Introduction

In the world of manufacturing and design, laser cutting aluminum has emerged as a game-changer, bringing precision and efficiency to various projects. This innovative technology allows for intricate designs and clean cuts that were once thought impossible with traditional methods. With its ability to transform ideas into reality, laser cutting aluminum is truly magical.

The Magic of Laser Cutting Aluminum

Laser cutting aluminum utilizes focused beams of light to slice through metal with incredible accuracy. This process not only minimizes waste but also enhances the quality of the finished product, making it a favorite among fabricators and designers alike. The precision offered by laser engravers cutters ensures that every detail is captured perfectly, allowing for stunning results in both functional and artistic applications.

Why Aluminum is Ideal for Laser Cutting

Aluminum stands out as an ideal material for laser cutting due to its lightweight nature and excellent thermal conductivity. These properties enable faster processing times without compromising on quality, making it a preferred choice in industries ranging from aerospace to automotive. Moreover, the ability to work with various thicknesses of sheet metal for laser cutting means that versatile designs can be achieved effortlessly.

Revolutionizing Projects with Precision

The integration of CNC cutting technology into metal fabrication has revolutionized how projects are approached today. With metal laser cutting services at their disposal, businesses can streamline production processes while ensuring high levels of accuracy in their cuts. As a result, creative professionals can explore new horizons in custom fabrication with metal cut techniques that push the boundaries of innovation.

Understanding Laser Cutting Technology

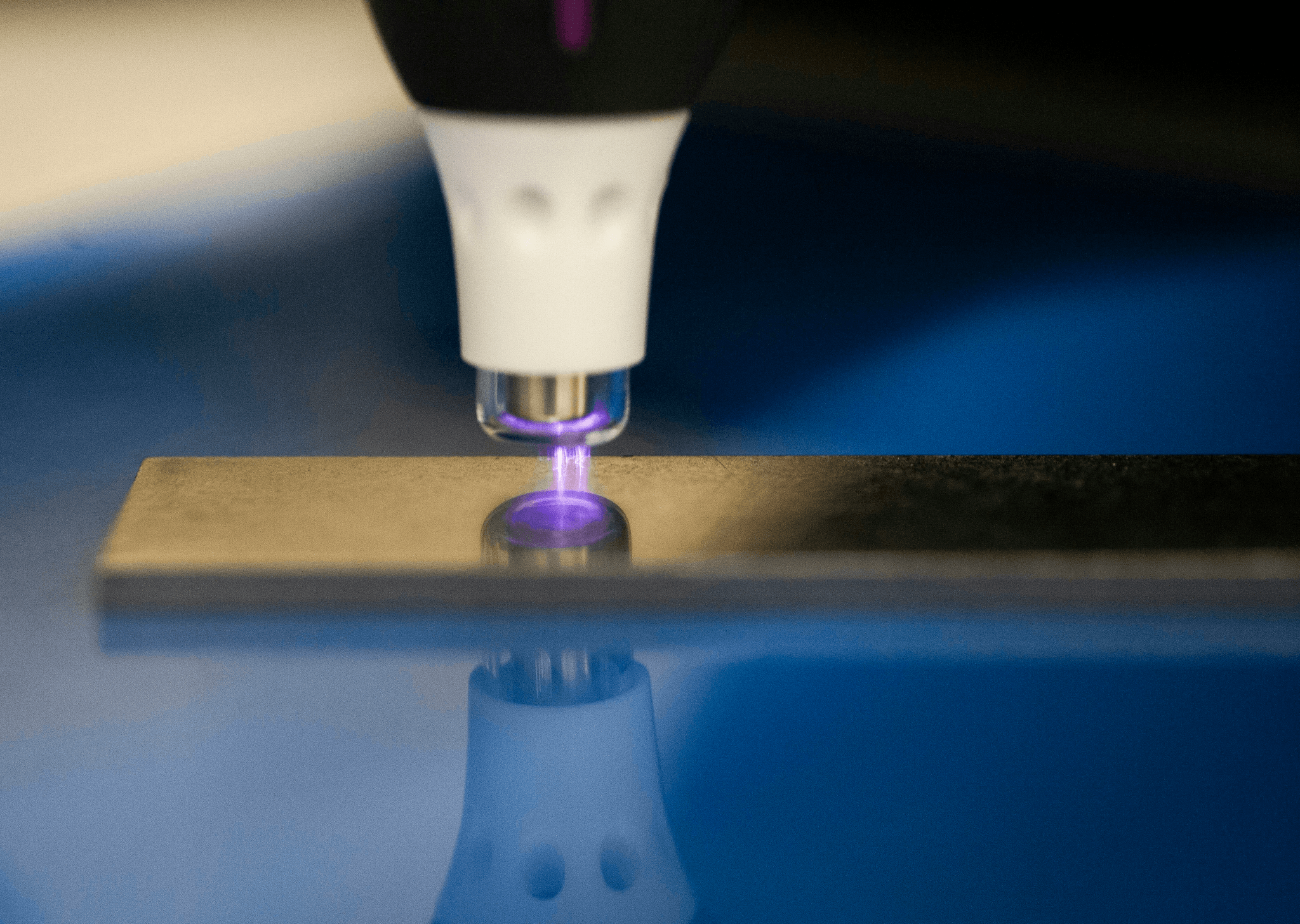

Overview of Laser Cutting Aluminum

When it comes to laser cutting aluminum, the technology operates by directing a high-powered laser beam onto the surface of the metal. The intense heat generated by the laser melts or vaporizes the aluminum, allowing for accurate and efficient cuts. This process is particularly effective for sheet metal for laser cutting since aluminum's lightweight nature and thermal conductivity make it an ideal candidate for this technique.

The versatility of laser cutting allows for both simple shapes and complex geometries, catering to diverse project needs. Whether you're crafting components for machinery or creating artistic pieces, understanding how laser cutting works will enhance your design capabilities significantly. As industries continue to adopt this technology, it's clear that mastering the art of cutting laser metal is essential for staying competitive.

Advantages of Metal Laser Cutting Services

Metal laser cutting services offer numerous advantages over traditional methods, making them increasingly popular among fabricators and designers alike. One major benefit is precision; with minimal kerf width and excellent repeatability, you can achieve intricate designs that would be challenging with other techniques. Additionally, using a metal laser cutting service reduces material waste since the cuts are so precise that less scrap material is produced.

Another advantage is speed; modern CNC cutting machines can operate at impressive speeds without sacrificing quality or accuracy. This efficiency translates into faster turnaround times on projects, which is crucial in today's fast-paced market environment. Furthermore, many service providers offer custom solutions tailored specifically to your needs—ensuring that whether you need one-off pieces or bulk orders, your requirements are met seamlessly.

How CNC Cutting Works

CNC (Computer Numerical Control) cutting is a pivotal component in modern fabrication processes like laser engraving cutters and other advanced machining techniques. In CNC systems used for metal cut operations such as those involving aluminum sheets, designs are programmed into a computer that controls the movement of the laser cutter along predetermined paths with pinpoint accuracy. This automation not only enhances precision but also allows operators to produce complex shapes consistently across multiple units.

The integration of CNC technology in metal fabrication means less manual intervention and improved safety during operations—reducing human error while maximizing productivity levels significantly. With advancements in software and hardware technologies continually evolving within this field, CNC systems are becoming more intuitive and user-friendly than ever before.

Applications of Laser Cutting Aluminum

Laser cutting aluminum has transformed various industries and creative endeavors, showcasing its versatility and precision. From manufacturing to artistic projects, the applications are vast and varied. Understanding these uses can help you appreciate the true potential of this cutting-edge technology.

Industry Uses for Cut Aluminum Sheets

In the industrial sector, laser cutting aluminum is a game changer for producing components with exact specifications. Industries such as automotive, aerospace, and electronics rely on precise cut aluminum sheets for everything from structural parts to intricate designs. The efficiency of metal laser cutting services allows for rapid production without compromising quality, making it an ideal choice for large-scale manufacturing.

Moreover, businesses benefit from the ability to customize orders easily with CNC cutting techniques that adapt to specific project needs. This flexibility means companies can produce small batches or large quantities while maintaining high standards in each piece produced. As a result, laser-cut aluminum sheets have become essential in reducing waste and optimizing costs across various sectors.

Creative Projects Utilizing Laser Engravers Cutters

The world of art and design has also embraced the magic of laser engravers cutters when working with aluminum materials. Artists use these tools to create stunning visual effects by engraving intricate patterns or designs onto aluminum surfaces. This technique not only enhances aesthetic appeal but also allows creators to experiment with depth and texture in their work.

In addition to traditional artistry, DIY enthusiasts have found innovative ways to incorporate laser cutting into their projects—think custom signs, decorative panels, or even personalized gifts! The precision offered by cutting laser metal ensures that every detail is captured beautifully, giving projects a professional finish without requiring extensive craftsmanship skills. With endless possibilities at their fingertips, creators are continually pushing the boundaries of what’s achievable through this technology.

Custom Fabrication with Metal Cut Techniques

Custom fabrication is another area where laser cutting aluminum shines brightly; it enables manufacturers to produce unique components tailored precisely for specific applications. By employing advanced metal cut techniques alongside CNC cutting capabilities, businesses can achieve remarkable accuracy in creating complex shapes and designs that would be difficult or impossible using traditional methods.

This level of customization opens doors for specialized products across various industries—from bespoke machinery parts to artistic installations that require a personal touch. Moreover, as more companies recognize the benefits of utilizing sheet metal for laser cutting processes in their production lines, they are increasingly investing in state-of-the-art equipment capable of handling diverse projects efficiently.

Key Considerations for Laser Cutting Aluminum

Selecting the right sheet metal for laser cutting is crucial because not all aluminum grades and thicknesses behave the same under a cutting laser. Additionally, understanding material properties will help you optimize your designs for better results.

Selecting the Right Sheet Metal for Laser Cutting

Choosing the right sheet metal for laser cutting can make or break your project. Different aluminum alloys have varying compositions that affect their machinability and response to heat generated by cutting lasers. For instance, 5052 aluminum is popular due to its excellent workability and corrosion resistance, making it ideal for many applications involving laser engravers cutters.

Another important factor is surface quality; sheets with pre-coated or polished finishes may yield cleaner cuts compared to those with rough surfaces. It's essential to consider these aspects when sourcing your materials to ensure that you get optimal performance from your metal laser cutting service. Ultimately, investing time in selecting appropriate sheet metal will pay off in terms of precision and finish.

Understanding Thickness and Material Properties

Thickness plays a pivotal role in the effectiveness of CNC cutting processes when working with aluminum sheets. Generally, thinner materials are easier to cut but may require different settings on your laser cutter than thicker sheets do—this is where understanding material properties becomes vital. For example, while 1/16 inch thick aluminum might be cut at high speeds without much trouble, thicker materials could necessitate slower speeds and higher power settings.

Moreover, different alloys have unique thermal conductivity levels which influence how they react during the cutting process. This means that understanding both thickness and alloy type helps in fine-tuning settings on your machine for optimal results in metal cut projects—ensuring you achieve clean edges without excessive dross or warping.

Choosing a Reliable Metal Laser Cutting Service

Finding a reliable metal laser cutting service can be daunting given the plethora of options available today; however, it's crucial for ensuring high-quality outcomes in your projects involving laser cutting aluminum. Look for providers with proven track records who use advanced technology like CNC systems designed specifically for efficient metal processing—this guarantees precision cuts every time!

It's also worth considering customer reviews and testimonials; satisfied clients often indicate a service’s reliability and ability to meet deadlines without compromising quality standards. Don’t shy away from asking potential partners about their experience with specific types of aluminum or any custom requirements you may have; this knowledge can greatly enhance collaboration on future projects.

The Role of Kiant Machinery in the Industry

Kiant Machinery has established itself as a key player in the laser cutting aluminum industry, continuously pushing the envelope with innovative solutions. Their commitment to enhancing metal laser cutting services has positioned them at the forefront of technology, making them a go-to choice for businesses seeking precision and efficiency. With a focus on high-performance equipment, Kiant is revolutionizing how industries approach CNC cutting and metal fabrication.

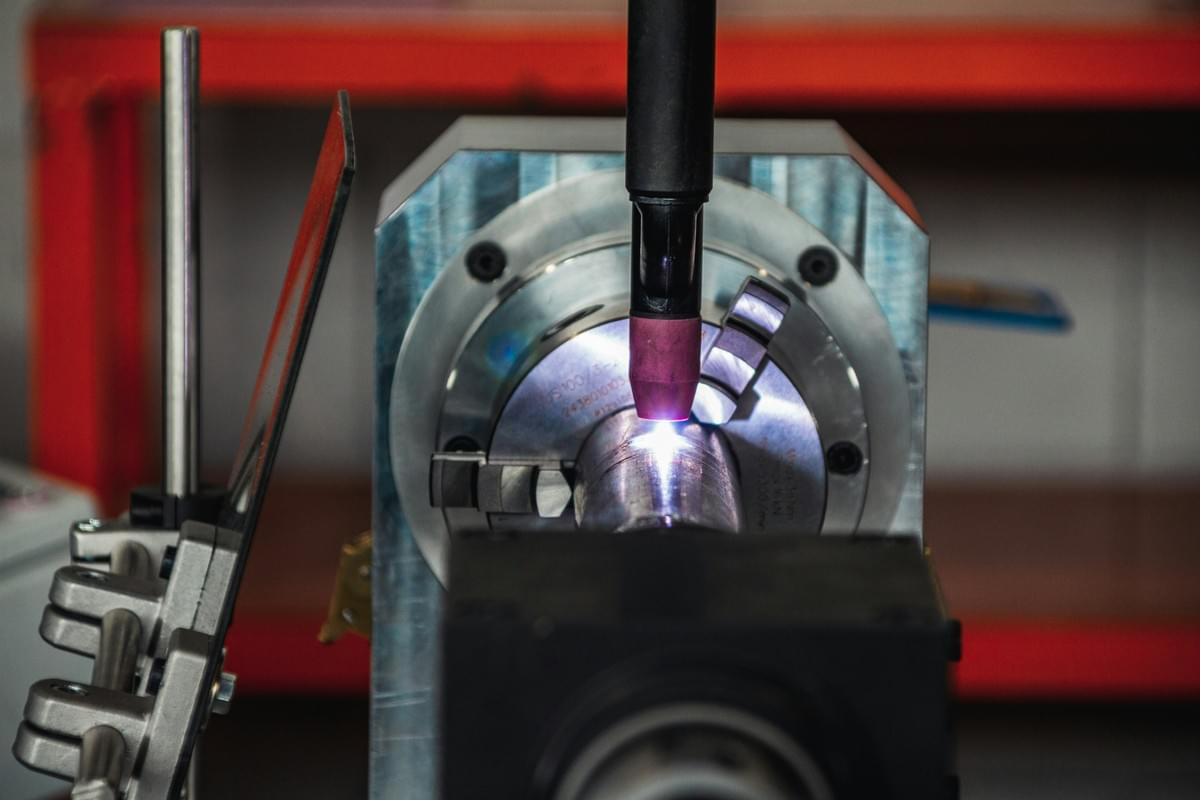

Innovations in Laser Tube Cutting Equipment

Kiant Machinery is leading the charge with groundbreaking innovations in laser tube cutting equipment that cater specifically to the needs of modern manufacturing. Their state-of-the-art machines are designed for optimal performance, enabling users to achieve intricate designs with unparalleled accuracy when it comes to cutting laser metal. By integrating advanced technology into their systems, Kiant ensures that every project involving sheet metal for laser cutting meets stringent quality standards while maximizing productivity.

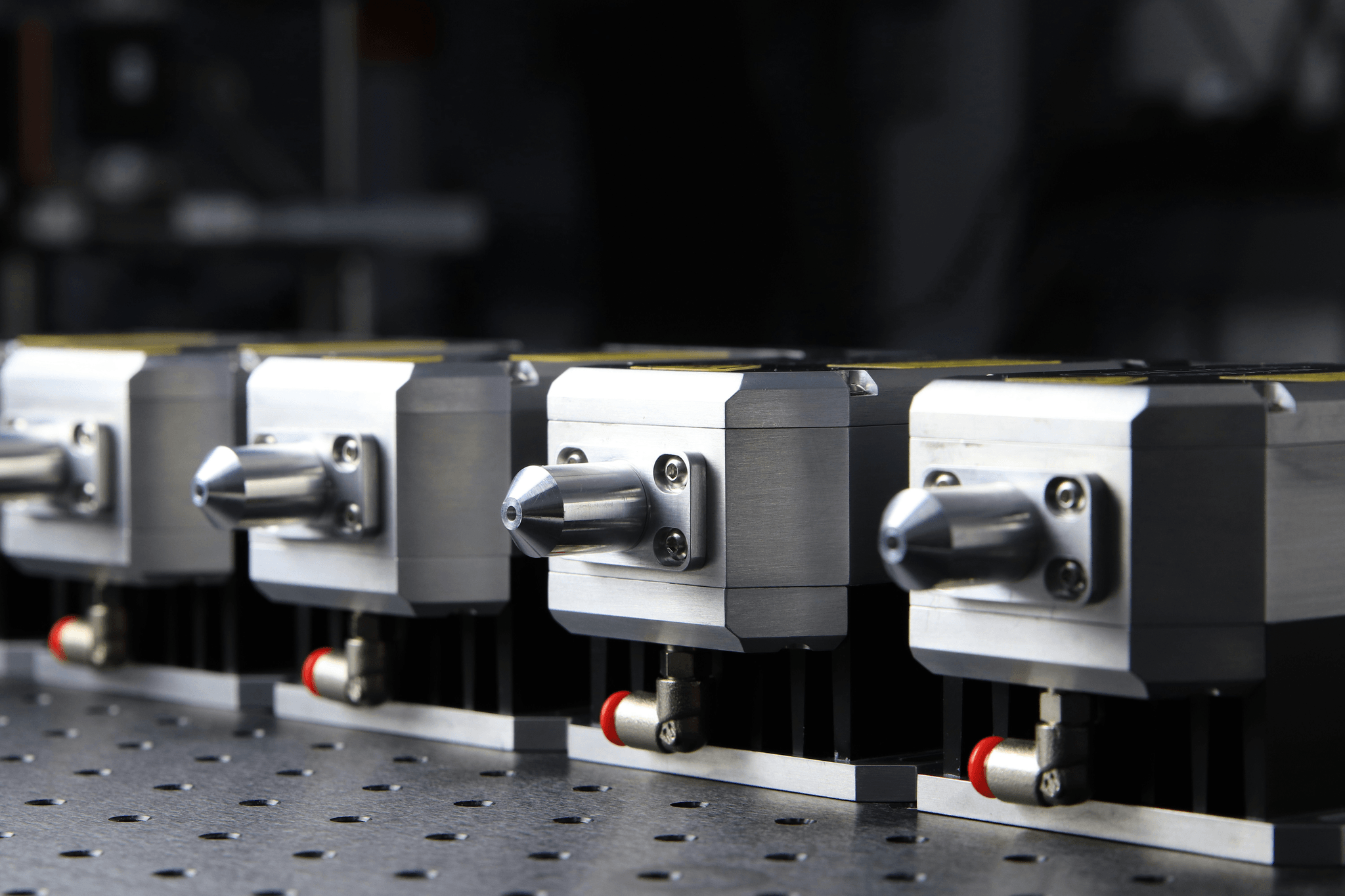

Enhancing Performance with Kiant Machinery

Performance enhancement is at the core of what Kiant Machinery offers its clients in the realm of laser cutting aluminum. Their machines are engineered not just for speed but also for precision, ensuring that every cut is clean and exact—essential traits when dealing with complex designs or large-scale projects. By utilizing advanced software and hardware solutions, Kiant empowers businesses to streamline their operations and reduce waste during the metal cut process.

Training and Support for Efficient Operations

Understanding how to effectively operate laser engravers cutters can be daunting without proper training and support; that's where Kiant Machinery shines even brighter! They provide comprehensive training programs designed to equip operators with essential skills needed for efficient operations within any facility using their equipment. Additionally, ongoing support ensures that businesses can troubleshoot issues quickly, ensuring minimal downtime while maximizing output from their metal laser cutting service.

Future Trends in Laser Cutting Aluminum

The landscape of laser cutting aluminum is rapidly evolving, driven by technological advancements, automation, and a growing emphasis on sustainability. As industries seek to enhance efficiency and precision, the future of metal laser cutting services is bright with innovation. These trends not only promise to improve operational capabilities but also to create more environmentally friendly practices in metal cut processes.

Advancements in Laser Cutting Technology

Recent advancements in laser cutting technology are transforming how we approach the cutting of aluminum and other metals. Innovations such as fiber lasers and high-powered CO2 lasers are making it possible to achieve finer cuts with greater speed and efficiency than ever before. These technologies allow for intricate designs that were once thought impossible, opening up new avenues for creativity in custom fabrication projects using sheet metal for laser cutting.

Moreover, the integration of artificial intelligence into CNC cutting systems is enhancing the precision of laser engravers cutters. AI algorithms can optimize cutting paths and settings based on material properties, leading to reduced waste and improved quality. This not only streamlines production but also ensures that businesses can meet the increasing demands for high-quality cut aluminum sheets across various industries.

The Rise of Automation in Metal Cutting

With the rise of automation in metal cutting, businesses are reaping the benefits of increased productivity and reduced labor costs. Automated systems equipped with advanced sensors can monitor performance in real-time, ensuring that every piece meets exact specifications without human intervention. This shift towards automated solutions is particularly beneficial for large-scale operations where consistency and speed are paramount.

Additionally, automated laser cutting machines can handle complex tasks that would typically require multiple setups or manual adjustments, further enhancing workflow efficiency. As a result, companies leveraging these technologies can offer superior metal laser cutting services while maintaining competitive pricing structures. The future will likely see even more sophisticated automation solutions that will redefine how we think about manufacturing processes involving aluminum.

Sustainable Practices in the Laser Cutting Industry

Sustainability is becoming a cornerstone principle within the laser cutting industry as companies look to reduce their environmental footprint while maintaining productivity levels. Advances in technology have led to more efficient energy use during the laser cutting process, minimizing carbon emissions associated with traditional methods of metal cut processing. By adopting greener practices, businesses not only comply with regulations but also appeal to an increasingly eco-conscious consumer base.

Moreover, recycling efforts have gained traction within this sector; scrap materials from laser-cutting operations can be reused or repurposed effectively rather than ending up as waste. This commitment to sustainability extends beyond just materials; many manufacturers are investing in eco-friendly equipment designed specifically for energy efficiency during operation—maximizing output while minimizing resource consumption. Embracing sustainable practices will not only enhance brand reputation but also pave the way for a greener future within the realm of sheet metal for laser cutting.

Conclusion

In the fast-paced world of manufacturing and creative projects, laser cutting aluminum stands out as a game-changer. This technology not only enhances precision but also allows for intricate designs that were once thought impossible. Whether you're working on industrial applications or artistic endeavors, embracing laser cutting can truly transform your projects into masterpieces.

Transform Your Projects with Laser Cutting

Laser cutting aluminum opens up a realm of possibilities for both professionals and hobbyists alike. With the ability to create precise shapes and detailed engravings, this method ensures that every piece meets high standards of quality and accuracy. By utilizing cutting laser metal techniques, you can turn ordinary materials into extraordinary products that capture attention and spark creativity.

Choosing the Best Service for Your Needs

When it comes to selecting a metal laser cutting service, it's essential to consider factors such as reliability, technology used, and customer support. Finding a provider who specializes in CNC cutting will ensure that your projects are handled by skilled professionals adept at managing complex specifications. Take the time to research various services; after all, the right partner can elevate your project from good to exceptional.

Embrace the Future of Metal Cutting Solutions

The landscape of metal cut technologies is evolving rapidly, with advancements paving the way for more efficient processes and sustainable practices in laser cutting aluminum. As automation becomes increasingly prevalent in manufacturing, staying ahead means adopting these innovations early on. By embracing these future trends today, you position yourself not just as a participant but as a leader in the exciting world of precision metal fabrication.