler machines that are easier to service.

Energy Efficiency of Large Laser Cutting Machines

Energy efficiency is another critical aspect when evaluating operational costs associated with a laser cutting welding machine. These machines consume varying amounts of power based on their technology; thus, selecting an energy-efficient model can lead to substantial savings over time. For instance, fiber lasers tend to have higher efficiency rates compared to CO2 lasers, making them a popular choice among manufacturers focused on minimizing operational expenses.

Additionally, energy-efficient machines often come equipped with features designed to optimize power usage during operation. Such features include standby modes or intelligent cooling systems that reduce energy consumption without compromising performance during laser cutting tasks. By prioritizing energy efficiency in your decision-making process, you'll not only lower your monthly utility bills but also contribute positively toward environmental sustainability.

Finally, don’t forget about how energy-efficient operations can enhance overall productivity in your facility as well! A less energy-intensive large laser cutting machine often means more resources allocated towards production rather than paying hefty electricity bills—leading you closer toward achieving cost-effectiveness without sacrificing quality.

Total Cost of Ownership

The total cost of ownership (TCO) encompasses all expenses related to acquiring and operating a large laser cutting machine over its entire lifespan—making it an essential metric for any business owner considering this investment. TCO includes initial purchase price alongside ongoing costs like maintenance fees, repair expenses (as discussed earlier), electricity consumption rates from operating machinery like metal cutting machines lasers or welding machines lasers.

To calculate TCO accurately involves understanding both direct costs (purchase price) and indirect ones (operational expenditures). It’s wise not only focus on upfront pricing but also evaluate how long-lasting each model will be before needing significant repairs or replacements—this ensures you're making an informed decision based on realistic expectations rather than just appealing marketing figures!

Lastly—but certainly not least—consider potential resale value when determining TCO! Some high-quality brands retain their worth better than others; thus factoring this into your calculations could lead you toward choosing an option that provides maximum returns down the line while still meeting all necessary functional requirements throughout its use phase!

Training and Support Services

When investing in a large laser cutting machine, the importance of training and support services cannot be overstated. Proper user training ensures that operators can effectively utilize the laser cutting welding machine to its full potential, maximizing productivity while minimizing errors. Additionally, ongoing support is crucial for addressing any issues that may arise during operation, ultimately leading to a smoother workflow.

Importance of User Training

User training is essential for anyone operating a metal cutting machine laser or a laser welding and cutting machine. Without adequate knowledge, even the best equipment can lead to costly mistakes or inefficient production processes. Comprehensive training programs not only cover basic operations but also delve into advanced techniques that enhance the capabilities of your cutting machine laser.

Moreover, understanding safety protocols is a critical component of user training. Operators must be well-versed in handling the large laser cutting machine safely to prevent accidents and ensure compliance with industry regulations. This investment in human capital pays off by fostering a skilled workforce capable of optimizing the performance of your laser cutting setup.

After-Sales Support Options

After purchasing a large laser cutting machine, it's vital to consider the after-sales support options available from your vendor. Reliable manufacturers should offer extensive technical support to assist with troubleshooting and maintenance needs as they arise. This assurance allows businesses to operate with confidence, knowing they have access to expert guidance when needed.

Additionally, many vendors provide regular maintenance services as part of their after-sales offerings. These services help extend the lifespan of your metal cutting machine laser and ensure it operates at peak efficiency over time. A good relationship with your supplier can further enhance this support through timely updates about software improvements or new features relevant to your specific model.

Finding a Reliable Vendor

Finding a reliable vendor for your large laser cutting machine is crucial for long-term success in any manufacturing operation involving laser welding and cutting machines. Start by researching potential suppliers who have established reputations within the industry—check customer reviews and case studies that highlight their service quality and product reliability. Engaging with other businesses that use similar equipment can provide valuable insights into which vendors consistently deliver excellent products and support.

It's also wise to evaluate whether potential vendors offer comprehensive training programs alongside their machines; this indicates their commitment not just to sales but also to customer success post-purchase. Look for companies that hold industry certifications or awards as these accolades often reflect dedication to quality standards in both products and service offerings related to your new equipment like the cutting machine laser you are considering.

In conclusion, investing time in training and selecting an appropriate vendor will pay dividends down the road through enhanced operational efficiency and reduced downtime associated with poorly understood machinery or inadequate support systems.

Conclusion

In the world of manufacturing, selecting the right large laser cutting machine can make all the difference in productivity and efficiency. As we’ve explored throughout this guide, understanding your unique cutting needs and comparing technologies are crucial steps in making informed decisions. The landscape of laser cutting is vast, but with the right knowledge, you can navigate it effectively and choose a machine that meets your requirements.

Making Informed Decisions

Making informed decisions about your laser cutting needs requires a thorough assessment of various factors like material types, thickness, and production volume. The right large laser cutting machine should align with your specific applications to ensure optimal performance. Engaging with knowledgeable vendors and seeking customer reviews can also provide valuable insights into which cutting machine laser suits your operations best.

Long-Term Benefits of the Right Machine

Investing in a high-quality laser welding and cutting machine offers long-term benefits that extend beyond initial costs. A reliable metal cutting machine laser enhances production capabilities while reducing downtime due to maintenance issues—an essential factor for any business aiming for growth. Moreover, choosing a durable model ensures consistent performance over time, resulting in better quality products that meet market demands.

Emphasizing Efficiency and Cost-Effectiveness

Efficiency is paramount when it comes to operating a large laser cutting machine; after all, time saved translates directly into cost savings. An energy-efficient laser cutting welding machine not only minimizes operational costs but also contributes to sustainability goals—a win-win situation for any forward-thinking business. By prioritizing both efficiency and cost-effectiveness in your selection process, you set the stage for long-term success in an increasingly competitive market.