Introduction

In the rapidly evolving world of manufacturing, understanding the tube laser machine landscape is essential for businesses aiming to enhance productivity and precision. These cutting-edge machines have revolutionized the way industries approach laser cutting, offering unmatched accuracy and versatility in processing various materials. As the demand for efficient cutting solutions grows, selecting the right cutting machine laser becomes a pivotal decision that can significantly impact operational efficiency.

Understand the Tube Laser Machine Landscape

The tube laser machine market has expanded exponentially, driven by advancements in technology and an increasing need for customized solutions across different sectors. With options ranging from fiber lasers to specialized laser pipe cutting machines, manufacturers now have a plethora of choices to meet their specific needs. Understanding these variations is crucial; it allows businesses to align their production capabilities with market demands effectively.

Importance of Choosing the Right Cutting Machine

Choosing the right cutting machine is not just about picking a model; it's about investing in your company's future. The right laser machinery can enhance production speed, improve quality, and reduce waste—factors that are critical in today's competitive environment. By carefully evaluating your options and needs, you can ensure that your investment yields substantial returns over time.

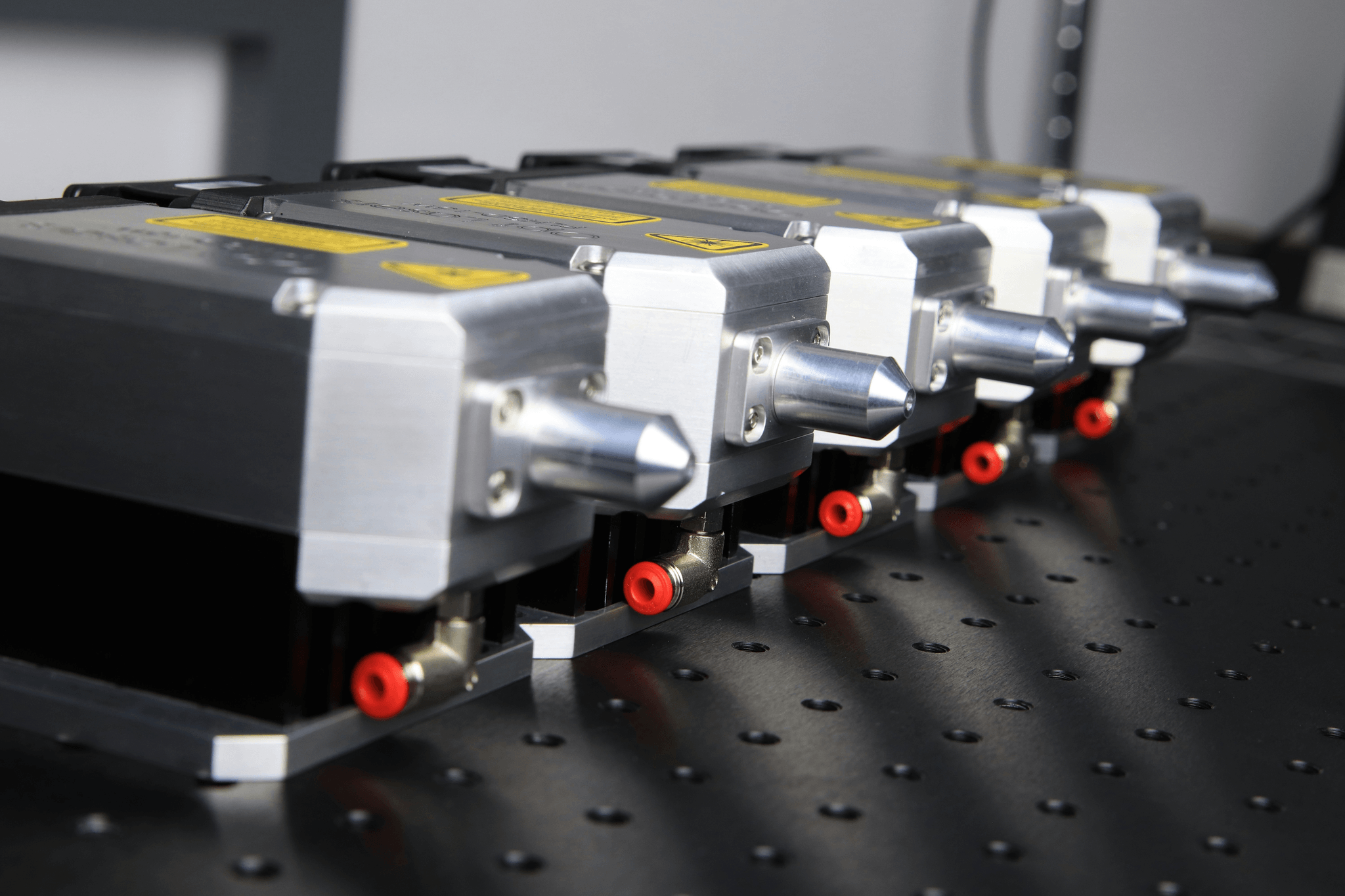

Key Features to Consider in Laser Machinery

When diving into the world of laser machinery, several key features should be at the forefront of your decision-making process. Precision and speed are paramount; after all, a fiber laser cutting machine’s ability to deliver intricate cuts efficiently can set your operation apart from competitors. Additionally, consider automation capabilities and software integration options that enhance usability and streamline workflows—these elements will play a crucial role in maximizing your tube laser machine's potential.

Assess Your Production Needs

Determine Tube Sizes and Materials

First up on your checklist should be determining the tube sizes and materials you'll be working with. Different cutting machine lasers have varying capabilities when it comes to thickness, diameter, and material compatibility—be it stainless steel, aluminum, or even plastic tubes. Knowing these specifics will ensure that the fiber laser cutting machine you choose can handle your current projects without breaking a sweat.

Furthermore, consider any special finishes or coatings that might affect the cutting process. For instance, if you're dealing with highly reflective materials like copper or brass, you'll need to confirm that your chosen laser machinery is equipped to handle such challenges effectively. Ultimately, understanding your tube specifications will help you select a laser pipe cutting machine that's tailored to meet your unique needs.

Analyze Production Volumes

Next on the agenda is analyzing production volumes—because let’s face it: no one wants to invest in a high-end cutting machine only for it to sit idle! Assessing how many pieces you'll need to cut daily or weekly will guide you toward selecting a laser cutting system that aligns with those demands. If you're ramping up production or anticipating larger orders in the future, it's essential to choose machinery that can scale accordingly.

You’ll also want to consider turnaround times; faster processing times mean more output per hour and greater profitability for your business. A fiber laser cutting machine typically offers quicker cut speeds compared to traditional methods—an aspect worth weighing heavily in this decision-making phase. When you analyze production volumes thoroughly, you'll set yourself up for success while maximizing return on investment.

Evaluate Future Growth Potential

Finally, let's talk about future growth potential because nobody wants their investment trapped in yesterday's technology! As industries evolve rapidly with new materials and applications emerging regularly, it's crucial for businesses like yours to stay ahead of the curve by choosing adaptable machinery like advanced tube laser machines.

Consider whether the equipment you're eyeing can accommodate new sizes or different materials down the line without requiring expensive upgrades or replacements later on. Investing in versatile laser machinery not only meets current demands but also opens doors for innovative projects down the road—ensuring you're not just keeping pace but leading from the front!

In summary, assessing production needs encompasses evaluating tube sizes and materials as well as analyzing volume requirements while keeping an eye on future growth potential—all vital steps toward selecting an effective cutting machine that suits both present and future demands.

Explore Different Types of Laser Cutting Machines

The two primary contenders in this arena are fiber lasers and CO2 lasers, each with its unique strengths and applications. Choosing between these machines can significantly affect your production efficiency, quality of cut, and overall operational costs.

Fiber Laser vs. CO2 Laser

Fiber lasers have taken the market by storm, primarily due to their efficiency and versatility in cutting various materials. Unlike CO2 lasers that rely on gas for beam generation, fiber lasers use solid-state technology which allows them to deliver a more focused beam with higher energy density. This results in faster cutting speeds and superior precision when working with metals, making fiber laser cutting machines particularly advantageous for industries requiring high-quality cuts.

On the flip side, CO2 lasers excel in cutting non-metallic materials such as plastics and wood but often fall short when it comes to metal thickness or speed compared to their fiber counterparts. Additionally, while CO2 laser machinery can be less expensive initially, they may incur higher maintenance costs over time due to the need for gas replacements and other upkeep requirements. Ultimately, your choice between a fiber laser or a CO2 laser should align with your specific production needs and material types.

Advantages of Fiber Laser Cutting Machine

One of the standout benefits of using a fiber laser cutting machine is its remarkable speed—often outpacing traditional methods by leaps and bounds! This increased efficiency translates into shorter lead times for projects without sacrificing quality; perfect for businesses looking to stay competitive in fast-paced markets. Furthermore, fiber lasers are known for their low operating costs since they consume less power than CO2 systems while also offering longer lifespans due to fewer moving parts.

Another key advantage lies in their ability to maintain consistent performance across various materials—whether you’re processing stainless steel tubes or aluminum profiles, the results remain sharp and precise every time. The integration of advanced software adds another layer of convenience by allowing operators to optimize settings quickly based on material type or thickness without extensive manual adjustments. In essence, investing in a fiber laser not only enhances productivity but also simplifies operations within your facility.

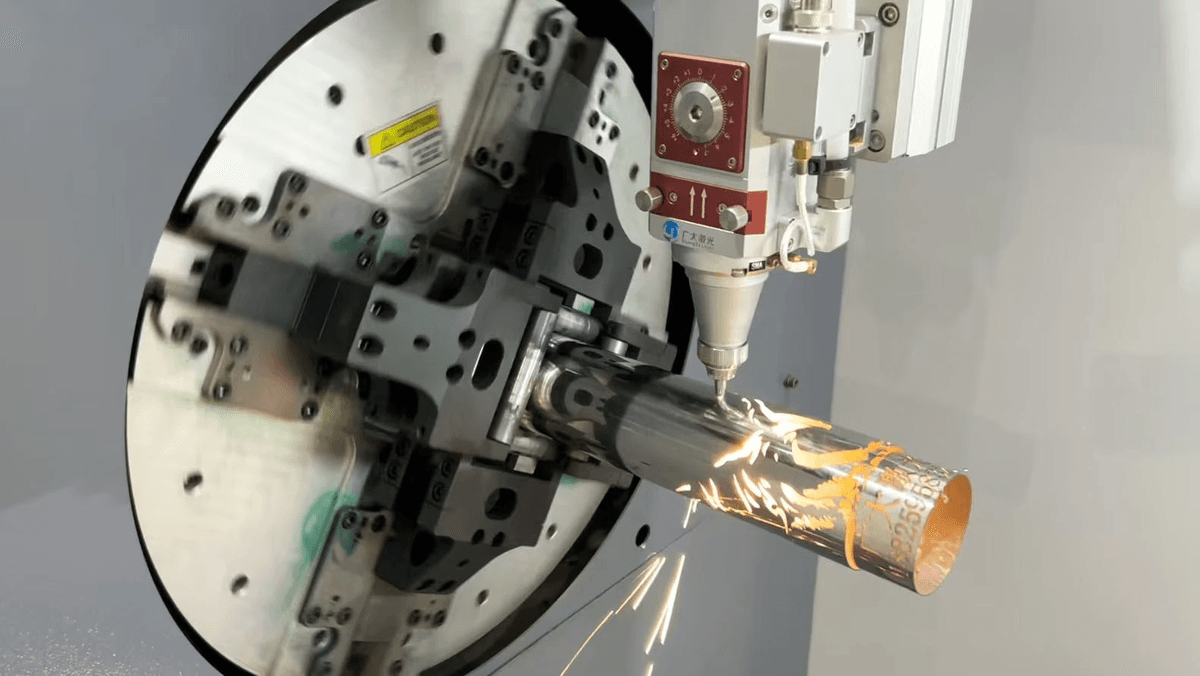

Niche Applications of Laser Pipe Cutting Machine

Laser pipe cutting machines have carved out a niche all their own within the realm of industrial manufacturing—particularly when dealing with tubular materials that require intricate designs or precise dimensions. These specialized machines are ideal for sectors like automotive manufacturing where precision-engineered components are paramount; think exhaust systems or chassis parts that demand flawless cuts every time!

Additionally, industries such as construction benefit from these machines as they allow for quick modifications on-site without compromising structural integrity—a game changer when time is money! Whether you’re crafting decorative railings or functional piping systems, investing in a tube laser machine designed specifically for pipe applications ensures you meet both design specifications and safety standards effortlessly.

Evaluate Technology and Features

When diving into the world of tube laser machines, evaluating technology and features is crucial to ensure you select the right cutting machine for your needs. The efficiency, precision, and overall performance of laser machinery play a significant role in determining your operational success. In this section, we’ll explore key aspects such as cutting precision and speed, automation capabilities, and maintenance considerations that will help you make an informed choice.

Precision and Speed of Cutting

Fiber laser cutting machines are particularly renowned for their ability to deliver high-quality cuts with minimal kerf width, which translates into less material waste and more accurate results. Coupled with impressive speed capabilities, these machines can significantly enhance production efficiency while maintaining exceptional cut quality—allowing businesses to meet demanding deadlines without sacrificing performance.

In addition to precision, the speed at which a cutting machine operates can dramatically impact overall productivity levels. Modern fiber lasers have advanced considerably in terms of both speed and accuracy; they can cut through various materials like steel or aluminum with remarkable agility. Investing in a fast yet precise tube laser machine means not only meeting current production demands but also positioning your business for future growth opportunities.

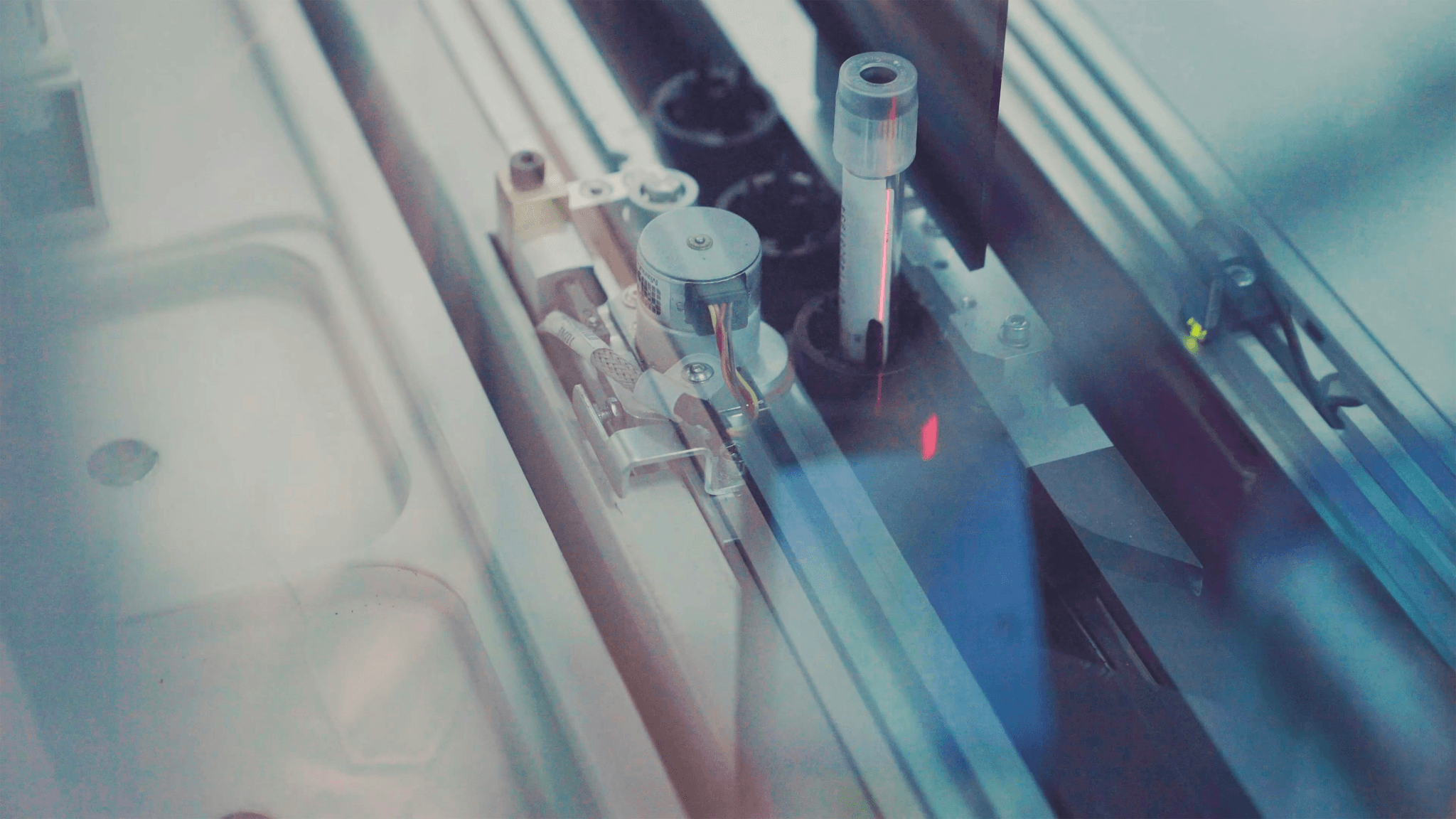

Automation and Software Integration

Automation is reshaping the landscape of manufacturing by streamlining processes that were once labor-intensive. When considering a laser pipe cutting machine, look for options that offer robust automation features designed to minimize human intervention while maximizing throughput. Advanced software integration allows operators to program multiple jobs efficiently, enabling seamless transitions between different tasks without compromising quality or accuracy.

The synergy between automation technology and fiber laser systems enhances productivity significantly by reducing setup times and human errors associated with manual operations. Furthermore, many modern machines come equipped with user-friendly interfaces that simplify operation even for those who may not be tech-savvy. By embracing automation in your tube laser machinery selection process, you’ll ensure smoother workflows that keep pace with evolving market demands.

Maintenance and Ease of Use

Look for tube laser machines designed with accessibility in mind—features like easy-to-replace parts or built-in diagnostics can save time during routine check-ups or troubleshooting sessions. A well-maintained fiber laser cutting machine not only extends its lifespan but also ensures consistent performance throughout its operational life.

Moreover, consider how intuitive the software interface is when evaluating potential purchases; user-friendly controls can drastically reduce training times for new operators while minimizing operational errors during production runs. Machines equipped with clear visual displays provide real-time feedback on performance metrics—a feature invaluable for maintaining optimal output levels across various projects involving different materials or thicknesses.

In conclusion, making an informed decision about technology features will empower you to choose a tube laser machine that meets all your production requirements while offering long-term value through reliability and efficiency.

Consider Cost vs. Value

When it comes to selecting a tube laser machine, understanding the financial implications is crucial. The decision isn't just about the initial price tag; it's about weighing that against long-term savings and operational efficiencies that a quality cutting machine can deliver. A well-chosen laser cutting system can significantly enhance productivity, ultimately leading to cost savings that outweigh the upfront investment.

Initial Investment vs. Long-Term Savings

The initial investment in a fiber laser cutting machine might seem steep at first glance, but consider it a strategic move for future gains. High-quality laser machinery tends to offer faster cutting speeds, precision, and reliability, which translates into reduced operational costs over time. Additionally, lower maintenance requirements and energy efficiency can lead to significant long-term savings that often justify the higher upfront expense.

Total Cost of Ownership

When evaluating your options for a cutting machine laser, it's essential to calculate the total cost of ownership (TCO). TCO includes not only the purchase price but also factors like maintenance costs, energy consumption, and potential downtime due to repairs or inefficiencies. By analyzing these components alongside your expected production volumes and material types, you can better assess which laser pipe cutting machine provides the best value for your investment.

Funding Options and ROI

Funding options for acquiring a tube laser machine vary widely and can significantly impact your cash flow management strategy. Many manufacturers offer financing plans or leasing options that allow you to spread out payments while still reaping the benefits of advanced technology immediately. Calculating your return on investment (ROI) by considering factors such as increased production capacity and reduced waste will help you make an informed decision about funding routes that align with your business goals.

Research Manufacturers and Suppliers

A reliable partner can provide not only high-quality laser machinery but also support throughout the lifecycle of your cutting machine laser. This section will explore why Kiant Machinery stands out, the critical importance of after-sales support, and insights from customer reviews and case studies.

Why Choose Kiant Machinery

Kiant Machinery has established itself as a leader in the field of fiber laser cutting machines, offering state-of-the-art technology that meets diverse production needs. Their commitment to innovation ensures that their tube laser machines are equipped with advanced features that enhance precision and efficiency in laser cutting operations. Furthermore, Kiant's reputation for quality means you can trust their products to deliver consistent performance over time.

Choosing Kiant means opting for a manufacturer that understands the nuances of different materials and tube sizes, ensuring you get a cutting machine tailored to your specific requirements. With an extensive range of options available, including specialized laser pipe cutting machines, they cater to niche applications while maintaining competitive pricing. Ultimately, selecting Kiant Machinery positions you well for both current demands and future growth potential in your production line.

Importance of After-Sales Support

After-sales support is a crucial aspect often overlooked when purchasing a cutting machine laser; however, it's vital for ensuring long-term success with your investment. With any sophisticated piece of equipment like a fiber laser or tube laser machine, having access to technical assistance can save you time and money when issues arise or maintenance is needed. Kiant Machinery excels in providing comprehensive after-sales services that include training, troubleshooting assistance, and readily available spare parts.

Moreover, effective after-sales support contributes significantly to minimizing downtime during critical production periods; this is where responsive service becomes invaluable. By partnering with manufacturers who prioritize customer care post-purchase, you ensure that your operations remain smooth and efficient over time. This level of support reinforces the value proposition associated with investing in high-quality laser machinery.

Customer Reviews and Case Studies

Customer reviews serve as powerful testimonials about the effectiveness of any tube laser machine or fiber laser cutting machine on the market today. Prospective buyers should pay attention to these insights as they reveal real-world experiences regarding performance reliability and overall satisfaction with various manufacturers' products—including Kiant Machinery's offerings. Many customers highlight how their investments have led to increased productivity while reducing waste during the cutting process.

Case studies also provide valuable context about how specific industries have successfully integrated these advanced technologies into their workflows—demonstrating clear returns on investment through enhanced operational efficiency using a cutting machine designed for precision work like those produced by Kiant Machinery. These examples not only showcase product capabilities but also illustrate how businesses have adapted their processes around modern solutions such as fiber lasers or specialized pipe-cutting equipment.

In summary, thorough research into manufacturers like Kiant Machinery highlights essential factors such as product quality assurance through customer feedback along with robust after-sales support systems—making it easier for businesses to make informed decisions about their next tube laser machine purchase.

Conclusion

In the world of manufacturing, selecting the right cutting machine laser is crucial for optimizing efficiency and quality. A tube laser machine can be a game-changer for your operations, but making an informed decision requires careful consideration of various factors. By assessing your production needs, exploring different types of laser machinery, and evaluating key features, you can ensure that your investment aligns with both current demands and future growth.

Making an Informed Decision on Machine Selection

Choosing the right fiber laser or CO2 laser involves more than just comparing prices; it’s about understanding how each cutting machine will fit into your production workflow. Take the time to analyze your specific requirements—such as tube sizes, materials, and anticipated production volumes—before diving into a purchase. This thoughtful approach will help you select a fiber laser cutting machine that not only meets today’s demands but also adapts seamlessly to future needs.

The Role of Quality in Cutting Performance

Investing in high-quality laser machinery ensures that you achieve clean cuts with minimal waste, enhancing overall productivity. Remember that a reliable tube laser machine will not only deliver superior performance today but also maintain its effectiveness as technology advances.

Future-Proofing Your Investment in Laser Technology

As industries evolve at breakneck speed, future-proofing your investment in a cutting machine is essential for staying competitive. Opting for advanced features such as automation and software integration can significantly extend the lifespan of your equipment while keeping operational costs down. By choosing a reputable manufacturer like Kiant Machinery with robust after-sales support, you’ll be better equipped to adapt to changing market dynamics without compromising on quality.