Introduction

In the world of precision cutting and engraving, CO2 laser cutters have carved out a significant niche. These cutting machines utilize advanced laser technology to create intricate designs in various materials, making them essential tools for many industries, from woodworking to manufacturing. Understanding the nuances of CO2 laser cutter price is crucial for anyone looking to invest in this technology.

Understanding CO2 Laser Cutters

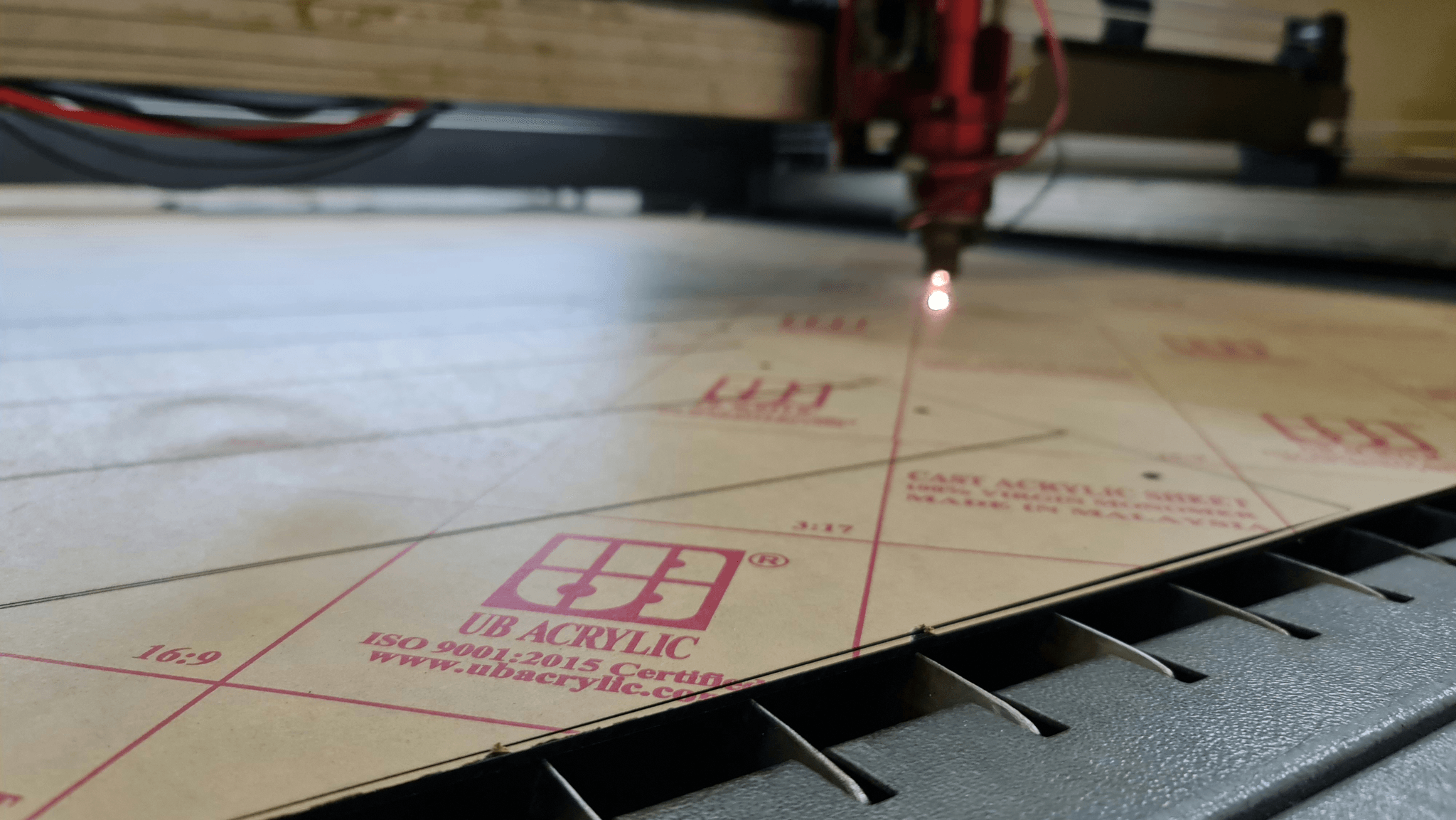

CO2 laser cutters operate by directing a high-powered beam of light through various mediums, allowing for clean and efficient cuts. This type of laser machinery is particularly favored for its versatility in cutting different materials such as wood, acrylic, and even some metals. As you delve into the realm of a laser cutter, it’s important to grasp how these machines function and their potential applications.

The Importance of Pricing in Laser Machinery

When considering a CO2 laser cutter, pricing plays a pivotal role in decision-making. The right investment can significantly impact your business's productivity and profitability; therefore, understanding what influences the cost is essential. From entry-level models to high-end woodworking laser cutters, knowing how each factor contributes to the overall price can help you make an informed choice.

Factors Influencing CO2 Laser Cutter Price

Several elements come into play when determining the price of a CO2 laser cutter. Material quality and build durability are paramount; higher-quality components often lead to better performance and longevity. Additionally, features such as cutting machine lasers' power output and brand reputation can greatly affect pricing dynamics within this competitive market.

What Affects CO2 Laser Cutter Price

The material and build quality, cutting machine laser features, and brand reputation all significantly influence the overall cost. By delving into these aspects, you can make a more informed decision about which woodworking laser cutter or laser engraver & cutter best suits your needs.

Material and Build Quality

The material and build quality of a CO2 laser cutter are paramount in determining its price. High-quality materials not only enhance durability but also improve the cutting precision of the machine. For instance, a well-constructed cutting machine laser made from robust components will naturally command a higher price than one built with cheaper materials that may compromise performance over time.

Investing in a solidly built CO2 laser engraver can save you money in the long run by reducing maintenance costs and extending the lifespan of your equipment. Additionally, machines made from premium materials often come with better warranties, providing further assurance of their value. Therefore, when considering CO2 laser cutter prices, it’s wise to evaluate how material choices impact both durability and functionality.

Cutting Machine Laser Features

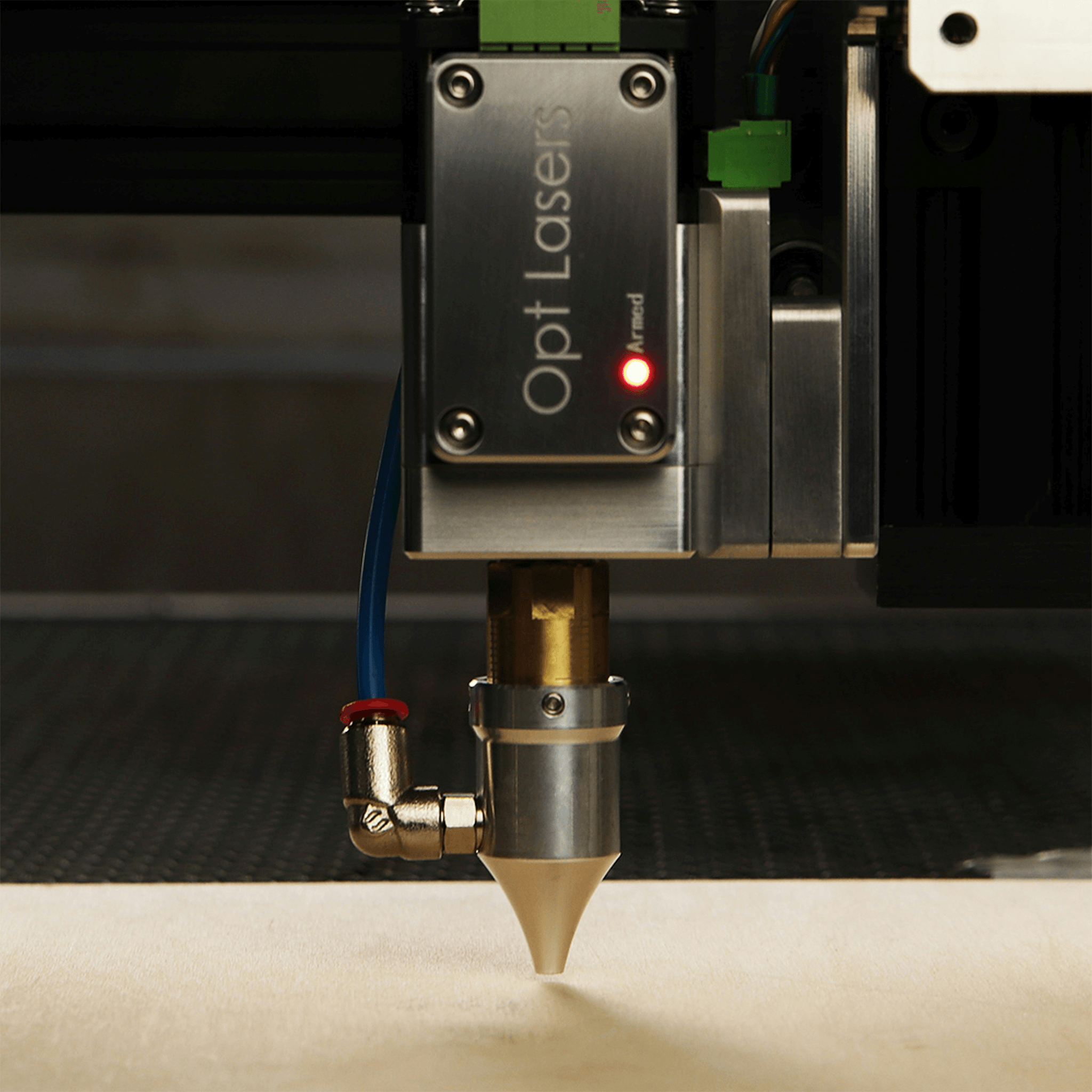

The features included in a cutting machine laser can significantly affect its price point as well. Advanced functionalities such as higher wattage options for faster cutting speeds or intricate engraving capabilities will typically increase costs compared to basic models. Features like automatic focus adjustment or integrated software for design work also add to the overall value of a CO2 laser cutter.

Moreover, specialized features designed for specific applications—like those found in woodworking laser cutters—can lead to varied pricing structures within the market. Buyers should carefully assess which features are essential for their projects versus those that might be nice to have but unnecessary for their current needs. Ultimately, understanding how these attributes impact both performance and cost is crucial when exploring CO2 laser cutter prices.

Brand Reputation and Warranty

Brand reputation plays an important role in determining the price of any machinery—including CO2 laser cutters—and this is especially true within specialized markets like engraving and cutting technology. Established brands often charge more because they have built trust through years of reliable performance and customer service support. A reputable brand usually offers better warranty options as well, which can provide peace of mind regarding your investment.

Choosing a lesser-known brand may save you some upfront costs; however, it could result in hidden expenses down the line due to poor customer support or inadequate parts availability for repairs or upgrades. Additionally, many high-end brands invest heavily in research and development to innovate their products continually; thus enhancing user experience while justifying higher co2 laser cutter prices over time. In summary, while it might be tempting to go for lower-priced options initially, considering brand reputation can lead you toward smarter long-term investments.

Comparing CO2 Laser Cutter Prices

When diving into the world of CO2 laser cutters, price comparison is essential for making an informed decision. The market offers a spectrum of options, from budget-friendly models to high-end machines that boast advanced features. Understanding these variations in pricing can help you find the perfect cutting machine laser for your needs.

Entry-Level vs. High-End Models

Entry-level CO2 laser cutters are designed for hobbyists and small businesses, typically ranging from $200 to $1,500. These models offer basic functionality and are often sufficient for simple projects like engraving and light cutting tasks. On the other hand, high-end models can range from $5,000 to over $20,000 and come equipped with superior features such as larger work areas, faster cutting speeds, and enhanced precision—ideal for professional woodworking laser cutter applications.

While entry-level machines may be tempting due to their lower CO2 laser cutter price, investing in a high-end model can provide long-term benefits that justify the higher initial cost. Users looking to expand their capabilities or handle more complex projects will find that high-quality machinery pays off in performance and reliability over time. Ultimately, choosing between entry-level and high-end models comes down to your specific needs and budget.

Cost of Woodworking Laser Cutters

Woodworking enthusiasts often seek specialized CO2 laser engravers tailored for crafting intricate designs on wood materials. The cost of woodworking laser cutters varies significantly based on power output (measured in watts), build quality, and additional features like rotary attachments or upgraded software packages. Generally speaking, prices for woodworking-focused machines start around $1,000 but can climb steeply depending on the specifications you require.

For those just starting out or running small-scale operations, budget-friendly options exist that still deliver decent performance without breaking the bank. However, as your business grows or if you plan on tackling larger projects with thicker materials, investing in a more powerful machine becomes necessary—often pushing the co2 laser cutter price into higher brackets but offering unmatched efficiency in return. Balancing initial costs against potential revenue generation is crucial when considering a woodworking-focused cutting machine laser.

Market Trends in Laser Engraver & Cutter Pricing

The market trends surrounding CO2 laser cutter prices are continually evolving due to advancements in technology and increasing competition among manufacturers. Recently observed trends indicate a gradual decrease in prices across many segments of the industry as new players enter with innovative solutions at competitive rates—making it easier than ever for businesses to invest in quality machinery without overspending.

Additionally, consumer demand has shifted toward eco-friendly practices; hence many manufacturers are focusing on sustainable production methods that can affect pricing structures positively over time while maintaining quality standards within their offerings of co2 laser engravers and cutters. As these trends continue to develop further into 2024 and beyond, staying informed about shifts within this dynamic marketplace will be vital for any business looking to make smart investments.

The Value of Investing in a Quality Laser Cutter

Investing in a quality CO2 laser cutter is more than just purchasing a cutting machine laser; it’s about securing your future in the competitive market of woodworking and engraving. While the initial CO2 laser cutter price may seem steep, the long-term benefits often outweigh the upfront costs. A reliable laser engraver & cutter can transform your business operations, leading to significant cost savings and improved productivity.

Long-Term Cost Savings

One of the most compelling reasons to invest in a high-quality CO2 laser cutter is the potential for long-term cost savings. Cheaper models may save you money initially, but they often require frequent repairs or replacements, driving up overall expenses over time. In contrast, a durable cutting machine laser from reputable brands tends to have lower maintenance costs and longer lifespans, making it a smarter financial choice.

Moreover, high-end woodworking laser cutters typically offer better energy efficiency and faster processing speeds. This means you can complete more projects in less time without sacrificing quality, ultimately allowing you to take on more clients or larger contracts. As profits increase due to these efficiencies, you'll find that your investment pays for itself faster than you might expect.

Efficiency and Performance Benefits

A well-built cutting machine laser will provide consistent results across various materials—be it wood, acrylic, or metal—enabling you to expand your service offerings with confidence. This versatility not only attracts more customers but also enhances your reputation as an expert in the field.

Additionally, advanced features found in higher-priced models enhance operational efficiency by minimizing downtime and maximizing output quality. For instance, features like automatic focus adjustments and enhanced cooling systems can dramatically reduce setup times while ensuring optimal performance during operation. Overall, these enhancements translate into greater productivity levels that directly impact your bottom line.

Case Study: Kiant Machinery Solutions

To illustrate these points further, let’s take a look at Kiant Machinery Solutions—a company that embraced quality over price when selecting their CO2 laser cutter. Initially hesitant about spending extra on their cutting machine laser purchase due to budget constraints, they soon discovered that investing in a premium model resulted in lower operational costs and increased throughput within just six months of use.

Kiant's decision paid off as they were able to handle larger projects without sacrificing quality or speed thanks to their reliable woodworking laser cutter’s capabilities. Their customer satisfaction skyrocketed due to quicker turnaround times and consistently high-quality products—leading them not only to recoup their initial investment but also significantly boost profits year-over-year.

In conclusion, choosing the right CO2 laser engraver is crucial for any business looking for growth opportunities while maintaining cost-effectiveness over time.

Budget-Friendly Options for Your Laser Needs

When diving into the world of CO2 laser cutters, finding a budget-friendly option can feel like searching for a needle in a haystack. Fortunately, there are several affordable choices that deliver excellent performance without breaking the bank. Whether you're a hobbyist or running a small business, investing wisely in laser machinery can yield impressive results while keeping your expenses in check.

Top Affordable CO2 Laser Engravers

The market is brimming with options when it comes to affordable CO2 laser engravers. Models such as the K40 and the Ortur Laser Master 2 are popular among beginners and those looking for cost-effective solutions. These woodworking laser cutters provide decent cutting capabilities while maintaining a competitive price point, making them ideal for anyone keen on exploring laser engraving and cutting without overspending.

Additionally, brands like Glowforge offer entry-level models that balance quality and affordability, catering to both enthusiasts and small business owners. While these options may not have all the bells and whistles of high-end machines, their reliability ensures you get good value for your investment in laser machinery. Remember to evaluate features like cutting speed and precision against their price tag to find the best fit for your needs.

Financing Options for Small Businesses

For small businesses eyeing a CO2 laser cutter but wary of upfront costs, financing options can be a game changer. Many retailers offer payment plans or leasing programs that allow you to spread out payments over time while still getting access to top-notch cutting machine lasers. This approach not only eases financial pressure but also enables you to invest in better technology that could enhance productivity.

Moreover, some financial institutions provide loans specifically tailored for equipment purchases, including CO2 laser engravers and cutters. Researching these options will help you identify which financing route aligns with your budgetary constraints and long-term goals as an entrepreneur in the woodworking industry or beyond. With smart financing strategies in place, you can secure a quality machine without compromising your cash flow.

Cost-Effective Maintenance Tips

Owning a CO2 laser cutter doesn’t end at purchase; proper maintenance is key to ensuring longevity and optimal performance of your equipment while keeping costs low. Regular cleaning of lenses and mirrors is essential; dirt buildup can affect cutting quality significantly over time if neglected. Additionally, creating an organized workspace minimizes debris accumulation around your cutting machine lasers.

Another cost-effective tip is to perform routine checks on belts and motors; replacing worn-out parts early can prevent more significant issues down the line that might lead to expensive repairs or downtime. Lastly, consider joining online communities where fellow users share advice on maintaining specific models—this collective knowledge can save you both time and money when troubleshooting minor problems with your CO2 laser cutter or engraver.

Future Trends in the CO2 Laser Market

As technology continues to evolve, the CO2 laser market is poised for significant advancements that will reshape how we view laser machinery. Innovations in laser cutters are not just about enhancing performance; they also focus on improving user experience and expanding capabilities for various applications. With the increasing demand for precision and efficiency, manufacturers are investing heavily in research and development to bring cutting-edge features to their CO2 laser engravers and cutters.

Innovations in Laser Machinery

The latest innovations in cutting machine lasers include features such as enhanced beam quality, faster cutting speeds, and improved software interfaces that simplify operation. These advancements allow users to achieve cleaner cuts with less waste, making a woodworking laser cutter more efficient than ever before. Additionally, integration with smart technologies like IoT (Internet of Things) enables real-time monitoring and maintenance alerts, ensuring optimal performance while minimizing downtime.

Another exciting development is the introduction of hybrid systems that combine CO2 lasers with fiber lasers. This combination allows users to cut a wider range of materials effectively, from wood to metals, providing versatility that can cater to diverse business needs. As these innovations emerge, it's clear that the future of laser machinery will be defined by adaptability and enhanced functionality.

Eco-Friendly Developments in Cutting Technology

Sustainability is becoming a key concern for many industries today, including those utilizing CO2 laser cutters. Manufacturers are now focusing on eco-friendly developments that reduce energy consumption during operation while maintaining high performance levels. Advances such as energy-efficient components and optimized cutting processes are helping businesses lower their carbon footprint without sacrificing quality.

Moreover, there’s a growing trend toward using sustainable materials with CO2 lasers—like biodegradable plastics or recycled woods—which aligns perfectly with eco-conscious consumer demands. This shift not only enhances brand reputation but also opens new markets for businesses willing to invest in greener technologies. As more companies adopt these practices, we can expect an increase in demand for eco-friendly laser engraver & cutter options.

Predictions for Pricing Changes

As innovations continue to shape the landscape of CO2 laser machinery, pricing trends will inevitably follow suit. The introduction of advanced features often leads to an initial increase in co2 laser cutter price; however, as technology matures and production processes become more efficient, prices typically stabilize or even decline over time. This means that while entry-level models may remain affordable initially due to lower feature sets, high-end models could see reduced costs as competition increases within the market.

Additionally, as manufacturers invest in sustainable technologies and practices within their production lines—such as using recycled materials—the overall cost structure may shift positively over time for consumers looking at purchasing a laser cutter or engraver. In essence, keeping an eye on market trends will be crucial for businesses aiming to make informed decisions about their investments in cutting machine lasers.

Conclusion

As we wrap up our exploration of CO2 laser cutters, it’s clear that understanding the price dynamics is essential for anyone considering investing in a laser cutter. The price of a CO2 laser cutter can vary significantly based on factors like build quality, features, and brand reputation. By keeping these elements in mind, you can make a more informed decision that aligns with your business needs.

Key Takeaways on CO2 Laser Cutter Costs

When evaluating CO2 laser cutter prices, remember that higher costs often correlate with superior materials and advanced cutting machine laser features. Entry-level models may be tempting due to their lower prices, but they might lack the longevity and efficiency found in high-end woodworking laser cutters. Ultimately, investing in a quality CO2 laser engraver can lead to better performance and long-term savings.

Making Informed Decisions for Your Business

To make informed decisions regarding your purchase of a cutting machine laser or any other type of laser machinery, it's crucial to analyze your specific needs and budget constraints. Take the time to compare different models and brands while considering warranty options; this could save you from costly repairs down the line. Remember that the cheapest option isn’t always the best choice—focus on value rather than just price.

Choosing the Right Laser Machinery for You

Selecting the right CO2 laser cutter involves balancing your budget with your operational requirements and future growth potential. Whether you're looking for a compact model for hobby projects or an industrial-grade woodworking laser cutter for commercial use, there's something out there tailored to meet your needs. Don’t forget to explore financing options if necessary; they can help ease the burden of upfront costs while allowing you to invest in quality machinery.