Introduction

In the world of fabrication and manufacturing, the debate of plasma vs laser cutting has become increasingly relevant. Both methods are powerful, but they serve different purposes and excel in various applications. Understanding these differences is crucial for businesses looking to optimize their cutting processes and achieve the best results.

Understanding Plasma vs Laser Cutting

Plasma cutting utilizes a high-velocity jet of ionized gas to slice through conductive materials, while laser cutting employs focused light beams to achieve precision cuts in a variety of materials. Each technique has its unique strengths; for instance, plasma cutters are often favored for thicker metals due to their speed and efficiency, while laser machines shine when it comes to intricate designs and thinner materials. Recognizing these distinctions can help you determine which method is better suited for your specific needs.

Importance of Choosing the Right Method

Selecting the appropriate cutting method can significantly impact production efficiency, material waste, and overall costs. The choice between plasma vs laser cutting should be guided by factors such as material type, thickness, desired precision, and budget constraints. Making an informed decision not only enhances productivity but also ensures that you invest in the best laser cutter or plasma system for your operations.

Overview of Cutting Machines

Cutting machines have evolved dramatically over the years, offering a range of technologies designed to meet diverse industrial demands. From traditional plasma cutters that deliver robust performance on heavy metals to advanced laser machinery capable of executing complex patterns with unmatched accuracy, there’s a solution for every application. This overview will set the stage for a deeper exploration into how each method operates and where they excel in real-world scenarios.

The Basics of Plasma Cutting

Plasma cutting is a process that uses a high-velocity jet of ionized gas, or plasma, to cut through electrically conductive materials. This method has gained popularity in various industries due to its efficiency and versatility. But how does it stack up when comparing plasma vs laser cutting?

How Plasma Cutting Works

At its core, plasma cutting involves creating an electrical arc between an electrode and the workpiece, which ionizes the gas and turns it into plasma. This superheated gas reaches temperatures of up to 30,000°F (16,649°C), allowing it to slice through metals like butter. The simplicity of the setup makes it a favorite among fabricators looking for a reliable cutting machine laser that can handle thick materials.

Applications in Various Industries

Plasma cutting is widely used in industries such as automotive, aerospace, and metal fabrication due to its ability to cut through various thicknesses of metals quickly and efficiently. From creating intricate designs in sheet metal to heavy-duty applications like shipbuilding, this technology proves invaluable across sectors. As businesses continue exploring options like laser machinery for precision tasks, plasma remains essential for robust industrial processes.

Advantages and Disadvantages

When weighing the pros and cons of plasma vs laser cutting, it's crucial to consider factors like speed versus precision. Plasma cutters excel at speed and can cut thicker materials more effectively than many laser machines; however, they may not achieve the same level of detail in intricate designs as their laser counterparts do. Additionally, while the initial investment for a plasma cutter is often lower than that for the best laser cutter on the market, ongoing costs related to consumables should also be factored into any cost analysis.

The Mechanics of Laser Cutting

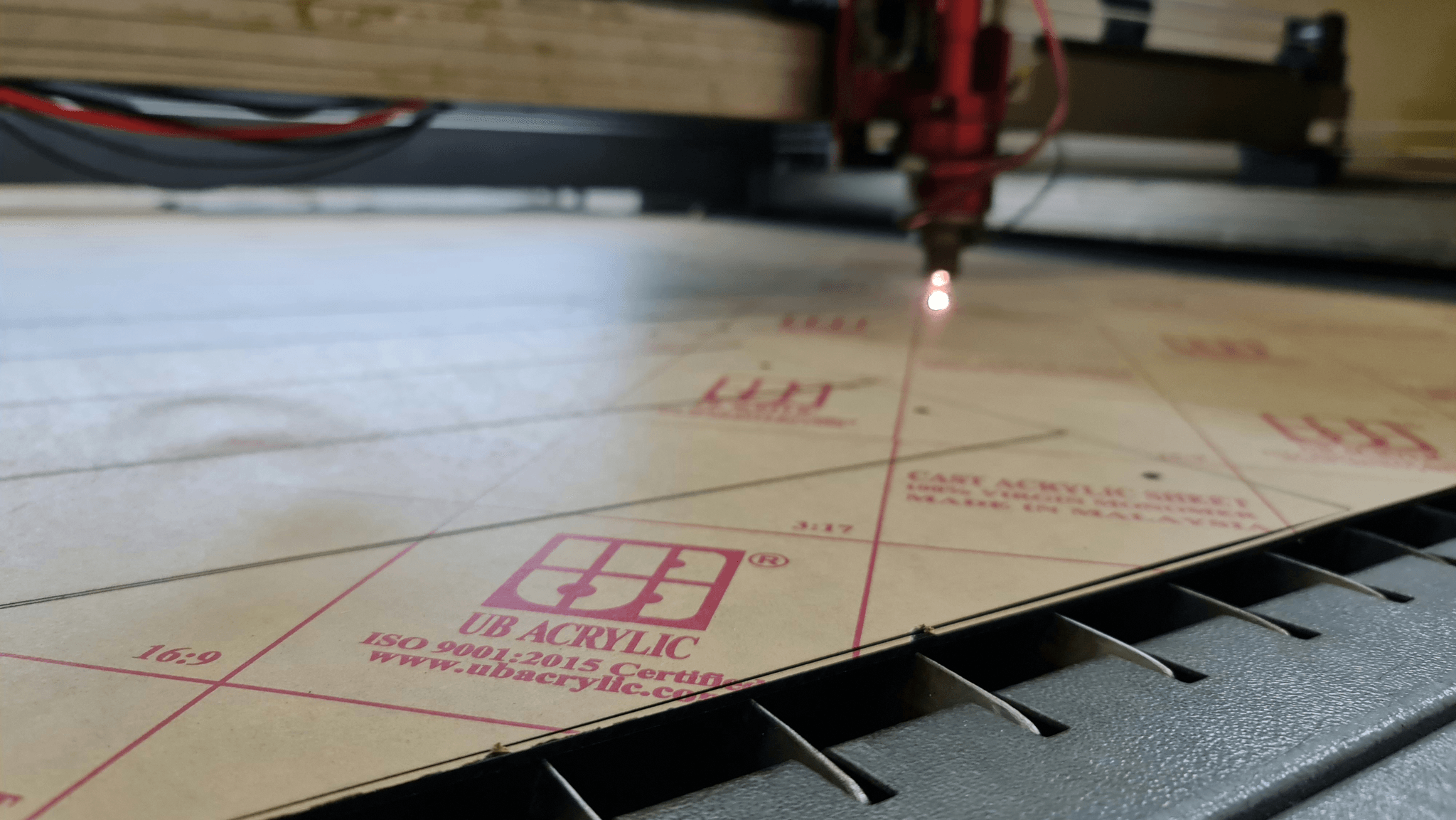

Laser cutting is a sophisticated technology that leverages focused light beams to cut through various materials with remarkable precision. Unlike plasma cutting, which uses ionized gas, laser machinery employs a concentrated beam of light that can be adjusted for different thicknesses and types of material. This method offers unparalleled accuracy, making it a popular choice in industries where fine details are crucial.

How Laser Machinery Operates

At the heart of every cutting machine laser is a powerful laser source, typically CO2 or fiber lasers, which generates an intense beam of light. This beam is directed through a series of mirrors and lenses to focus it onto the material being cut. The focused light heats the material to its melting point, allowing for clean cuts without the need for additional tools or processes.

The operation of laser machinery involves not just cutting but also engraving and marking capabilities, enhancing its versatility in various applications. Additionally, advanced computer software controls the movement and speed of the laser head, ensuring consistent results across multiple projects. This level of automation significantly reduces human error and boosts productivity compared to traditional methods like plasma vs laser cutting.

Popular Uses for Laser Cutters

Laser cutters are widely utilized across numerous industries due to their precision and efficiency. In manufacturing, they play a vital role in creating intricate parts for automotive and aerospace applications where tolerances are tight. Beyond manufacturing, these machines are also favored in fields such as fashion design for fabric cutting and signage production where detailed graphics are required.

Moreover, artists have embraced laser technology for crafting unique pieces that demand high levels of detail that other methods might struggle to achieve. From personalized gifts to architectural models, the best laser cutter can cater to both industrial needs and creative endeavors alike. This versatility makes laser machinery an essential tool in today’s fast-paced production environments.

Pros and Cons of Laser Technology

While there’s no denying that laser technology has revolutionized cutting processes with its speed and precision, it does come with its own set of advantages and disadvantages when compared to plasma vs laser cutting techniques. One major advantage is the cleaner edges produced by lasers; this often eliminates secondary processing steps like sanding or finishing which can save time and resources.

On the flip side, one drawback is that certain materials—such as reflective metals—can pose challenges for some types of lasers unless specifically designed equipment is used. Additionally, while initial investments in high-quality equipment may be steep when looking at options like the best laser cutter available on the market today, ongoing operational costs can vary depending on maintenance needs and energy consumption rates over time.

Comparing Efficiency and Precision

Speed of Cutting Machines

In the race of plasma vs laser cutting, speed is often a decisive factor. Plasma cutting machines can slice through materials at impressive speeds, particularly when working with thicker metals; they excel in rapid operations and high-volume production environments. On the other hand, while cutting machine lasers may not be as fast on thicker materials, they shine when it comes to intricate designs on thinner sheets—making them ideal for detailed work without compromising too much on speed.

However, it's essential to note that the actual speed can vary based on several factors such as material type and thickness. For instance, a high-powered laser machine may outperform plasma in terms of speed when dealing with thin metals but could lag behind when tackling more robust materials. Ultimately, your choice will depend on whether you prioritize rapid throughput or detailed finesse in your projects.

Accuracy: Plasma vs Laser Cutting

When discussing accuracy in plasma vs laser cutting, laser technology generally takes the crown. Laser machinery offers incredibly fine tolerances—often within 0.1 mm—making it perfect for applications requiring high precision like electronics or intricate art pieces. Conversely, plasma cutting typically has a wider kerf (the width of the cut) which can lead to less precise outcomes; however, it still holds its ground well enough for most industrial applications where extreme precision isn't critical.

The ability to maintain consistent accuracy over time is another advantage that laser machines hold over their plasma counterparts. This consistency makes them a favorite among manufacturers who rely on repeatability for mass production runs or complex assembly processes. Therefore, if your project demands meticulous detail and minimal margin for error, investing in the best laser cutter might be your best bet.

Material Compatibility and Limitations

Material compatibility is another crucial aspect when comparing these two methods in the context of plasma vs laser cutting technology. Plasma cutters are versatile beasts capable of handling various metals like steel and aluminum with ease; they're particularly effective on thicker materials where they can cut through with power and speed unmatched by lasers. However, they struggle with non-metal materials like plastics or wood—areas where laser machines excel due to their ability to finely control heat input.

On the flip side, while laser cutters are champions at slicing through thin sheets of metal as well as non-metals (like acrylics), they face limitations when it comes to thicker metals due to slower processing times or higher operational costs associated with increased power requirements. As such, knowing what materials you'll be working with is vital before deciding which machine suits your needs best—after all, there's no point in investing in a top-tier laser machine if you're primarily handling thick steel plates!

Cost Analysis of Both Methods

When it comes to selecting the right cutting technology, cost plays a pivotal role in the decision-making process. Both plasma and laser cutting have their unique financial implications, from initial investments to ongoing operational expenses. Understanding these costs can help businesses determine which method is more suitable for their specific needs.

Initial Investment for Equipment

The initial investment for equipment can vary significantly between plasma vs laser cutting systems. Plasma cutting machines tend to be more affordable upfront, making them an attractive option for smaller businesses or those just starting out. On the other hand, a quality laser machine often comes with a heftier price tag due to its advanced technology and precision capabilities, which can be seen as an investment in quality.

For those considering the best laser cutter available on the market, it's essential to weigh this cost against potential long-term benefits. While the initial price may be higher for laser machinery, it often results in reduced waste and increased efficiency over time. Therefore, understanding your budget constraints while also considering future savings is crucial when deciding between these two types of cutting machines.

Ongoing Operational Expenses

Once you've made your choice between plasma vs laser cutting, ongoing operational expenses will impact your overall budget significantly. Plasma cutters typically require less maintenance and have lower consumable costs than their laser counterparts; however, they might consume more energy during operation. This means that while you save on maintenance with plasma cutting machines, you could end up spending more on electricity.

In contrast, although laser machinery has higher consumable costs—such as lenses and gases—its energy efficiency can lead to lower utility bills overall. Additionally, if you're using a high-quality laser machine designed for industrial applications, it may offer longer lifespans for parts compared to plasma systems. Balancing these factors will ensure that you make an informed decision regarding ongoing operational expenses.

Cost-Effectiveness in Large Projects

Cost-effectiveness becomes particularly important when evaluating large projects where both plasma vs laser cutting methods are applicable. For extensive jobs requiring high precision and intricate designs, investing in a top-tier laser cutter may yield better results despite its higher initial cost and operating expenses. The enhanced accuracy of a good-quality laser machine can minimize material waste and reduce rework costs over time.

Conversely, if speed is your primary concern—especially in large-scale production—a plasma cutter might provide faster throughput at a lower upfront cost but could compromise on detail in some cases. Ultimately, the choice between these two technologies should consider not only immediate financial implications but also how well each method aligns with project requirements and long-term goals.

Selecting the Best Laser Cutter

Choosing the right laser cutter can feel like navigating a maze of options, especially with so many cutting machines on the market. Whether you’re a hobbyist or a professional, understanding what to look for in a laser machine is crucial for maximizing efficiency and output quality. With the right features, your cutting projects can go from mundane to magnificent.

Features to Look For in a Laser Machine

When searching for the best laser cutter, several key features should top your checklist. First and foremost, consider the power of the laser; higher wattage typically translates into faster cuts and greater material thickness capabilities. Additionally, look for advanced cooling systems that prevent overheating during prolonged use, ensuring consistent performance—after all, nobody wants their cutting machine laser to burn out mid-project!

Another important factor is software compatibility; a user-friendly interface with robust design software can significantly enhance your workflow. Furthermore, assess the machine's versatility by checking its ability to handle various materials—from wood and acrylic to metals—making it suitable for diverse applications. Lastly, don’t forget about after-sales support; having access to reliable customer service can save you headaches down the line.

Leading Brands in Laser Machinery

In the world of laser machinery, certain brands have carved out a reputation for excellence through innovation and reliability. Companies like Epilog and Trotec are often hailed as industry leaders due to their high-quality products that cater to both small businesses and large-scale manufacturers alike. Their machines are known not just for precision but also for their user-friendly designs that make them accessible even to beginners.

Another noteworthy contender is Universal Laser Systems, which offers customizable solutions tailored to specific needs—perfect if you're caught up in that plasma vs laser cutting debate! Then there’s Glowforge, which has gained popularity among makers and crafters due to its compact size and impressive features at an affordable price point. Each brand brings something unique to the table; it’s essential to evaluate your specific requirements before making a decision.

Kiant Machinery’s Offerings for Laser Cutting

Kiant Machinery stands out in this competitive landscape with its impressive lineup of cutting machines designed specifically for laser technology enthusiasts. They provide an array of models suitable for various applications—from small workshops needing precision tools to larger enterprises requiring heavy-duty performance without compromising quality or speed during operations.

One of Kiant's standout offerings includes their flagship model equipped with advanced motion control systems that ensure accuracy while minimizing waste—a critical factor when comparing plasma vs laser cutting techniques! Additionally, Kiant's commitment to customer satisfaction shines through with comprehensive training programs and ongoing support services designed to help users maximize their investment in these powerful tools.

Whether you're looking at entry-level options or high-end industrial models, Kiant Machinery has something that fits every budget while delivering exceptional value in terms of performance and reliability.

Conclusion

In the debate of plasma vs laser cutting, both methods have their unique strengths and weaknesses. Understanding these differences is crucial for making an informed decision when selecting a cutting machine laser. Ultimately, the choice depends on specific project requirements, budget constraints, and material types.

Key Takeaways on Plasma vs Laser Cutting

Plasma cutting excels in speed and versatility, making it ideal for thicker materials and industrial applications. Conversely, laser machinery offers exceptional precision and a clean finish, particularly beneficial for intricate designs and thinner materials. By weighing the pros and cons of each method, you can determine the best laser cutter or plasma system that suits your needs.

Final Thoughts on Choosing the Right Method

When deciding between plasma vs laser cutting, consider factors such as material thickness, desired precision, and operational costs. While plasma cutters may be more suitable for heavy-duty tasks, laser machines shine in applications requiring fine detail. The right choice will not only enhance productivity but also ensure high-quality results tailored to your specific projects.

Future Trends in Cutting Technologies

The landscape of cutting technologies is evolving rapidly with advancements in automation and artificial intelligence. Future developments may lead to hybrid systems that combine features of both plasma and laser cutting for unmatched efficiency. As industries continue to innovate, staying updated on these trends will help you select the most effective cutting solutions available.