Introduction

This advanced technology allows for precision and efficiency that traditional methods simply can't match, making it a go-to choice for many industries. Understanding the intricacies of laser cutting processes is essential for anyone looking to optimize their production capabilities.

Understanding Laser Cutting Processes

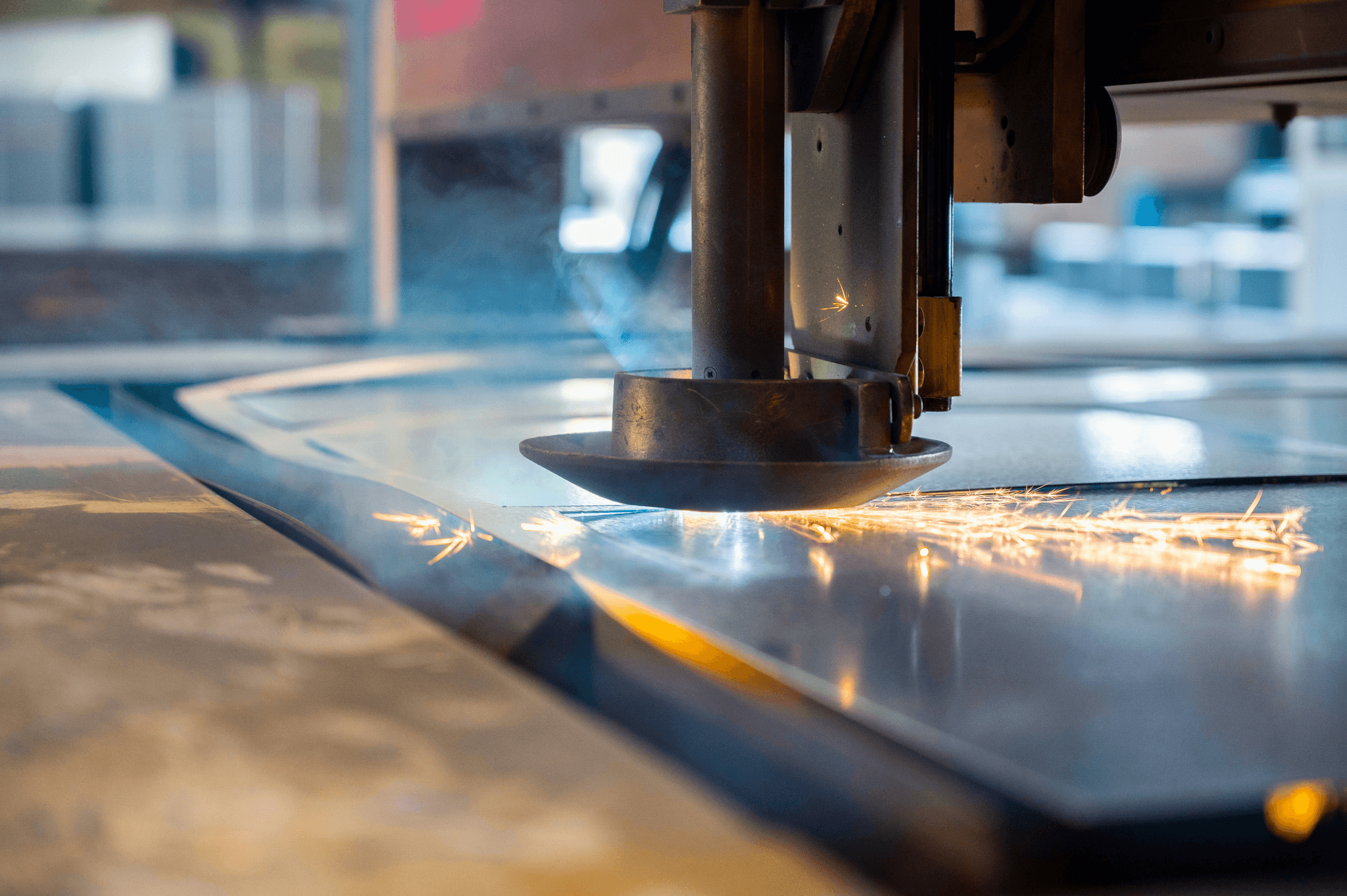

Laser cutting galvanized steel employs focused beams of light to slice through materials with remarkable accuracy. The process involves directing a high-powered laser beam onto the metal surface, where it melts or vaporizes the material along a predetermined path. This method not only minimizes waste but also enhances the quality of cuts in steel sheet metal, providing clean edges and intricate designs.

Importance of Galvanized Steel in Industry

Galvanized steel is vital in various sectors due to its corrosion resistance and durability. Its application ranges from construction to automotive manufacturing, where strength and longevity are paramount. The ability to efficiently cut this material using a cutting laser metal technique ensures that businesses can maintain high standards while meeting demanding production schedules.

Overview of Techniques and Equipment

When discussing laser cutter for metal sheets, it's important to recognize the different types available on the market today. From CO2 lasers known for their versatility to fiber lasers that excel in speed and efficiency, each type has unique advantages tailored for specific applications. Choosing the right equipment is crucial; it not only affects performance but also influences overall project costs and timelines.

What is Laser Cutting Galvanized Steel?

Laser cutting galvanized steel is a modern technique that utilizes focused laser beams to precisely cut through metal sheets coated with zinc for corrosion resistance. This method has gained popularity due to its ability to produce intricate designs and clean edges while minimizing waste and ensuring superior quality. Understanding the nuances of this technology can help industries make informed choices when selecting a cutting laser metal for their specific needs.

Defining Laser Cutting Technology

At its core, laser cutting technology involves directing a high-powered laser beam onto the material, which melts or vaporizes it along a predetermined path. The precision of this process allows for complex shapes and fine details that traditional cutting methods struggle to achieve.

Advantages of Laser Cutting Galvanized Steel

One of the standout advantages of laser cutting galvanized steel is its exceptional precision, which results in minimal kerf width and reduced material waste. Additionally, this method produces clean cuts without the need for extensive post-processing, saving both time and labor costs. Furthermore, using a cutting laser metal minimizes heat-affected zones (HAZ), preserving the integrity of the surrounding material and ensuring structural reliability.

Common Applications of Laser Cut Steel Sheet

Laser cut steel sheets find their way into various industries, from automotive manufacturing to architectural design. In automotive applications, precision-cut parts are essential for performance and safety standards; hence, many manufacturers rely on laser cutting galvanized steel for components like brackets or chassis elements. Similarly, in architecture, intricate designs made from laser cut steel sheet can enhance aesthetic appeal while maintaining durability—making it a popular choice among designers and builders alike.

Types of Laser Cutters for Metal Sheets

CO2 Laser Cutters

CO2 laser cutters have been a staple in the industry for years, particularly favored for their versatility when cutting steel sheet metal. These lasers utilize a gas mixture that produces a high-powered beam capable of slicing through various materials, including thicker gauges of galvanized steel. While they are excellent for detailed work and can produce clean edges on laser cut steel sheets, their slower cutting speeds compared to fiber lasers may not make them ideal for high-volume production environments.

Fiber Laser Cutters

Fiber laser cutters have gained popularity due to their superior efficiency and speed when dealing with metal sheets, especially in applications involving laser cutting galvanized steel. Unlike CO2 lasers, fiber lasers use solid-state technology that allows them to cut through metals with remarkable precision and less energy consumption. This makes them an attractive option for businesses looking to optimize their operations while maintaining high-quality results in cutting steel sheet metal.

Selecting the Right Cutting Laser Metal

Choosing the right cutting laser metal involves considering various factors such as material type, thickness, and application purpose. For instance, if you're primarily working with thinner sheets or require intricate designs on galvanized steel, a CO2 cutter might be suitable; however, if speed and efficiency are paramount—especially in industrial settings—fiber lasers could be your best bet. Ultimately, understanding your specific needs will guide you toward selecting the most appropriate equipment for achieving optimal results in your projects.

Preparing for the Laser Cutting Process

Before diving into the world of laser cutting galvanized steel, it’s essential to lay a solid foundation. Proper preparation can make all the difference in achieving clean, precise cuts and maximizing efficiency. This section will guide you through material selection, surface preparation, and setting up your laser cutter for optimal performance.

Material Selection and Thickness Considerations

Different grades of galvanized steel have varying thicknesses that can significantly affect how well your cutting laser metal performs. Generally, thinner sheets are easier to cut but may require adjustments in speed and focus settings when using a laser cutter for metal sheets.

Thickness considerations also play a vital role in determining the power level needed for your equipment. For instance, if you're working with thicker steel sheet metal, you'll need a more powerful laser cutter to ensure clean cuts without compromising quality. Always consult manufacturer guidelines regarding maximum thickness capacities to avoid frustration down the line.

Additionally, consider the intended application of your laser cut steel sheet; certain projects may demand specific material properties such as corrosion resistance or tensile strength. By carefully selecting materials based on their intended use and thickness, you set yourself up for success right from the start.

Surface Preparation for Optimal Results

Surface preparation is often an overlooked step that can significantly impact the quality of your cuts when working with galvanized steel. Before placing your material into the laser cutter for metal sheets, ensure that it's clean and free from contaminants like oil or dirt which could affect beam absorption during cutting processes. A quick wipe-down with appropriate cleaning agents can do wonders!

Furthermore, any rust or oxidation present on older sheets must be addressed as well; even minor imperfections can lead to uneven cuts or increased wear on your equipment over time. Taking these extra steps will not only enhance cutting efficiency but also prolong the lifespan of both your materials and machinery.

Lastly, consider how you arrange multiple pieces if you're working with several sheets at once—ensuring they are flat and stacked properly will help prevent any potential warping during operation that could compromise accuracy in cutting steel sheet metal.

Setting Up Your Laser Cutter for Success

Now that you've selected suitable materials and prepped them adequately, it's time to turn our attention to setting up your laser cutter for success! Start by ensuring that all components are functioning correctly; check mirrors and lenses for cleanliness since even minor smudges can disrupt beam quality during operation when cutting galvanized steel.

Next comes configuring machine settings tailored specifically to your chosen material's thickness—this includes adjusting speed settings as well as focusing techniques based on guidelines specific to each type of equipment used in cutting laser metal applications. Don’t forget about gas assistance options—using oxygen or nitrogen can improve cut quality while reducing dross formation!

Finally, run test cuts on scrap pieces before proceeding with actual projects; this allows you to fine-tune parameters while ensuring everything operates smoothly without wasting valuable resources on imperfect outcomes when dealing with intricate designs in laser cut steel sheet production.

Techniques for Efficient Cutting Steel Sheet Metal

Focus and Speed Settings

Getting the focus and speed settings just right is crucial for successful laser cut steel sheet operations. The focal point of the laser should be precisely adjusted to ensure a clean cut without excessive heat that could warp the material. Additionally, varying the speed of the laser cutter for metal sheets allows you to balance between cutting depth and quality; slower speeds often yield cleaner edges, while faster speeds can increase productivity.

Finding that sweet spot requires experimentation based on material thickness and type. For instance, thicker steel sheet metal may need slower speeds to maintain precision, whereas thinner materials can be processed more quickly without compromising quality. Ultimately, understanding how focus and speed interact will help you master efficient cutting techniques.

Gas Assistance for Better Cuts

Utilizing gas assistance during laser cutting galvanized steel can dramatically improve your results. Commonly used gases include oxygen or nitrogen; each offers distinct advantages depending on your desired finish. Oxygen assists in combustion for faster cuts but may leave a rough edge, while nitrogen provides a cleaner finish at a slightly slower rate.

Implementing gas assistance not only enhances cut quality but also reduces oxidation on the surface of galvanized steel sheets during processing. This is particularly important when working with materials that require a pristine finish or further treatment post-cutting. By choosing the right gas combination, you can optimize both speed and quality in your cutting steel sheet metal projects.

Troubleshooting Common Issues

Even seasoned professionals encounter hiccups when operating a laser cutter for metal sheets; however, most issues are easily resolved with some troubleshooting know-how. Common problems include inconsistent cuts or excessive dross formation on edges—both of which can stem from incorrect focus settings or inadequate power levels during operation. Regularly inspecting your equipment's alignment will also help maintain consistent performance.

Another frequent issue arises from poor material preparation; ensuring that surfaces are clean and free from contaminants will lead to better outcomes in laser cut steel sheet processes. If you're experiencing unexpected results despite following best practices, consider reviewing your gas settings as well—improper gas flow rates could hinder performance significantly. Remember that troubleshooting is part of mastering any technology; embrace it as an opportunity to learn!

Kiant Machinery: A Leader in Laser Cutting

Kiant Machinery has established itself as a powerhouse in the laser cutting industry, particularly when it comes to processing galvanized steel. Their state-of-the-art technology and innovative approaches have set new standards for precision and efficiency. With a comprehensive range of equipment designed specifically for cutting steel sheet metal, Kiant Machinery is at the forefront of this dynamic field.

Overview of Kiant Machinery's Offerings

Kiant Machinery offers an impressive lineup of laser cutters tailored for various applications, including those focused on laser cutting galvanized steel. Their machines utilize advanced CO2 and fiber laser technologies that ensure high-quality cuts with minimal waste. Additionally, they provide a variety of accessories and software solutions that enhance the functionality of their cutting laser metal equipment.

Benefits of Using Kiant Machinery Equipment

Using Kiant Machinery's equipment for your projects means you can expect enhanced efficiency and superior cut quality when working with laser cut steel sheets. The durability and reliability of their machines translate into less downtime, allowing businesses to meet tight production deadlines without compromising on quality. Moreover, their customer support is top-notch, providing users with expert guidance to optimize their processes when cutting steel sheet metal.

Case Studies of Successful Laser Cutting Projects

Kiant Machinery has been instrumental in numerous successful projects across various industries involving laser cutting galvanized steel. One notable case involved a manufacturing firm that significantly reduced its production time by 30% after integrating Kiant’s fiber laser cutter into its operations. Another project showcased how a custom fabrication shop improved its accuracy while reducing material waste by utilizing advanced settings on Kiant's CO2 lasers for intricate designs in steel sheet metal.

Conclusion

In wrapping up our exploration of laser cutting galvanized steel, it’s clear that this technology is shaping the future of metal fabrication. As industries continue to evolve, the demand for precision and efficiency in cutting steel sheet metal will only increase. Embracing advancements in laser cutting technology will be essential for businesses looking to stay competitive.

The Future of Laser Cutting Technology

The future of laser cutting technology looks bright, with innovations paving the way for even more efficient processes. Emerging technologies like AI and automation are set to revolutionize how we operate laser cutters for metal sheets, enhancing both speed and accuracy. Additionally, as materials science progresses, we can expect new alloys and coatings that will further optimize the results when laser cutting galvanized steel.

Choosing the Right Equipment and Techniques

Selecting the right equipment is crucial when it comes to successfully executing projects involving cutting laser metal. Factors such as material thickness, desired finish quality, and production volume should guide your choice between CO2 or fiber lasers. Furthermore, understanding techniques specific to laser cut steel sheet applications can lead to improved outcomes and reduced waste.

Enhancing Efficiency with Expert Guidance

To maximize efficiency in your operations, seeking expert guidance on best practices is invaluable. Skilled professionals can provide insights into optimizing settings like focus and speed while troubleshooting common issues that may arise during cutting steel sheet metal projects. By leveraging their expertise alongside state-of-the-art equipment from reputable manufacturers like Kiant Machinery, you can elevate your production capabilities significantly.