Introduction

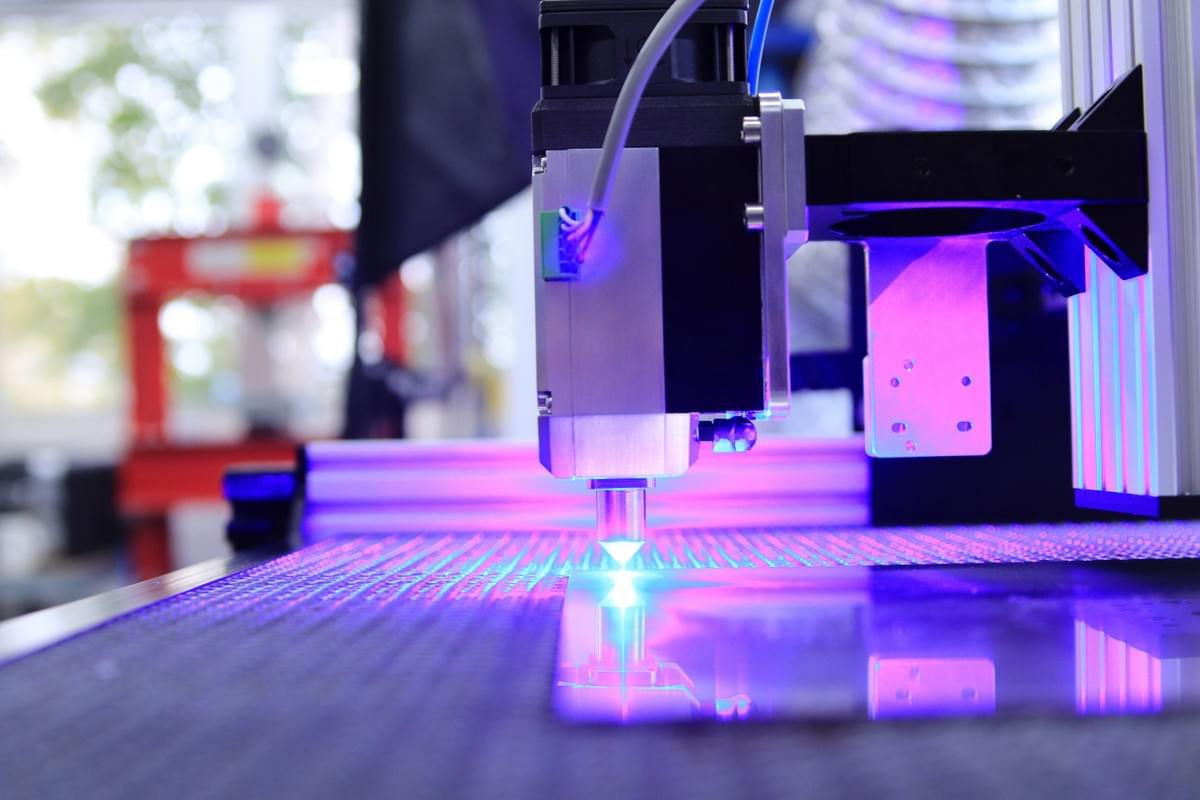

In the ever-evolving world of manufacturing, the advent of fiber laser technology has truly revolutionized metalwork. The fiber laser cutter machine stands at the forefront of this transformation, offering unparalleled precision and efficiency in cutting various metals. With its advanced capabilities, this cutting machine laser is reshaping industries, making processes faster and more cost-effective.

Revolutionizing Metalwork with Fiber Lasers

Fiber lasers have emerged as a game changer in the field of industrial laser cutters, surpassing traditional CO2 laser cutters in numerous ways. Their ability to deliver high-quality cuts with minimal waste is transforming how manufacturers approach metal fabrication. This innovation not only enhances productivity but also opens up new possibilities for intricate designs and applications that were once deemed challenging.

Understanding the Fiber Laser Cutter Machine

At its core, a fiber laser cutter machine utilizes a solid-state laser source to generate a beam that is directed through optical fibers. This technology allows for superior beam quality and efficiency compared to older methods like CO2 lasers. By harnessing this cutting-edge mechanism, users can achieve remarkable results in both speed and accuracy when working with various materials.

Key Benefits of Laser Machinery

The benefits of using laser machinery extend far beyond mere efficiency; they encompass versatility, precision, and cost savings as well. Fiber lasers can cut through thicker materials while maintaining exceptional detail—making them ideal for everything from simple tasks to complex projects requiring a fiber laser engraver or engraving laser cutting machine. As industries continue to embrace these advancements, it’s clear that investing in a fiber laser cutter machine is synonymous with future-proofing operations.

The Science Behind Fiber Laser Technology

This innovative approach not only enhances the efficiency of the cutting machine laser but also opens up new possibilities for industries relying on high-quality metalwork.

How Fiber Lasers Work

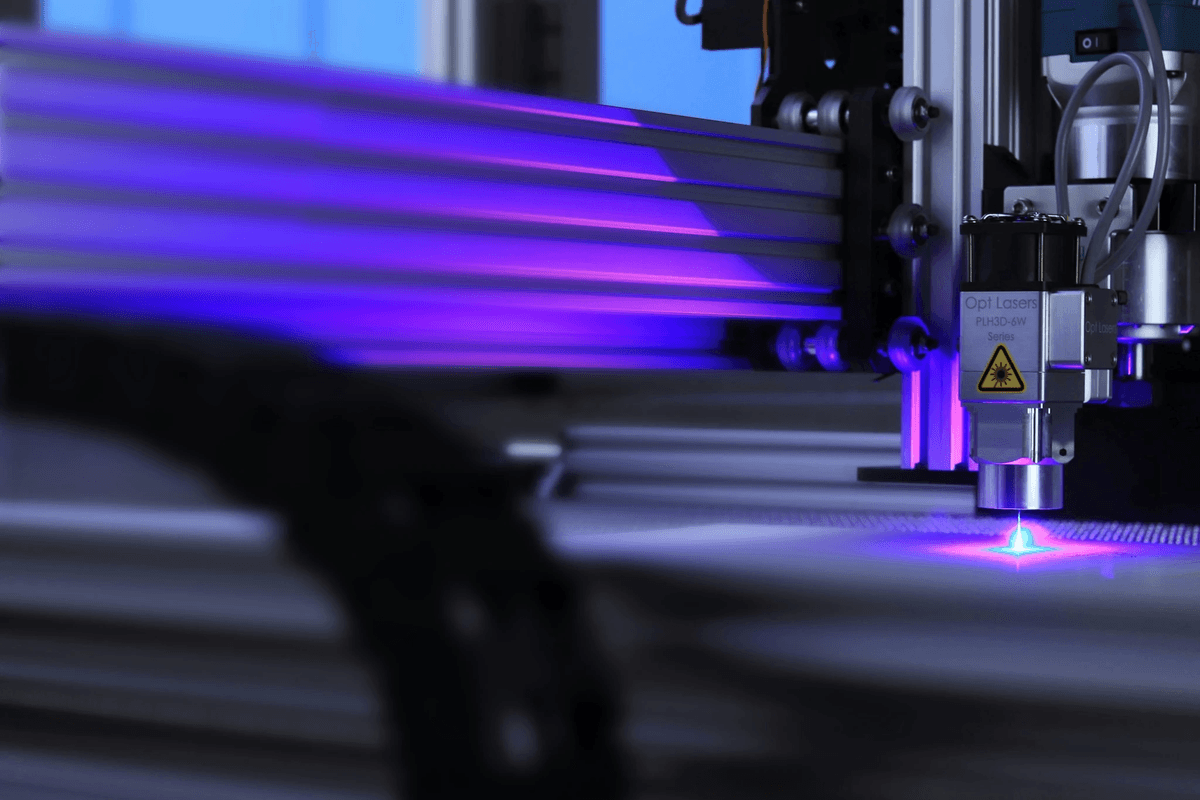

At the heart of a fiber laser cutter machine lies a unique design that utilizes optical fibers as the medium for light generation and amplification. When electrical energy is fed into these fibers, they produce photons that travel through them, resulting in an intensely focused beam capable of cutting through metals with remarkable precision. This process is further enhanced by advanced beam delivery systems that ensure optimal performance, making fiber lasers a preferred choice for industrial laser cutters.

The ability to fine-tune the output power and focus allows fiber lasers to adapt seamlessly to different materials and thicknesses, which is crucial in applications ranging from automotive manufacturing to intricate engraving tasks. Unlike traditional CO2 laser cutters, which rely on mirrors for beam delivery, fiber lasers offer reduced complexity and improved reliability due to their solid-state design. As such, they have become increasingly popular among manufacturers seeking efficient and versatile solutions.

Advantages Over CO2 Laser Cutters

When comparing fiber lasers to CO2 laser cutters, several key advantages emerge that highlight why many industries are making the switch. First and foremost is efficiency; fiber lasers convert up to 30% more electrical energy into usable laser light compared to their CO2 counterparts. This increased efficiency translates into lower operational costs and reduced energy consumption over time—a win-win for businesses looking to optimize their processes.

Additionally, fiber laser cutter machines excel in terms of maintenance requirements; they typically require less upkeep than CO2 systems due to fewer moving parts and no gas refills needed for operation. This not only minimizes downtime but also extends the lifespan of the machinery itself—keeping production lines running smoothly without constant interruptions caused by maintenance issues. Furthermore, their compact size makes them easier to integrate into existing workflows without requiring extensive modifications or additional space.

Precision and Speed in Metal Cutting

One of the standout features of a fiber laser engraver is its unparalleled precision when it comes to cutting metal materials—an essential factor in today’s manufacturing landscape where accuracy can make or break a project. The focused beam generated by these machines allows for intricate cuts with minimal kerf width, ensuring clean edges even on complex designs that would challenge other cutting methods like traditional saws or plasma cutters.

Speed is another critical aspect where fiber lasers shine brightly; they can achieve cutting speeds several times faster than those offered by CO2 systems without sacrificing quality or accuracy. This capability enables businesses using industrial laser cutters to significantly increase productivity while maintaining high standards in their final products—ultimately leading to higher customer satisfaction rates and better profit margins over time.

In conclusion, understanding how fiber lasers work reveals why they have become indispensable tools across various industries—from automotive manufacturing to artistic engraving projects requiring precision craftsmanship—showcasing their versatility as both cutting machine lasers and engraving solutions alike.

Applications of Fiber Laser Cutter Machines

Fiber laser cutter machines are revolutionizing the manufacturing landscape with their unparalleled versatility. These cutting-edge tools can handle a wide range of materials, from stainless steel to aluminum and even intricate designs on plastics. The adaptability of a fiber laser cutter machine makes it an essential asset in various sectors, allowing manufacturers to produce everything from simple components to complex assemblies with ease.

Versatility in Manufacturing

Unlike traditional CO2 laser cutters, which may struggle with certain materials, fiber lasers excel at cutting through metals with precision and speed. This versatility allows businesses to streamline their operations, as one cutting machine laser can effectively replace multiple machines tailored for different tasks.

Moreover, the ability of fiber laser engravers to execute both cutting and engraving tasks enhances their utility in production environments. Whether you’re creating detailed engravings on metal surfaces or executing clean cuts for intricate parts, the engraving laser cutting machine does it all without compromising quality. This multifunctionality not only saves time but also reduces costs associated with maintaining multiple machines.

Industries Benefiting from Laser Technology

The impact of fiber laser technology spans various industries, making it a game-changer for many sectors. Automotive manufacturers leverage industrial laser cutters for high-speed production of parts that require precision engineering, ensuring safety and reliability in vehicles. Similarly, the aerospace industry benefits from the accuracy and efficiency that fiber lasers provide when fabricating lightweight components that meet stringent regulatory standards.

In addition to automotive and aerospace applications, industries such as electronics and medical device manufacturing have also embraced this advanced technology. The ability to cut intricate patterns on small components without damaging them is invaluable in these fields where precision is paramount. As more industries recognize the advantages of using a fiber laser cutter machine over traditional methods like CO2 lasers or mechanical cutters, we can expect this trend to continue growing.

Custom Solutions for Unique Needs

Every business has its unique challenges when it comes to production requirements; that’s where custom solutions come into play with fiber lasers! Manufacturers are increasingly turning toward tailored systems that cater specifically to their operational needs—whether it's adjusting power levels for different materials or incorporating specialized software for design modifications on-the-fly.

These personalized setups allow companies not only greater efficiency but also enhanced creativity in product design—a win-win scenario! For instance, an engraving laser cutting machine could be customized specifically for creating intricate designs on promotional items or custom parts that stand out in competitive markets.

Ultimately, partnering with experts in fiber laser technology can yield solutions designed uniquely for your business needs while maximizing productivity and minimizing waste—qualities every manufacturer aims for today!

Choosing the Right Cutting Machine Laser

Selecting the right cutting machine laser is crucial for optimizing your production processes and achieving quality results. With various options available, including fiber laser cutter machines and CO2 laser cutters, understanding your specific needs is essential. Factors such as material type, thickness, desired precision, and budget will guide your decision-making process.

Factors to Consider for Selection

When choosing a fiber laser cutter machine, consider the materials you’ll be working with. Different lasers excel with various metals; for instance, fiber lasers are ideal for cutting reflective materials like copper and brass that can challenge CO2 laser cutters. Additionally, evaluate the thickness of the materials you plan to cut—fiber lasers generally handle thicker metals better than traditional methods.

Another factor is speed; fiber lasers can significantly reduce cutting time while maintaining high precision. If your business demands quick turnaround times without sacrificing quality, investing in a high-performance industrial laser cutter could be beneficial. Also, think about the level of automation you desire; modern engraving laser cutting machines often come equipped with advanced features that enhance productivity.

Lastly, don’t overlook maintenance requirements and operational costs associated with each type of laser machinery. Fiber lasers typically require less frequent maintenance compared to their CO2 counterparts due to fewer moving parts and longer-lasting components. Assessing these factors will help ensure long-term satisfaction with your chosen cutting machine.

Comparing Fiber with Traditional Cutting Methods

Fiber laser cutter machines are known for their superior energy efficiency—consuming less power while delivering more output compared to older technologies. This efficiency translates into lower operational costs over time.

Precision is another area where fiber lasers shine brightly; they offer finer cuts and intricate designs that traditional methods struggle to achieve consistently. Whether you're working on an industrial scale or needing a reliable fiber laser engraver for detailed projects, these machines provide unmatched accuracy that enhances product quality significantly.

Furthermore, the versatility of fiber lasers allows them to cut through a broader range of materials effortlessly—making them suitable for diverse applications across industries from automotive to aerospace manufacturing. In contrast, traditional methods may be limited by material compatibility or slower processing speeds when dealing with complex shapes or thicker substrates.

Recommendations from Kiant Machinery

At Kiant Machinery, we understand that selecting the right equipment can be daunting given the myriad options available in today's market for cutting machine lasers. We recommend starting with our flagship fiber laser cutter machine designed specifically for optimal performance across various applications—from simple cuts to complex engravings using our advanced engraving laser cutting machine technology.

For businesses focused on maximizing efficiency while minimizing downtime and maintenance costs, our state-of-the-art industrial laser cutters are engineered for longevity and reliability under heavy use conditions. Additionally, we offer tailored solutions based on specific industry needs—ensuring you have access to technology that aligns perfectly with your operational goals.

Finally, don't hesitate to reach out! Our team at Kiant Machinery is always ready to assist you in evaluating your requirements and guiding you toward making an informed investment in top-tier laser machinery that will elevate your production capabilities today and into the future.

Maintenance and Longevity of Laser Machinery

Maintaining your fiber laser cutter machine is essential for ensuring its longevity and optimal performance. Like any sophisticated piece of machinery, regular care can prevent costly repairs and downtime. By following best practices, you can maximize the lifespan of your cutting machine laser while enjoying consistent results.

Best Practices for Care

To keep your fiber laser engraver in top shape, start with a routine cleaning schedule. Dust and debris can accumulate in the machine's components, leading to inefficiencies or damage over time; therefore, a simple wipe-down after each use goes a long way. Additionally, ensure that the optics are regularly inspected and cleaned to maintain precision in your engraving laser cutting machine's performance.

Another critical aspect is monitoring the coolant levels if your industrial laser cutter utilizes liquid cooling systems. Keeping these levels adequate not only helps prevent overheating but also enhances overall efficiency during operation. Lastly, always refer to the manufacturer's guidelines for maintenance schedules specific to your model; this will ensure you don't miss any crucial steps in caring for your laser machinery.

Troubleshooting Common Issues

Even with diligent care, issues may arise with your fiber laser cutter machine from time to time. One common problem is inconsistent cutting quality; this could stem from misalignment or worn-out lenses that need replacement or adjustment. Regularly check for signs of wear on consumables like nozzles and lenses—catching these early can save you from more significant problems down the line.

Another frequent concern involves software glitches or communication errors between the cutting machine laser and design software. If you experience unexpected shutdowns or failures during operation, restarting both systems often resolves minor bugs or connectivity issues. Keep an eye on error messages displayed on the control panel; they often provide helpful clues that guide you in diagnosing problems effectively.

Ensuring Peak Performance Over Time

To ensure peak performance over time with your fiber laser technology, consider investing in regular professional servicing as part of a maintenance plan tailored to industrial needs. These services often include comprehensive checks on all mechanical parts as well as software updates that enhance functionality and security features within your cutting machine laser system. Establishing a relationship with qualified technicians familiar with both fiber lasers and CO2 laser cutters will further extend equipment life.

Additionally, staying informed about advancements in technology can help you integrate new features into existing machinery seamlessly—this not only boosts productivity but also keeps operations competitive within the industry landscape. Finally, encourage operators to undergo training sessions regularly; skilled personnel are key players in maximizing efficiency and minimizing risks associated with improper handling of complex equipment like engraving laser cutting machines.

Future Trends in Industrial Laser Cutters

The future of industrial laser cutters is bright, with advancements poised to redefine manufacturing processes and capabilities. As technology evolves, the fiber laser cutter machine stands at the forefront, promising enhanced performance, efficiency, and versatility. Innovations in this field are set to revolutionize how industries approach metalworking and precision cutting.

Innovations on the Horizon

Emerging technologies are continually enhancing the capabilities of fiber lasers, making them more efficient and user-friendly. For instance, developments in beam quality and power density are allowing fiber laser engravers to achieve even finer details with faster cutting speeds than traditional CO2 laser cutters. Additionally, new software solutions are being integrated into cutting machine lasers, enabling smarter operation through real-time monitoring and predictive maintenance.

These innovations not only improve productivity but also expand the range of materials that industrial laser cutters can handle effectively. Manufacturers can expect advancements that allow for greater customization options while reducing waste—making processes leaner than ever before. As we look ahead, these breakthroughs will undoubtedly make fiber lasers indispensable tools across various sectors.

The Role of Automation in Laser Cutting

Automation is becoming increasingly vital in enhancing the efficiency of laser machinery operations. With automated systems integrated into fiber laser cutter machines, businesses can streamline their workflow from design to production without compromising on precision or speed. This shift towards automation not only reduces human error but also maximizes output by allowing machines to operate continuously with minimal downtime.

Furthermore, automation enables manufacturers to quickly adapt to changing demands by reprogramming engraving laser cutting machines for different tasks with ease. This flexibility is particularly beneficial for industries that require rapid prototyping or custom solutions tailored to specific client needs. As automation continues to evolve within this space, we can anticipate a future where industrial laser cutters become even more intelligent and autonomous.

Sustainability and Eco-Friendly Practices

As industries strive for sustainability, fiber laser technology is emerging as a champion of eco-friendly practices in metalworking. Compared to traditional CO2 laser cutters, fiber lasers consume less energy while delivering superior performance—making them an environmentally friendly choice for manufacturers looking to reduce their carbon footprint. The precise nature of these cutting machine lasers also minimizes material waste during production.

Moreover, many companies are exploring ways to recycle scrap materials generated during the cutting process effectively; innovations in this area can further enhance sustainability efforts within manufacturing environments using fiber lasers. By embracing eco-conscious practices alongside advanced technology like the fiber laser cutter machine, industries not only contribute positively towards environmental preservation but also appeal to consumers who prioritize sustainable products.

Conclusion

In an era where precision and efficiency are paramount, the fiber laser cutter machine stands out as a game-changer. With its ability to handle various materials with unmatched accuracy, businesses can maximize productivity while minimizing waste. As industries continue to evolve, investing in advanced laser machinery like fiber lasers is essential for staying competitive.

Maximizing Efficiency with Fiber Lasers

The fiber laser cutter machine is engineered to deliver superior performance, making it an ideal choice for modern manufacturing needs. Its rapid cutting speeds and high precision reduce production times significantly compared to traditional methods like the CO2 laser cutter. By harnessing the power of fiber lasers, companies can streamline operations and achieve remarkable efficiency gains.

Transforming Industries through Laser Technology

Laser technology has revolutionized sectors ranging from automotive to aerospace, enabling intricate designs and complex shapes that were once difficult or impossible to achieve. The versatility of the cutting machine laser allows for seamless transitions between tasks, whether it's cutting or engraving with a fiber laser engraver or more specialized applications using an engraving laser cutting machine. As industries embrace this transformative technology, they unlock new possibilities for innovation and growth.

Partnering with Kiant Machinery for Success

To fully leverage the benefits of fiber laser technology, partnering with a reputable provider like Kiant Machinery is crucial. Their expertise in industrial laser cutters ensures you receive tailored solutions that meet your specific requirements while optimizing your operational efficiency. With Kiant Machinery by your side, you can confidently invest in state-of-the-art equipment that drives success in your business.