Introduction

In the fast-paced world of manufacturing, metal fabrication has undergone a revolutionary transformation, paving the way for more efficient and precise methods. At the forefront of this change is the cutting machine laser, which utilizes advanced technology to redefine how we approach metal cutting. Among these innovations, the rise of the China high power fiber laser cutting machine stands out, offering unparalleled capabilities that are reshaping industries worldwide.

Revolutionizing Metal Fabrication

The introduction of metal laser cutting machines has fundamentally altered traditional fabrication processes. With their ability to deliver intricate designs and superior finishes, these machines have become essential tools for manufacturers looking to stay competitive. By utilizing a cutting laser metal approach, businesses can enhance their production capabilities while reducing waste and improving overall efficiency.

Unleashing Precision with Laser Technology

Laser technology has brought a new level of precision to metal machining that was previously unattainable with conventional methods. The accuracy provided by a laser machine allows for tighter tolerances and cleaner cuts, making it ideal for complex projects requiring meticulous attention to detail. As industries increasingly adopt this technology, they benefit from improved product quality and reduced rework costs associated with traditional metal machine cutters.

The Rise of China High Power Fiber Laser Machines

China high power fiber laser machines have emerged as game-changers in the market due to their remarkable performance and affordability. These advanced systems combine high-speed operation with exceptional energy efficiency, allowing manufacturers to maximize productivity without sacrificing quality. As businesses invest in these state-of-the-art solutions, they position themselves at the forefront of innovation in metal fabrication.

What is a China High Power Fiber Laser Cutting Machine?

The China high power fiber laser cutting machine represents a significant leap in metal fabrication technology. Utilizing advanced fiber laser technology, this cutting machine laser offers unparalleled precision and efficiency compared to traditional methods. As industries increasingly demand high-quality metal parts, the metal laser cutting machine has become an essential tool in modern manufacturing.

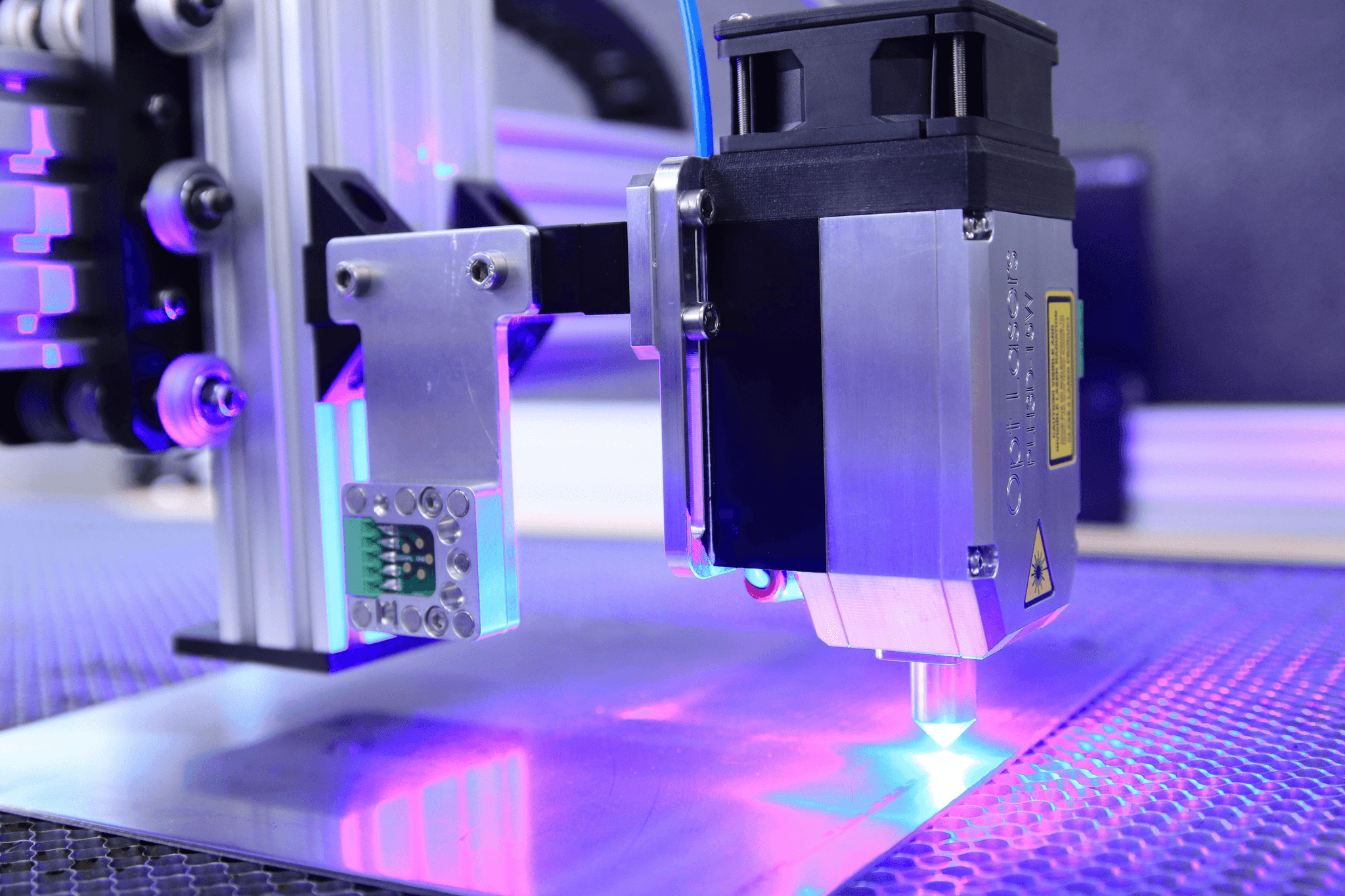

Understanding the Technology Behind the Laser

At its core, the technology behind the china high power fiber laser cutting machine is rooted in fiber optics. This innovative design allows for better light transmission and energy efficiency, making it ideal for cutting various metals with exceptional accuracy. The result? A metal cutting laser cutter that can slice through materials like steel and aluminum with ease, producing clean edges and intricate designs.

Moreover, the compact size of these machines means they can be integrated into existing production lines without requiring extensive modifications. This seamless integration is crucial for manufacturers looking to enhance their operations without significant downtime or investment. In essence, understanding this technology helps businesses appreciate why investing in a cutting laser metal solution can transform their production capabilities.

Key Features and Benefits

One of the standout features of a china high power fiber laser cutting machine is its remarkable speed. These machines can operate at much faster rates than traditional plasma or oxy-fuel cutters, drastically reducing production times while maintaining quality standards. Additionally, they offer enhanced precision—capable of achieving tolerances as tight as 0.01 mm—making them ideal for applications where detail matters most.

Cost-effectiveness also plays a pivotal role in their popularity; companies find that the operational costs associated with running a metal machine cutter are significantly lower than those of other methods due to reduced material waste and energy consumption. Furthermore, maintenance requirements are minimal thanks to fewer moving parts compared to older technologies, leading to longer-lasting equipment and fewer interruptions in workflow.

In summary, the key features of these machines—their speed, precision, cost-effectiveness—combine to create an attractive package for any business involved in metal fabrication or manufacturing processes.

Applications in Various Industries

The versatility of a china high power fiber laser cutting machine makes it suitable for a wide range of industries including automotive, aerospace, electronics, and more. In automotive manufacturing, for instance, these machines are used to produce intricate components that require precise cuts while ensuring structural integrity—critical factors when safety is paramount. Similarly, aerospace applications benefit from their ability to handle lightweight yet strong materials essential for aircraft construction.

Beyond these sectors, industries such as signage production utilize metal laser cutting machines for creating custom designs that stand out visually while being durable against outdoor elements. Even art installations have embraced this technology; artists leverage the capabilities of a cutting machine laser to bring their creative visions to life through precise cuts on various metals.

As we delve deeper into how different sectors utilize these advanced tools—cutting through not just materials but also previous limitations—we see that embracing this technology could redefine what’s possible across manufacturing landscapes worldwide.

Advantages of Metal Laser Cutting Machines

Metal laser cutting machines have transformed the landscape of manufacturing, offering unparalleled advantages that set them apart from traditional methods. The precision and speed they deliver make them essential tools in a variety of industries. By understanding these benefits, businesses can make informed decisions about investing in a cutting machine laser for their operations.

Enhanced Precision and Accuracy

One of the standout features of a china high power fiber laser cutting machine is its ability to achieve remarkable precision and accuracy in metal fabrication. Unlike conventional methods that may leave room for error, the cutting laser metal technology ensures that every cut is executed with pinpoint accuracy, minimizing material waste. This precision not only enhances the quality of the final product but also reduces the need for additional machining processes, saving both time and resources.

Furthermore, metal laser cutting machines can handle intricate designs and complex geometries that traditional metal machine cutters struggle with. The ability to maintain tight tolerances means that manufacturers can confidently produce components that meet exact specifications without compromising on quality. In an industry where every millimeter counts, this level of accuracy is invaluable.

Speed and Efficiency in Production

The rapid processing capabilities of these machines enable manufacturers to significantly increase their output without sacrificing quality. With a china high power fiber laser cutting machine, tasks that once took hours can now be completed in minutes, allowing companies to meet tight deadlines effortlessly.

Moreover, the automation features integrated into modern metal laser cutting machines streamline operations further by reducing manual intervention needed during production runs. This not only speeds up workflows but also minimizes human errors commonly associated with manual handling. As a result, businesses can optimize their production lines while maintaining consistent quality across all manufactured parts.

Cost-Effectiveness Compared to Traditional Methods

Investing in a metal cutting laser cutter may seem daunting initially due to upfront costs; however, when weighing long-term benefits against traditional methods, it's clear they are cost-effective solutions. While traditional techniques often require extensive labor and additional processing steps—leading to increased operational costs—a china high power fiber laser cutting machine significantly reduces these expenses over time through its efficiency and reduced waste generation.

Additionally, lower energy consumption compared to older technologies translates into savings on utility bills as well as reduced environmental impact—a win-win scenario! As industries increasingly prioritize sustainability alongside profitability, adopting advanced technologies like the laser machine becomes an attractive option for forward-thinking manufacturers looking to stay competitive.

The Role of Cutting Laser Metal in Modern Manufacturing

The advent of cutting laser metal technology has dramatically reshaped modern manufacturing processes. With the introduction of the china high power fiber laser cutting machine, production lines have become more efficient and precise than ever before. This shift not only enhances product quality but also significantly reduces lead times, allowing manufacturers to meet the demands of a fast-paced market.

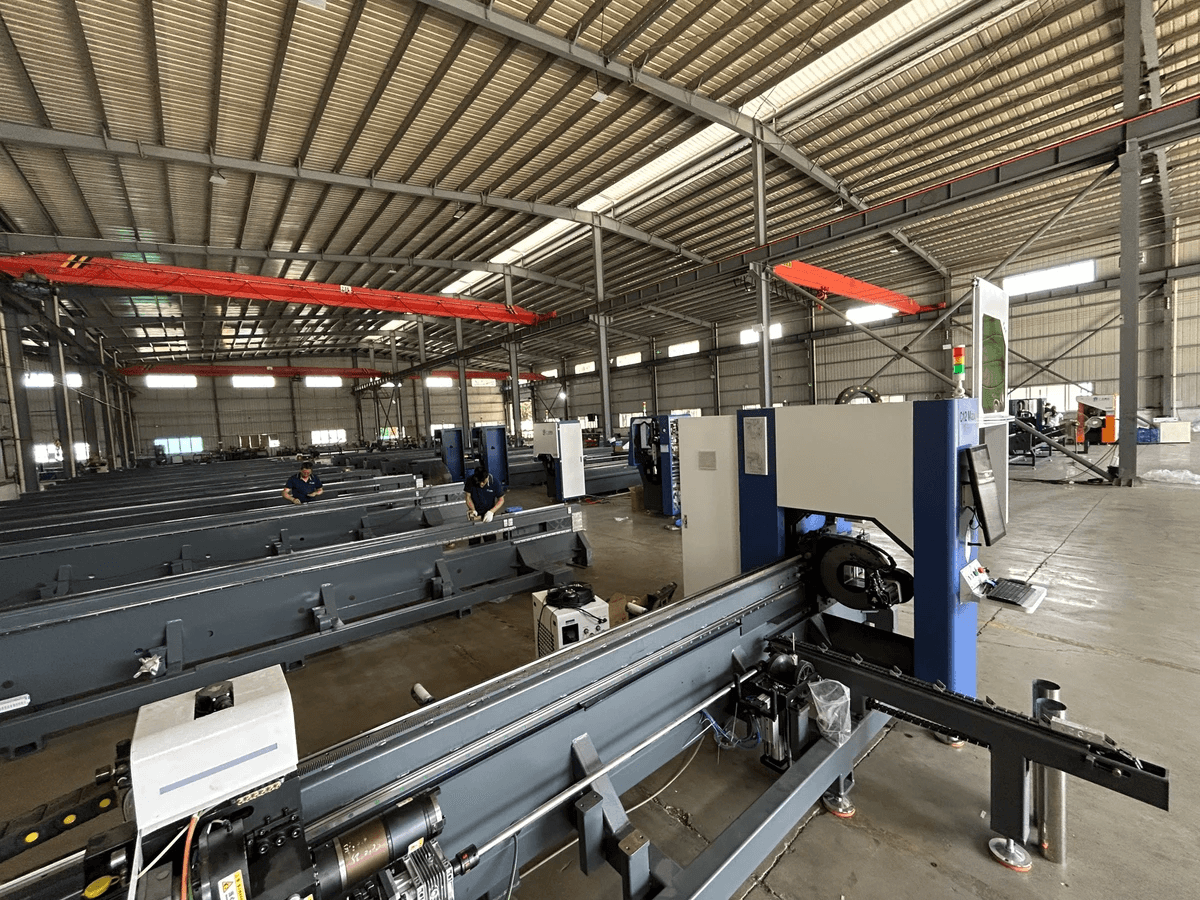

Transforming Production Lines

Production lines across various industries are undergoing a transformation thanks to advanced laser cutting machines. The metal machine cutter, particularly the high power fiber laser variety, streamlines operations by providing unparalleled speed and precision in cutting tasks. By integrating this technology into their workflows, manufacturers can achieve higher throughput while minimizing waste and maximizing resource utilization.

The versatility of a cutting machine laser allows for intricate designs and complex geometries that were once challenging to produce with traditional methods. This adaptability means that businesses can respond quickly to changing customer needs without sacrificing quality or efficiency. As a result, companies equipped with metal laser cutting machines find themselves at a competitive advantage in their respective markets.

Applications in Automotive and Aerospace

In industries such as automotive and aerospace, where precision is paramount, the role of metal cutting laser cutters cannot be overstated. These sectors utilize the china high power fiber laser cutting machine for everything from creating lightweight components to intricate assemblies that require tight tolerances. The ability to cut through various materials with ease makes these machines indispensable in meeting strict safety standards and performance requirements.

Automotive manufacturers leverage laser technology for body panels, chassis components, and engine parts—ensuring every piece fits perfectly together for optimal performance. Similarly, aerospace applications benefit from the lightweight yet strong materials that can be precisely shaped using advanced laser systems. By employing these technologies, companies not only enhance their production capabilities but also contribute to innovations that drive efficiency across entire supply chains.

Integration with Other Manufacturing Technologies

The integration of metal cutting lasers into existing manufacturing setups opens new avenues for innovation and efficiency gains. When combined with automation technologies like robotics or CNC systems, a metal machine cutter becomes part of a seamless production ecosystem capable of operating around the clock with minimal human intervention. This synergy creates opportunities for real-time monitoring and adjustments that optimize output while maintaining quality standards.

Moreover, integrating these advanced systems allows manufacturers to adopt Industry 4.0 principles—where data analytics inform decision-making processes on-the-fly based on production metrics gathered from multiple sources including the laser machine itself. Such interconnectedness ensures that every aspect of manufacturing is fine-tuned for peak performance while reducing downtime caused by manual interventions or outdated practices.

In conclusion, embracing technologies like the cutting laser metal is essential for modern manufacturing success across various sectors including automotive and aerospace industries while facilitating robust integration with other technological advancements.

Kiant Machinery: Your Partner in Laser Solutions

In the ever-evolving landscape of metal fabrication, Kiant Machinery stands out as a key player in providing cutting-edge laser solutions. Specializing in the latest technologies, including the highly sought-after China high power fiber laser cutting machine, Kiant Machinery offers an extensive range of products designed to meet diverse manufacturing needs. From robust metal machine cutters to advanced laser cutting machines, their offerings are tailored to enhance precision and efficiency in various industries.

Overview of Kiant Machinery's Offerings

Kiant Machinery boasts a comprehensive lineup of laser technology solutions that cater to both small-scale operations and large industrial applications. Their flagship products include the state-of-the-art metal laser cutting machines, which utilize innovative fiber laser technology for unparalleled performance. With features like high-speed precision and versatility, these cutting machine lasers are designed to tackle everything from intricate designs to heavy-duty tasks with ease.

In addition to their impressive array of laser machines, Kiant also provides essential support services such as installation, training, and maintenance. This ensures that clients not only receive top-notch equipment but also benefit from expert guidance on how to maximize their investment in a metal cutting laser cutter. With a commitment to quality and innovation, Kiant Machinery is poised to be your go-to partner for all things related to laser solutions.

Customer-Centric Approach to Laser Solutions

Therefore, they take the time to listen and tailor solutions specifically designed around each client's needs—whether it’s customizing features on a China high power fiber laser cutting machine or providing ongoing support after purchase.

This customer-centric approach extends beyond just selling machines; it encompasses building long-lasting relationships with clients through exceptional service and support. Their team of experts works closely with customers throughout the entire process—from initial consultation through implementation—to ensure seamless integration into existing workflows and optimal performance of the metal machine cutter or any other equipment purchased.

Success Stories from Kiant Machinery Clients

The effectiveness of Kiant Machinery's products is best illustrated through the success stories shared by satisfied clients across various industries. Many businesses have reported significant improvements in production speed and accuracy after integrating a metal laser cutting machine into their operations—transforming them into leaders within their respective markets. One notable example includes an automotive manufacturer that increased its output by 30% thanks to the precision offered by their new cutting laser metal system.

Another success story comes from an aerospace company that utilized Kiant’s advanced technology for complex part fabrication while maintaining stringent safety standards—demonstrating how versatile these machines can be across different sectors. These testimonials highlight not only the reliability of Kiant’s offerings but also underscore how investing in a quality cutting machine can lead directly to enhanced operational efficiencies and profitability for businesses willing to embrace modern manufacturing techniques.

Future Trends in Laser Cutting Technology

The future of laser cutting technology is poised for remarkable advancements that will reshape the landscape of manufacturing. With the continuous evolution of the china high power fiber laser cutting machine, we can expect enhanced capabilities and applications that were once thought to be science fiction. Innovations such as improved beam quality and higher power outputs are just the tip of the iceberg in this exciting field.

Innovations on the Horizon

Emerging technologies promise to revolutionize how we perceive metal cutting processes. For instance, advancements in optics and software are set to enhance the performance of metal laser cutting machines, leading to more intricate designs and faster production times. Moreover, new materials and coatings for laser machine components will reduce wear and tear, thereby extending their lifespan significantly.

Additionally, hybrid systems that combine traditional machining with cutting laser metal technologies are gaining traction. These systems offer flexibility by allowing manufacturers to switch between methods depending on project requirements while maintaining accuracy and speed. As these innovations unfold, they will undoubtedly redefine efficiency standards in various industries.

The Impact of AI and Automation

Artificial Intelligence (AI) is not just a buzzword; it's becoming an integral part of modern manufacturing processes, including those involving cutting machines laser technology. By integrating AI algorithms into metal machine cutters, manufacturers can achieve predictive maintenance schedules that minimize downtime and optimize operational efficiency. This means fewer surprises during production runs and a smoother workflow overall.

Automation also plays a critical role in enhancing productivity levels with laser cutting machines. Automated loading systems paired with smart software can streamline operations by managing inventory more effectively and facilitating quicker changeovers between jobs. This synergy between AI and automation ensures that companies leveraging these technologies remain competitive in an ever-evolving market.

Sustainability and Eco-Friendliness in Manufacturing

As environmental concerns take center stage globally, sustainability is becoming a key focus for manufacturers using metal cutting laser cutter technology. The energy efficiency associated with china high power fiber laser cutting machines leads to reduced operational costs while minimizing carbon footprints—an enticing proposition for businesses aiming for eco-friendliness without sacrificing performance.

Furthermore, advancements in recycling practices within the industry mean that waste generated during metal processing can be significantly reduced or repurposed effectively. Manufacturers are increasingly adopting closed-loop systems where scrap material from one process becomes raw material for another—a win-win scenario! Emphasizing sustainability not only meets regulatory requirements but also resonates well with consumers who favor environmentally responsible brands.

In conclusion, future trends indicate a vibrant horizon for laser technology within manufacturing sectors worldwide—driven by innovations on multiple fronts including AI integration, automation enhancements, alongside sustainable practices paving pathways toward greener operations.

Conclusion

As we stand on the brink of a new era in metal fabrication, it’s clear that embracing advanced technologies like the china high power fiber laser cutting machine is essential for staying competitive. The evolution of metal cutting techniques has revolutionized how industries operate, enabling unprecedented levels of precision and efficiency. This transformation not only enhances productivity but also paves the way for innovative designs and applications that were once deemed impossible.

Embracing the Future of Metal Cutting

The future of metal cutting is undoubtedly bright, with advancements in laser technology leading the charge. The integration of cutting laser metal into manufacturing processes means that businesses can achieve higher quality results while reducing waste and operational costs. As industries continue to adopt these sophisticated machines, we can expect to see a significant shift towards more sustainable practices in metal fabrication.

The Importance of Choosing the Right Cutting Machine

Selecting the right cutting machine laser is crucial for any business aiming to enhance its production capabilities. A china high power fiber laser cutting machine offers unique advantages over traditional methods, including superior speed and accuracy that can significantly impact your bottom line. Investing in a reliable metal machine cutter ensures you're equipped to meet customer demands while maintaining high standards of quality.

How to Get Started with Laser Technology

Getting started with laser technology doesn’t have to be daunting; it begins with understanding your specific needs and researching suitable options like a metal laser cutting machine or other advanced solutions available on the market today. Collaborating with experienced suppliers such as Kiant Machinery can provide invaluable insights into selecting and implementing a cutting laser metal system tailored for your operations. With guidance from experts, you’ll be well on your way to harnessing the full potential of modern manufacturing technologies.