Introduction

In the world of precision manufacturing, the China laser cutting machine has emerged as a game-changer, revolutionizing how industries approach metal and material processing. Laser cutting technology offers unparalleled accuracy and efficiency, making it an essential tool for various applications—from intricate designs to mass production. Understanding the nuances of different laser cutting machines can help businesses make informed decisions that align with their specific needs.

Understanding China Laser Cutting Machines

China has become a global leader in producing advanced laser machinery, offering a wide range of options tailored to diverse industry requirements. The typical cutting machine laser utilizes focused beams of light to slice through materials with remarkable precision, ensuring clean edges and minimal waste. As the demand for efficient manufacturing processes grows, understanding the capabilities and specifications of these machines is crucial for any business looking to invest in a metal cutting machine laser.

Key Factors in Machine Selection

Selecting the right laser cutting machine involves evaluating multiple factors that can significantly impact productivity and cost-effectiveness. From understanding material compatibility to assessing production volume requirements, each aspect plays a vital role in ensuring you choose the most suitable model for your operations. Additionally, considering features like automation and software integration can enhance efficiency, making it essential to weigh all options carefully before committing to a purchase.

Applications of Laser Cutting Technology

The versatility of laser cutting technology allows it to be employed across various sectors, including automotive, aerospace, and even artistic endeavors like sign-making or custom jewelry fabrication. With its ability to handle different materials—ranging from metals to plastics—the applications are virtually limitless. As industries continue to evolve towards more sophisticated manufacturing techniques, embracing this technology will be key for businesses aiming to stay competitive in today's fast-paced market.

Types of China Laser Cutting Machines

When it comes to selecting a china laser cutting machine, understanding the various types available is crucial for making an informed decision. Different machines cater to specific needs and applications, from industrial manufacturing to artisanal crafts. Let’s explore the main categories of laser cutting machines that are popular in the market today.

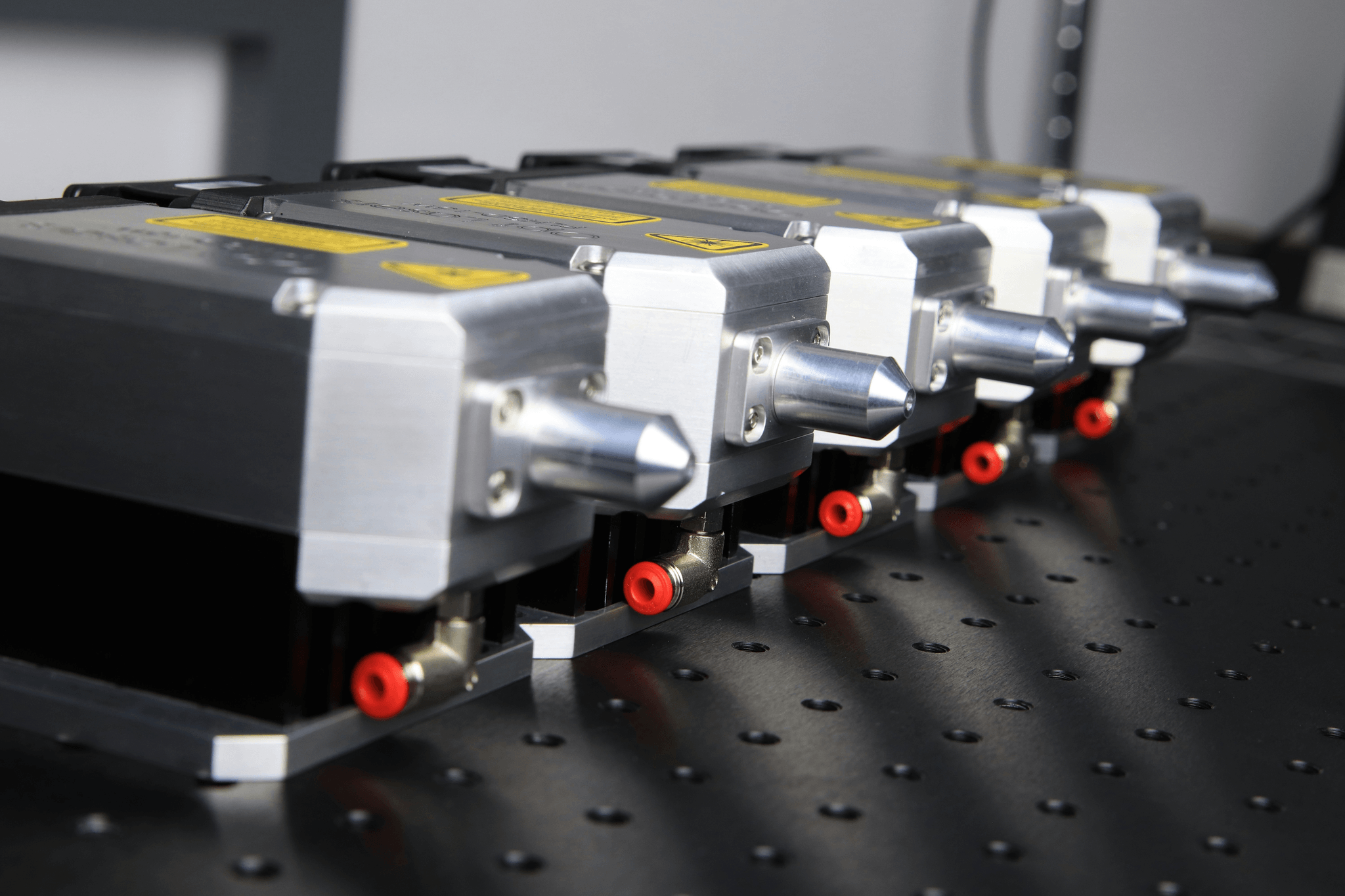

CO2 vs. Fiber Laser Machines

CO2 and fiber laser machines are two primary types of laser cutting technology, each with its own advantages and drawbacks. CO2 lasers are often praised for their versatility, making them suitable for cutting a wide range of materials including wood, plastics, and textiles. On the other hand, fiber laser machines excel at metal cutting; their ability to cut through thick metals with speed and precision makes them a favorite in industries requiring high-performance metal cutting machine lasers.

While CO2 lasers tend to be more cost-effective upfront, fiber lasers offer lower operating costs due to their energy efficiency and reduced maintenance requirements. For businesses focused on high-volume production or intricate designs in metalwork, investing in a fiber laser machine is often worth considering despite the higher initial outlay. Ultimately, your choice between CO2 and fiber will depend on your specific material needs and production goals.

Portable vs. Industrial Models

When it comes to portability versus industrial capabilities in laser machinery, there’s no one-size-fits-all solution; each option has its unique benefits tailored for different users or applications. Portable laser cutting machines are ideal for small workshops or hobbyists who require flexibility without sacrificing quality; they can easily be transported from one job site to another while still delivering impressive results on various materials. These compact models often cater well to smaller projects where space is limited.

In contrast, industrial models are designed for heavy-duty tasks that demand high precision and speed over extended periods—think large-scale manufacturing environments where efficiency is key! These robust china laser cutting machines typically feature larger work areas and more powerful lasers capable of handling thicker materials consistently. Depending on your operational scale, choosing between portable or industrial models will significantly impact your productivity levels.

High-Precision vs. General-Purpose

The distinction between high-precision and general-purpose cutting machine lasers cannot be overstated when selecting the right equipment for your needs. High-precision machines are engineered specifically for intricate designs that require meticulous attention to detail; they’re essential when working with delicate materials or complex geometries where even minor imperfections can lead to significant issues down the line. Industries such as aerospace or medical device manufacturing often rely on these specialized tools.

Conversely, general-purpose laser cutting machines provide versatility across various applications without focusing solely on precision work; they’re perfect for businesses looking for an all-around performer that can handle multiple tasks efficiently—from signage creation to prototyping products quickly! While these general-purpose options may not achieve the same level of detail as their high-precision counterparts, they offer substantial value by accommodating diverse projects at a lower cost point overall. Understanding whether you need precision or versatility will help streamline your decision-making process when investing in a china laser cutting machine.

Assessing Your Cutting Needs

When it comes to investing in a china laser cutting machine, understanding your specific cutting needs is paramount. Each project may require different capabilities, and selecting the right laser cutting machine can significantly enhance your productivity and efficiency. By evaluating material types, production requirements, and customization options, you can ensure that you make an informed choice.

Material Types and Thickness

The first step in assessing your cutting needs is identifying the materials you'll be working with. Laser machinery can handle a variety of materials including metals, plastics, wood, and fabrics; however, the type of laser cutting machine you choose must align with these materials' unique properties. For instance, a metal cutting machine laser will excel at slicing through steel or aluminum but may struggle with thicker or denser materials if not designed for such tasks.

Additionally, thickness plays a crucial role in determining the capabilities of your chosen laser cutting machine. Different machines have varying power levels that dictate how thick a material they can cut effectively without compromising precision or quality. Therefore, carefully considering the types of materials and their thicknesses will help narrow down your options when selecting the perfect laser machine for your needs.

Volume and Production Speed Requirements

Another critical factor is understanding your volume and production speed requirements. If you're operating in a high-demand environment where rapid turnaround times are essential, investing in an industrial-grade china laser cutting machine might be necessary to meet those demands efficiently. On the other hand, if you're working on smaller projects or prototypes, a portable model could suffice while still delivering quality results.

Production speed also varies between different models of laser machinery; some are designed for high-speed operations while others focus on precision cuts at slower speeds. Balancing these aspects will enable you to select a cutting machine laser that aligns perfectly with both your current workload and future growth projections. Take into account not only how quickly you need to produce parts but also how many units you'll need over time to make an informed decision.

Customization and Versatility

Lastly, consider how much customization and versatility you'll need from your china laser cutting machine. Many modern machines offer software compatibility that allows for tailored designs and intricate patterns—ideal for businesses looking to create unique products or components regularly. This level of customization can set you apart from competitors who may rely solely on standard offerings.

Versatility is equally important; having a metal cutting machine laser capable of handling various materials expands your operational capabilities significantly without requiring multiple machines for different tasks. Look for features like adjustable settings that allow quick transitions between projects—this adaptability can save both time and resources as you scale up operations or pivot to new markets.

Evaluating Manufacturer Reputation

When investing in a laser cutting machine, the reputation of the manufacturer plays a crucial role in ensuring you get quality and reliability. A well-regarded company will typically offer advanced technology, robust customer support, and solid warranties that can protect your investment over time. In contrast, lesser-known brands may not provide the same level of assurance or service, which could lead to headaches down the line.

Notable Brands like Kiant Machinery

One standout in the realm of china laser cutting machines is Kiant Machinery, known for its innovative designs and high-performance models. Their laser cutting machines are tailored for various applications, from metalworking to intricate designs on softer materials. With a strong focus on durability and efficiency, Kiant has established itself as a reliable choice for businesses looking to enhance their production capabilities.

Customer Reviews and Case Studies

Customer reviews are an invaluable resource when evaluating a laser cutting machine's effectiveness and user satisfaction. Many users of Kiant's products rave about their precision and speed, highlighting how these machines have transformed their workflows and increased productivity. Additionally, case studies often reveal success stories where companies have significantly reduced waste and improved output quality thanks to advanced features offered by reputable manufacturers.

After-Sales Support and Service

After-sales support is another critical factor when assessing a manufacturer’s reputation in the laser machinery market. A good manufacturer should provide comprehensive training for your new cutting machine laser as well as ongoing technical support to troubleshoot any issues that may arise during operation. Companies like Kiant Machinery often excel in this area by offering extensive resources such as manuals, online tutorials, and dedicated customer service teams ready to assist with any questions or concerns.

Cost Considerations

When investing in a cutting machine laser, it's essential to weigh the initial costs against potential long-term savings. A china laser cutting machine may come with a hefty price tag upfront, but its efficiency and precision can lead to significant reductions in material waste and labor costs over time. This means that while the initial investment might make you wince, the overall financial benefits could have you grinning from ear to ear.

Initial Investment vs. Long-Term Savings

The initial investment in a laser cutting machine can vary widely based on features and capabilities. For instance, a high-end metal cutting machine laser may require more capital than a basic model, but it often pays off through increased productivity and reduced operational downtime. Additionally, advanced technology in these machines often results in lower energy consumption, which adds up to considerable savings on utility bills over the years.

Maintenance and Operating Costs

Owning a laser machinery involves ongoing maintenance and operating costs that should not be overlooked. Regular servicing is crucial for keeping your china laser cutting machine running smoothly; however, these costs are typically lower than those associated with traditional machining methods due to fewer moving parts and less wear-and-tear. Moreover, understanding how much materials like gas or electricity will cost you can help create an accurate budget for operating your new laser cutting equipment.

Financing Options for Your Machine

Financing options are available for those looking to acquire a high-quality laser cutting machine without breaking the bank upfront. Many manufacturers offer leasing plans or installment payments that make it easier to manage cash flow while still gaining access to top-tier technology like fiber or CO2 lasers. Additionally, exploring government grants or incentives for energy-efficient machinery can further ease financial burdens while allowing you to embrace modern manufacturing techniques.

Technological Features to Look For

When investing in a China laser cutting machine, it's essential to consider the technological features that can significantly enhance your cutting experience. The right laser cutting machine can streamline your operations, improve safety, and increase efficiency. Here are some key features to keep in mind during your search for the perfect cutting machine laser.

Software Compatibility and Ease of Use

The software that accompanies a laser cutting machine is crucial for optimizing its performance and ensuring ease of use. A user-friendly interface allows operators to efficiently design and execute cuts without extensive training, making it easier for businesses to integrate new technology into their workflow. Additionally, compatibility with popular design software can save time and reduce errors when transitioning from design to production with your metal cutting machine laser.

Investing in a laser machine that supports various file formats will also enhance versatility, allowing you to adapt quickly to different projects or client needs. With robust software features, you can automate repetitive tasks and improve overall productivity in your operations. Therefore, prioritize machines that offer intuitive software solutions alongside their hardware capabilities for maximum efficiency.

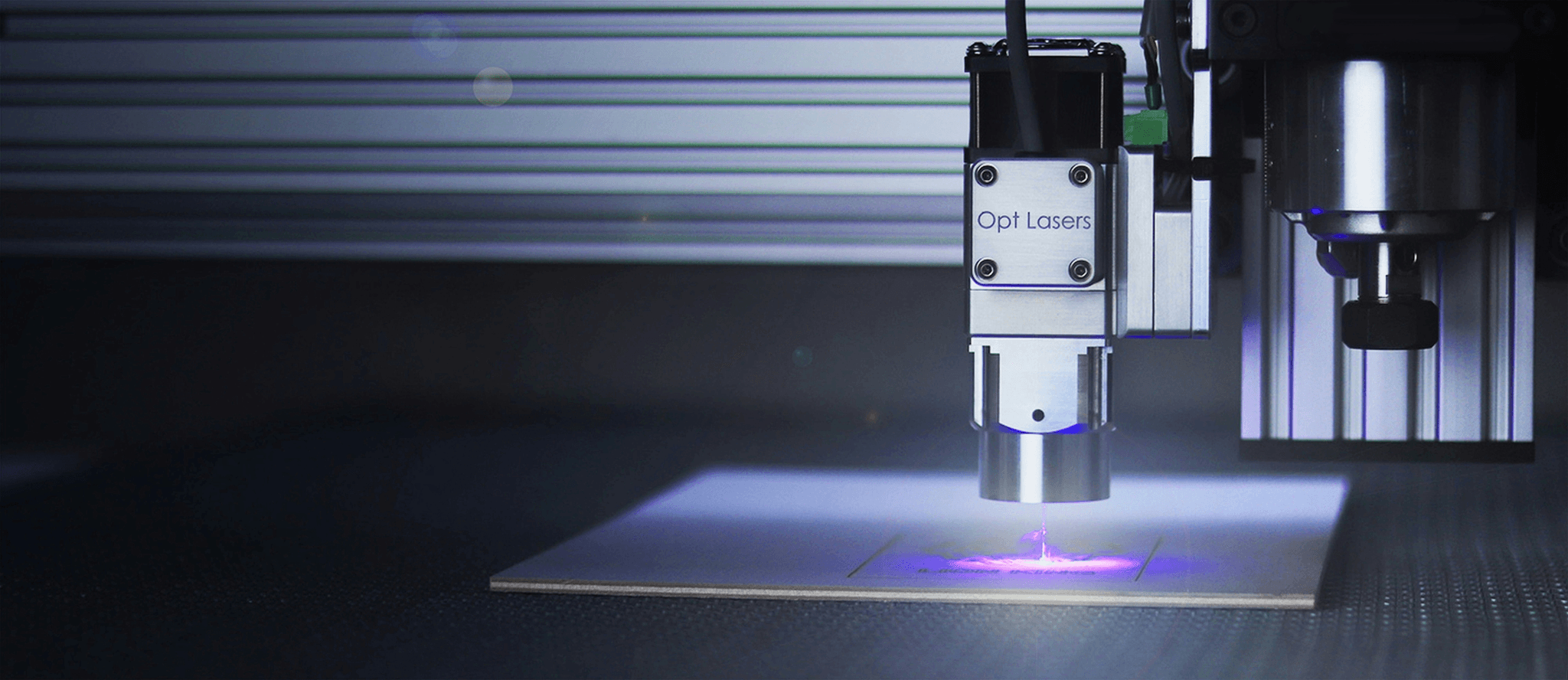

Advanced Safety Features and Automation

Safety should always be a top priority when using any type of machinery, especially when dealing with high-powered tools like a laser cutting machine. Look for models equipped with advanced safety features such as automatic shut-off systems, protective enclosures, and safety sensors that prevent accidents during operation. These enhancements not only protect workers but also minimize downtime due to mishaps or equipment failures.

Automation is another feature worth considering in modern laser machinery; it allows for increased precision and consistency while reducing manual labor requirements. Automated loading/unloading systems can significantly boost production speed by minimizing idle time between cuts. By investing in a China laser cutting machine with these advanced safety measures and automation capabilities, you'll create a safer work environment while enhancing operational efficiency.

Energy Efficiency and Sustainability

In today's environmentally conscious world, energy efficiency is more than just a buzzword—it's an essential factor in selecting the right metal cutting machine laser. Machines designed with energy-saving technologies not only reduce operational costs but also contribute positively to sustainability efforts within your business model. By choosing an energy-efficient laser cutting machine, you’re not just saving money; you're also reducing your carbon footprint.

Look for features such as optimized power consumption settings or regenerative braking systems which help conserve energy during operation without compromising performance quality. Additionally, some manufacturers are now producing eco-friendly machines made from recyclable materials or designed to minimize waste generation during the cutting process. Embracing sustainable practices through careful selection of your China laser cutting machine will position your business as a responsible player in the industry while ensuring long-term savings.

Conclusion

In the ever-evolving landscape of manufacturing, understanding the nuances of a China laser cutting machine can significantly impact your operations. The right laser cutting technology not only enhances efficiency but also ensures precision and quality in production. Therefore, thorough research is essential to navigate the myriad options available in the market.

The Importance of Thorough Research

When considering a cutting machine laser, diving deep into research can save you both time and money in the long run. Evaluating different types of laser machinery allows you to match your specific needs with the right technology, whether it’s CO2 or fiber lasers. Additionally, understanding manufacturer reputations and customer experiences will provide insights that are invaluable for making sound investment decisions.

Making an Informed Decision

Making an informed decision about which metal cutting machine laser to purchase involves weighing various factors such as cost, functionality, and support services. By comparing features and benefits across different models, you can identify a laser cutting machine that aligns with your production goals and budget constraints. Remember that investing in a high-quality laser machine today could lead to significant long-term savings through improved productivity and reduced operational costs.

Embracing the Future with Laser Technology

As industries increasingly adopt innovative technologies, embracing advancements in laser cutting is crucial for staying competitive. A modern China laser cutting machine not only boosts efficiency but also opens up new avenues for creativity and design flexibility in manufacturing processes. By integrating these advanced solutions into your operations, you're not just keeping pace—you're setting the stage for future growth.