Introduction

In the realm of modern manufacturing, fiber laser cutting technology has emerged as a game-changer, revolutionizing how industries approach precision cutting. This advanced method utilizes concentrated laser beams to slice through materials with remarkable accuracy, making it an essential tool for any metal fabrication shop. However, selecting the right fiber laser cutting machine manufacturer is crucial to harnessing the full potential of this innovative technology.

Choosing a reputable manufacturer can significantly impact your operational efficiency and overall production quality. With numerous options available in the market, it's vital to evaluate which laser cutting machine aligns with your specific needs and budget. A reliable industrial laser cutter not only enhances productivity but also ensures that you receive ongoing support throughout your investment journey.

To make an informed decision, several key factors must be assessed when evaluating potential manufacturers. These include their experience in the industry, product quality and innovation, customer support services, customization options, and a thorough understanding of cost versus value. By carefully considering these elements, you can confidently select a fiber laser cutting machine manufacturer that meets your expectations and drives your business forward.

Understanding Fiber Laser Cutting Technology

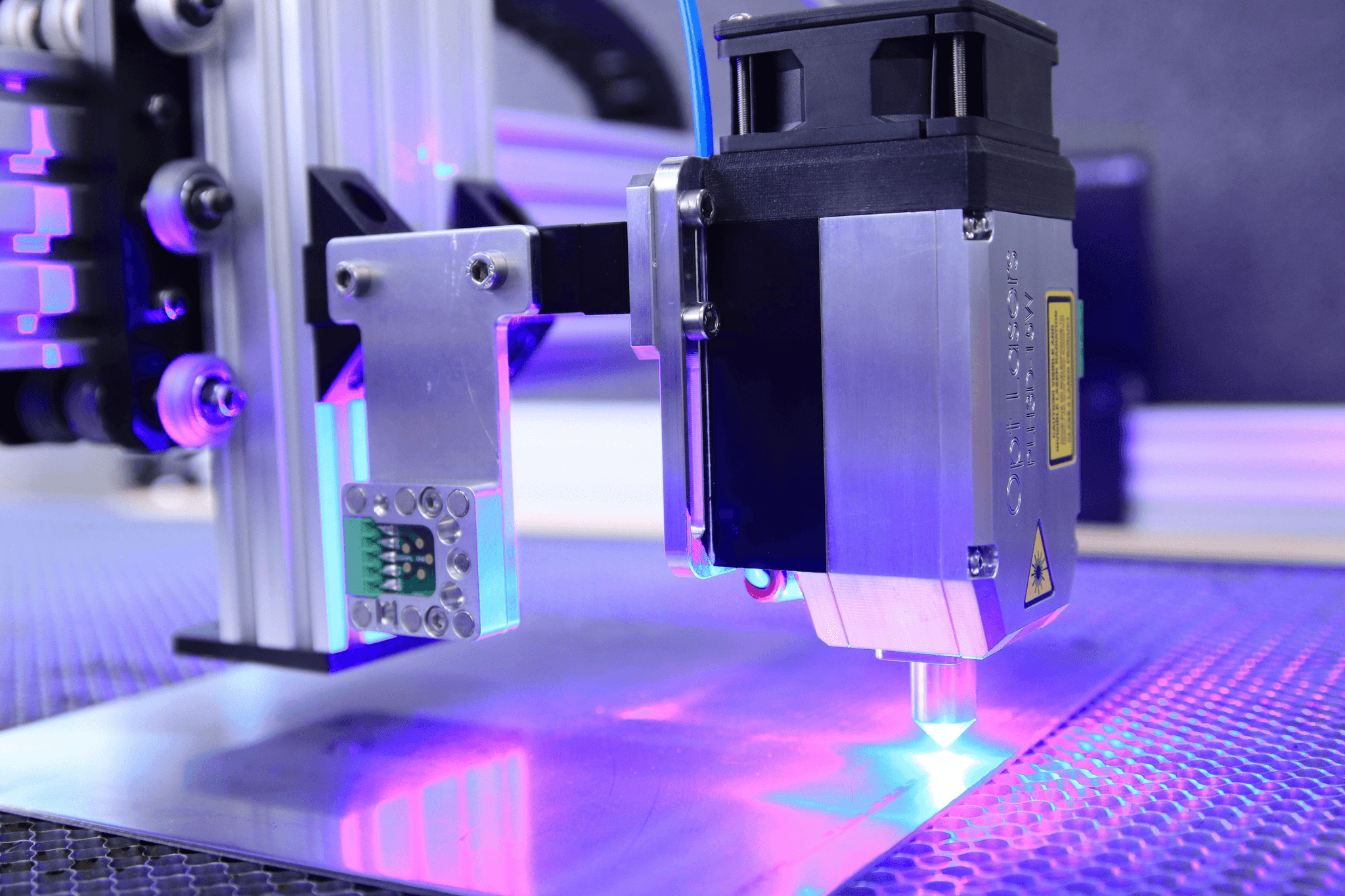

Fiber laser cutting technology represents the pinnacle of precision in the world of industrial manufacturing. Unlike traditional methods that rely on mechanical blades or gas lasers, this technique employs high-powered fiber lasers to achieve clean cuts with minimal thermal distortion. The result? Faster processing times and higher-quality finishes on various materials such as metals and plastics.

The efficiency of a metal cutting machine laser stems from its ability to focus energy tightly onto a small area, allowing for intricate designs without compromising structural integrity. This level of accuracy is particularly beneficial for industries requiring detailed work—think automotive parts or intricate signage where every millimeter counts. As such, understanding how this technology works is vital for anyone looking to invest in a reliable laser cutting machine.

Moreover, advancements in fiber laser technology have led to machines that are not only faster but also more energy-efficient compared to their predecessors. This means businesses can enjoy lower operating costs while maintaining high production standards—a win-win scenario! As you explore options among various manufacturers, being well-versed in these technological nuances will empower you to make more informed choices regarding your future investments.

Importance of Choosing the Right Manufacturer

When it comes to acquiring a fiber laser cutting machine, choosing the right manufacturer can be just as important as selecting the right model itself. An experienced manufacturer often brings invaluable expertise and insights into what works best for different applications within various industries. Their reputation within the market speaks volumes about their commitment to quality and innovation—a factor that should never be overlooked when investing in industrial equipment.

A reputable manufacturer will not only provide superior products but also ensure comprehensive customer support throughout your partnership—something critical for maximizing uptime on your new cutting machine laser. From installation assistance to ongoing maintenance services, having access to knowledgeable professionals can save you time and money down the line while enhancing productivity at every turn.

Furthermore, aligning yourself with a trustworthy fiber laser cutting machine manufacturer fosters long-term relationships built on mutual success rather than mere transactions. Such partnerships often lead to collaborative innovations tailored specifically for unique business needs—an advantage that many competitors may lack! Therefore, taking time during this selection process is essential; it could very well determine how effectively you leverage this powerful technology moving forward.

Key Factors for Evaluation

As you embark on evaluating potential manufacturers for your next industrial laser cutter purchase or upgrade project; several key factors should guide your decision-making process effectively! First up: assessing each company's experience within relevant sectors—this includes examining their history in producing reliable machinery along with customer satisfaction ratings over time (hint: testimonials matter!).

Next comes product quality—what kind of innovations do they offer? Are there specific features designed around enhancing user-friendliness or improving overall performance? Comparing different models from various providers allows buyers insight into which machines stand out based on functionality versus cost-effectiveness ratios too!

Finally—and perhaps most importantly—considering after-sales service capabilities ensures peace-of-mind knowing assistance remains readily available whenever needed post-purchase! Comprehensive training programs help operators get up-to-speed quickly while regular maintenance checks keep everything running smoothly over time without unexpected hiccups disrupting workflow efficiencies either way!

Assessing Manufacturer Experience

When it comes to selecting a fiber laser cutting machine manufacturer, experience is key. A company’s industry reputation and longevity can provide insights into their reliability and expertise in the field of laser cutting technology. The more established a manufacturer is, the more likely they are to have refined their processes, ensuring you receive a high-quality product.

Industry Reputation and Longevity

The reputation of a fiber laser cutting machine manufacturer speaks volumes about their credibility in the market. Companies that have been around for years often have a solid track record of delivering reliable products and services, which is crucial when investing in a cutting machine laser. Longevity also indicates that they have weathered market fluctuations and maintained customer trust over time.

Furthermore, an established industrial laser cutter manufacturer typically has experience across various sectors. This breadth of knowledge allows them to understand diverse customer needs, providing tailored solutions that newer companies may not offer yet. A strong reputation often correlates with consistent performance; therefore, it's worth investigating how long they've been in business and what others say about them.

Portfolio of Successful Projects

A robust portfolio of successful projects is another critical factor when evaluating potential manufacturers for your metal cutting machine laser needs. Reviewing previous work showcases not only the capabilities of the manufacturer but also gives you confidence in their ability to deliver quality results tailored to your specifications. Look for case studies or project summaries that highlight successful implementations relevant to your industry.

Moreover, diversity in projects can indicate flexibility and innovation within the company. If a fiber laser cutting machine manufacturer has tackled various applications—from intricate designs to large-scale production runs—it's likely they possess the expertise needed for your specific requirements. This versatility can be invaluable as industries evolve and demand changes.

Customer Testimonials and Case Studies

Customer testimonials provide real-world insights into what you can expect from a laser cutting machine supplier. Positive feedback from satisfied clients indicates not just product quality but also effective customer service throughout the buying process and beyond. Look for detailed case studies that illustrate how the manufacturer's machines performed under different conditions or challenges faced by other businesses.

Additionally, consider reaching out directly to past customers if possible; personal experiences can offer invaluable perspectives on reliability and support after purchase—key aspects when investing in equipment like an industrial laser cutter. Remember, what others say about their experiences can often reveal much more than glossy marketing materials ever could!

Product Quality and Innovation

In the fast-paced world of manufacturing, the quality and innovation of products are paramount. When selecting a fiber laser cutting machine manufacturer, it’s essential to evaluate their commitment to technological advancements and product excellence. A top-tier laser cutting machine can significantly enhance operational efficiency, precision, and overall productivity.

Technology Advancements in Laser Cutting

The landscape of laser cutting technology is evolving rapidly, with innovations that push the boundaries of what’s possible in metal processing. Fiber laser cutting machines have emerged as game-changers due to their superior speed, accuracy, and energy efficiency compared to traditional CO2 lasers. Manufacturers that stay ahead in technology often integrate features like automated loading systems and advanced software for enhanced user experience.

Moreover, advancements such as intelligent beam shaping and adaptive optics make modern industrial laser cutters more versatile than ever before. These technologies allow for intricate designs and complex geometries that were previously challenging or impossible to achieve. When evaluating a potential manufacturer, consider how they incorporate these advancements into their product offerings.

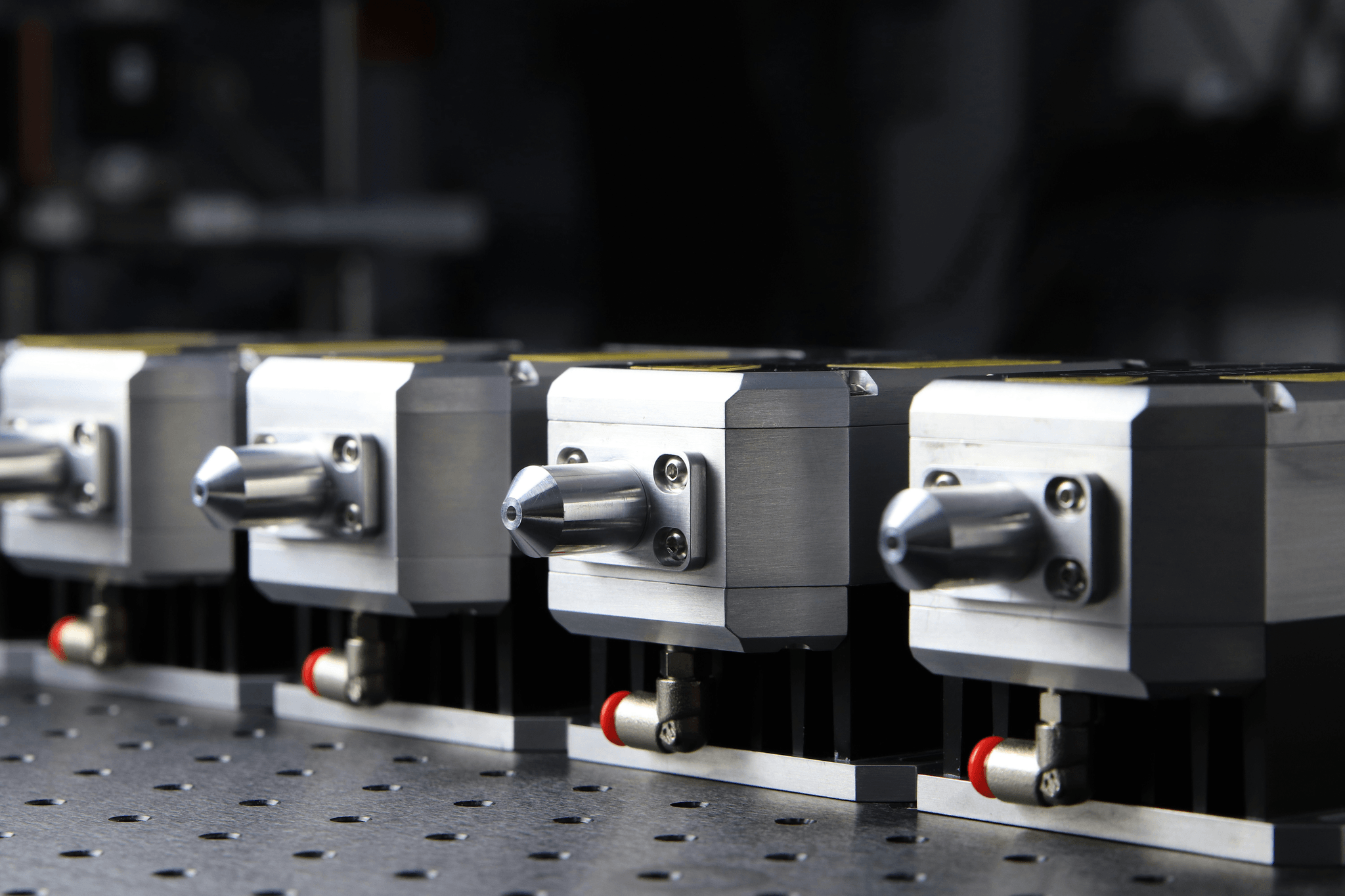

Comparison of Different Laser Cutting Machines

With a plethora of options available on the market today, comparing different laser cutting machines is crucial for making an informed decision. Each model comes with unique features tailored for various applications—from basic metal cutting machines to high-end industrial laser cutters designed for heavy-duty tasks. Understanding the specifications such as wattage, cut speed, and material compatibility will help you discern which machine best fits your needs.

Additionally, consider how manufacturers position their products in terms of innovation versus affordability; some may offer budget-friendly options without compromising on quality while others focus on premium machines packed with advanced features. It’s also beneficial to look at user reviews or conduct hands-on demonstrations when possible since real-world performance often tells a different story than glossy brochures can convey.

Commitment to Quality Control Standards

A fiber laser cutting machine manufacturer’s dedication to quality control standards is essential for ensuring reliable performance over time. Look for manufacturers who adhere to international quality certifications such as ISO 9001; this indicates a structured approach to maintaining high manufacturing standards throughout production processes. Rigorous testing protocols during development stages also reflect a manufacturer's commitment to delivering durable products.

Moreover, regular audits and feedback loops are critical components in maintaining consistent quality across all units produced by the manufacturer—this ensures that every industrial laser cutter meets or exceeds industry benchmarks before it reaches your shop floor. By prioritizing manufacturers who take quality seriously, you not only invest in superior machinery but also safeguard your operations against downtime caused by equipment failures.

Customer Support and Service

When investing in a fiber laser cutting machine, the importance of robust customer support and service cannot be overstated. A reliable manufacturer not only sells you a laser cutting machine but also stands by you throughout its life cycle. This commitment to customer care ensures that your industrial laser cutter operates smoothly, enabling maximum productivity.

Availability of Technical Support

A key aspect of choosing a fiber laser cutting machine manufacturer is the availability of technical support. You want to ensure that help is just a phone call away when you're facing challenges with your metal cutting machine laser. Manufacturers that offer 24/7 technical assistance demonstrate their dedication to customer satisfaction and operational efficiency, allowing you to resolve issues quickly and minimize downtime.

Comprehensive Training Programs

Training is essential when it comes to operating any sophisticated machinery, including a cutting machine laser. A reputable manufacturer will provide comprehensive training programs tailored to your specific needs, ensuring that your team is well-equipped to handle the intricacies of the laser cutting process. Well-trained staff can significantly enhance productivity and safety while using the industrial laser cutter, making this an essential factor in your selection process.

After-Sales Service and Maintenance

After-sales service plays a crucial role in maintaining the longevity and performance of your fiber laser cutting machine. A good manufacturer offers regular maintenance checks and prompt repairs when necessary, helping you avoid costly downtimes due to equipment failure. By establishing a solid after-sales relationship with your chosen manufacturer, you can rest assured that your investment in a metal cutting machine laser will continue to yield returns for years to come.

Customization and Flexibility

In the world of laser cutting, one size definitely does not fit all. The right fiber laser cutting machine manufacturer understands that every business has unique needs, and they offer tailored solutions to meet those specifications. This level of customization can significantly enhance productivity and efficiency, allowing your operations to run smoothly while addressing specific challenges.

Tailored Solutions for Specific Needs

When evaluating a laser cutting machine, consider how well the manufacturer can adapt their offerings to your specific requirements. A good fiber laser cutting machine manufacturer will work closely with you to understand your production goals, material types, and desired outcomes. This collaborative approach ensures that the resulting industrial laser cutter is perfectly suited for your applications, whether you're focusing on metal or other materials.

Options for Upgrades and Scalability

As your business evolves, so too should your equipment capabilities. Many leading manufacturers provide options for upgrades and scalability within their laser cutting machines. This means that you won't be boxed into a single solution; instead, you can enhance features or expand capacity as needed without having to invest in entirely new cutting machines—saving both time and money in the long run.

Understanding the Manufacturer’s Design Capabilities

Before settling on a particular fiber laser cutting machine manufacturer, it’s important to assess their design capabilities thoroughly. A robust design process indicates that they can create innovative solutions tailored specifically for your needs while ensuring top-notch performance from their metal cutting machine lasers. Look for manufacturers who showcase a portfolio of diverse projects; this reflects their ability to adapt designs based on various industry demands.

Cost vs. Value

When investing in a fiber laser cutting machine, understanding the cost versus value proposition is crucial. It’s not just about the initial price tag; you need to consider the total cost of ownership over the machine's lifespan. A well-chosen industrial laser cutter can significantly enhance productivity and reduce operational costs, making it a worthwhile investment.

Analyzing Total Cost of Ownership

The total cost of ownership (TCO) encompasses much more than just the purchase price of your cutting machine laser. It includes factors like maintenance costs, energy consumption, and even potential downtime due to malfunctions or inefficiencies. By evaluating these aspects, you can identify which fiber laser cutting machine manufacturer provides machines that offer long-term savings and reliability.

For instance, a high-quality metal cutting machine laser may have a higher upfront cost but could save you money in repairs and operational efficiency over time. Additionally, consider any hidden costs associated with training staff or integrating new technology into your existing workflow. Ultimately, understanding TCO will help you make an informed decision that balances quality with affordability.

Weighing Features Against Budget

When selecting a laser cutting machine, it’s essential to weigh its features against your budget constraints carefully. Different manufacturers offer various options that cater to specific needs—some may prioritize speed while others focus on precision or versatility in materials they can cut. The key is to find a balance where you get the features that matter most for your operations without overspending on unnecessary extras.

While it might be tempting to go for the cheapest option available from any fiber laser cutting machine manufacturer, doing so could lead to compromises on quality or functionality down the line. Instead, focus on what features are essential for your business goals—whether that's advanced automation capabilities or superior software integration—and ensure those are included within your budgetary limits. This approach ensures you're investing wisely without sacrificing performance.

Long-Term Investment in Efficiency

Investing in an industrial laser cutter is not merely about immediate gains; it's about securing long-term efficiency for your operations as well. A reliable laser cutting machine can streamline production processes, reduce waste materials, and improve overall output quality—all factors that contribute significantly to profitability over time. Therefore, viewing this purchase as an investment rather than an expense will change how you assess potential options.

Moreover, many modern metal cutting machines lasers come equipped with advanced technologies designed for energy efficiency and minimal maintenance requirements—further enhancing their long-term value proposition. When evaluating different fiber laser cutting machine manufacturers, look for those who emphasize innovation and sustainability within their product offerings; this will ensure you're making a forward-thinking choice that aligns with future industry trends.

In conclusion, while upfront costs are important when selecting a laser cutting machine, considering factors like total cost of ownership and long-term efficiencies will ultimately lead you to make a more informed decision that benefits your business in the years ahead.

Conclusion

In the world of laser cutting, selecting the right fiber laser cutting machine manufacturer is crucial for achieving optimal performance and efficiency. The decision-making process involves evaluating several key factors, including manufacturer experience, product quality, customer support, and customization options. By focusing on these criteria, businesses can ensure they invest in a cutting machine laser that meets their specific needs and enhances productivity.

Summarizing Key Selection Criteria

When choosing a fiber laser cutting machine manufacturer, it’s essential to assess their industry reputation and longevity. A portfolio showcasing successful projects can provide insights into their expertise and reliability in delivering high-quality laser cutting machines. Additionally, customer testimonials serve as valuable indicators of satisfaction and performance, helping you determine which industrial laser cutter aligns best with your operational goals.

The Role of Manufacturer Partnerships

Building a strong partnership with your chosen fiber laser cutting machine manufacturer can significantly impact your business's success. A reliable manufacturer not only provides superior products but also offers ongoing support throughout the lifecycle of the equipment. This collaborative relationship fosters innovation and ensures that you have access to the latest advancements in metal cutting machine laser technology.

Final Thoughts on Making the Right Choice

Ultimately, making an informed choice about a fiber laser cutting machine manufacturer will pay dividends in terms of efficiency and productivity over time. By weighing cost against value while considering long-term investments in technology upgrades, you can find the perfect balance for your business needs. Remember that selecting a partner who understands your unique requirements will lead to enhanced performance from your new laser cutting machinery.