Introduction

In the world of precision cutting, fiber laser cutters have emerged as a game-changer. These advanced cutting machines utilize fiber laser technology to deliver unparalleled accuracy and efficiency, making them a favorite in various industries. Whether you're in manufacturing or creative arts, understanding the benefits and applications of these laser machinery marvels is essential.

What Are Fiber Laser Cutters

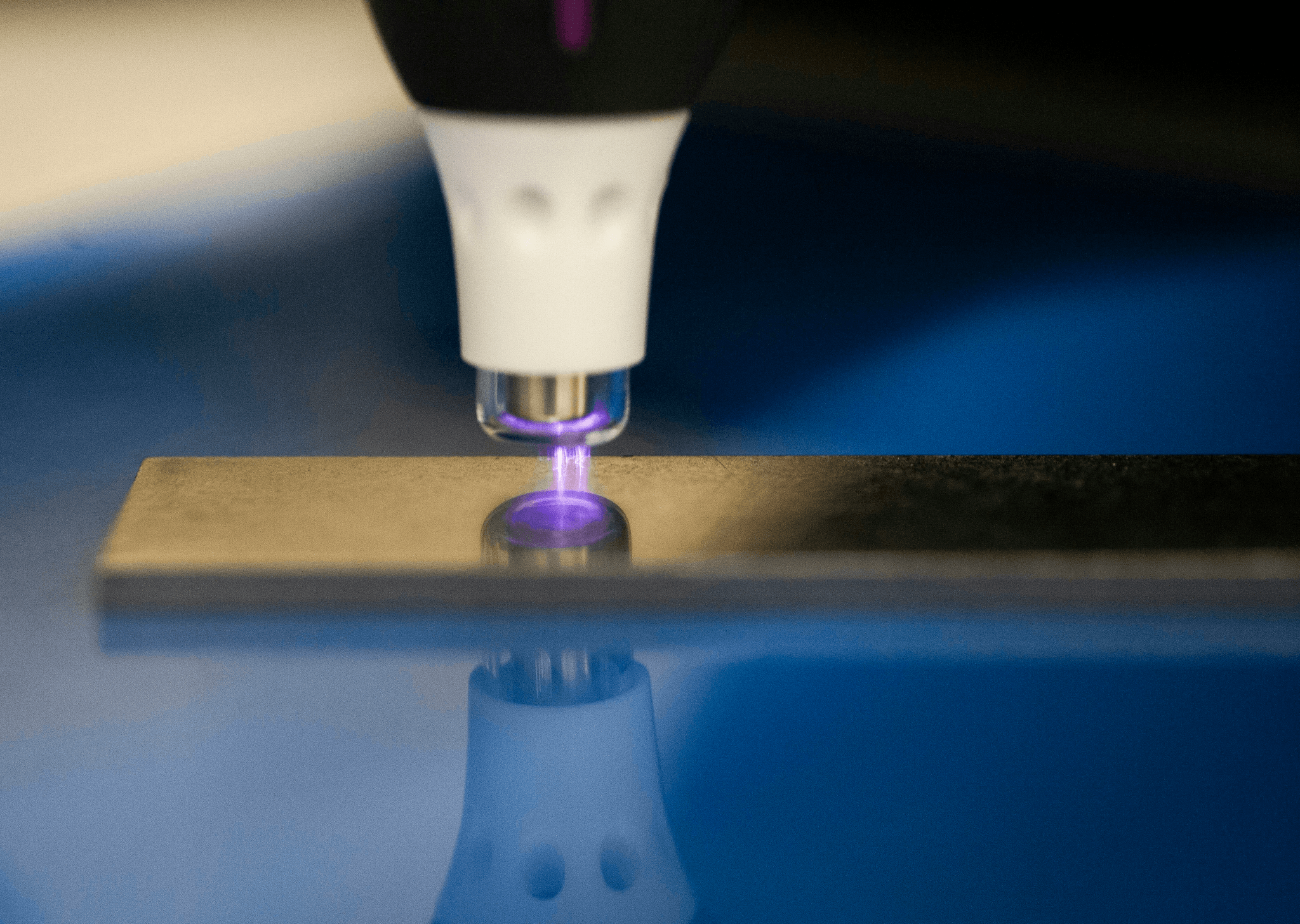

Fiber laser cutters are specialized tools that use concentrated light beams to cut through materials with exceptional precision. Unlike traditional cutting methods, which rely on mechanical force, these cutting machines harness the power of fiber optics to generate a high-quality beam that can slice through metals and other materials effortlessly. This innovative approach has positioned fiber lasers as essential equipment for modern production lines.

Benefits of Using Fiber Laser Technology

The advantages of using fiber laser technology are numerous and compelling. For starters, fiber lasers offer faster cutting speeds compared to other methods, significantly reducing production time and costs associated with labor and materials. Additionally, their energy efficiency means lower operating costs, making them an attractive option when considering laser machine prices.

Key Applications for Fiber Laser Cutters

Fiber laser cutters are versatile tools employed across various sectors including automotive, aerospace, and electronics manufacturing. Beyond industrial applications, they also find creative uses in art installations and signage production where intricate designs are required. The adaptability of these laser metal cutting machines showcases their ability to meet diverse needs while maintaining high performance standards.

Understanding Fiber Laser Technology

Fiber laser technology has revolutionized the manufacturing landscape, particularly in the realm of cutting metal. At its core, a fiber laser cutter uses a solid-state laser that generates light through optical fibers doped with rare-earth elements like ytterbium. This method allows for highly concentrated beams of light, resulting in precise cuts and minimal material waste—perfect for industries where detail matters.

How Fiber Laser Works

The operation of fiber lasers hinges on their unique design, which employs a series of mirrors to amplify the light generated by the fiber itself. This amplified light is then directed through a lens that focuses it onto the material being cut, creating an intense heat that melts or vaporizes the metal. The result? A clean cut with smooth edges, making fiber laser cutters ideal for applications ranging from intricate engravings to heavy-duty industrial tasks.

Advantages Over Other Cutting Methods

One of the standout benefits of using fiber lasers over traditional cutting methods is their efficiency and speed. Fiber laser machines can operate at higher speeds while consuming less energy compared to CO2 lasers or plasma cutters, translating into lower operational costs—an important consideration when evaluating cutting machine laser price. Additionally, they require less maintenance due to fewer moving parts and longer-lasting components, making them a smart investment for businesses looking to optimize their production processes.

Common Myths Debunked

Despite their growing popularity, several myths surround fiber laser technology that can lead to misconceptions about its capabilities and suitability. One common myth is that fiber lasers are only suitable for thin materials; however, advancements in technology have made them effective for cutting thicker metals as well. Another misconception is regarding cost; while initial investments like cutting laser machine price may seem high, the long-term savings on maintenance and operational efficiency often outweigh these upfront costs—making them a wise choice in modern manufacturing environments.

Choosing the Right Cutting Machine Laser

Selecting the ideal cutting machine laser can feel like navigating a maze, especially with the plethora of options available today. Fiber laser cutters have revolutionized precision metal cutting, but not all models are created equal. Understanding what factors influence your choice, how to compare prices, and which brands stand out can make your decision easier.

Factors to Consider

When choosing a fiber laser cutter, it's crucial to consider several factors that will impact your operational efficiency and output quality. First, assess the material types you'll be working with; different laser machinery excels at cutting various metals like steel, aluminum, or brass. Additionally, think about the thickness of materials you typically handle—some cutting laser machines are better suited for thicker materials while others shine in precision cuts on thinner sheets.

Another key factor is power and speed; higher wattage generally means faster cuts and thicker material capabilities. However, this often comes at a higher price point in terms of both initial investment and operating costs. Lastly, consider the machine's software compatibility and ease of use—after all, you want a fiber laser engraver that integrates smoothly into your existing workflow without causing headaches.

Comparing Laser Machine Prices

Price comparison is essential when looking for a cutting machine laser that fits your budget without compromising on quality. While it might be tempting to go for the cheapest option available, remember that investing in a reliable fiber laser cutter pays off in terms of durability and performance over time. Look beyond just the upfront cost; consider maintenance expenses and potential downtime costs associated with lower-quality machines.

Many manufacturers provide quotes based on specific configurations or features tailored to your needs; thus it's wise to request multiple quotes from different suppliers for an apples-to-apples comparison. Additionally, keep an eye out for warranties or service agreements—these can significantly impact overall ownership costs over time if something goes awry with your equipment. Ultimately, finding a balance between price and functionality will lead you to the right choice for your operations.

Top Brands to Explore

As you dive into the world of fiber lasers and their applications in metal cutting machinery, several top brands consistently stand out for their quality and innovation in this space. Companies like Trumpf and Bystronic have established themselves as leaders by offering robust solutions that cater to both small workshops and large industrial operations alike—making them worthy contenders when considering a new cutting laser machine.

Another brand worth exploring is Amada; known for its user-friendly interfaces combined with powerful performance specs that make their machines ideal choices for various industries—from automotive to aerospace manufacturing. Don’t overlook newer players either; companies like Trotec are making waves with advanced technology designed specifically for engraving applications using fiber lasers.

Finding reputable brands means you're more likely to receive support post-purchase as well as access to upgrades or accessories down the line—a crucial consideration if you plan on scaling operations in future years.

Applications of Laser Metal Cutting Machines

Laser metal cutting machines have revolutionized various industries by providing precision, speed, and versatility. The technology behind fiber laser cutters allows for intricate designs and clean cuts on a wide range of materials. From automotive to aerospace, the applications are virtually limitless, making fiber lasers a go-to choice for manufacturers.

Industries Utilizing Fiber Lasers

Fiber laser technology has found its home in numerous industries, including automotive, aerospace, electronics, and metal fabrication. In the automotive sector, cutting machine lasers are essential for producing components with tight tolerances and complex geometries. Aerospace manufacturers rely on laser machinery for lightweight yet strong parts that meet stringent safety standards while reducing overall weight.

The electronics industry benefits from fiber lasers in circuit board production and component manufacturing where precision is paramount. Additionally, metal fabricators use laser metal cutting machines to create custom parts quickly and efficiently. With such diverse applications across multiple sectors, it's no wonder that fiber laser technology is leading the charge in modern manufacturing.

Creative Uses Beyond Manufacturing

Beyond traditional manufacturing settings, fiber lasers have sparked creative innovations across various fields. Artists have embraced fiber laser engravers to create intricate designs on wood, glass, and even stone surfaces. This versatility allows artists to push boundaries by incorporating detailed engravings into sculptures or personalized gifts.

In the world of fashion design, some designers utilize cutting laser machines to craft unique patterns or embellishments on textiles with remarkable precision. Even in architecture and interior design, fiber lasers are employed to produce customized decorative elements that enhance aesthetics while maintaining structural integrity. These creative uses showcase how versatile these tools can be beyond their conventional applications.

Case Studies of Successful Implementations

One notable case study involves an automotive manufacturer that integrated a state-of-the-art laser metal cutting machine into its production line. By doing so, they significantly reduced material waste while increasing production speed by 30%. The transition not only enhanced efficiency but also improved product quality due to the precision offered by fiber lasers.

Another example comes from a jewelry company that adopted a fiber laser engraver for creating custom pieces tailored to individual customers' desires. This shift allowed them to offer personalized designs without compromising on quality or turnaround time—resulting in higher customer satisfaction rates and repeat business. These case studies highlight how adopting advanced technology like fiber lasers can lead to substantial improvements in productivity and creativity across various sectors.

Getting Started with Fiber Laser Engravers

Diving into the world of fiber laser engravers can be an exciting venture, especially if you're looking to enhance your cutting capabilities. Understanding the basics of operation, adhering to safety precautions, and implementing maintenance tips are crucial steps in ensuring that your experience with fiber laser cutters is both efficient and enjoyable. Let’s break down each aspect to get you started on the right foot.

Basics of Operation

Operating a fiber laser engraver is not as daunting as it may seem; it's all about understanding its core functions. First, familiarize yourself with the control panel and software that drives the cutting machine laser, as these will allow you to set parameters such as speed and power settings tailored for different materials. Once you’ve uploaded your design file, simply position your material on the bed of the laser metal cutting machine and start the engraving process—watching those precise cuts come to life is truly mesmerizing!

It's important to note that each fiber laser engraver may have unique features or settings that cater to various applications, so taking time to read through manuals or instructional videos can be immensely beneficial. Regularly experimenting with different materials will also help you better understand how adjustments affect results—after all, practice makes perfect! With a bit of patience and exploration, you'll soon become proficient in operating your cutting laser machine.

Safety Precautions and Best Practices

Safety should always be a top priority when working with any type of laser machinery. First off, make sure you're equipped with appropriate personal protective equipment (PPE), such as safety goggles designed specifically for protecting against harmful light emissions from fiber lasers. Additionally, ensure that your workspace is well-ventilated; fumes generated during cutting can be hazardous if not properly managed.

Moreover, keep a fire extinguisher nearby just in case things go awry—better safe than sorry! Familiarize yourself with emergency shut-off procedures for your fiber laser cutter so you’re prepared for any unexpected situations while operating your machine. By following these best practices and maintaining a clean work environment free from clutter or flammable materials, you'll significantly reduce risks associated with using a cutting machine laser.

Maintenance Tips for Longevity

To keep your fiber laser engraver running smoothly over time, regular maintenance is key! Start by conducting routine inspections of critical components like lenses and mirrors; keeping these clean ensures optimal performance when using your laser metal cutting machine. Dust buildup can lead to inefficiencies or even damage if left unchecked—so don’t skip this step!

Additionally, periodically check alignment settings on your cutting laser machine and recalibrate if necessary; this will help maintain precision in every cut or engraving job you undertake. Lastly, always refer back to manufacturer guidelines regarding servicing schedules; staying proactive about maintenance will extend the life span of both your equipment and investment in quality fiber lasers.

Kiant Machinery: Your Partner in Laser Solutions

When it comes to laser machinery, Kiant Machinery stands out as a leading provider of advanced fiber laser solutions. With a diverse range of offerings, including cutting machine lasers and fiber laser engravers, Kiant caters to various industries seeking precision and efficiency. Their dedication to quality ensures that customers receive top-notch equipment designed for optimal performance in metal cutting applications.

Overview of Kiant's Offerings

Kiant Machinery boasts an impressive lineup of fiber laser cutters and laser metal cutting machines tailored to meet the needs of different sectors. From compact models suitable for small workshops to large-scale industrial machines, their products are engineered for versatility and durability. Additionally, they offer customizable solutions that allow businesses to optimize their cutting processes according to specific requirements.

Benefits of Choosing Kiant Machinery

Choosing Kiant Machinery means investing in reliable technology that enhances productivity while reducing operational costs. Their fiber laser cutters are known for their speed and precision, ensuring high-quality cuts with minimal waste—an essential factor when considering cutting laser machine prices. Moreover, customers benefit from exceptional after-sales support, including training programs and maintenance services that extend the lifespan of your investment.

Customer Success Stories

Kiant Machinery has empowered numerous businesses with its innovative fiber laser technology, leading to remarkable success stories across various industries. For instance, a local automotive parts manufacturer saw production efficiency soar by 40% after integrating a Kiant fiber laser cutter into their workflow. Similarly, a creative design studio transformed its operations using a fiber laser engraver from Kiant, enabling intricate designs on diverse materials while significantly reducing turnaround times.

Conclusion

In wrapping up our exploration of fiber laser technology and its myriad benefits, it’s clear that investing in fiber laser cutters can significantly elevate your manufacturing processes. The precision, speed, and versatility offered by these cutting machines make them indispensable in today’s competitive landscape. As industries continue to innovate, the demand for advanced laser machinery will only grow, making it a wise choice for businesses looking to stay ahead.

Making the Right Investment in Laser Technology

When considering a cutting machine laser for your operations, it's essential to assess not just the upfront costs but also long-term value. Fiber laser cutters often have lower operational costs due to reduced energy consumption and maintenance needs compared to traditional methods. Investing wisely means evaluating your specific requirements against available options while keeping an eye on cutting laser machine prices that fit your budget.

The Future of Fiber Laser Cutting

The future of fiber laser cutting looks incredibly promising as advancements in technology continue to emerge. With improvements in efficiency and capabilities, we can expect even more innovative applications beyond conventional manufacturing—think creative designs and intricate engravings with fiber laser engravers that push boundaries further than ever before. As industries evolve, adapting to these changes will be key; embracing fiber lasers could very well set you apart from competitors.

Resources for Further Learning on Laser Machinery

For those eager to dive deeper into the world of fiber lasers and their applications, a wealth of resources is available online and through industry publications. Websites dedicated to advancements in laser technology provide insights into new trends and best practices for operating a laser metal cutting machine efficiently. Additionally, attending workshops or webinars can help you understand the intricacies of different models while comparing features—making informed decisions about which cutting machine suits your needs best.