Introduction

In today's fast-paced industrial landscape, the rise of industrial laser machines has revolutionized the way manufacturing and fabrication processes are conducted. These advanced tools utilize focused beams of light to cut, engrave, and mark materials with unparalleled precision and efficiency. As industries continue to embrace automation and technological innovation, laser machines have become indispensable assets for enhancing productivity.

The Rise of Industrial Laser Machines

The emergence of industrial laser machines can be traced back to significant advancements in laser technology over the past few decades. Initially used for niche applications, these machines have now found their way into mainstream manufacturing sectors such as automotive, aerospace, and electronics. With their ability to deliver high-quality results while reducing waste and operational costs, it's no wonder that businesses are increasingly investing in industrial lasers.

Key Applications of Laser Machines

Laser machines serve a multitude of purposes across various industries, making them incredibly versatile tools in modern manufacturing. From cutting intricate designs in metal sheets to engraving personalized logos on products, the applications are virtually limitless. Moreover, sectors like textiles and woodworking also benefit from the precision that industrial laser machines provide, ensuring high-quality outputs every time.

Why Features Matter in Industrial Laser

High-quality lasers ensure consistent output while robust optics enhance accuracy during operations—both critical for maintaining competitive advantage in today’s market. By focusing on essential features such as speed, user interface design, and maintenance support from manufacturers like Kiant Machinery, businesses can make informed decisions that lead to long-term success.

Core Components of Laser Machines

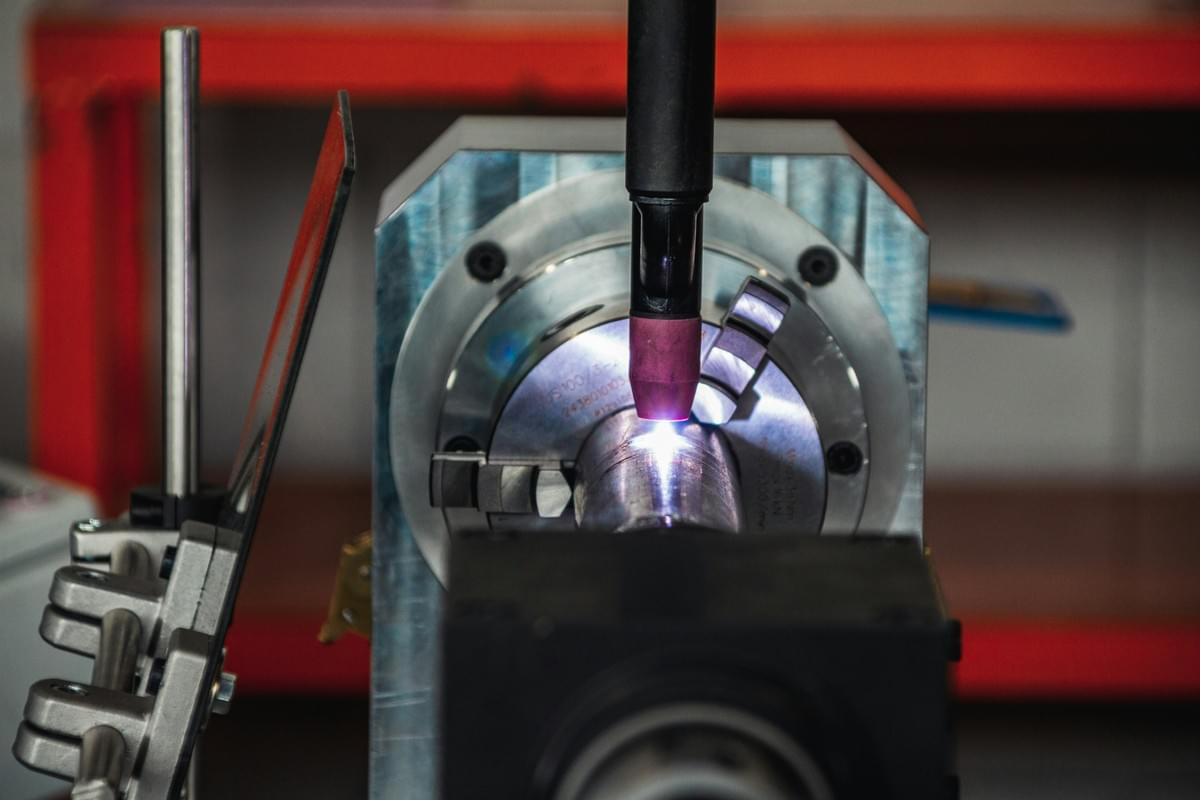

Importance of High-Quality Lasers

High-quality lasers are the heart and soul of any industrial laser machine. The type of laser used directly affects both the power output and beam quality, which are crucial for achieving optimal cutting or engraving results. Investing in superior lasers ensures that your industrial laser performs consistently over time, reducing downtime and maintenance costs while enhancing productivity.

Moreover, high-quality lasers enable greater versatility in applications, allowing operators to work with various materials ranging from metals to plastics with ease. This flexibility is essential for businesses looking to expand their service offerings without needing multiple machines. Therefore, when selecting an industrial laser machine, prioritizing high-quality lasers should be at the top of your checklist.

Role of Optics in Performance

Optics play a significant role in maximizing the performance of industrial laser machines by focusing and directing the laser beam accurately onto the material being processed. The quality of optical components—such as lenses and mirrors—can make or break a machine's efficiency; even minor imperfections can lead to energy loss or reduced precision during operation. Thus, investing in top-notch optics is non-negotiable for anyone serious about achieving excellent results.

Additionally, advanced optical systems can improve beam quality and stability while minimizing distortion during cutting or engraving processes. This not only enhances precision but also prolongs the lifespan of both the optics themselves and other machine components that might suffer from wear due to poor beam focus. In essence, well-designed optics are key players that elevate an industrial laser’s capabilities beyond mere functionality.

Stability Through Solid Construction

The construction quality of an industrial laser machine significantly impacts its stability during operation—a factor that cannot be overlooked if you desire precise outcomes consistently. Machines built with robust materials minimize vibrations that could compromise accuracy during intricate tasks such as engraving detailed designs or cutting complex shapes. A solid construction also contributes to better alignment over time, ensuring that your investment remains reliable throughout its lifespan.

Furthermore, heavy-duty frames often translate into less maintenance effort since they resist wear better than lighter alternatives typically found in lower-end models. This durability means fewer disruptions due to repairs or recalibrations—an essential consideration for businesses operating on tight schedules where downtime can lead to significant losses. Ultimately, choosing an industrial laser machine with solid construction will provide peace of mind knowing you have a reliable tool at your disposal.

Precision and Accuracy in Operations

In the world of industrial laser machines, precision and accuracy are not just buzzwords; they are vital components that define the quality of production. The ability to deliver exact cuts, engravings, or markings can significantly influence the efficiency and outcomes of manufacturing processes. As industries continue to evolve, the demand for laser machines that ensure high levels of precision is more important than ever.

How Laser Machines Ensure Precision

Laser machines achieve remarkable precision through a combination of advanced technology and meticulous engineering. The core component, the laser itself, generates a focused beam that can be manipulated with extreme accuracy to cut or engrave materials with minimal tolerance for error. Additionally, features such as computer numerical control (CNC) systems allow for intricate designs and repeatable patterns, ensuring that every piece produced meets stringent specifications.

Moreover, modern industrial laser machines often incorporate feedback systems that monitor performance in real-time. This capability enables adjustments on the fly to maintain precision even during high-speed operations. Consequently, manufacturers can rely on these machines to deliver consistent results across various applications.

Importance of Repeatability

RThis consistency is essential not only for quality assurance but also for maintaining customer trust in manufactured goods. When businesses invest in high-quality laser machines with robust repeatability features, they position themselves as leaders in their respective markets.

The significance of repeatability extends beyond mere aesthetics; it impacts overall production efficiency and cost-effectiveness as well. In industries where thousands or millions of parts are produced—think automotive or electronics—having a machine that can replicate exact specifications without deviation saves time and reduces waste significantly. Thus, repeatability becomes an integral part of any successful manufacturing strategy.

Applications Benefiting from Accuracy

The applications benefiting from accuracy in industrial laser machines span across numerous sectors—from aerospace to medical device manufacturing—each requiring precise measurements and flawless execution. For instance, in the automotive industry, lasers are used for cutting body panels where even a millimeter off can lead to assembly issues down the line. Similarly, in electronics manufacturing, accurate engraving on circuit boards is crucial for functionality.

Furthermore, industries like jewelry making utilize lasers for intricate designs demanding exceptional detail accuracy; this level of craftsmanship would be nearly impossible without advanced laser technology at their disposal. As we move forward into an era increasingly reliant on automation and precision engineering, it’s clear that industrial laser machines will play a pivotal role across various sectors demanding high standards of accuracy.

Speed and Efficiency Considerations

In the fast-paced world of manufacturing, speed and efficiency are paramount. Industrial laser machines are designed to deliver rapid results without compromising on quality, making them an indispensable tool for businesses looking to optimize their production processes. The right laser machines can significantly enhance throughput, ensuring that projects are completed on time and within budget.

Impact of Speed on Production

The speed at which industrial laser machines operate directly influences overall production rates. Faster cutting speeds mean that more materials can be processed in a shorter amount of time, boosting productivity and reducing labor costs. Additionally, high-speed operations allow manufacturers to meet tight deadlines and respond swiftly to market demands, giving them a competitive edge.

Comparisons with Traditional Cutting Methods

When comparing industrial laser machines with traditional cutting methods, the differences become glaringly obvious. Traditional methods often involve slower processing times and require more manual intervention, which can lead to inconsistencies in quality. In contrast, laser machines offer precision cuts at impressive speeds, minimizing waste while maximizing efficiency—an attractive proposition for any manufacturer.

Boosting Efficiency with Advanced Features

To further elevate performance, many modern industrial laser machines come equipped with advanced features designed specifically to boost efficiency. Innovations such as automated material handling systems or advanced cooling technologies help streamline operations and reduce downtime between tasks. These enhancements not only improve workflow but also ensure that companies can achieve higher output levels without sacrificing quality.

User-Friendly Interfaces and Software

In the world of industrial laser machines, user-friendly interfaces and robust software solutions play a pivotal role in enhancing productivity. As these machines become more sophisticated, the need for intuitive control systems that simplify operations has never been greater. A seamless user experience not only minimizes training time but also maximizes efficiency, allowing operators to focus on what truly matters—getting the job done.

The Role of Intuitive Control Systems

Intuitive control systems are the backbone of effective operation in industrial laser machines. These systems allow users to navigate complex functionalities with ease, reducing the learning curve significantly. When operators can quickly adapt to new machinery without extensive training, it leads to smoother production processes and fewer costly errors.

Moreover, a well-designed interface facilitates real-time monitoring of machine performance, enabling quick adjustments when necessary. This adaptability is crucial in high-stakes environments where precision is paramount. Ultimately, intuitive control systems empower users to harness the full potential of their laser machines while maintaining a high level of operational efficiency.

Importance of Software in Streamlining Workflows

The software that accompanies industrial laser machines is just as critical as the hardware itself; it serves as the command center for operations. Advanced software solutions streamline workflows by automating routine tasks and providing analytical insights that drive decision-making processes. This integration ensures that every aspect of production—from design to execution—is optimized for maximum output.

Furthermore, effective software can facilitate communication between different departments within an organization, ensuring everyone is on the same page regarding project specifications and timelines. By minimizing manual input and potential errors, businesses can significantly enhance their operational efficiency while reducing downtime associated with miscommunication or miscalculations. In short, investing in top-notch software not only boosts productivity but also fosters a culture of collaboration.

Examples of Leading Software Solutions

Several leading software solutions have emerged as favorites among users of industrial laser machines due to their functionality and ease-of-use features. For instance, programs like AutoCAD and SolidWorks are widely used for design purposes before transferring files directly into cutting software compatible with various laser machines. These applications streamline design-to-production workflows by allowing seamless transitions from concept to execution.

Additionally, specialized software like LaserCAD or RDWorks offers tailored functionalities specifically for managing laser cutting jobs efficiently—providing operators with tools designed explicitly for maximizing their equipment's capabilities. Each solution brings unique benefits to the table; however, they all share a common goal: enhancing user experience while optimizing machine performance across various applications.

Maintenance and Support from Manufacturers

In the world of industrial laser machines, maintenance and support from manufacturers are crucial for ensuring optimal performance and longevity. Regular upkeep not only prevents unexpected breakdowns but also maximizes the efficiency of laser machines, keeping production lines running smoothly. A well-maintained industrial laser can significantly reduce downtime, ultimately leading to increased profitability.

Importance of Regular Maintenance

Regular maintenance is essential for any industrial laser machine to operate at peak performance levels. Just like a car needs oil changes and tune-ups, these sophisticated machines require routine inspections and adjustments to keep them in top shape. Neglecting maintenance can lead to decreased accuracy, slower processing speeds, and even costly repairs that could have been avoided with proper care.

Furthermore, consistent maintenance helps maintain the integrity of critical components such as lasers and optics. By regularly checking these parts, operators can identify potential issues before they escalate into major problems. In a competitive landscape where precision and efficiency are paramount, ensuring your industrial laser machines are well-maintained is non-negotiable.

How Kiant Machinery Enhances Support

Kiant Machinery stands out in the industry for its commitment to customer support tailored specifically for users of industrial laser machines. They offer comprehensive service packages that include everything from installation assistance to ongoing technical support, ensuring that customers feel confident in their investment. Their team of knowledgeable technicians is always ready to provide guidance on troubleshooting issues or optimizing machine performance.

Moreover, Kiant Machinery emphasizes proactive communication with clients regarding upcoming maintenance needs or potential upgrades available for their laser machines. This approach not only fosters strong relationships but also empowers users with the information they need to make informed decisions about their equipment's upkeep. With Kiant’s extensive support network, customers can focus on what they do best—producing high-quality products.

Training and After-Sales Services

Training is another vital aspect of maximizing the benefits of industrial laser machines; even the most advanced technology requires skilled operators who know how to use it effectively. Kiant Machinery offers extensive training programs designed to equip users with the necessary skills and knowledge for operating their systems efficiently. This hands-on training ensures that operators understand both basic functions and advanced features of their laser machines.

In addition to training, after-sales services play a significant role in enhancing user experience with industrial lasers. Kiant provides ongoing support through regular check-ins and updates on new software or hardware improvements relevant to existing machinery. This level of commitment not only boosts user confidence but also fosters an environment where continuous improvement becomes part of everyday operations.

Conclusion

In wrapping up our exploration of industrial laser machines, it's clear that these sophisticated devices have revolutionized various sectors by enhancing productivity and precision. Investing in quality industrial laser machines is not just about acquiring equipment; it's about embracing a future where technology meets efficiency and innovation. As industries continue to evolve, the demand for reliable and high-performing laser machines will only increase, making it essential for businesses to prioritize their investments wisely.

Investing in Quality Industrial Laser Machines

When considering the purchase of industrial laser machines, quality should be at the forefront of your decision-making process. High-quality laser machines not only ensure superior performance but also offer longevity and reliability, minimizing downtime and repair costs. By investing in a reputable brand or manufacturer, companies can secure machinery that stands the test of time while delivering exceptional results across various applications.

The Future of Laser Technology in Industry

The future of laser technology in industry looks incredibly promising as advancements continue to unfold at a rapid pace. With innovations such as fiber lasers and improved automation technologies, we can expect even greater efficiency and versatility from industrial laser machines. As industries seek sustainable solutions, these cutting-edge technologies will play a pivotal role in driving productivity while reducing waste and energy consumption.

Choosing the Right Features for Your Needs

Selecting the right features for your industrial laser machine is crucial to maximizing its potential within your operations. Consider factors such as power output, cutting speed, software compatibility, and ease of use when making your choice; each feature can significantly influence overall performance. By aligning your specific needs with the capabilities offered by modern laser machines, you can ensure that your investment yields optimal results tailored to your business objectives.