Introduction

In the ever-evolving world of manufacturing, the large format laser cutter stands out as a transformative tool that can redefine production processes. With the ability to deliver precision and versatility, laser cutting technology is revolutionizing how industries approach design and fabrication. Whether you’re a seasoned manufacturer or just starting out, understanding the benefits of investing in a laser cutting machine can open up new horizons for your projects.

Discover the Power of Large Format Laser Cutters

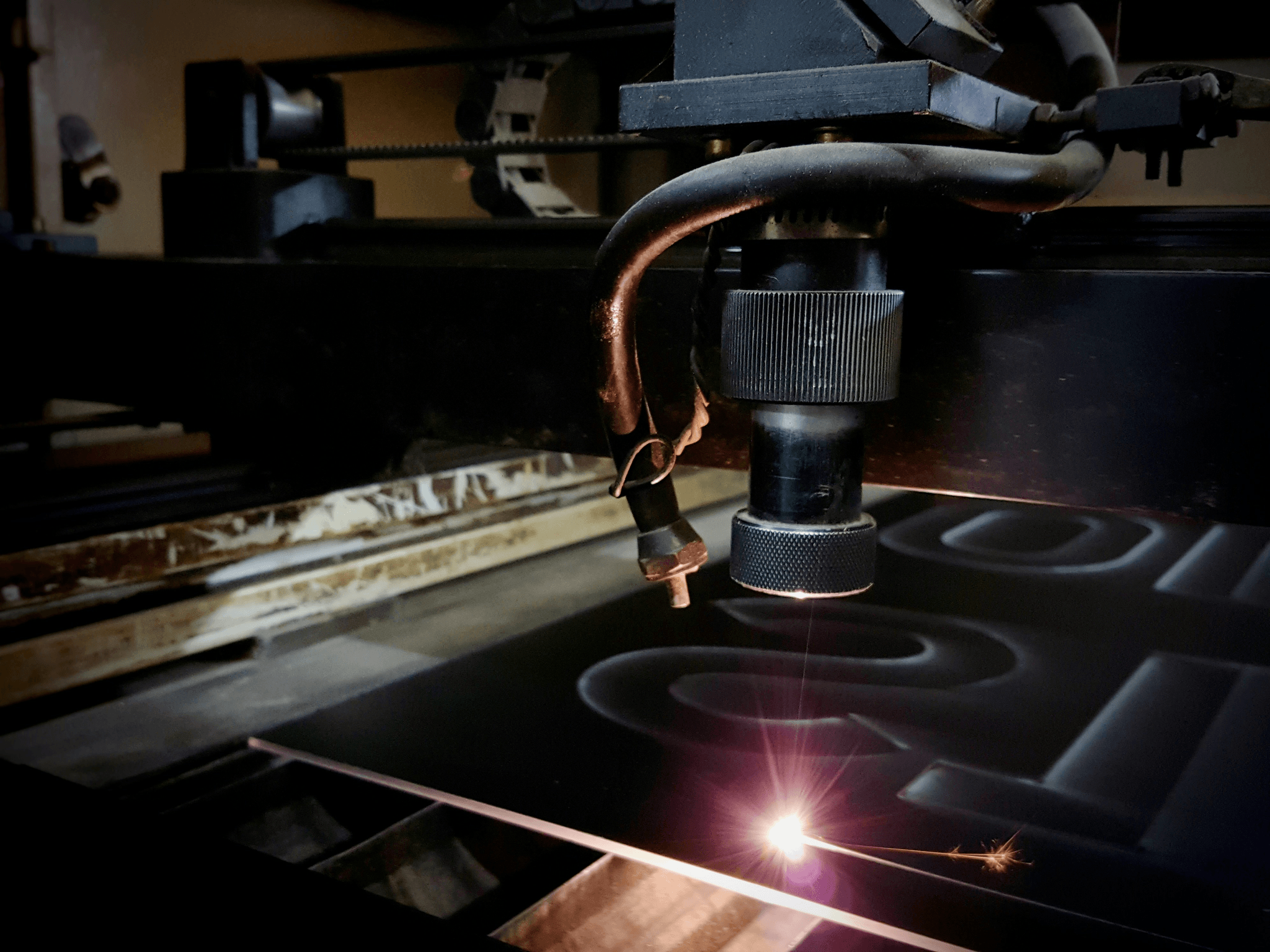

Large format laser cutters are not just machines; they are powerhouses of creativity and efficiency. These advanced laser machines leverage high-intensity beams to achieve intricate cuts across various materials, making them ideal for everything from signage to industrial components. The precision offered by a metal cutting laser cutter ensures that every project meets exact specifications with minimal waste.

Revolutionizing the Manufacturing Landscape

The introduction of laser machinery has dramatically changed the manufacturing landscape, enabling businesses to streamline operations and enhance productivity. Traditional methods often fall short when it comes to speed and accuracy; however, with a cutting machine laser, manufacturers can achieve rapid turnaround times without compromising quality. This shift toward automation not only boosts efficiency but also fosters innovation by allowing designers to experiment with complex shapes and designs.

Why Choose a Laser Cutting Machine

Choosing a laser cutting machine is about more than just investing in equipment; it's about embracing a new way of working that prioritizes both quality and cost-effectiveness. Laser cutting technology minimizes material waste while maximizing output, making it an environmentally friendly option for manufacturers looking to reduce their carbon footprint. Furthermore, with options like metal cutting machines lasers available on the market, there’s no limit to what you can create—whether it’s detailed artwork or robust industrial parts.

Enhanced Precision and Accuracy

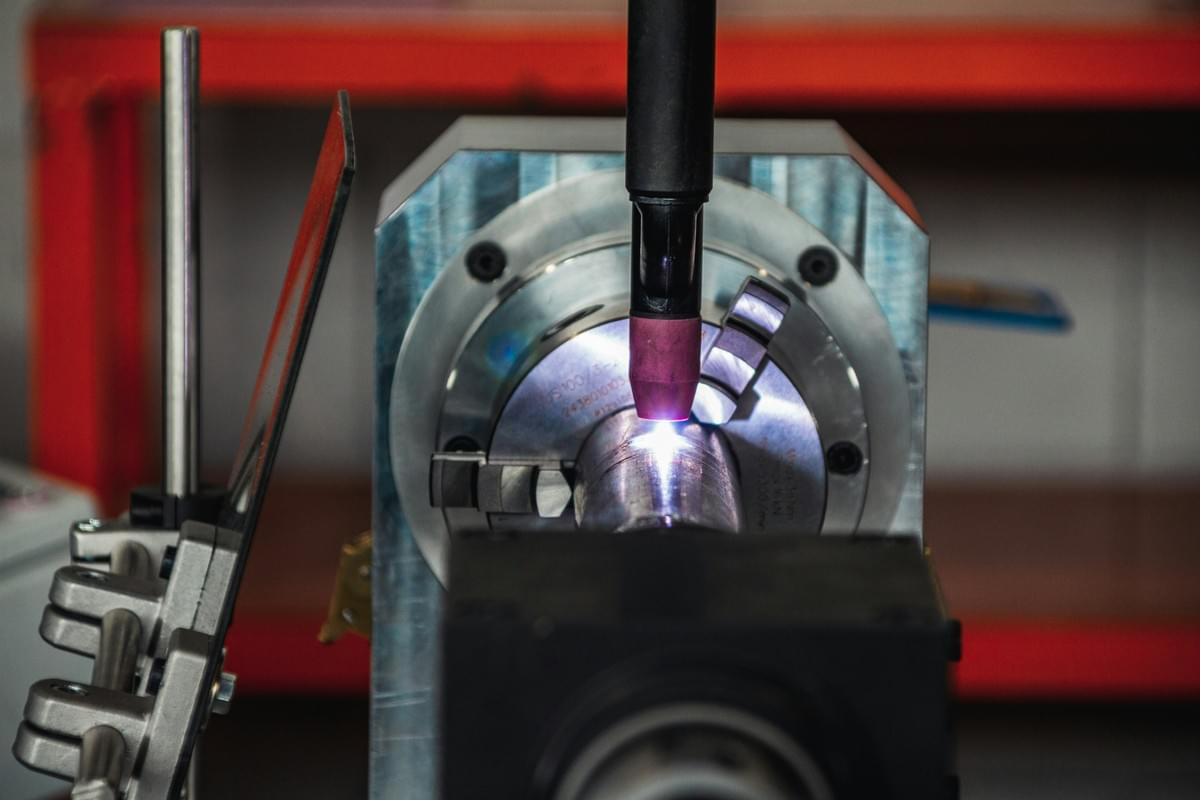

Large format laser cutters leverage advanced technology to achieve intricate cuts that traditional methods simply can't match. This level of detail opens up a world of possibilities for designers and manufacturers alike, ensuring that every project meets exact specifications.

Achieving Detailed Cuts with Laser Technology

Laser technology has revolutionized how we approach cutting tasks, allowing for incredibly detailed cuts that can be executed with ease. With a large format laser cutter, even the most complex designs can be reproduced flawlessly, thanks to the focused beam that slices through materials with pinpoint accuracy. This capability is particularly beneficial in industries where precision is paramount, such as aerospace and automotive manufacturing.

The Role of Software in Laser Cutting

The magic behind effective laser cutting doesn't just lie in the hardware; software plays an equally vital role in optimizing performance. Modern laser cutting machines are paired with sophisticated design software that allows users to create intricate patterns and control every aspect of the cut. This synergy between laser machinery and software ensures that projects are not only accurate but also efficient, reducing errors and enhancing overall output quality.

Tolerances and Quality Control

With their ability to operate within tight tolerances, metal cutting machine lasers ensure consistent quality across all components produced. Implementing rigorous quality control measures further enhances this reliability, making laser cutting a preferred choice for businesses aiming for excellence in their products.

Versatile Material Applications

When it comes to versatility, large format laser cutters are the superheroes of the manufacturing world. These cutting machines can handle a myriad of materials, making them indispensable for various industries. From wood and acrylic to textiles and glass, the range of materials you can cut with a laser cutting machine is truly impressive.

Materials You Can Cut with a Large Format Laser Cutter

The beauty of a large format laser cutter lies in its ability to slice through diverse materials with ease. Whether you're working on intricate designs in plywood or crafting stunning signage from acrylic, this laser machinery excels at delivering clean edges and precise cuts. Additionally, even softer materials like foam and paper can be expertly handled by these machines, ensuring that your creative visions come to life seamlessly.

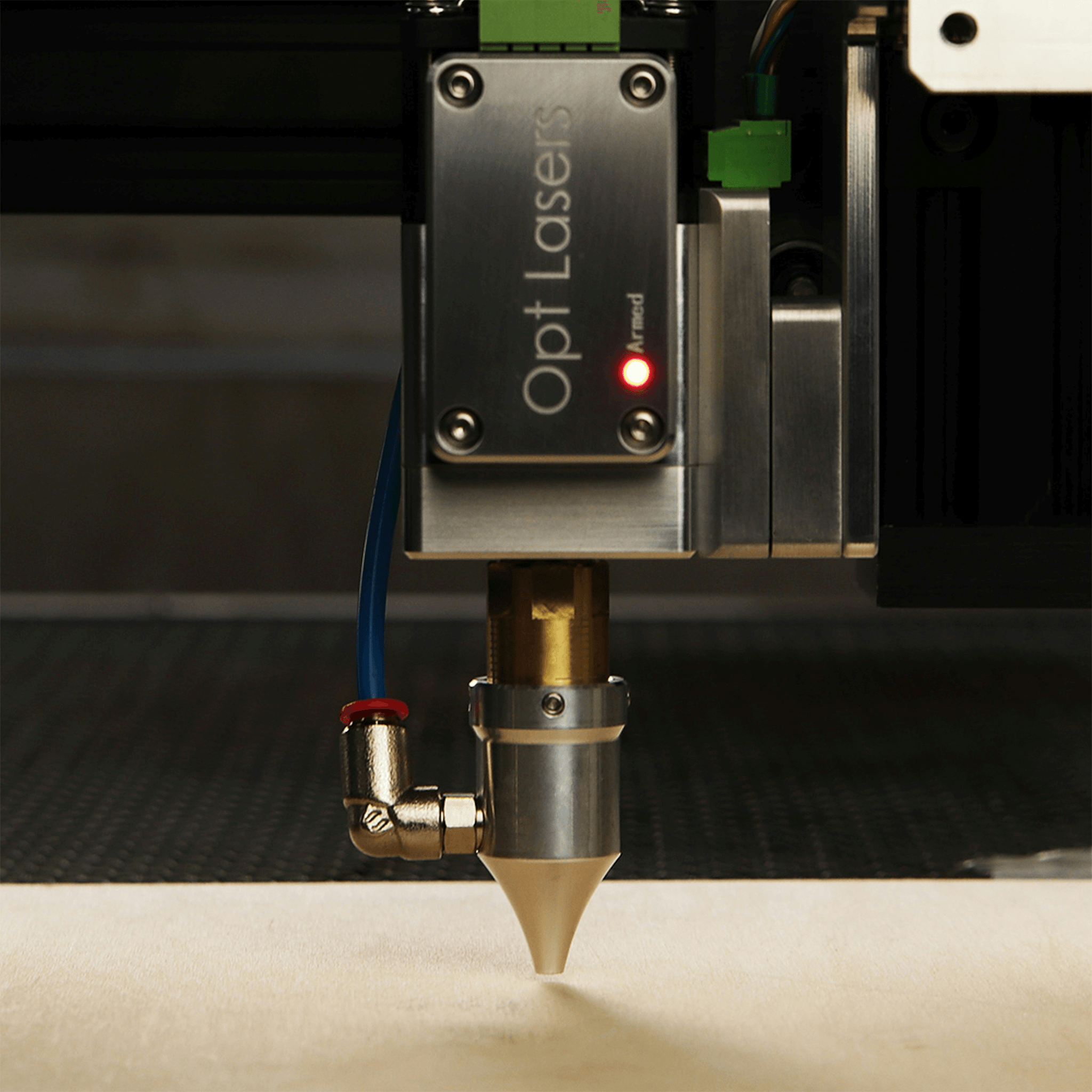

Metal Cutting Laser Cutter Capabilities

Metal cutting laser cutters take precision to new heights when it comes to working with metals like stainless steel, aluminum, and brass. With advanced technology embedded in modern metal cutting machine lasers, you can achieve intricate designs that were once thought impossible. The speed and accuracy of these laser cutting machines not only enhance productivity but also ensure minimal distortion in metal pieces during the cutting process.

Integrating Different Materials into One Project

One of the standout features of using a large format laser cutter is its ability to integrate multiple materials into a single project effortlessly. Imagine creating an eye-catching display that combines wood accents with metal engravings or acrylic overlays—all done using one machine! This fusion not only adds depth and texture but also allows designers to push boundaries creatively while maintaining efficiency through the capabilities of their laser machinery.

Improved Production Efficiency

In today’s fast-paced manufacturing environment, efficiency is paramount. Large format laser cutters have emerged as game-changers, dramatically speeding up production processes while maintaining high-quality output. With advanced laser machinery, businesses can streamline their operations and consistently meet tight deadlines without sacrificing precision.

Speed and Efficiency of Laser Machinery

One of the standout features of a laser cutting machine is its remarkable speed. Unlike traditional cutting methods that may require multiple passes or slow setups, a large format laser cutter can execute intricate designs in a fraction of the time. This efficiency not only enhances productivity but also allows manufacturers to take on more projects simultaneously, maximizing their output.

Moreover, the precision of these machines means that they can operate at high speeds without compromising accuracy. The metal cutting laser cutter can handle complex shapes and fine details effortlessly, making it an invaluable asset for industries ranging from automotive to aerospace. As businesses strive for greater throughput, investing in a cutting machine laser becomes an intelligent choice for those looking to stay competitive.

Reducing Waste with Laser Cutting Technology

Waste reduction is another significant advantage offered by modern laser cutting technology. Traditional cutting techniques often result in excess material being discarded due to inefficient layouts or inaccuracies during the process. In contrast, large format laser cutters utilize advanced software that optimizes material usage and minimizes scrap.

Laser machines are designed to make precise cuts with minimal kerf (the width of the cut), which translates into less wasted material overall. This not only conserves resources but also lowers costs associated with purchasing raw materials for projects involving metal cutting machines lasers or other materials. By reducing waste, businesses can enhance their sustainability efforts while improving their bottom line.

Cost-Effectiveness of Using a Cutting Machine Laser

When considering production efficiency, cost-effectiveness is always at the forefront of decision-making processes in manufacturing environments. While initial investments in a high-quality large format laser cutter may seem substantial, the long-term savings quickly become apparent through reduced labor costs and minimized waste expenditures.

Additionally, these machines often require less maintenance than traditional machinery due to fewer moving parts and lower wear rates associated with laser technology's non-contact nature. As companies experience decreased operational costs over time while boosting production capacity with efficient metal cutting machine lasers or versatile general-purpose models, it becomes clear that investing in a quality cutting machine laser is both practical and financially sound.

User-Friendly Operation

When it comes to operating a large format laser cutter, user-friendliness is paramount. The design of modern laser cutting machines ensures that even those with minimal experience can quickly grasp the basics and start creating impressive projects. With intuitive interfaces and straightforward controls, anyone can harness the power of laser cutting technology without feeling overwhelmed.

Ease of Use for All Skill Levels

One of the standout features of a metal cutting machine laser is its accessibility to users at all skill levels. Whether you're a seasoned professional or just dipping your toes into the world of laser machinery, you'll find that these machines are designed with ease of operation in mind. The learning curve is gentle; many users report being able to produce quality cuts within hours of their first interaction with a cutting machine laser.

Moreover, most large format laser cutters come equipped with pre-set settings for different materials and thicknesses, making it even easier to get started. This means you can focus on your creative vision rather than getting bogged down by complex technicalities. With such user-friendly technology at your fingertips, the possibilities for innovative designs are endless.

Training and Support from Kiant Machinery

At Kiant Machinery, we understand that investing in a laser cutting machine is just the beginning; that's why we offer comprehensive training and support tailored to your needs. Our dedicated team ensures that you not only know how to operate your new metal cutting laser cutter but also understand best practices for maintenance and safety protocols. This commitment helps you maximize efficiency while minimizing downtime.

In addition to hands-on training sessions, we provide detailed manuals and video tutorials that make mastering your large format laser cutter an achievable goal for anyone. Our customer support team is always ready to assist you with any questions or challenges you may encounter along the way. With Kiant Machinery by your side, you'll feel confident navigating through any project using our advanced laser machinery.

Safety Features of Modern Laser Machines

Safety should never be an afterthought when operating powerful tools like a metal cutting machine laser; fortunately, modern laser machines come equipped with numerous safety features designed to protect both users and equipment alike. These include automatic shut-off mechanisms that activate if something goes awry during operation—ensuring peace of mind as you work on intricate designs with precision cuts.

Additionally, many large format laser cutters have built-in ventilation systems that help manage fumes generated during the cutting process, contributing to a safer working environment overall. Clear safety guidelines are also provided alongside each machine purchase so users can familiarize themselves with best practices before they start using their new equipment fully. By prioritizing safety in our design philosophy at Kiant Machinery, we empower users to explore their creativity without compromising their well-being.

Customization and Design Flexibility

In the world of manufacturing, customization is key, and large format laser cutters excel in this area. With the ability to create intricate designs tailored to specific needs, a laser cutting machine can transform ideas into reality with remarkable precision. Whether you're crafting signage, architectural models, or custom parts, the versatility of laser cutting allows for endless possibilities.

Tailoring Projects with Laser Cutting

One of the standout features of a large format laser cutter is its ability to tailor projects precisely to client specifications. By adjusting settings such as speed and power, users can achieve different finishes and cut depths on various materials. This adaptability makes it a go-to tool for industries ranging from fashion design to engineering—where every detail counts.

The Impact of CAD Software on Design

The integration of CAD software with laser machinery has revolutionized how designers approach their projects. Using advanced software tools, creators can draft intricate patterns and layouts that are directly compatible with their metal cutting machine laser. This synergy not only streamlines the design process but also enhances accuracy, ensuring that what you envision is exactly what you get when the cutting begins.

Creativity Unleashed through Laser Technology

Laser technology opens up a world where creativity knows no bounds. Artists and designers are leveraging large format laser cutters to experiment with complex shapes and structures that would be nearly impossible to achieve through traditional methods. With a metal cutting laser cutter at your disposal, you can push creative boundaries further than ever before—turning imaginative concepts into tangible masterpieces.

Conclusion

In the ever-evolving world of manufacturing, a large format laser cutter stands out as a game-changer, unlocking new possibilities for creativity and efficiency. The precision and versatility offered by laser cutting machines are transforming how businesses approach design and production. As we conclude our exploration, it’s clear that embracing this technology can propel your projects to new heights.

Unlock New Possibilities with Laser Cutting

The capabilities of laser cutting extend far beyond simple shapes; they allow for intricate designs that were once unimaginable. With a metal cutting laser cutter, you can craft detailed components that fit seamlessly into your projects, enhancing both aesthetics and functionality. Imagine the freedom to experiment with various materials and complex geometries—laser machinery makes this not just possible but easy.

Choosing the Right Laser Cutting Machine

Selecting the perfect laser cutting machine is crucial for maximizing your project outcomes. Consider factors such as material compatibility, size requirements, and specific features like speed and precision when evaluating different models. A well-chosen cutting machine laser will not only meet your immediate needs but also grow with your ambitions in the future.

Partnering with Kiant Machinery for Success

Their expertise in providing top-notch equipment ensures that you have access to high-quality large format laser cutters tailored to your needs. With comprehensive training and support from Kiant Machinery, you’ll be equipped to make the most of your metal cutting machine laser investment.