Introduction

In the ever-evolving world of manufacturing, tube laser cutting has emerged as a game-changer, revolutionizing how industries approach metal fabrication. This advanced technique utilizes a laser cutting machine to achieve precise and intricate cuts in various materials, particularly metals. With the ability to machine cut metal with unparalleled accuracy and speed, laser pipe cutting is quickly becoming the go-to solution for businesses looking to enhance their production capabilities.

Overview of Tube Laser Cutting

Tube laser cutting is a specialized form of laser cutting that focuses on processing tubular materials with high precision. Utilizing powerful laser machinery, this method allows for complex shapes and designs to be cut effortlessly into metal pipes and tubes. The versatility of a cutting machine laser makes it suitable for various applications across multiple industries, from automotive to construction.

Benefits of Using Laser Cutting Machines

One of the most significant benefits of using a metal cutting machine laser is its efficiency; it drastically reduces production time while maintaining exceptional quality. Unlike traditional methods that can leave rough edges or require additional finishing processes, laser cutting ensures smooth and clean cuts right out of the gate. Furthermore, the precision offered by these machines minimizes material waste, making them an economically sound choice for manufacturers aiming for sustainability.

Why Choose Kiant Machinery

With innovative technology integrated into their products, Kiant ensures that users can maximize their productivity without sacrificing quality or ease of use. Additionally, their commitment to customer satisfaction means you’ll receive ongoing support and tailored solutions designed specifically for your unique needs in metal fabrication.

Understanding Laser Pipe Cutting

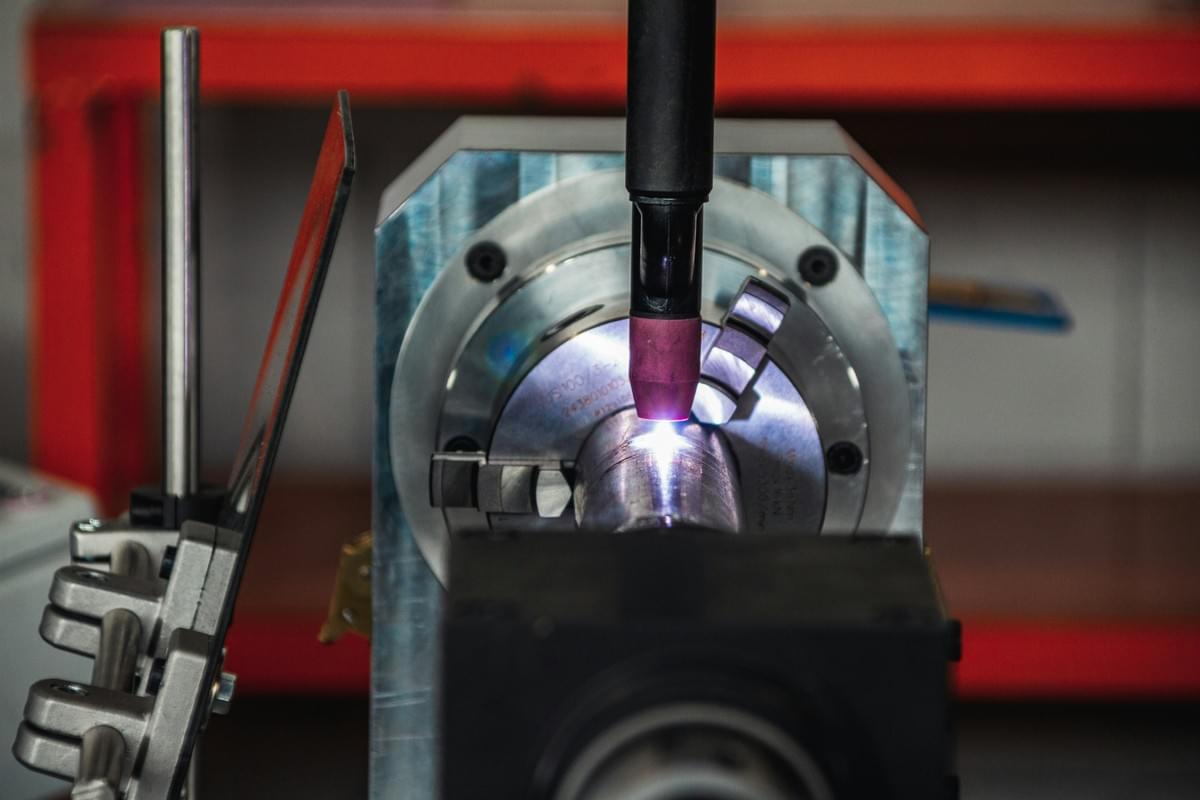

Laser pipe cutting is a revolutionary technique that has transformed the way industries approach metal fabrication. This method utilizes highly focused laser beams to cut through various types of pipes and tubes with precision and speed. Unlike traditional methods, laser pipe cutting allows for intricate designs and complex geometries, making it an invaluable tool in modern manufacturing.

What is Laser Pipe Cutting?

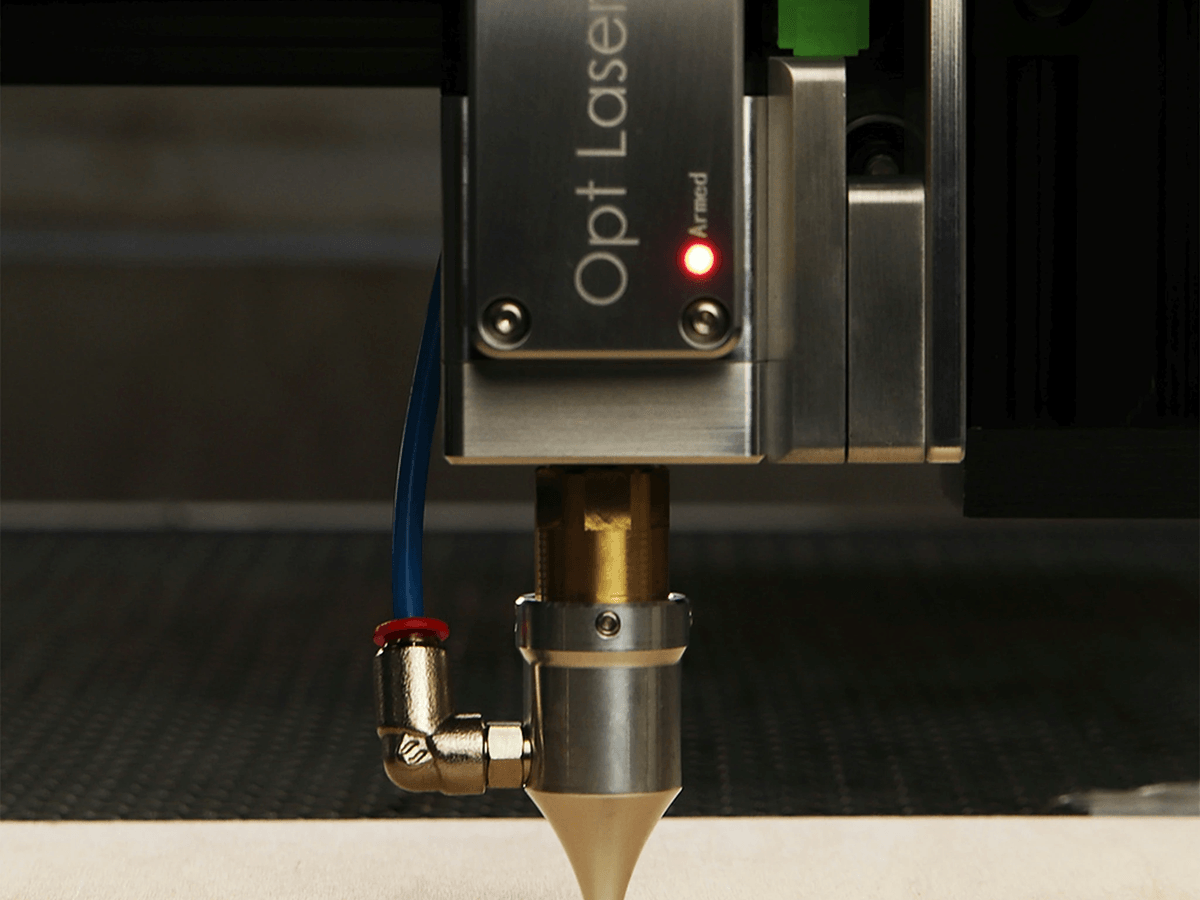

At its core, laser pipe cutting employs a powerful laser cutting machine to slice through metal pipes with exceptional accuracy. The process involves directing a concentrated beam of light onto the material, which melts or vaporizes the metal along predefined paths. This technology not only enhances the quality of cuts but also minimizes waste, making it an eco-friendly choice for those looking to machine cut metal efficiently.

Applications of Laser Cutting in Industries

Laser cutting machines have found applications across a wide range of industries, from automotive and aerospace to construction and art. In automotive manufacturing, for instance, precision cuts are essential for creating parts that fit together seamlessly. Similarly, in construction, laser machinery is used to fabricate complex piping systems that require exact specifications—ensuring safety and efficiency on job sites.

Advantages of Laser Pipe Cutting Over Traditional Methods

When comparing laser pipe cutting to traditional methods such as saws or plasma cutters, the benefits are clear as day—or rather, sharp as a laser! First off, the precision offered by a metal cutting machine laser is unmatched; it can achieve tolerances that would be nearly impossible with conventional techniques. Additionally, the speed at which these machines operate means reduced production times and lower labor costs—who wouldn’t want that?

Types of Laser Cutting Machines

Exploring Different Laser Technologies

Laser technologies have evolved significantly, providing options that cater to various materials and thicknesses. The most common types include CO2 lasers and fiber lasers, each with its own strengths. CO2 lasers are typically used for non-metal materials like wood and plastics, while fiber lasers excel at cutting metal with precision and speed, making them ideal for metal cutting machine laser applications.

The choice between these technologies often depends on the specific requirements of your projects. For instance, if you’re focused on laser pipe cutting in metals such as stainless steel or aluminum, a fiber laser might be your best bet due to its efficiency in handling reflective materials. Additionally, advancements in solid-state technology are paving the way for even more innovative solutions in the laser machinery landscape.

Comparing CO2 and Fiber Laser Machines

When comparing CO2 and fiber laser machines, it’s essential to consider factors like cost-effectiveness, maintenance needs, and operational efficiency. CO2 machines generally have lower initial costs but may incur higher operational expenses over time due to gas requirements and maintenance needs. On the other hand, fiber lasers are typically more energy-efficient and require less maintenance since they do not rely on gas.

In terms of performance for metal cutting machine laser applications, fiber lasers take the lead with faster processing speeds and superior cut quality on reflective metals—an important factor for industries relying on precision cuts in their production processes. Ultimately, your choice should align with both your budget constraints and your production goals; understanding these differences will help you make an informed decision when selecting a cutting machine laser.

Choosing the Right Cutting Machine for Your Needs

Selecting the right laser cutting machine involves assessing several critical factors tailored to your specific operations. First off, consider the types of materials you'll be working with; if you primarily handle metals or need versatility across different substrates like plastics or ceramics, this will guide your choice between CO2 or fiber lasers. Additionally, evaluate factors such as thickness requirements—thicker materials may necessitate more powerful machines capable of delivering consistent results across various jobs.

Next up is understanding your production volume; high-output environments may benefit from investing in advanced models that offer automation features designed to enhance efficiency during extended runs—this is where modern laser machinery shines! Finally, don’t overlook after-sales support; partnering with a reputable supplier like Kiant Machinery ensures access to ongoing service that keeps your equipment running smoothly over time.

Features of Kiant Machinery

When it comes to laser pipe cutting, Kiant Machinery stands out with its exceptional features designed for efficiency and precision. The integration of innovative technology in our laser machinery ensures that you receive not only high-quality cuts but also enhanced productivity in your operations. Our cutting machine laser solutions are engineered to meet the evolving demands of various industries, making metal cutting a breeze.

Innovative Technology in Laser Machinery

Kiant Machinery incorporates state-of-the-art innovations in its laser cutting machines that revolutionize the way industries approach metal fabrication. With advanced optics and control systems, our machines deliver unparalleled accuracy for intricate designs and complex geometries, ensuring every machine cut metal is executed flawlessly. This commitment to innovation means you can trust that our laser machines will keep you ahead of the competition while minimizing waste and maximizing output.

User-Friendly Design and Operation

One of the standout features of Kiant Machinery's offerings is their user-friendly design, which simplifies operation even for those new to laser cutting technology. The intuitive interface allows operators to navigate through settings with ease, making adjustments quick and efficient—perfect for those busy production environments where time is money! Additionally, our metal cutting machine laser models come equipped with safety features that ensure a secure working environment while maintaining optimal performance.

Customization Options for Your Cutting Machine

Every business has unique needs when it comes to laser pipe cutting; that's why Kiant Machinery offers extensive customization options for your cutting machine. From adjustable power settings tailored to specific materials to specialized software designed for particular applications, we ensure your machine fits seamlessly into your workflow. With these customizable features, you can enhance the capabilities of your laser machinery, allowing it to adapt as your projects evolve over time.

Installation and Training Services

When you invest in a laser cutting machine, the installation process is crucial for ensuring optimal performance from day one. At Kiant Machinery, we prioritize a seamless installation experience tailored to your specific setup. Our team of experts will arrive on-site to handle everything from unpacking the equipment to calibrating the laser machinery for precision metal cutting.

What to Expect During Installation

During the installation of your laser pipe cutting machine, you can expect a thorough walkthrough of the entire process. Our technicians will assess your workspace to ensure that all safety protocols are met while setting up your cutting machine laser. Once everything is in place, they’ll conduct a series of tests to confirm that your new metal cutting machine laser operates flawlessly before handing it over to you.

Comprehensive Training for Your Team

A top-notch laser cutting machine is only as effective as the team operating it, which is why we provide comprehensive training tailored specifically for your staff. Our training sessions cover everything from basic operation techniques to advanced troubleshooting methods, ensuring everyone feels confident using the laser machinery. With hands-on practice and expert guidance, your team will be well-equipped to maximize efficiency and productivity with their new laser pipe cutting system.

Ongoing Support and Maintenance

Investing in a quality laser cutting machine is just the beginning; ongoing support and maintenance are vital for long-term success. Kiant Machinery offers continuous assistance through regular check-ups and prompt responses to any operational questions or concerns you may have about your metal cutting machine laser. Plus, our maintenance packages ensure that any issues are addressed quickly, keeping downtime at bay so you can focus on what matters most—getting those precise cuts!

Success Stories with Kiant Machinery

Kiant Machinery has transformed numerous businesses with its state-of-the-art laser cutting solutions. Clients from various industries have experienced firsthand the efficiency and precision of laser pipe cutting, leading to remarkable improvements in their operations. These success stories highlight how investing in a quality laser cutting machine can yield significant returns.

Case Studies from Satisfied Clients

One notable case study involves a metal fabrication company that switched to Kiant's advanced laser machinery for their metal cutting needs. Previously reliant on traditional methods, they faced challenges with speed and accuracy, often resulting in wasted materials and time. After integrating a cutting machine laser from Kiant, they reported a 50% reduction in production time while achieving flawless precision, showcasing the advantages of modern laser technology.

Another client specializing in automotive components turned to Kiant for their laser pipe cutting requirements. The transition allowed them to streamline their workflow significantly; they could now cut intricate designs into pipes with ease and accuracy that was previously unattainable with conventional methods. This switch not only enhanced product quality but also led to an increase in customer satisfaction due to quicker turnaround times.

Efficiency Boosts with Laser Machine Solutions

The efficiency boosts realized through Kiant's laser cutting machines are nothing short of impressive. One manufacturing plant noted that the adoption of a fiber laser machine resulted in less downtime due to its rapid processing capabilities and minimal maintenance requirements compared to older technologies. As a result, this facility increased its output by 40%, allowing them to take on more projects without compromising quality.

In another instance, an aerospace parts manufacturer leveraged the precision of Kiant's metal cutting machine laser to produce complex components more rapidly than ever before. With the ability to execute detailed cuts without manual intervention, they freed up valuable labor resources for other critical tasks within their operations. This optimization not only improved productivity but also reduced operational costs dramatically.

Long-Term Benefits of Investing in Quality Equipment

Investing in high-quality laser machinery like those offered by Kiant yields long-term benefits that extend beyond immediate efficiency gains. Many clients report lower operational costs over time due to reduced waste and energy consumption associated with advanced laser pipe cutting technology compared to traditional methods. Additionally, these machines often come equipped with features designed for durability and reliability, ensuring that businesses can rely on them for years without frequent repairs or replacements.

Moreover, companies using Kiant's equipment have found that the superior quality of their finished products enhances brand reputation and attracts new customers seeking reliable suppliers for intricate metal work or custom designs. The adaptability of these machines means businesses can pivot quickly as market demands change—allowing them not just to survive but thrive amid competition.

Conclusion

In the rapidly evolving world of manufacturing, choosing the right equipment can make all the difference, and Kiant Machinery stands out as a leader in laser technology. With a commitment to innovation and quality, Kiant offers cutting-edge solutions for laser pipe cutting that enhance productivity and precision. As businesses strive to stay competitive, investing in a reliable laser cutting machine from Kiant ensures long-term success and efficiency.

Advantages of Choosing Kiant Machinery

Kiant Machinery brings unparalleled advantages to the table, particularly with its advanced laser machinery designed for various industries. Their laser cutting machines are renowned for their reliability and efficiency, making them ideal for anyone looking to machine cut metal with precision. Additionally, Kiant's commitment to customer service means you’ll receive ongoing support and training, ensuring your team is well-equipped to maximize the capabilities of your new cutting machine laser.

Maximizing Efficiency with Laser Cutting

When it comes to maximizing efficiency in production processes, laser pipe cutting is a game-changer. The speed and accuracy of a metal cutting machine laser allow for quicker turnaround times without sacrificing quality. By integrating a top-tier laser cutting machine into your operations, you can streamline workflows and reduce material waste—ultimately enhancing your bottom line.

Future Trends in Laser Cutting Technology

The landscape of laser cutting technology is continuously evolving, promising exciting advancements on the horizon. Innovations such as AI integration and enhanced automation are set to revolutionize how we approach tasks like laser pipe cutting in the near future. As manufacturers embrace these trends, investing in high-quality laser machinery now will prepare businesses for tomorrow's challenges while keeping them at the forefront of industry standards.