Introduction

In the rapidly evolving world of manufacturing, laser cutting technology stands out as a game-changer, revolutionizing how industries approach precision cutting. This innovative process employs focused laser beams to slice through various materials with unparalleled accuracy and efficiency. As demand for high-quality metal components grows, understanding the intricacies of this technology becomes essential for businesses looking to stay competitive.

Overview of Laser Cutting Technology

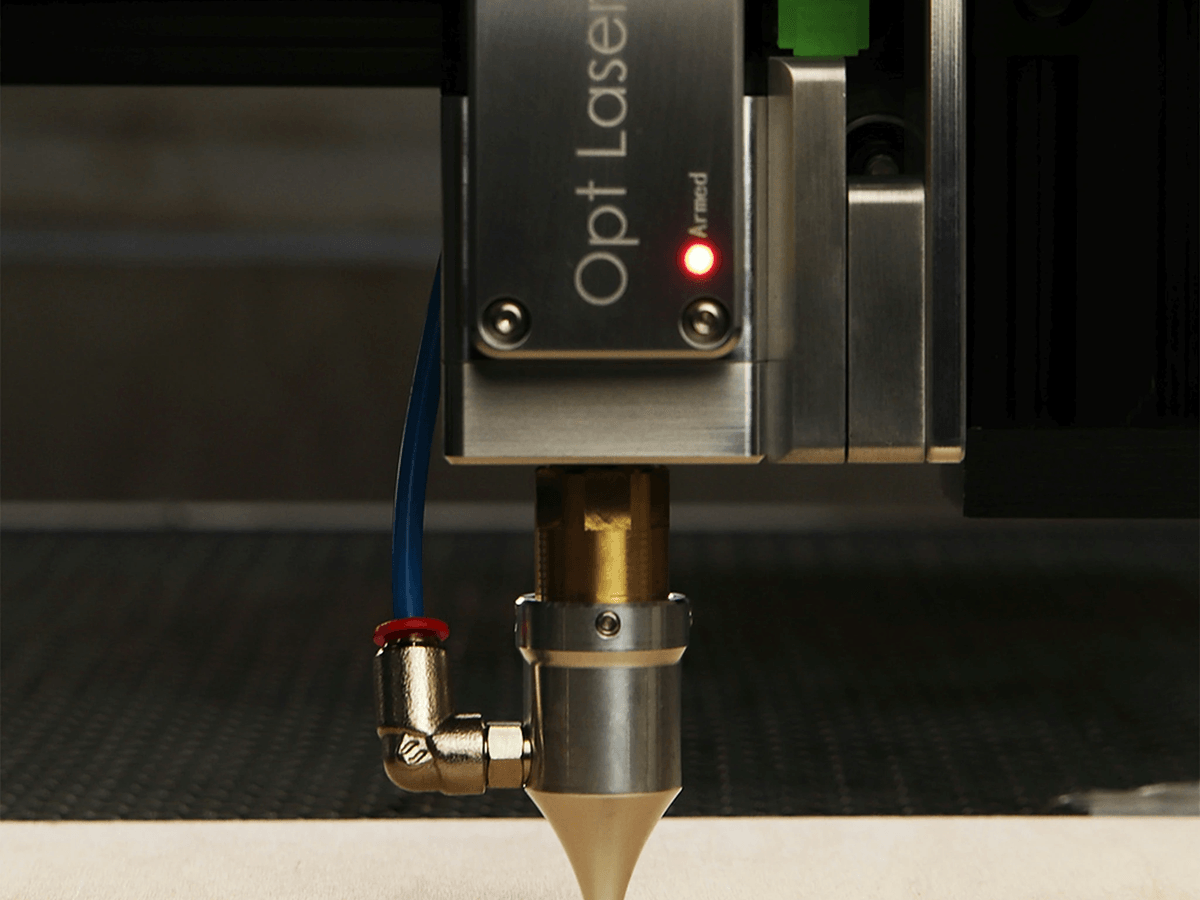

Laser cutting machines utilize high-powered lasers to cut through metal sheets and tubes with remarkable precision. By directing a concentrated beam of light onto the material, these machines can create intricate designs and clean edges that traditional cutting methods often struggle to achieve. The versatility of laser machinery allows it to handle a wide range of materials, making it a preferred choice among tube laser manufacturers.

Importance of Metal Sheet and Tube Cutting

Metal sheet and tube cutting are integral processes in various industries, including automotive, aerospace, and construction. The ability to produce precise cuts not only enhances product quality but also significantly reduces waste during manufacturing. With the rise in demand for customized solutions, efficient metal cutting laser cutters have become indispensable tools for manufacturers aiming to meet specific client needs.

Spotlight on Kiant Machinery

Kiant Machinery has emerged as a leading player among tube laser manufacturers by offering state-of-the-art laser machines tailored for diverse applications. Their commitment to innovation ensures that customers benefit from advanced features designed for ease of use and maximum efficiency in metal fabrication processes. With an extensive range of cutting machine lasers available for sale, Kiant Machinery is well-positioned to support businesses seeking reliable solutions in today’s competitive landscape.

Understanding Laser Cutting Machines

Laser cutting machines have revolutionized the way we approach metal fabrication, offering precision and efficiency that traditional methods simply can't match. Whether you're in need of a robust cutting machine laser for industrial applications or a more specialized solution from tube laser manufacturers, understanding how these machines work is crucial. Let’s dive into the mechanics, types, and advantages of this innovative technology.

How Laser Cutting Works

At its core, laser cutting operates by focusing a high-powered beam of light onto the material to be cut. This concentrated energy generates intense heat that melts or vaporizes the metal, creating an incredibly clean and precise cut. The process can be controlled with remarkable accuracy through computer numerical control (CNC), allowing for intricate designs and shapes that would be nearly impossible to achieve with conventional cutting methods.

The versatility of laser machinery means it can handle various materials beyond just metal sheets; plastics and wood are also fair game. When it comes to metal cutting laser cutters specifically designed for tubes, they offer unique capabilities tailored to tubular shapes as opposed to flat sheets. This adaptability makes them essential tools in diverse industries ranging from automotive manufacturing to aerospace engineering.

Types of Laser Cutting Machines

There are several types of laser cutting machines available on the market today, each suited for different applications and materials. CO2 lasers are popular for their efficiency in cutting non-metal materials like plastics and wood, while fiber lasers excel at processing metals due to their shorter wavelengths and higher absorption rates in metals. Then there are solid-state lasers which combine aspects of both technologies, offering versatility across various mediums.

For those looking specifically at tube laser manufacturers, there are dedicated tube-cutting machines that allow for precision cuts on cylindrical materials without compromising quality or speed. These specialized systems often come equipped with advanced features such as automatic loading systems and integrated software solutions that streamline operations even further. Choosing the right type ultimately depends on your specific needs—whether that's high-speed production or intricate detailing.

Advantages of Laser Technology

The benefits of using a cutting machine laser extend far beyond mere precision; they also include speed, cost-effectiveness, and minimal waste generation during production processes. Unlike traditional methods which may require extensive tooling changes or setups for different cuts, a single laser machine can handle multiple tasks with ease—reducing downtime significantly. Moreover, since lasers produce less mechanical stress on materials compared to other techniques like plasma or water jet cutting, there's less risk of warping or damage.

Another significant advantage lies in the reduced operational costs associated with maintenance when using modern laser machinery compared to older models or alternative technologies. With fewer moving parts involved in operation and less wear-and-tear over time due to their precision nature, these machines often lead to lower overall expenses over their lifespan—a win-win scenario! As you explore options like a reliable laser machine for sale from reputable tube laser manufacturers like Kiant Machinery, consider how these advantages align with your business goals.

Features of Kiant Machinery's Laser Systems

Kiant Machinery stands out in the competitive landscape of tube laser manufacturers, thanks to its cutting-edge laser systems that embody innovation and efficiency. Their advanced technology ensures precision and reliability, making them a preferred choice for businesses looking to invest in a laser cutting machine. With a focus on quality, Kiant Machinery’s products are designed to meet the diverse needs of metal fabrication.

Advanced Technology at Work

At the heart of Kiant Machinery's offerings is their commitment to advanced technology, which enhances the capabilities of their laser machinery. Utilizing state-of-the-art components and software, these machines deliver unparalleled accuracy in every cut, whether it’s for intricate designs or large-scale production runs. The integration of smart features allows operators to optimize performance while minimizing downtime—an essential aspect for any cutting machine laser.

Kiant’s metal cutting laser cutter systems leverage high-power lasers that can seamlessly handle various materials and thicknesses, ensuring versatility across different applications. This means businesses can tackle everything from delicate sheet metal work to robust tube cutting without needing multiple machines. As a result, customers benefit from reduced operational costs while enjoying superior output quality.

User-Friendly Operation

One of the standout features of Kiant Machinery's laser systems is their user-friendly operation, designed with operators in mind. The intuitive interface simplifies machine control and programming, enabling even novice users to quickly become proficient with the equipment—a significant advantage in fast-paced manufacturing environments. This ease of use translates into higher productivity levels as operators spend less time troubleshooting and more time producing high-quality cuts.

Moreover, many models come equipped with automated functions that further enhance usability by streamlining setup processes for different projects. These features not only save time but also reduce the risk of human error during operation—an essential factor when precision is non-negotiable in metal fabrication tasks. With such thoughtful design considerations, it's no wonder Kiant Machinery has earned praise among leading tube laser manufacturers.

Customization Options Available

Understanding that each business has unique requirements, Kiant Machinery offers extensive customization options for its laser machines available for sale. Customers can tailor their equipment based on specific needs such as size specifications, power output adjustments, or additional features like automatic loading systems—ensuring maximum efficiency tailored to individual workflows. This flexibility allows companies to invest in a solution that aligns perfectly with their operational goals rather than settling for one-size-fits-all machinery.

Furthermore, Kiant provides expert consultation during the purchasing process to help clients determine which customization options will yield the best return on investment based on their particular applications and industry demands. By prioritizing customer satisfaction through tailored solutions and ongoing support services, Kiant reaffirms its position as a leader among tube laser manufacturers committed to advancing metal fabrication technologies.

Applications of Metal Cutting Laser Cutters

Laser cutting technology has made significant inroads across various industries, transforming how metal components are produced. The precision and efficiency of metal cutting laser cutters make them indispensable in sectors ranging from automotive to aerospace. As industries continue to embrace automation and advanced manufacturing techniques, the demand for laser machinery will only increase.

Industries Benefiting from Laser Cutting

Numerous industries are reaping the rewards of incorporating laser cutting machines into their production processes. The automotive industry, for instance, utilizes these machines for creating intricate parts with high accuracy while minimizing waste. Similarly, the construction sector employs cutting machine lasers for fabricating steel structures and components that meet stringent safety standards.

In addition to automotive and construction, the electronics industry also benefits from laser cutting technology by producing precise circuit boards and enclosures with minimal thermal distortion. Even the fashion industry has tapped into this technology for creating unique designs in fabric and leather. With so many sectors enjoying the advantages of laser machinery, it's clear that metal cutting is here to stay.

Specific Use Cases Illustrated

To illustrate the versatility of metal cutting laser cutters, consider their role in producing custom signage for businesses. Companies can leverage these machines to create eye-catching designs that capture attention while being cost-effective. Another compelling use case is in prototyping; designers can quickly produce metal prototypes to test ideas before mass production.

In aerospace manufacturing, laser machines are employed to cut lightweight materials such as aluminum and titanium with remarkable precision, ensuring parts fit together perfectly without unnecessary weight additions. Additionally, tube laser manufacturers utilize advanced systems to create complex shapes in tubing used for various applications like furniture design or structural supports. These examples showcase how adaptable and essential these tools have become across multiple fields.

Future Trends in Metal Fabrication

The future of metal fabrication is poised for exciting innovations driven by advancements in laser technology. One notable trend is the integration of artificial intelligence (AI) into laser cutting systems, which enhances operational efficiency by optimizing cut paths and reducing downtime during setup changes. This evolution will likely lead to even more sophisticated laser machinery capable of handling a broader range of materials with improved speed.

Moreover, as sustainability becomes a priority across industries, eco-friendly practices will start influencing the design and functionality of laser machines for sale—leading manufacturers to develop energy-efficient models that minimize waste during operations. Finally, we can expect enhanced connectivity features allowing seamless integration with Industry 4.0 initiatives—enabling real-time monitoring and data analytics that further streamline production processes.

Selecting the Right Laser Machinery

Choosing the right laser machinery can feel like navigating a maze, especially with so many options available in the market today. Whether you're looking for a cutting machine laser for intricate designs or a robust metal cutting laser cutter for heavy-duty tasks, understanding your needs is crucial. With the right information, you can make an informed decision that will enhance your production capabilities.

Key Considerations for Buyers

When selecting a laser cutting machine, buyers should consider several key factors to ensure they make the best choice. First and foremost, evaluate the material types and thicknesses you'll be working with; different machines excel at cutting various metals and thicknesses. Additionally, think about the precision and speed required for your projects—some laser machinery offers advanced features that can significantly increase efficiency while maintaining high-quality cuts.

Another important consideration is the machine's ease of use. A user-friendly interface can reduce training time and improve productivity as operators become familiar with its functions more quickly. Lastly, don’t forget to factor in after-sales support; reliable service from tube laser manufacturers can save you from potential headaches down the line.

Comparing Tube Laser Manufacturers

Not all tube laser manufacturers are created equal, which is why comparing them is essential before making a purchase. Start by researching their reputation within the industry—look for reviews or testimonials from previous customers to gauge satisfaction levels with their products and services. Additionally, consider how long each manufacturer has been in business; experience often correlates with reliability and expertise.

Another critical aspect is assessing the technology used in their laser systems; some manufacturers may offer innovative features that set them apart from competitors. For instance, advanced cooling systems or enhanced software capabilities could greatly influence your decision-making process when choosing a cutting machine laser that meets your specific requirements. Finally, check if they provide customization options tailored to your unique production needs—this flexibility can often lead to better overall performance.

Tips for Evaluating Laser Machine for Sale

When hunting for a quality laser machine for sale, it’s vital to conduct thorough evaluations before making any commitments. Start by examining specifications such as wattage and beam quality; these factors directly impact cut precision and speed on various materials using metal cutting laser cutters. Moreover, inquire about warranty terms—an extended warranty may indicate confidence in product durability.

Next on your checklist should be exploring financing options offered by tube laser manufacturers; flexible payment plans can ease budget constraints while securing top-notch equipment essential for future projects. Don’t shy away from asking questions during demonstrations or consultations—the more you know about how each machine operates under real conditions, the better equipped you'll be to make an informed choice.

Lastly, remember that price isn’t everything; sometimes investing slightly more upfront in high-quality machinery pays off over time through reduced operational costs and improved output quality! By following these tips diligently during your search process, you'll undoubtedly find a reliable solution tailored perfectly to meet all of your metal fabrication needs.

Maintenance and Support for Laser Machines

Maintaining a laser cutting machine is not just a suggestion; it’s an absolute necessity. Regular maintenance ensures that your metal cutting laser cutter operates at peak efficiency, prolonging the life of the equipment and minimizing downtime. Without proper upkeep, even the most advanced laser machinery can fall victim to wear and tear, leading to costly repairs or replacements.

Importance of Regular Maintenance

Regular maintenance of your laser machine is crucial for several reasons. First, it helps maintain optimal cutting quality, ensuring that every cut is precise and clean—a must-have for any serious fabricator. Second, routine check-ups can identify potential issues before they escalate into major problems, saving you both time and money in the long run.

Moreover, neglecting maintenance can lead to inefficient operation and increased energy consumption. This not only affects your bottom line but also impacts production schedules and customer satisfaction. In an industry where precision is key, staying ahead with regular service checks becomes a competitive advantage.

Kiant Machinery’s After-Sales Services

Kiant Machinery stands out among tube laser manufacturers by offering comprehensive after-sales services tailored to your needs. Their dedicated support team is always ready to assist you with troubleshooting or technical inquiries related to your cutting machine laser. This commitment ensures that any hiccup in production doesn’t turn into a full-blown crisis.

Additionally, Kiant Machinery provides access to genuine replacement parts designed specifically for their machines—because using subpar components can compromise performance and safety. The company also offers service contracts that include regular inspections and preventive maintenance schedules tailored just for you.

Their after-sales services extend beyond just fixing problems; they aim to build long-term relationships with clients by ensuring their laser machinery remains in top-notch condition throughout its lifespan.

Training Programs for Operators

Investing in training programs for operators is another critical aspect of maintaining a high-performing laser machine for sale. Kiant Machinery understands this need well; they provide comprehensive training sessions that cover everything from basic operations to advanced troubleshooting techniques specific to their machines.

These programs not only empower operators but also enhance overall workplace safety—after all, well-trained staff are less likely to make mistakes that could damage equipment or compromise quality standards. Plus, operators who are knowledgeable about their metal cutting laser cutter will feel more confident in their roles, leading to increased productivity on the shop floor.

By equipping your team with the right skills through Kiant's training initiatives, you're investing in the longevity of your investment while ensuring operational excellence across all projects involving your cutting machine laser.

Conclusion

In summary, choosing the right laser cutting machine can significantly enhance your metal fabrication processes. Kiant Machinery stands out among tube laser manufacturers with its commitment to quality, innovation, and customer satisfaction. By investing in a cutting machine laser from Kiant, you're not just purchasing equipment; you're gaining a partner dedicated to your success.

Why Choose Kiant Machinery

Kiant Machinery has earned its reputation as a leader in the industry for good reason. Their focus on advanced technology ensures that their laser machinery meets the diverse needs of various sectors while maintaining top-notch performance. With customizable solutions and user-friendly operation, Kiant's offerings are designed to empower businesses to achieve their goals efficiently.

The Benefits of Laser Cutting Solutions

The advantages of using metal cutting laser cutters are numerous and compelling. From precision cuts to reduced waste, laser cutting solutions provide unmatched efficiency compared to traditional methods. Additionally, with the versatility of a laser machine for sale from Kiant Machinery, businesses can adapt quickly to changing demands without compromising quality.

Future of Metal Tube and Sheet Cutting

Looking ahead, the future of metal tube and sheet cutting is bright as technology continues to evolve at an unprecedented pace. Innovations in laser technology promise even greater efficiency and capabilities for manufacturers seeking competitive advantages in their industries. As more companies turn to reliable tube laser manufacturers like Kiant Machinery, we can expect significant advancements that will shape the landscape of metal fabrication for years to come.