Introduction

In the world of manufacturing and fabrication, laser cut tubes have become a game changer, offering unparalleled precision and efficiency. A laser cutter can transform raw metal into intricate designs with remarkable accuracy, making it an essential tool for various projects. Whether you’re working on steel tube laser cutting or pipe laser cutting, understanding the nuances of a laser cutting machine is crucial for achieving the best results.

Understanding Laser Cut Tubes

Laser cut tubes are created using advanced technology that employs focused laser beams to slice through metal with exceptional precision. This method allows for intricate designs and shapes that traditional cutting methods struggle to achieve. With a metal tube laser cutter, artisans can create parts that fit together seamlessly, enhancing both aesthetics and functionality in their projects.

Importance of Precision in Projects

Precision is paramount in any project involving cutting materials; even the slightest error can lead to costly mistakes or rework. In industries where exact measurements are critical—like automotive or aerospace—using a cutting laser metal ensures every piece meets stringent specifications. By utilizing steel tube laser cutting techniques, manufacturers can guarantee high-quality outcomes that meet client demands and industry standards.

Choosing the Right Equipment

Selecting the right equipment is vital when embarking on any project involving pipe cutting lasers or other types of metal cutters. The market offers various options tailored to different needs; hence, understanding what each machine brings to the table is essential for making an informed choice. Investing in a reliable and efficient laser cutting machine not only enhances productivity but also ensures consistent quality across all finished products.

What is Laser Cutting?

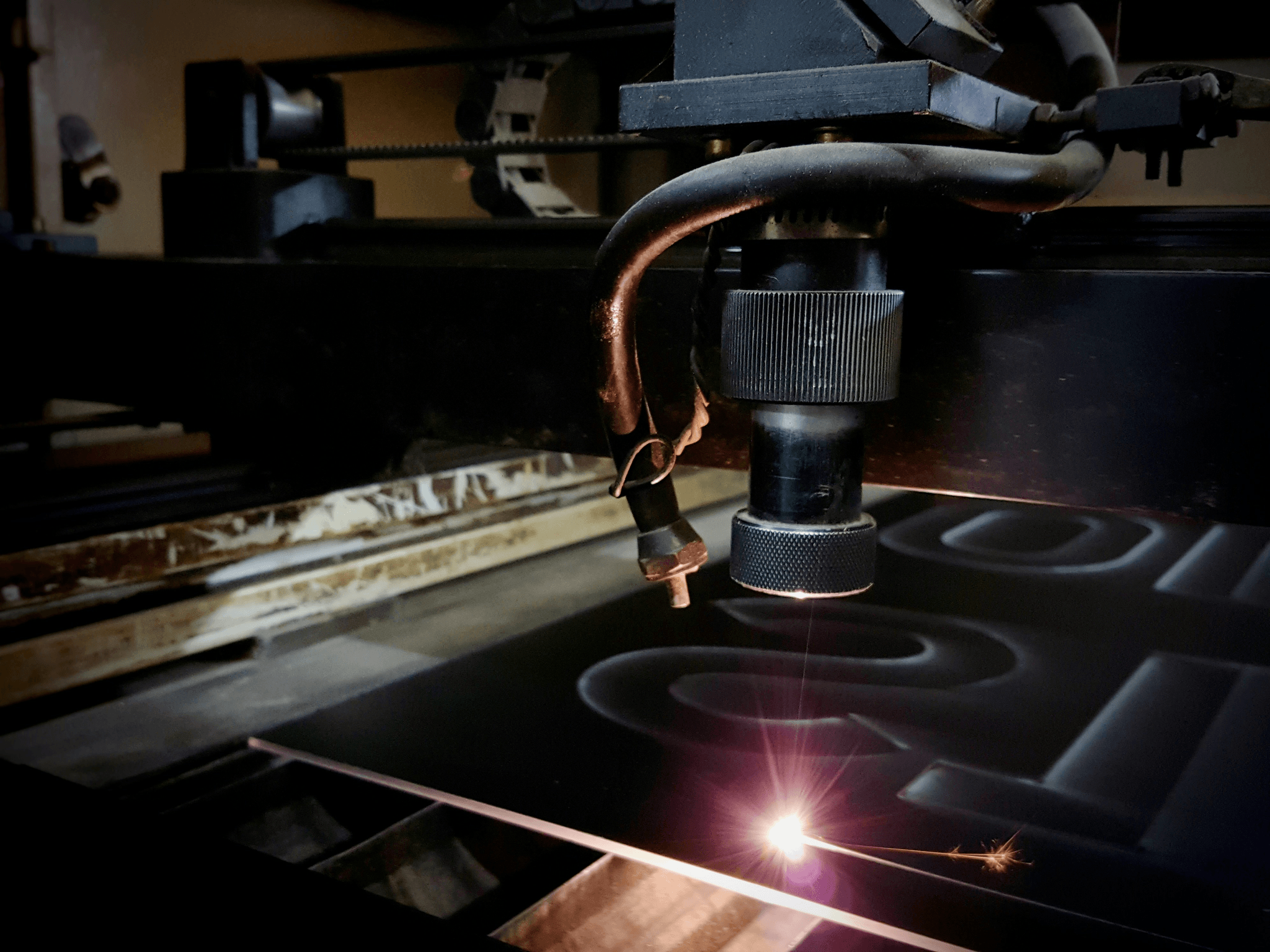

The Basics of Laser Cutting Machines

At its core, a laser cutting machine consists of several key components: a laser source, focusing optics, and a motion control system. These machines generate a high-intensity beam of light that can be directed onto the material being cut. For metal tube laser cutters, the precision of this process allows for intricate shapes and patterns while maintaining structural integrity.

The operation of these machines typically involves CNC (Computer Numerical Control) technology, which allows for automated cutting processes based on pre-programmed designs. This automation not only enhances accuracy but also significantly reduces the time required for projects involving steel tube laser cutting or pipe laser cutting. With advancements in technology, modern machines are becoming increasingly user-friendly and efficient.

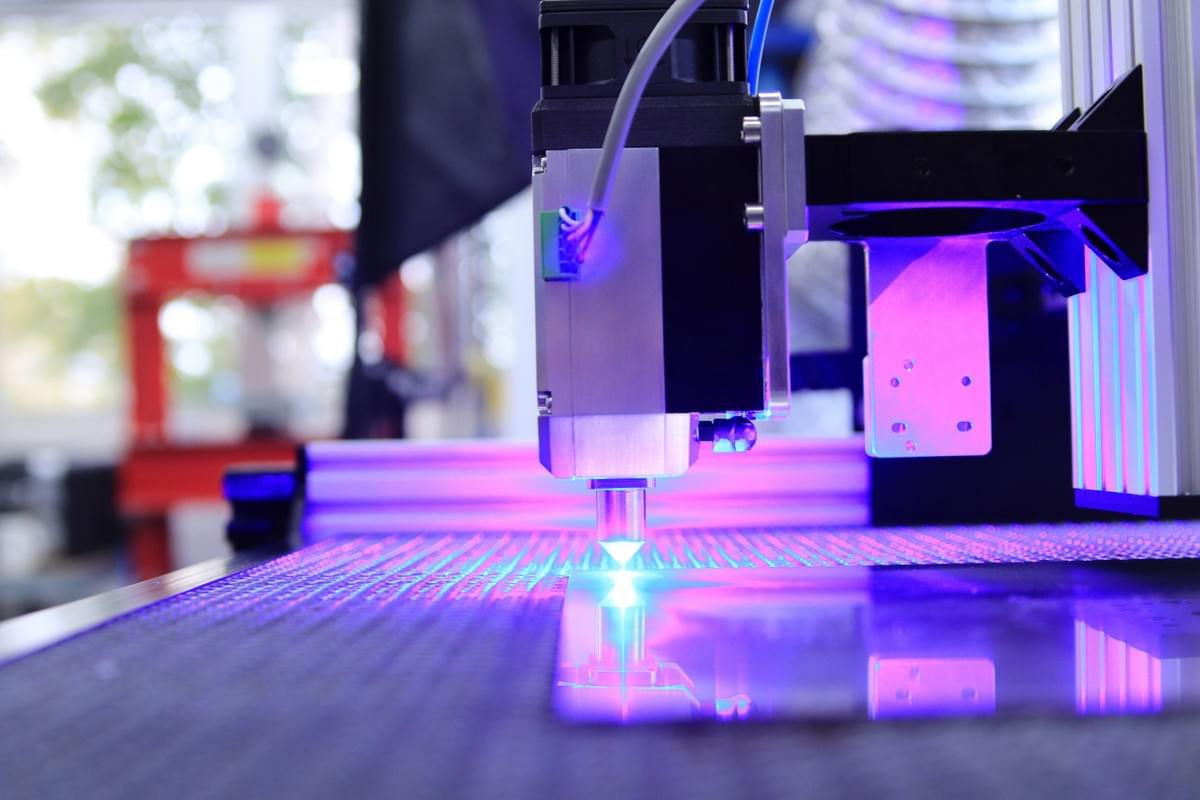

Types of Laser Cutters for Metal

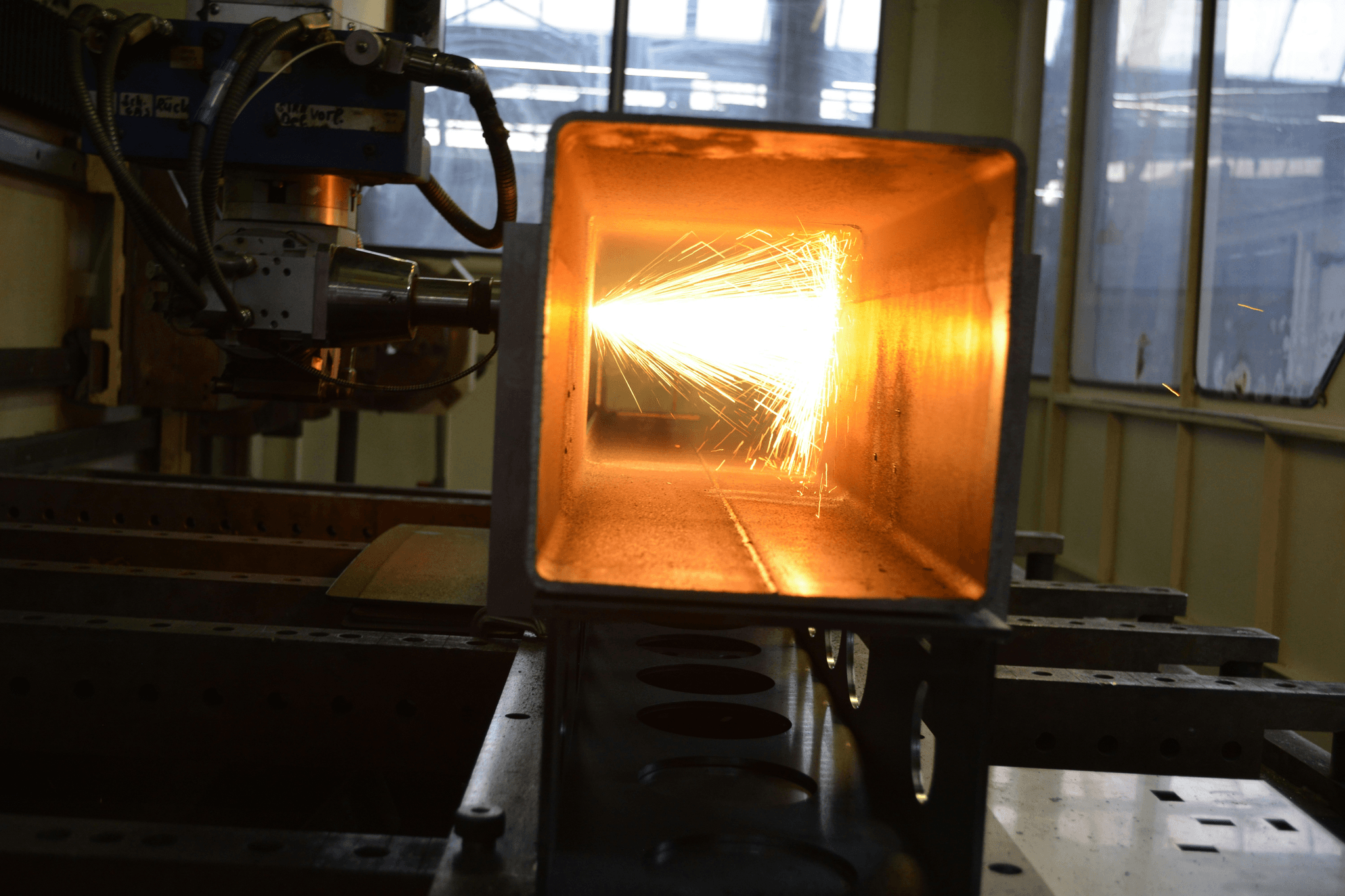

CO2 lasers are popular for their versatility and effectiveness on non-metal materials but can also handle thin metals with ease. On the other hand, fiber lasers have gained popularity due to their efficiency in cutting thicker metals like steel tubes.

Each type offers distinct advantages depending on your project requirements; for instance, pipe cutting lasers excel at producing complex cuts in cylindrical shapes while ensuring minimal waste material. Understanding these differences can help you choose the best option among metal tube laser cutters available in today's market. Ultimately, selecting the right type can make all the difference when aiming for precision cuts.

Advantages of Using a Laser Cutter

One major advantage of using a laser cutter is its ability to produce high-quality cuts with minimal kerf width—this means less wasted material during your project! The precision offered by these machines results in cleaner edges compared to traditional methods such as saws or plasma cutters; this is especially important when working with delicate designs on a laser cut tube or intricate patterns on metal sheets.

Moreover, laser cutting machines operate at high speeds without compromising accuracy—allowing you to complete projects quickly while maintaining excellent quality standards across all cuts made through steel tube laser cutting or pipe laser cutting techniques. Additionally, they require less post-processing work due to their ability to create smooth finishes straight from the machine.

In summary, investing in a reliable cutting laser metal machine not only enhances productivity but also elevates overall project outcomes by delivering unparalleled precision and efficiency that traditional methods simply cannot match.

Selecting the Right Laser Cutter

Choosing the right laser cutter can feel like finding a needle in a haystack, especially with so many options available. With advancements in technology, metal tube laser cutters have become more sophisticated, offering precision and efficiency that can enhance your projects significantly. Whether you're focused on steel tube laser cutting or pipe laser cutting, understanding what each machine brings to the table will help you make an informed decision.

Comparing Metal Tube Laser Cutters

When comparing metal tube laser cutters, it’s essential to consider factors such as power output, cutting speed, and versatility. Different machines are designed for various applications; some excel at intricate designs while others are built for high-volume production.

You should also compare the types of materials each cutter can handle. While most machines are adept at cutting steel tubes and other metals, some may struggle with thicker materials or specific alloys. Ultimately, aligning your project needs with the capabilities of a laser cutting machine will ensure you find the perfect fit for your tasks.

Features to Look for in a Laser Cutting Machine

When shopping for a cutting laser metal machine, several key features should be on your radar. First up is power—higher wattage typically means faster cuts and the ability to handle thicker materials effectively without compromising quality. Look for machines equipped with advanced optics and cooling systems that enhance precision while extending the life of your equipment.

Another critical feature is software compatibility; modern machines often come with user-friendly design software that simplifies project planning and execution. A robust automation system can further streamline operations by reducing manual intervention during pipe cutting laser processes. Finally, consider safety features such as enclosed workspaces or automatic shut-off mechanisms that protect both operators and equipment during use.

Kiant Machinery's Offerings in Laser Tube Cutting

Kiant Machinery stands out in the market by providing high-quality solutions tailored specifically for laser cut tube applications. Their range of metal tube laser cutters combines advanced technology with user-friendly interfaces to cater to both novice users and seasoned professionals alike. With models designed specifically for steel tube laser cutting as well as versatile options suitable for various metals, Kiant Machinery has something for everyone.

Their commitment to innovation means you’ll find features like integrated software solutions that simplify design processes while optimizing cut quality across different materials and thicknesses. Plus, Kiant’s customer support ensures you won’t be left hanging if you run into issues or need guidance on maximizing your new equipment's capabilities during pipe laser cutting projects. Investing in a Kiant Machinery product not only enhances your productivity but also gives you peace of mind knowing you're backed by industry experts.

Material Considerations

Different metals have varying properties that can affect how well they respond to a laser cutter. Understanding the best materials for laser cut tubes will not only help you achieve precision but also enhance the overall quality of your work.

Best Metals for Laser Cutting

Steel, aluminum, and stainless steel are among the top contenders when it comes to using a metal tube laser cutter. These materials allow for clean cuts and intricate designs, making them ideal for various applications in industries ranging from construction to automotive.

In particular, mild steel is favored due to its excellent weldability and cost-effectiveness. Aluminum is another popular choice because it’s lightweight yet sturdy, perfect for projects requiring portability without sacrificing strength. Stainless steel offers corrosion resistance, making it suitable for applications exposed to harsh environments; thus, it's often used in food processing or medical equipment.

Understanding Steel Tube Laser Cutting

Steel tube laser cutting is an art form in itself; it involves precision and technique that can turn raw metal into beautifully crafted components. When utilizing a cutting laser metal on steel tubes, understanding the specific requirements of your project becomes essential—such as thickness and type of cut desired. The process allows for intricate shapes and patterns while maintaining tight tolerances that traditional methods simply can't match.

One key aspect of steel tube laser cutting is managing heat input effectively; too much heat can warp or damage your material while too little may result in incomplete cuts. Utilizing advanced features available on modern laser cutting machines can help control this factor efficiently. Moreover, with advancements in technology, many machines now come equipped with features like automatic focusing systems that optimize performance based on material type.

Pipe Type and Thickness for Optimal Results

When diving into pipe laser cutting or pipe cutting lasers specifically designed for different types of pipes, knowing which pipe type works best with your chosen equipment is crucial. Round pipes are often easier to cut than square or rectangular ones due to their uniform shape; however, each has its unique challenges during the cutting process. For instance, square pipes may require more precise alignment but can yield stunning results when done correctly.

Thickness also plays a significant role—generally speaking, thinner pipes are easier to cut compared to thicker ones due to lower energy requirements from the laser cutter. However, if you’re working with thicker materials like heavy-duty structural tubing or large diameter pipes, ensure your machine has adequate power capacity and focuses well on delivering consistent results throughout the length of the cut tube. Achieving optimal results hinges not just on selecting suitable materials but also on matching them with appropriate settings tailored specifically for each type.

Project Planning and Design

Key Steps in Preparing Your Project

The first step in preparing for your project is defining your objectives clearly. What dimensions do you need for your metal tube laser cutter? Once you have a clear vision, gather all necessary materials and tools, including software that can interface with your laser cutting machine to streamline the design process. Don't forget to consider factors such as material type and thickness; these will significantly impact how you approach pipe laser cutting.

Next, create a detailed design plan that outlines every aspect of your project. This plan should include sketches or digital designs that specify dimensions and features needed for each cut. Making adjustments at this stage can save time and resources later when you're operating the pipe cutting laser.

Finally, ensure you have all safety protocols in place before starting any work with a laser cutter. Proper preparation minimizes risks associated with operating powerful machinery like a steel tube laser cutting tool while ensuring optimal performance throughout the project.

Tools for Designing Your Laser Cut Tube

To effectively design your laser cut tube, you'll want to leverage advanced software tools tailored for precision engineering. Programs like AutoCAD or SolidWorks are excellent choices as they allow for detailed modeling and simulation of cuts before they’re made with the cutting laser metal equipment. These tools enable users to visualize their projects thoroughly, making it easier to spot potential issues before they arise.

In addition to traditional CAD software, consider utilizing specialized applications designed specifically for pipe cutting tasks. These platforms often include features tailored for optimizing designs based on material properties—perfect when working with various metals in a metal tube laser cutter context. They also help generate accurate nesting layouts that minimize waste during production.

Lastly, don't overlook the importance of having access to templates or pre-designed files that can simplify some aspects of your project planning process. Many online resources offer free or paid templates compatible with popular design software; these can provide inspiration or serve as starting points for custom designs aimed at achieving precise cuts on steel tubes.

Tips for Achieving Accurate Cuts

Achieving accurate cuts with a pipe cutting laser requires attention to detail both during preparation and execution phases of your project. First off, ensure that material setup is done correctly; any misalignment could lead to wasted materials or subpar results from the metal tube laser cutter you've chosen. Double-checking measurements before initiating cuts will save time by preventing costly mistakes later on.

Another critical factor is maintaining optimal settings on your cutting laser metal machine based on the type of material being used—this includes adjusting power levels and speed settings accordingly during steel tube laser cutting operations. Each material has its own unique characteristics affecting how it interacts with lasers; understanding these nuances will greatly improve accuracy in achieving desired outcomes.

Finally, take advantage of test cuts whenever possible! Running small samples prior to full-scale production allows you not only to verify settings but also helps identify any adjustments needed beforehand without risking larger batches of materials being compromised during actual operations involving pipe laser cutting techniques.

Safety and Best Practices

Safety Protocols When Using a Laser Cutter

Before operating a laser cutting machine, ensure you’re wearing appropriate personal protective equipment (PPE). This includes safety goggles to protect your eyes from bright light and potential debris, as well as gloves to shield your hands from sharp edges on the metal tube laser cutter’s workpieces. Additionally, keep the workspace clear of flammable materials; lasers generate heat that could ignite nearby substances during steel tube laser cutting or pipe laser cutting tasks.

Always familiarize yourself with the specific operational manual for your model of a laser cutter before use. Each machine may have unique features or requirements that are crucial for safe operation. Lastly, never leave the machine unattended while it's in operation; even a moment's distraction can lead to accidents when working with powerful equipment like a pipe cutting laser.

Maintenance Tips for Your Cutting Laser Metal

Regular maintenance is key to ensuring optimal performance from your metal tube laser cutter. Start by routinely checking and cleaning the lenses and mirrors; any buildup of residue can diminish cut quality over time. Additionally, inspect all moving parts for wear and tear because maintaining smooth operation is vital for precision during steel tube laser cutting.

Keep an eye on coolant levels if your machine uses them; proper cooling helps prevent overheating during extensive pipe cutting operations. Also, don’t forget about software updates! Many modern machines come equipped with sophisticated technology that benefits from regular updates to improve functionality and efficiency in operations like pipe laser cutting.

Finally, develop a maintenance schedule based on usage frequency—this proactive approach will help catch potential issues before they escalate into costly repairs or downtime.

Handling Materials Safely During Pipe Cutting Laser

Handling materials safely is crucial when working with heavy tubes or sheets during pipe cutting processes. Always use proper lifting techniques or mechanical aids when moving large pieces of metal to avoid injury—your back will thank you later! When placing materials onto the bed of the machine, make sure they are secure and stable to prevent shifting during operation.

Additionally, be mindful of sharp edges created by previously cut pieces; these can pose serious cuts if mishandled after steel tube laser cutting operations are complete. Use tools designed for handling sharp objects whenever possible and avoid reaching into areas where you might accidentally touch hot surfaces or moving parts of the machine.

Lastly, ensure that everyone in the vicinity understands safe practices around working machinery; communication is key in preventing accidents related to improper handling during projects involving a cutting laser metal.

Conclusion

In the ever-evolving world of manufacturing, mastering the art of laser cutting can significantly enhance productivity and precision in your projects. A laser cutter not only offers unparalleled accuracy but also streamlines the process, allowing for intricate designs that were once deemed impossible with traditional methods. By leveraging advanced technology in laser cutting machines, businesses can maximize efficiency and reduce operational costs, all while delivering high-quality results.

Maximizing Efficiency with Laser Cutting

Maximizing efficiency with laser cut tubes requires a blend of proper equipment and meticulous planning. The right metal tube laser cutter can drastically reduce waste and minimize production time, making it an invaluable asset in any workshop. Additionally, understanding the nuances of steel tube laser cutting enables operators to optimize settings for various materials, ensuring that every cut is precise and clean.

Using a cutting laser metal not only enhances speed but also improves repeatability in production runs. This consistency is crucial for industries where quality control is paramount; any deviation could lead to costly errors or rework. Therefore, investing time in training and familiarization with your pipe cutting laser will yield significant dividends in efficiency and output quality.

Future Trends in Laser Tube Technology

The future of laser tube technology looks bright as innovations continue to emerge at a rapid pace. With advancements like automation integration and smart software solutions, manufacturers are poised to revolutionize how they approach pipe laser cutting processes. These technologies promise to enhance precision further while reducing human error—an exciting prospect for anyone involved in metal fabrication.

Moreover, we are witnessing an increasing trend toward eco-friendly practices within the industry; newer models of laser cutters are being designed to consume less power while maintaining high performance levels. This shift not only benefits the environment but also aligns with corporate sustainability goals that many companies are adopting today. As these trends evolve, staying informed about new capabilities will be essential for those looking to remain competitive.

How Kiant Machinery Can Benefit Your Projects

By choosing Kiant Machinery's products, you’re equipping yourself with state-of-the-art technology designed to elevate your project outcomes.

With their user-friendly interfaces and robust construction, Kiant's machines make pipe cutting lasers accessible even for those new to the field or looking to upgrade their current operations. Plus, their commitment to customer support ensures that you’ll have guidance every step of the way—from installation through maintenance—allowing you to focus on what really matters: creating exceptional products efficiently!

Investing in Kiant Machinery means investing in quality craftsmanship that translates into successful projects time after time.