Introduction

In the fast-paced world of manufacturing, staying ahead of the competition means embracing innovative technologies. One such game-changer is the flatbed laser cutting machine, a powerful tool that revolutionizes how businesses approach precision and efficiency in their operations. With its ability to deliver intricate cuts and designs with remarkable speed, investing in a laser cutter is no longer just an option; it’s a necessity for modern enterprises.

The Power of a Flatbed Laser Cutting Machine

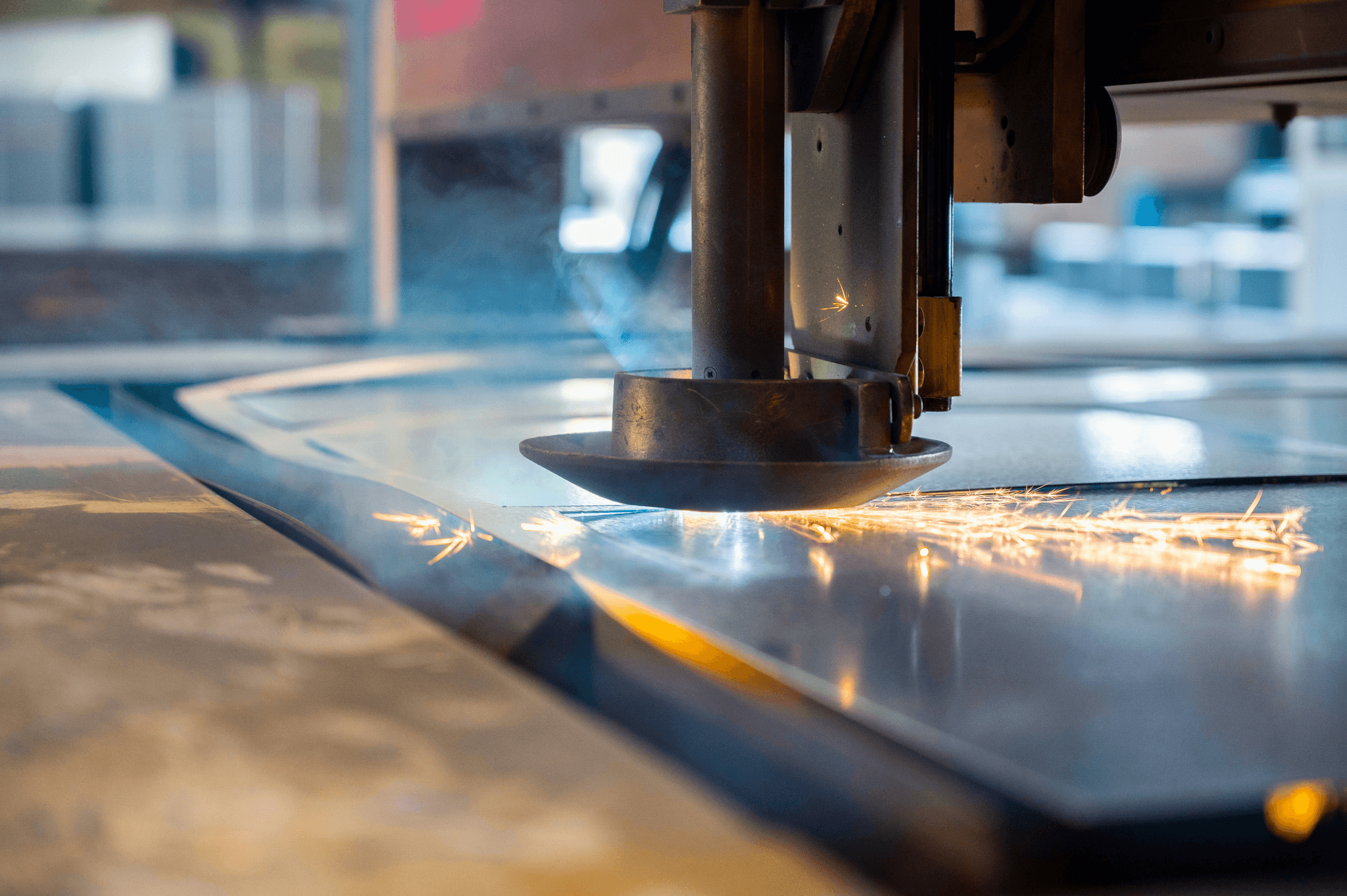

The flatbed laser cutting machine harnesses advanced technology to perform metal cutting with unparalleled accuracy. This industrial laser cutter can handle various materials, making it an essential asset across multiple industries. Whether you're producing prototypes or final products, the power of a metal cutting machine laser ensures that you achieve exceptional results every time.

Unleashing Precision with Laser Cutting

Laser cutting technology has transformed traditional manufacturing processes by offering precision that simply can't be matched by conventional methods. With an industrial laser cutting machine, you can create intricate designs and components that meet exact specifications without compromising quality. This level of detail not only enhances product aesthetics but also improves functionality, giving businesses a competitive edge.

Why Your Business Needs This Technology

In today’s market, efficiency and quality are paramount to success; therefore, adopting laser cutting technology is crucial for any business looking to thrive. A metal cutting laser cutter allows for faster production times while reducing material waste—leading to significant cost savings over time. By investing in a cutting machine laser like the flatbed model, your business can streamline operations and respond more quickly to customer demands.

What is a Flatbed Laser Cutting Machine?

When it comes to precision and efficiency in manufacturing, the flatbed laser cutting machine stands out as a revolutionary tool. This technology harnesses the power of focused laser beams to cut through various materials with incredible accuracy. Whether you’re in the metalworking industry or looking to create intricate designs, understanding this machinery is essential for staying competitive.

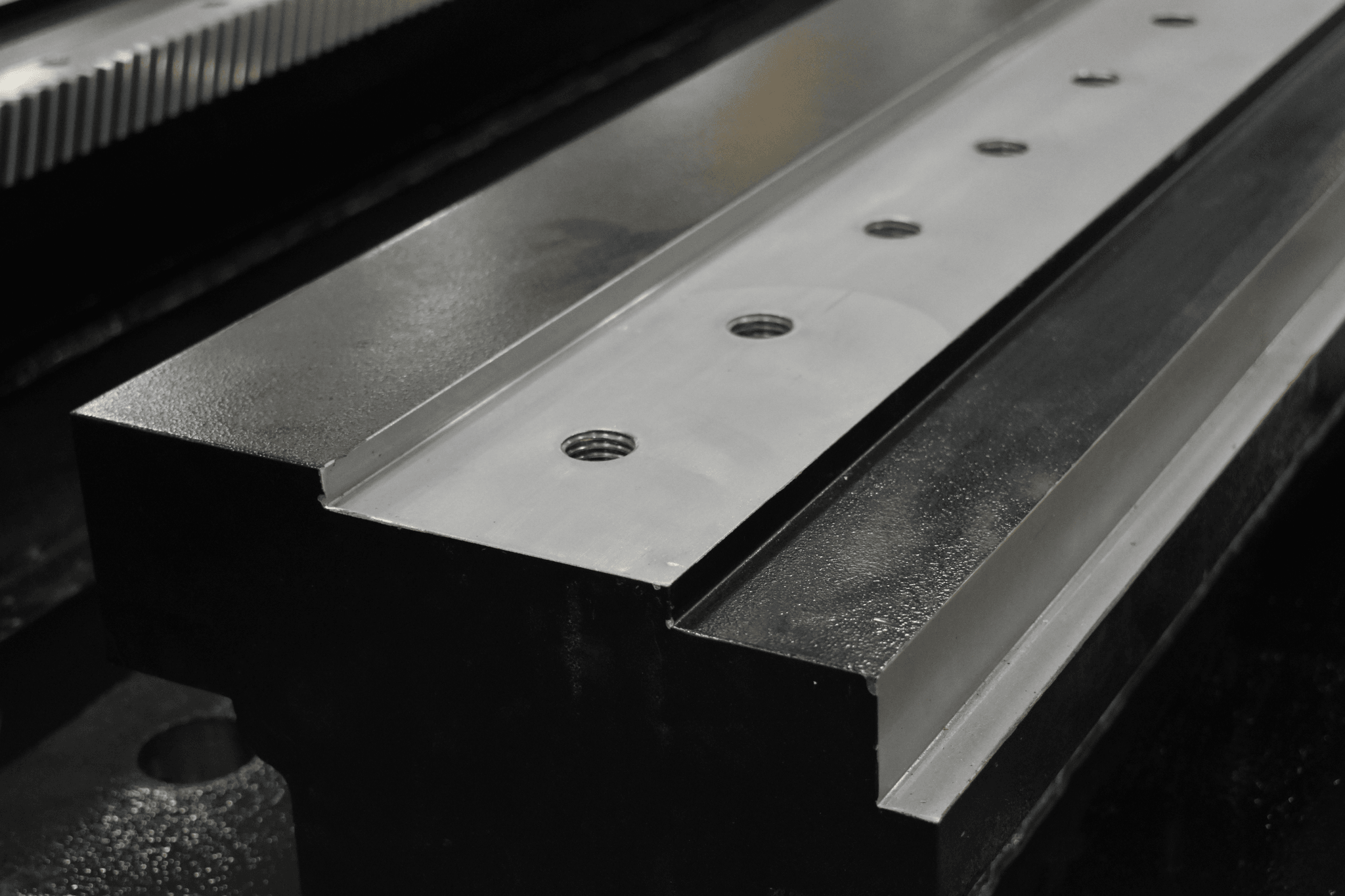

Overview of Flatbed Laser Cutting

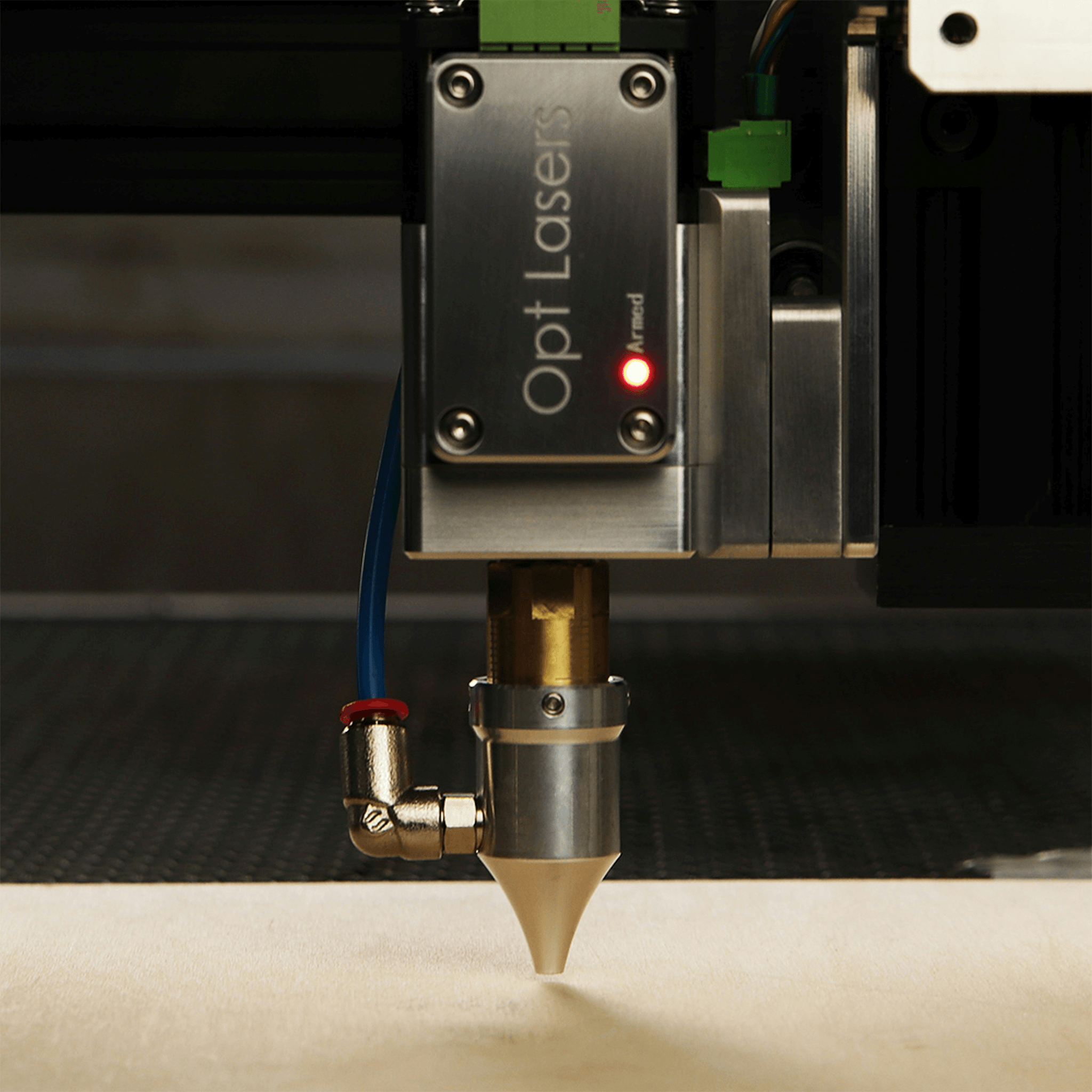

A flatbed laser cutting machine utilizes a high-powered laser beam directed onto a material's surface, effectively melting or vaporizing it away to create precise cuts. Unlike traditional cutting methods that can be cumbersome and less accurate, this industrial laser cutting machine ensures that every cut is clean and exact. With advancements in technology, these machines have become increasingly user-friendly, allowing operators to execute complex designs with minimal training.

Types of Materials It Can Cut

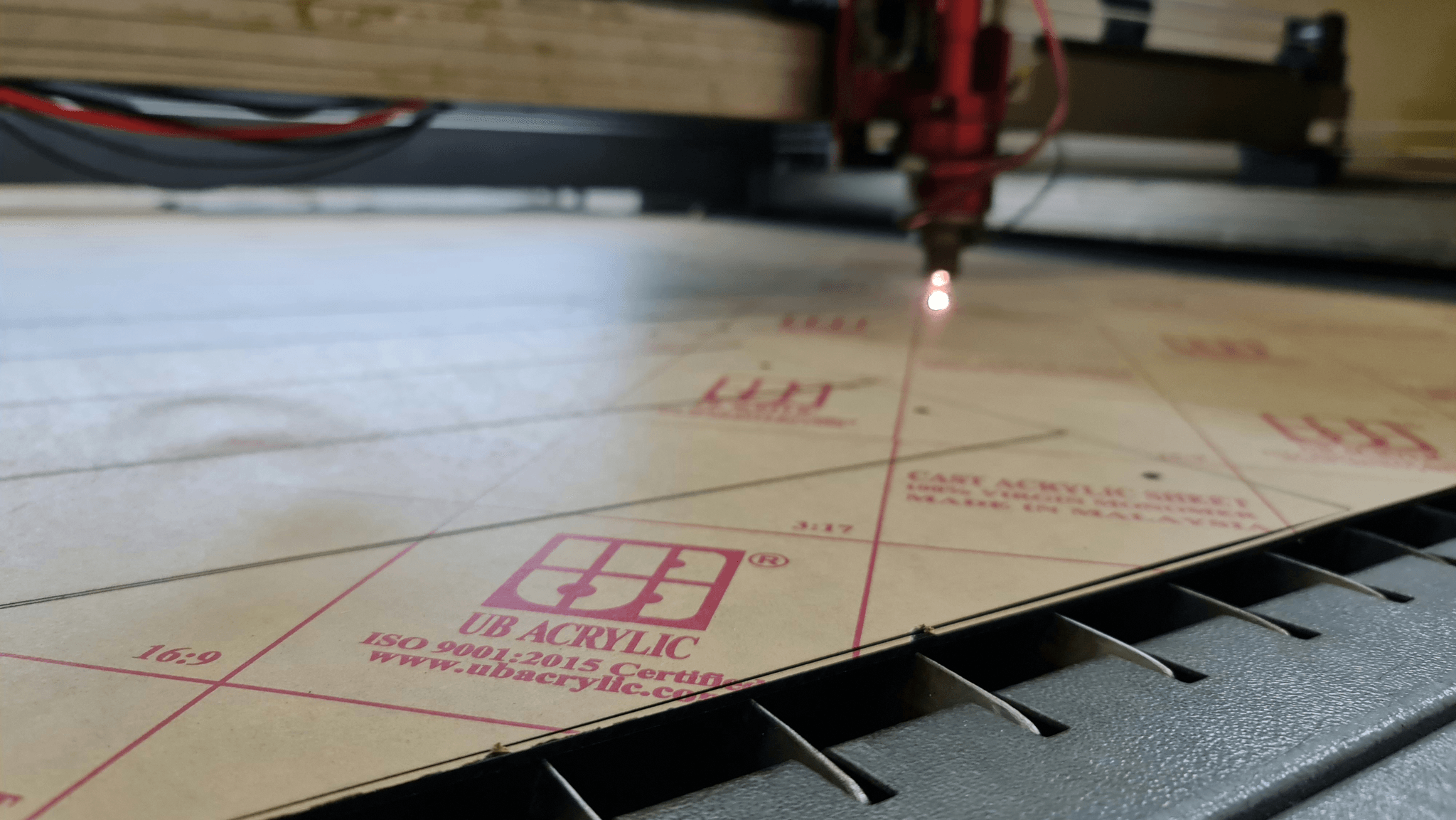

The versatility of a metal cutting machine laser is one of its most appealing features; it can handle an array of materials including metals like steel and aluminum, plastics, wood, and even fabrics. This adaptability makes the industrial laser cutter an invaluable asset across various industries—from automotive and aerospace to fashion design and signage production. As businesses seek innovative solutions for their production needs, the capability to cut multiple materials efficiently has made laser cutting technology indispensable.

Advantages Over Traditional Methods

One significant advantage of using a metal cutting laser cutter over traditional methods lies in its precision—laser cutting produces incredibly fine details that are often unattainable with mechanical tools. Additionally, the reduced heat affected zone minimizes warping or damage to surrounding areas during the cutting process. Finally, because a flatbed laser cutting machine operates without contact with the material being cut, it reduces wear on tools and maintenance costs over time—making it not just effective but also economical for businesses looking to invest in long-term solutions.

Exceptional Accuracy and Detail

In the realm of manufacturing, precision is paramount, and that's where the flatbed laser cutting machine shines. This industrial laser cutting machine utilizes advanced technology to deliver unparalleled accuracy, ensuring that every cut is executed with meticulous detail. Whether it's intricate designs or simple shapes, a laser cutter guarantees that your specifications are met with exactitude.

Precision in Industrial Laser Cutting

When it comes to precision in industrial laser cutting, few technologies can compete with a metal cutting machine laser. The focused beam of light allows for incredibly fine cuts that traditional methods simply can't match. With tolerances often reaching the thousandths of an inch, a laser cutter ensures that your projects maintain their integrity and quality throughout the production process.

Applications in Various Industries

The versatility of a flatbed laser cutting machine makes it invaluable across multiple industries—from aerospace to automotive and beyond. In the automotive sector, for instance, metal cutting lasers are used to create complex components that require high precision and durability. Similarly, the fashion industry employs industrial laser cutters to produce detailed patterns on fabrics, showcasing just how widely applicable this technology can be.

Real World Examples of Success

Consider a company that invested in an industrial laser cutter to streamline its production line; they reported a significant increase in efficiency and product quality within months. Another success story involves a furniture manufacturer using a metal cutting laser cutter to create intricate designs on wood panels—resulting in unique pieces that stand out in the market. These real-world examples illustrate how embracing advanced technologies like cutting machine lasers can lead businesses toward remarkable achievements.

Speed and Efficiency

In the fast-paced world of manufacturing, speed and efficiency are crucial for maintaining a competitive edge. A flatbed laser cutting machine is designed to deliver rapid results without compromising on quality. With its advanced technology, a laser cutter can process materials at impressive speeds, significantly reducing production times.

How a Laser Cutter Saves Time

One of the standout features of industrial laser cutting machines is their ability to execute complex cuts quickly and accurately. Unlike traditional cutting methods that may require multiple passes or setups, a metal cutting machine laser can complete intricate designs in one go. This streamlined process not only saves time but also enables businesses to meet tight deadlines without sacrificing quality.

Moreover, the automation capabilities of a laser cutter mean that once set up, it can run with minimal oversight. This allows operators to focus on other tasks while the cutting machine laser works efficiently in the background. As a result, companies can maximize their productivity and output while minimizing labor costs.

Comparison with Other Cutting Methods

When comparing an industrial laser cutter to other cutting methods like plasma or waterjet cutting, it's clear that laser technology holds significant advantages in terms of speed and precision. Traditional methods often involve slower processing times due to their mechanical nature and may require additional finishing work after cutting is completed. In contrast, flatbed laser cutting machines provide clean edges and detailed finishes straight from the cut.

Additionally, while other methods might struggle with thicker materials or intricate designs, metal cutting lasers excel in these areas thanks to their focused energy beam. This precision means fewer errors during production runs—saving both time and resources in the long run. Overall, investing in a flatbed laser cutting machine offers manufacturers an opportunity to enhance both speed and efficiency dramatically compared to conventional techniques.

Case Studies from Kiant Machinery Clients

Kiant Machinery has partnered with numerous clients who have experienced remarkable improvements in speed and efficiency after integrating an industrial laser cutter into their operations. For instance, one client specializing in automotive parts saw their production time cut by 50% after adopting a metal cutting machine laser for their fabrication processes. The ability to quickly produce high-quality components allowed them not only to fulfill orders faster but also take on more projects simultaneously.

Another case involved a furniture manufacturer that utilized a flatbed laser cutting machine for intricate designs on wooden panels and metal accents alike. By switching from traditional saws to an industrial laser cutter, they reduced waste significantly while enhancing design capabilities—leading to increased customer satisfaction due to faster delivery times without compromising quality.

These success stories highlight how investing in advanced technologies like a metal cutting laser cutter can revolutionize manufacturing processes by boosting speed and efficiency across various industries.

Cost-Effective Production

In the fast-paced world of manufacturing, cost-effective production is paramount. A flatbed laser cutting machine stands out as a champion in this arena, offering unparalleled efficiency and precision. By investing in a metal cutting machine laser, businesses can dramatically reduce operational costs while increasing output quality.

Reducing Material Waste with Laser Cutting

One of the most significant advantages of using a laser cutter is its ability to minimize material waste during the cutting process. Unlike traditional methods that often result in excess scrap, the precision of an industrial laser cutter ensures that cuts are made accurately, maximizing usable material from each sheet. This reduction in waste not only conserves resources but also translates into substantial savings for companies utilizing metal cutting laser cutters.

Moreover, the high level of accuracy offered by a flatbed laser cutting machine means that intricate designs can be achieved without compromising material integrity. This is particularly beneficial for businesses working with expensive materials, where every inch counts. In essence, reducing material waste through efficient laser cutting directly contributes to a healthier bottom line.

Long-Term Savings of an Industrial Laser Cutter

Investing in an industrial laser cutting machine may seem daunting upfront; however, the long-term savings it offers are undeniable. Compared to conventional cutting methods, a laser cutter requires less maintenance and fewer consumables over time—resulting in lower operational costs across its lifespan. Furthermore, the speed and efficiency of these machines mean they can complete jobs faster than traditional alternatives, allowing businesses to take on more projects without additional labor costs.

Moreover, as companies scale their operations, having a reliable metal cutting machine laser can lead to increased productivity and reduced turnaround times for clients. This competitive edge not only attracts more business but also enhances customer satisfaction due to timely deliveries and high-quality products. Ultimately, investing wisely in an industrial laser cutter pays off handsomely when considering both immediate and future financial gains.

ROI Analysis for Businesses Investing in Metal Cutting

When evaluating the return on investment (ROI) for businesses considering metal cutting with lasers, several factors come into play. First off, it's crucial to assess initial costs against potential savings from reduced material waste and lower labor expenses over time—both key benefits of adopting a flatbed laser cutting machine into your production line. Many companies find that within just a few months of operation, they begin to see positive returns as efficiency skyrockets.

Additionally, ROI analysis should include qualitative benefits such as improved product quality and enhanced design capabilities made possible by advanced features of modern industrial laser cutters. These factors contribute not only to customer retention but also open doors for new markets due to versatility in design options offered by these machines—a game-changer for any manufacturer looking to innovate or expand their offerings.

In conclusion, investing in a metal cutting machine laser is not merely about purchasing equipment; it’s about making strategic decisions that yield long-term financial health and sustainability for your business.

Versatility in Design

The versatility of a flatbed laser cutting machine is one of its most compelling features, allowing businesses to push the boundaries of creativity and innovation. With the ability to cut, engrave, and etch various materials, a laser cutter can bring intricate designs to life that traditional methods simply cannot match. This capability not only enhances product offerings but also opens new avenues for customization that appeal to diverse customer needs.

Customization Capabilities with Laser Technology

Customization is at the heart of what makes a flatbed laser cutting machine invaluable for modern manufacturing. The precision offered by industrial laser cutting machines allows businesses to create tailor-made solutions for their clients, whether it's unique shapes or intricate patterns on metal surfaces. By utilizing a metal cutting machine laser, companies can rapidly prototype designs and iterate based on customer feedback without incurring significant costs or delays.

Additionally, the software that accompanies a laser cutter enables designers to easily modify existing templates or create entirely new ones from scratch. This flexibility means that even small businesses can compete in markets dominated by larger players by offering personalized products that resonate with consumers. The result is an efficient workflow where creativity meets practicality—an essential combination in today’s fast-paced market.

Integration into Existing Production Lines

One of the standout features of an industrial laser cutter is its seamless integration into existing production lines. Unlike bulky machinery that requires extensive reconfiguration, a cutting machine laser can be incorporated with minimal disruption, enhancing productivity without sacrificing output quality. This adaptability ensures that businesses can leverage their current infrastructure while still benefiting from advanced technology.

Moreover, integrating a metal cutting laser cutter into your operations means you get the best of both worlds: traditional craftsmanship combined with modern efficiency. As workflows evolve and demand fluctuates, this flexibility becomes increasingly vital; companies can scale up production or pivot quickly based on market trends without missing a beat. In essence, investing in an industrial laser cutting machine empowers organizations to stay agile and responsive.

Examples of Innovative Designs Enabled by Cutting Machine Laser

The creative possibilities unlocked by flatbed laser cutting technology are nothing short of astounding; industries across the board have embraced this tool for groundbreaking design work. For instance, furniture manufacturers use metal cutting machines lasers to produce intricate patterns in tabletops or decorative elements in cabinetry—transforming standard pieces into stunning works of art. Similarly, fashion designers have begun incorporating customized embellishments through precise engraving on fabrics and leather goods using industrial laser cutters.

Another noteworthy application lies within architectural design; professionals are leveraging these machines to create detailed facade panels and custom signage that stand out in urban landscapes. These innovative designs not only elevate aesthetic appeal but also enhance functionality—think lightweight yet sturdy structures made possible through meticulous cuts only achievable with advanced technology like flatbed lasers offer. The marriage between artistry and engineering is truly exemplified here as businesses explore uncharted territories thanks to their investment in state-of-the-art machinery.

Conclusion

As we stand on the brink of a manufacturing revolution, the flatbed laser cutting machine is at the forefront, redefining precision and efficiency. The future of manufacturing is bright with laser cutting technology, promising not just speed but also unparalleled accuracy in metal fabrication. Industries that embrace a laser cutter will find themselves equipped to meet the growing demands for customization and quality in an ever-competitive market.

The Future of Manufacturing with Laser Cutting

The evolution of industrial laser cutting machines signifies a shift towards more innovative manufacturing processes. With advancements in laser technology, businesses can achieve intricate designs and complex cuts that were previously unimaginable. As companies adopt metal cutting machines that leverage these capabilities, they position themselves as leaders in their respective fields.

Investing in the Right Machinery Matters

When it comes to production efficiency and quality output, investing in an industrial laser cutter is crucial for any business aiming for success. A reliable metal cutting laser cutter not only enhances productivity but also reduces operational costs over time through minimized waste and increased material yield. Choosing the right cutting machine laser can be the difference between staying ahead or falling behind competitors.

Partnering with Kiant Machinery for Success

To navigate this landscape effectively, partnering with Kiant Machinery offers businesses access to top-tier flatbed laser cutting machines tailored to their specific needs. With expert support and guidance from Kiant Machinery, companies can seamlessly integrate advanced laser technology into their operations, ensuring they maximize both performance and profitability. Together, we can forge a path toward success in an ever-evolving manufacturing environment.