Introduction

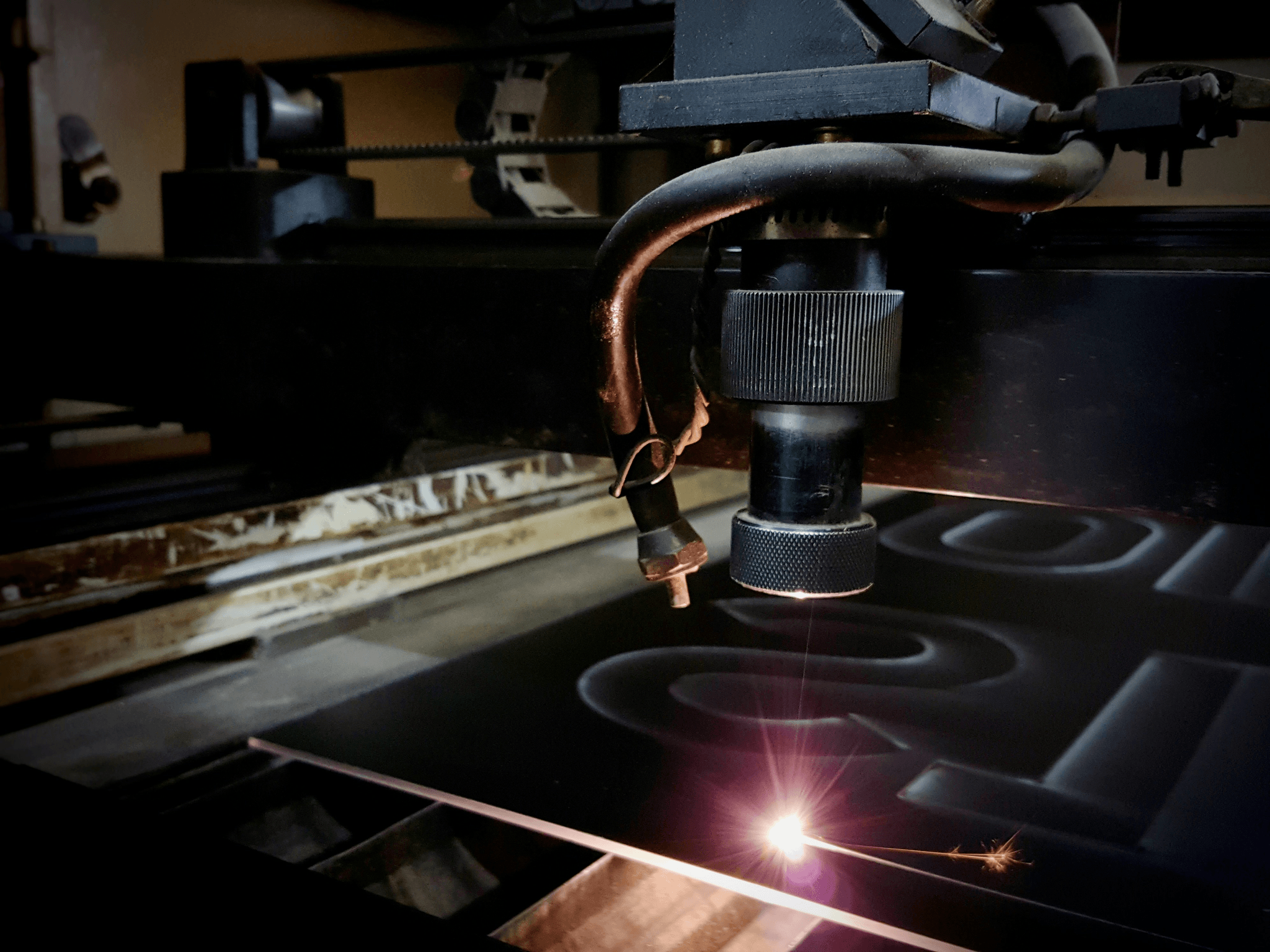

In the world of manufacturing and fabrication, a laser cutting machine for steel has emerged as a game-changer. This advanced technology utilizes focused light beams to precisely cut through various types of steel, making it an essential tool for industries ranging from automotive to aerospace. With its ability to deliver clean edges and intricate designs, the laser cutter has become synonymous with efficiency and precision in metalworking.

What is a Laser Cutting Machine for Steel

A laser cutting machine for steel is a specialized device that employs high-powered lasers to melt or vaporize material along predetermined paths. Unlike traditional cutting methods that rely on mechanical blades, this metal cutting machine harnesses the power of light to achieve unparalleled accuracy and speed. Whether you're working with thin sheets or thick plates, a laser cutter for metal can handle diverse projects with ease.

Advantages of Using a Laser Cutter

The advantages of using a laser cutter are numerous and compelling. First off, these machines offer exceptional precision, allowing operators to create intricate designs without compromising on quality. Additionally, laser cutting minimizes material waste since it uses narrow beams that require less space than conventional cutting methods—saving both time and money in the long run.

Key Factors to Consider

When considering investing in a laser cutting machine, there are several key factors you should keep in mind. Power specifications play a crucial role in determining the thickness of steel you can cut effectively; therefore, understanding your specific needs is vital. Other considerations include software compatibility for seamless operation and maintenance support to ensure your metal cutting laser cutter remains efficient over time.

Understanding Laser Cutting Technology

A laser cutting machine for steel uses focused light energy to slice through various materials with incredible accuracy and speed. This section will delve into how laser cutting works, explore the different types of machines available, and compare various methods to help you make an informed choice.

How Laser Cutting Works

At its core, laser cutting utilizes a highly concentrated beam of light that is directed through optics and lenses onto the material being cut. This focused beam generates intense heat, melting or vaporizing the steel in its path, allowing for clean and intricate cuts. The process is not only fast but also minimizes waste by creating precise shapes without requiring extensive post-processing work.

The versatility of a metal cutting laser cutter means it can tackle a variety of thicknesses and materials beyond just steel, expanding its utility in manufacturing settings. As the beam moves across the surface, it can be adjusted in real-time for different thicknesses or complexities in design. This adaptability makes a laser cutter for metal an invaluable tool in industries ranging from automotive to aerospace.

Types of Laser Cutting Machines

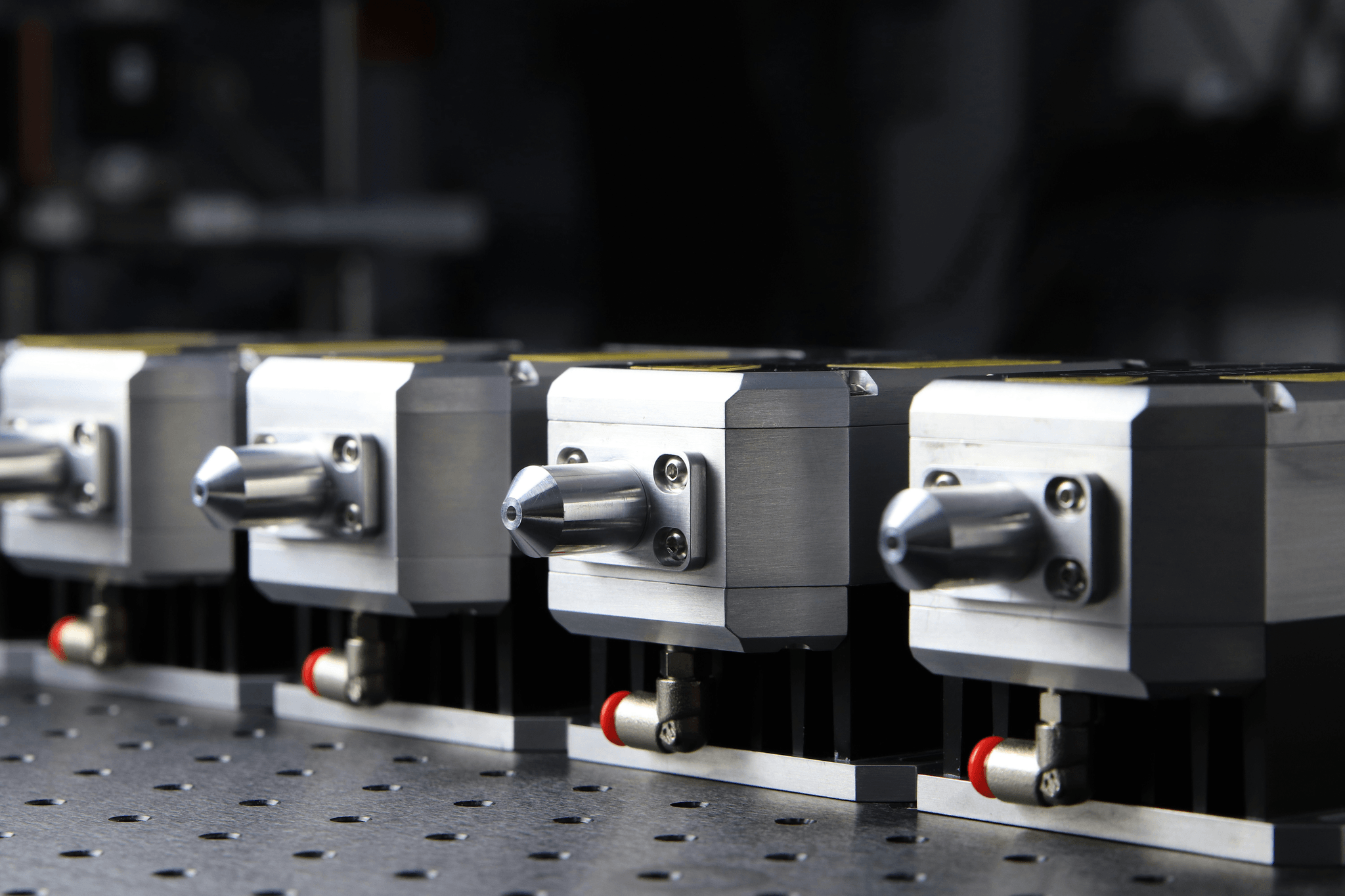

Laser cutting machines come in several types, each designed with specific applications in mind. The most common types include CO2 lasers, fiber lasers, and solid-state lasers; each has its own strengths depending on the material being cut and required precision levels. For instance, fiber lasers are particularly effective for metal cutting due to their high energy efficiency and ability to cut reflective materials like aluminum or copper.

A CO2 laser cutting machine excels at working with non-metal materials such as wood or plastics but may struggle with thicker steel compared to fiber options. Solid-state lasers offer high power output but are less common than their CO2 and fiber counterparts when it comes to industrial applications. Understanding these distinctions will help you select the right metal cutting machine for your specific needs.

Comparing Laser Cutting Methods

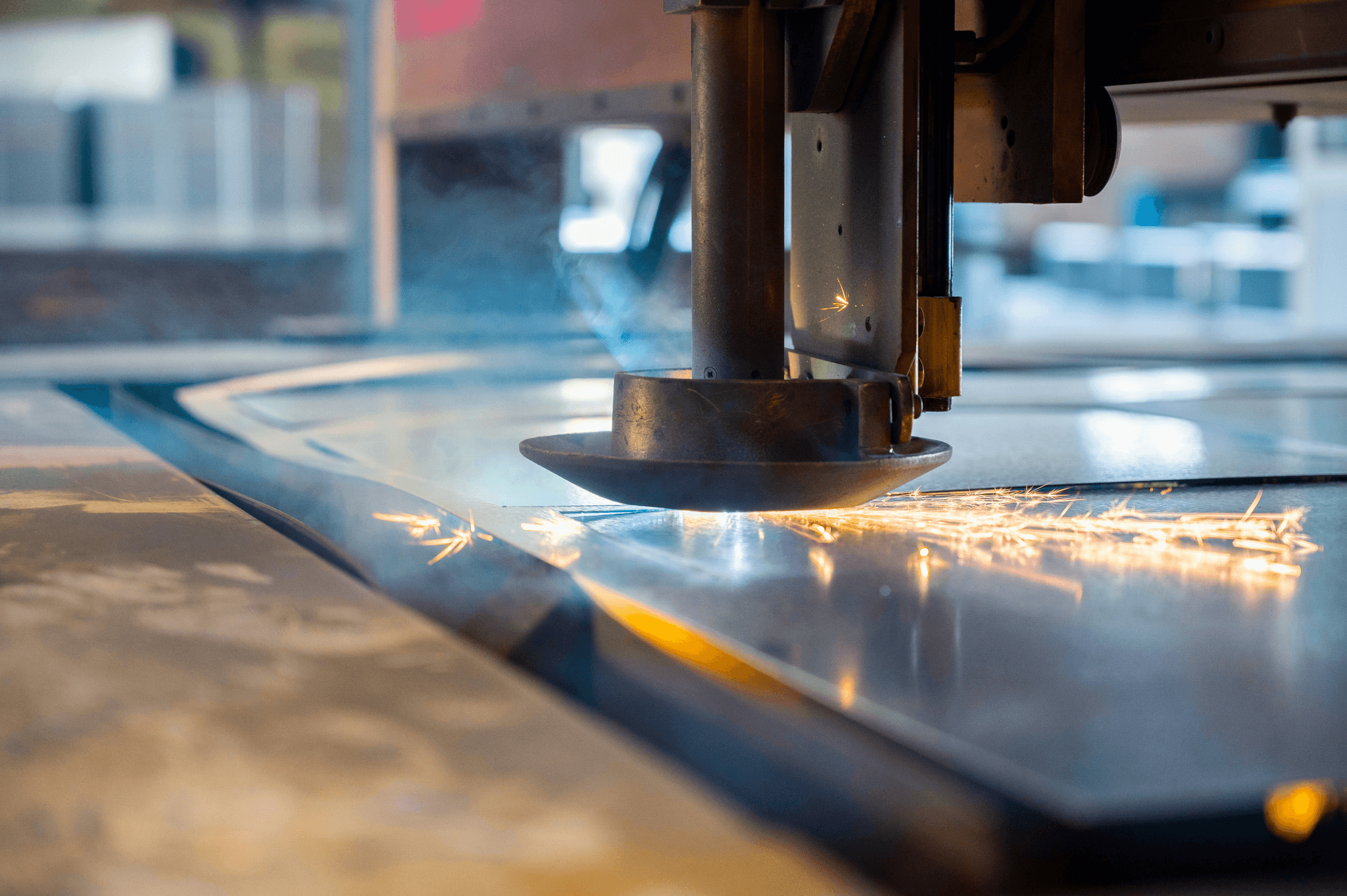

When evaluating your options for a laser cutter, it's essential to consider how different methods stack up against one another regarding efficiency, cost-effectiveness, and application suitability. Traditional methods like plasma or oxy-fuel cutting may be less expensive upfront but often compromise on precision compared to a modern laser cutting machine for steel.

Laser cutters offer superior edge quality with minimal kerf width (the width of material removed during cutting), making them ideal for intricate designs where detail matters most—think fine art pieces or complex mechanical components! Additionally, while some older technologies require more maintenance and downtime due to wear on consumables like tips or electrodes, modern metal cutting lasers are often more reliable over time with lower operational costs.

In conclusion, understanding how laser technology works alongside recognizing various types of machines allows businesses to optimize their production processes effectively while ensuring top-notch quality control across projects.

Determining Your Steel Cutting Needs

Assessing Material Thickness

One of the first considerations when selecting a metal cutting laser cutter is the thickness of the steel you'll be working with. Different laser cutting machines are designed to handle varying thicknesses, so it's essential to know whether you'll primarily cut thin sheets or thicker plates. For instance, a high-powered laser cutter for metal may be necessary for thicker materials, while lower-powered models suffice for lighter tasks.

Understanding material thickness not only affects the type of cutting machine you choose but also impacts speed and precision during operation. A robust laser cutting machine can provide clean cuts even at greater depths, reducing the need for secondary processing and saving time in your workflow. Thus, assessing material thickness is foundational in determining which laser cutter will best meet your production needs.

Understanding Production Volume

Next on the agenda is assessing your production volume requirements—how much steel you plan to cut regularly can significantly influence your choice of a metal cutting machine. If you're operating at high volumes, investing in an industrial-grade laser cutting machine may be worthwhile due to its efficiency and durability under continuous use. Conversely, if you're working on smaller projects or prototypes, a more compact or entry-level model might suffice.

Understanding production volume also helps gauge how often you'll need maintenance or replacements parts for your equipment—high-volume operations often require more robust support services due to wear and tear on components from frequent use. Additionally, knowing whether you need quick turnaround times or can afford slower processes can alter which features are essential in a laser cutter for metal. Ultimately, aligning your chosen equipment with expected production levels ensures optimal performance without unnecessary costs.

Evaluating Cutting Precision Requirements

Different applications require different levels of precision—while some projects may tolerate slight deviations from specifications, others demand near-perfect accuracy that only advanced technology can offer. Therefore, evaluating how precise you need cuts to be will help narrow down options among various models available on the market.

A high-precision laser cutter typically offers features such as advanced optics and control systems that enhance accuracy during operation—these machines are ideal if you're producing intricate designs or components with tight tolerances. On the flip side, if you're primarily performing general fabrication tasks where minor imperfections won't affect functionality significantly, then standard models might serve just fine without breaking the bank on extras you don't genuinely need.

In conclusion, determining your steel cutting needs involves carefully assessing material thicknesses you'll encounter regularly while considering both production volumes and required precision levels for each job type ahead of time; this ensures that whatever investment you make into a metal cutting machine pays off handsomely!

Features to Look for in a Laser Cutter

When diving into the world of laser cutting machines for steel, it’s essential to understand the key features that will make your investment worthwhile. A laser cutter is not just about cutting; it’s about precision, efficiency, and adaptability to your specific needs. Here, we’ll explore critical aspects such as power and performance specifications, software compatibility, and maintenance services that can elevate your metal cutting experience.

Power and Performance Specifications

The power of a laser cutting machine for steel is one of the most crucial factors determining its effectiveness. Generally measured in watts, higher wattage translates to faster cutting speeds and the ability to handle thicker materials. Selecting a powerful metal cutting laser cutter ensures you can tackle diverse projects without compromising on quality or efficiency.

Performance specifications also include the speed at which the machine operates and its ability to maintain consistent results across various materials. A reliable laser cutter for metal should provide smooth cuts with minimal burrs or dross left behind. Always check for performance benchmarks from manufacturers; this insight will help you make an informed decision when choosing your next cutting machine laser.

Software Compatibility and Ease of Use

In today’s tech-savvy world, software compatibility plays a pivotal role in maximizing the potential of your laser cutter for metal. Look for machines that come with user-friendly software designed specifically for metal cutting applications—this will streamline your workflow significantly. The right software not only enhances ease of use but also allows for intricate designs that can be executed flawlessly on a high-quality laser cutting machine.

Ease of use extends beyond just software; consider how intuitive the machine's controls are as well. An accessible interface means less time spent troubleshooting and more time focusing on creating exceptional products with your new metal cutting machine. Additionally, check if there are training resources available—this can be invaluable when getting started with advanced features.

Maintenance and Support Services

Investing in a laser cutting machine requires consideration not just of upfront costs but also long-term maintenance needs. Regular maintenance ensures optimal performance from your metal cutting laser cutter over time, so look into brands offering comprehensive support services post-purchase. Inquire about warranties as well; a solid warranty reflects confidence from manufacturers in their products’ durability.

Support services should ideally include access to technical assistance whenever needed—whether it's troubleshooting issues or seeking advice on best practices in using your new equipment effectively. Additionally, consider whether replacement parts are readily available; this can save you significant downtime if repairs are required down the line. Ultimately, ensuring robust support services will lead you toward making an informed decision about which laser cutter fits seamlessly into your production environment.

Choosing the Right Brand

When it comes to investing in a laser cutting machine for steel, selecting the right brand can significantly impact your operations. The market is filled with options, and each brand offers unique features and capabilities tailored to various needs. A well-chosen brand not only ensures quality but also provides reliable support and service, making your investment worthwhile.

Top Brands in the Market

Several top brands have established themselves as leaders in the laser cutting industry, particularly for metal cutting machines. Companies like Trumpf, Bystronic, and Amada are renowned for their innovative technologies and robust performance in laser cutting applications. However, emerging brands such as Kiant Machinery are also gaining traction by offering competitive pricing without compromising on quality or efficiency.

When evaluating these brands, consider their reputation within the industry as well as customer feedback on their products. Each brand has its unique selling points; for instance, Trumpf is known for its advanced automation features while Bystronic excels in user-friendly software solutions. Ultimately, understanding what each brand brings to the table will help you make an informed decision when selecting a laser cutter for metal.

Why Kiant Machinery Stands Out

Kiant Machinery distinguishes itself from competitors through a combination of affordability and exceptional performance in laser cutting technology. Their metal cutting laser cutters are designed with precision engineering that caters specifically to steel materials, ensuring clean cuts with minimal waste. Moreover, Kiant’s commitment to customer support sets them apart; they provide extensive training resources and responsive service teams to assist users at every step.

Another notable advantage of choosing Kiant Machinery is their focus on innovation without breaking the bank—offering high-quality machines that don’t require exorbitant upfront investments compared to other leading brands. This means you can acquire a reliable laser cutter without sacrificing essential features or capabilities needed for effective metal fabrication tasks. With Kiant’s reputation growing rapidly among professionals seeking value-driven solutions, it’s no wonder many are considering them as a top choice.

Customer Reviews and Case Studies

Customer reviews play a vital role in assessing any product's reliability—including laser cutting machines for steel—so it's important to examine real-world experiences before making your choice. Many users of Kiant Machinery's products report high satisfaction levels due to their machines' durability and precision during operation. Case studies highlight how businesses have successfully integrated these cutting machines into their workflows, resulting in increased productivity and reduced operational costs.

For instance, one manufacturing company shared how switching to a Kiant metal cutting machine significantly improved their production speed while maintaining high-quality standards across various steel components they produced daily. Such testimonials reinforce the idea that investing in a reputable brand like Kiant can lead not only to superior performance but also long-term savings through efficiency gains over time. Therefore, taking into account customer feedback alongside technical specifications will help ensure you select the right machine that meets your specific needs.

Budgeting for Your Laser Cutting Machine

When it comes to investing in a laser cutting machine for steel, understanding the financial implications is crucial. The initial investment can be significant, but it’s essential to weigh this against long-term costs associated with operation and maintenance. A well-chosen laser cutter can save you money over time through efficiency and reduced material waste.

Initial Investment vs. Long-Term Costs

The initial investment in a metal cutting machine varies widely based on its capabilities and features. High-quality laser cutting machines typically come with a higher price tag, but they often deliver superior performance and durability, which can minimize long-term costs. Additionally, consider factors like energy consumption and maintenance requirements; a more efficient laser cutter for metal may have higher upfront costs but lower operating expenses over its lifespan.

Investing in advanced technology can also lead to increased productivity, allowing your business to take on more projects without significantly increasing overheads. This means that while the sticker price of your chosen cutting machine laser might seem steep initially, the return on investment could be substantial in the long run. Ultimately, balancing initial costs with potential savings is key when selecting your ideal laser cutting solution.

Financing Options Available

Financing options for purchasing a laser cutter are abundant and can make acquiring a metal cutting laser cutter much more manageable. Many manufacturers offer financing plans that allow businesses to spread payments over time rather than paying upfront for their equipment outright. This flexibility enables you to invest in quality machinery without straining your cash flow.

Additionally, banks and credit institutions may provide loans specifically tailored for equipment purchases, including those for a laser cutting machine for steel. Leasing is another option worth considering; it allows you to use the equipment while making monthly payments without committing to full ownership right away. Exploring these various financing avenues ensures that you find an arrangement that aligns with your budgetary constraints.

DIY vs. Professional Installation Costs

Deciding whether to go the DIY route or hire professionals for installing your new laser cutting machine can significantly impact your overall budget. While handling installation yourself may seem like an appealing way to save money initially, consider the potential pitfalls of improper setup—this could lead to costly repairs or downtime later on if things don’t go as planned with your metal cutting machine installation.

On the other hand, professional installation services ensure that everything is set up correctly from day one while often providing warranties or guarantees on their work—worth its weight in gold when dealing with complex machinery like a laser cutter for metal! If you're unsure about what’s best suited for you financially or technically, consulting with industry experts before making this decision is always wise.

Conclusion

In the world of precision engineering, selecting the right laser cutting machine for steel is crucial for optimizing production efficiency and achieving high-quality results. With various types of laser cutters available, understanding your specific needs—whether that’s material thickness, production volume, or cutting precision—will guide you toward making an informed choice. By considering factors like power specifications and software compatibility, you can ensure that your investment in a metal cutting machine pays off in the long run.

Recap on Laser Cutting Machine Choices

Throughout this guide, we’ve explored the many facets of choosing a laser cutter for metal applications. From understanding how laser cutting technology works to evaluating different brands and their offerings, it’s clear that not all machines are created equal. Whether you're looking for a robust metal cutting laser cutter or a more compact option, knowing what features matter most will help streamline your decision-making process.

Making an Informed Decision

When it comes to investing in a laser cutting machine for steel, knowledge is power—literally! Weighing the advantages of each option against your specific requirements will allow you to choose a cutting machine laser that best suits your business needs. Don’t forget to consider customer reviews and case studies; they can provide invaluable insights into real-world performance and reliability.

Next Steps to Get Started

Ready to take the plunge into the world of laser cutting? Start by assessing your current steel cutting needs and identifying which features are non-negotiable for your operations. Once you've narrowed down your options, reach out to reputable suppliers like Kiant Machinery for quotes and demos; this hands-on experience can be crucial before making such an important investment.