Introduction

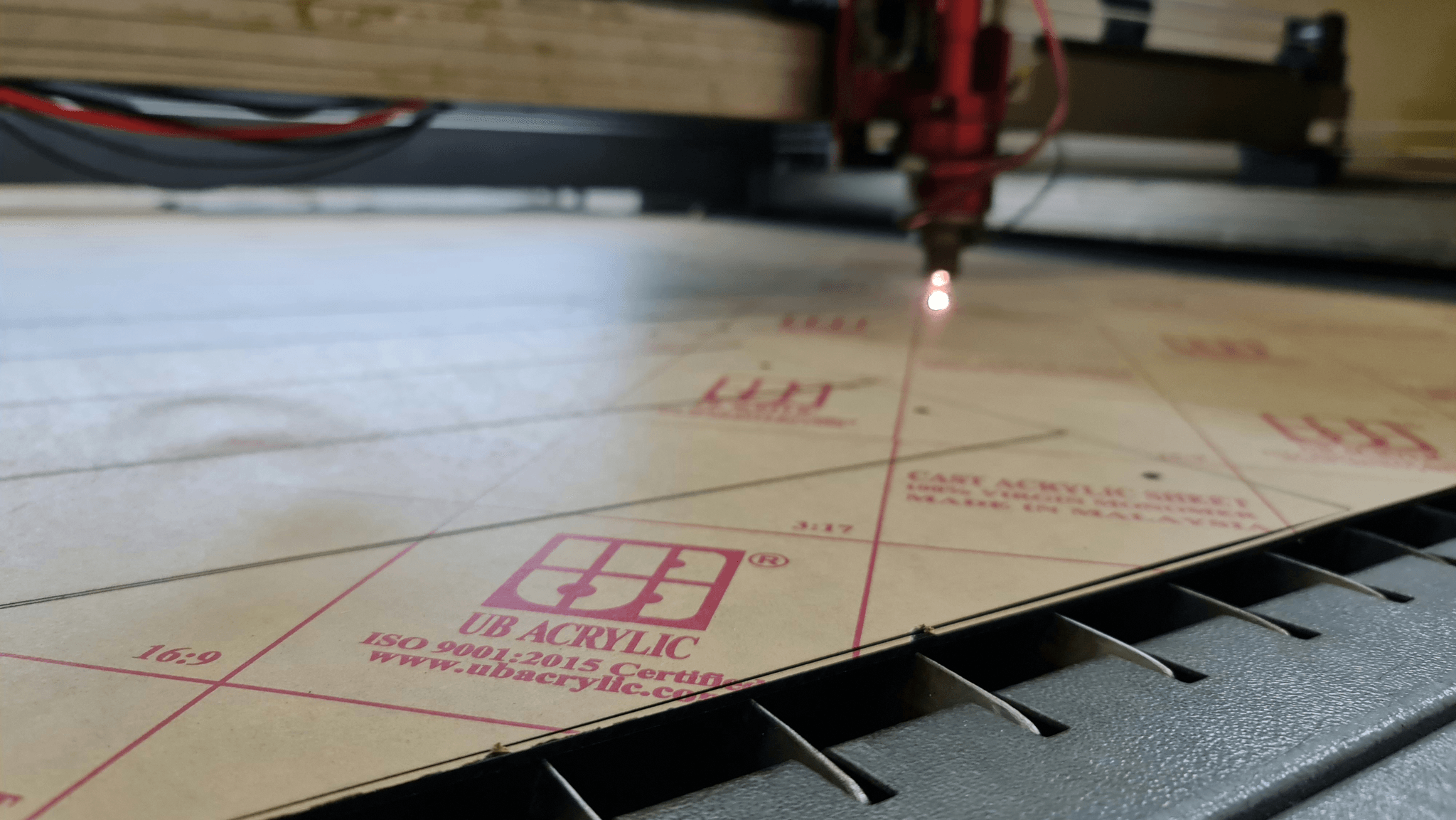

In the world of manufacturing and design, large format laser cutting has emerged as a game-changer, revolutionizing how materials are processed. This advanced technology utilizes powerful beams of light to cut through a variety of materials with unparalleled precision and speed. Whether it's wood, acrylic, metal, or fabric, industrial laser cutters have become essential tools in various industries.

What is Large Format Laser Cutting

Large format laser cutting refers to the process of using high-powered lasers to cut large sheets of material into specific shapes and designs. Unlike traditional cutting methods that may involve blades or saws, a laser cutter employs focused light beams that can slice through thick materials with ease. This technique not only enhances efficiency but also minimizes waste by ensuring accurate cuts every time.

Benefits of Laser Engravers and Cutters

The benefits of using laser engravers and cutters are numerous and compelling for businesses seeking efficiency and quality in their production processes. For starters, these machines offer remarkable precision; intricate designs that would be impossible with manual methods can be achieved effortlessly. Additionally, the versatility of a laser engraving machine allows for various applications—from signage to custom jewelry—making it a valuable asset across multiple sectors.

Applications of Laser Technology

Laser technology has found its way into countless applications across various industries due to its adaptability and effectiveness. From creating detailed engravings on promotional items to cutting complex shapes for architectural models, the possibilities are nearly limitless. Moreover, fields like automotive manufacturing and aerospace engineering rely heavily on industrial laser cutters for producing lightweight yet robust components efficiently.

Understanding Industrial Laser Cutters

When it comes to precision and versatility in manufacturing, industrial laser cutters are the unsung heroes of modern production. These machines utilize focused beams of light to slice through various materials with remarkable accuracy, making them indispensable in many industries. Understanding the different types, features, and operational principles of these cutting-edge tools is essential for anyone interested in maximizing their potential.

Types of Industrial Laser Cutters

Industrial laser cutters come in several varieties, each suited for specific applications and materials. The most common types include CO2 laser cutters, which are excellent for non-metal materials like wood and acrylic; fiber laser cutters, known for their efficiency with metals; and diode lasers that offer compact solutions for lighter tasks. Each type has its unique strengths, making it crucial to choose the right machine laser engraving system based on your project requirements.

Additionally, hybrid systems combine features from different types of industrial laser cutters to provide even greater flexibility. For instance, a machine may incorporate both CO2 and fiber technology to handle a wider range of materials seamlessly. This adaptability not only enhances productivity but also allows businesses to expand their service offerings without investing in multiple machines.

Key Features of Laser Cutting Systems

A high-quality laser cutting system boasts several key features that set it apart from traditional cutting methods. First and foremost is precision; industrial laser cutters can achieve tolerances as tight as 0.1 mm or less, ensuring clean edges and intricate designs every time. Moreover, many systems come equipped with advanced software that facilitates easy design importing and real-time adjustments during the cutting process.

Another critical feature is speed; these machines can operate at remarkable rates without sacrificing quality or accuracy. This efficiency translates into increased output for businesses looking to boost productivity while maintaining exceptional standards in their products or services. Furthermore, safety mechanisms such as enclosed workspaces and automatic shut-off features enhance user protection during operation.

How Industrial Laser Cutters Work

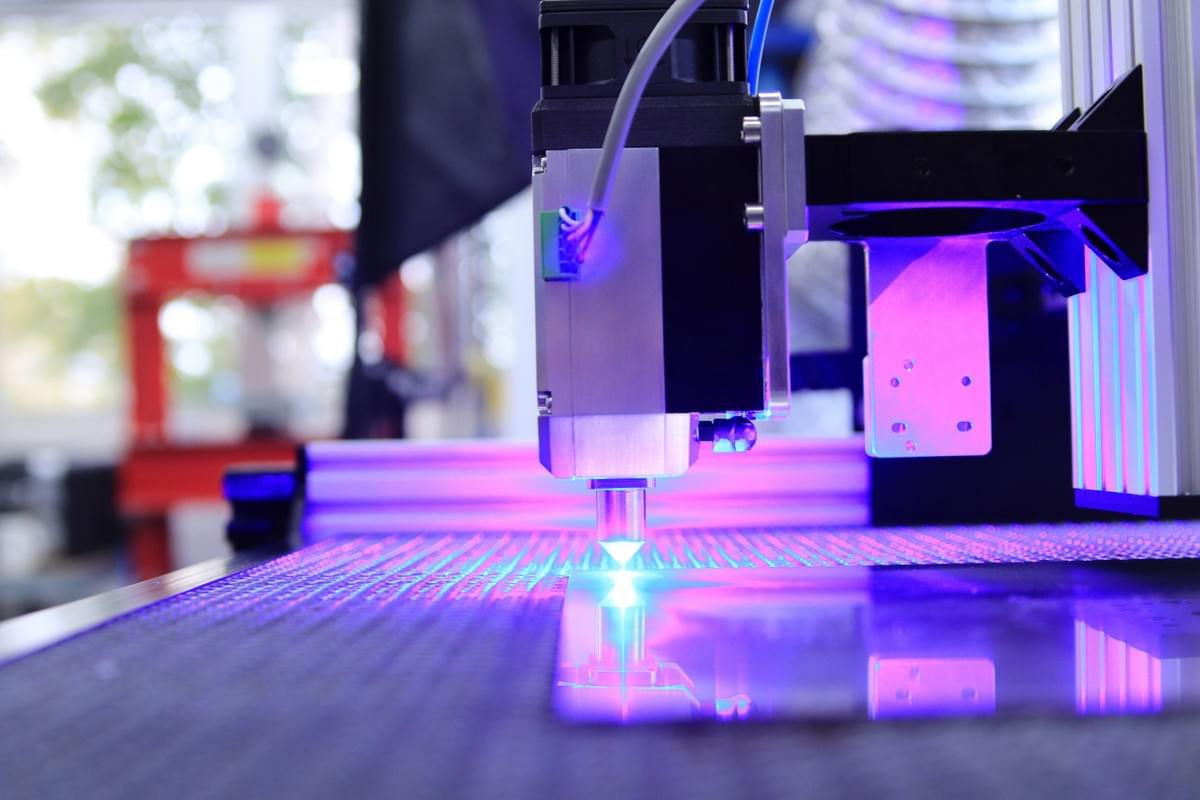

To understand how industrial laser cutters function involves delving into some fascinating physics! At the core of a typical operation is a focused beam of light generated by a high-powered laser source—this beam is directed through optics onto the material being cut or engraved. When aimed precisely at the material's surface, the intense heat from the beam vaporizes or melts away parts of the material along predetermined paths.

The process can vary slightly depending on whether you're using a laser engraving machine or a standard laser cutter; however, both rely on computer numerical control (CNC) technology for precise movements along X-, Y-, and Z-axes. This automation allows for intricate designs that would be nearly impossible to replicate manually—a true game-changer in industries ranging from automotive manufacturing to custom signage creation!

With advancements continually emerging in this field—like improved cooling systems that enhance efficiency—industrial lasers remain at the forefront of modern manufacturing technology.

Exploring Laser Engraving Machines

Laser engraving machines are fascinating tools that have revolutionized the way we create intricate designs and markings on various materials. Understanding the nuances of laser engraving compared to other processes, such as etching, is essential for anyone looking to invest in a laser engraving machine or related equipment. This section will delve into the differences between laser engraving and etching, key components of these machines, and some popular brands in the market.

Differences Between Laser Engraving and Etching

At first glance, laser engraving and etching might seem interchangeable, but they serve distinct purposes with different techniques. Laser engraving involves removing material from the surface to create a design or text by using a focused beam from a laser cutter; it results in deeper marks that can withstand wear over time. In contrast, laser etching merely alters the surface of the material without significant depth, producing lighter markings that may not be as durable but are often more aesthetically pleasing for certain applications.

Understanding these differences is crucial when choosing between a laser engraving machine and a laser etching machine for your projects. For instance, if you require precise details on hard materials like metal or glass, investing in an industrial laser cutter designed for engraving would be beneficial. However, if you're looking to add subtle designs on softer materials like wood or acrylics, then an etching approach may suffice.

Ultimately, knowing when to use each technique can enhance your project's quality while maximizing efficiency with your chosen equipment. With advancements in technology continually blurring these lines further, it's essential to stay informed about which method best suits your needs.

Key Components of a Laser Engraving Machine

A typical laser engraving machine comprises several key components that work together seamlessly to produce high-quality engravings. The most crucial part is the laser source itself—this could be either CO2 or fiber lasers—depending on what materials you plan to work with; CO2 lasers are excellent for organic materials while fiber lasers excel at metals.

Another important component is the motion system that directs the movement of the laser head across your material; this can include stepper motors or servo motors which determine precision levels during operation. Additionally, features such as cooling systems help maintain optimal temperatures during prolonged use while exhaust systems remove smoke and debris generated during cutting or engraving processes.

Lastly, software plays an integral role in operating any industrial laser cutter efficiently; it allows users to upload designs easily and configure settings tailored specifically for their projects—making it indispensable for achieving desired results consistently across various applications with minimal hassle.

Popular Laser Engraving Equipment Brands

When it comes to purchasing reliable laser engraving equipment, several brands stand out due to their reputation for quality and performance within this niche industry. One prominent name is Epilog Laser known for its versatile range of machines suitable both for hobbyists and professionals alike—offering user-friendly interfaces along with impressive speed capabilities tailored towards enhancing productivity levels significantly.

Another notable brand is Trotec which specializes in high-end industrial solutions featuring advanced technologies designed explicitly around efficiency without compromising quality output—a favorite among businesses requiring consistent results across multiple substrates including wood plastics metals among others! Lastly, Glowforge has gained popularity among DIY enthusiasts thanks largely due its compact design combined with intuitive software making it accessible even if you're new into world of machine laser engraving!

By understanding these leading brands' offerings alongside their unique specifications ensures you make informed decisions when selecting equipment tailored specifically towards fulfilling individual project requirements effectively!

Advantages of Laser Carving Machines

Laser carving machines have revolutionized the way industries approach design and manufacturing. With their ability to deliver intricate designs with astounding precision, these machines are becoming indispensable in various sectors. From creating custom signage to intricate art pieces, the advantages of laser carving technology are numerous and compelling.

Precision and Accuracy in Laser Carving

When it comes to precision, few tools rival a laser carving machine. These machines utilize focused laser beams that can cut or engrave with pinpoint accuracy, ensuring that even the most delicate designs come out flawlessly. This level of detail is hard to achieve with traditional methods, making industrial laser cutters a preferred choice for professionals seeking perfection in their projects.

The accuracy of a laser engraving machine also minimizes waste, as the cuts are exact and clean. This means less material is discarded during production, which is not only cost-effective but also environmentally friendly. As industries increasingly prioritize sustainability, the precise nature of laser etching machines aligns perfectly with these goals.

Furthermore, the repeatability factor cannot be overlooked; once a design is programmed into a machine laser engraving system, it can produce identical results time after time without deviation. This reliability ensures that businesses can maintain high standards while scaling their operations.

Versatility Across Materials

One of the standout features of laser carving machines is their versatility across various materials. Whether working with wood, acrylics, metals, or even glass, these machines can handle an impressive range of substrates with ease. This adaptability makes them an essential tool for businesses that require flexibility in their production processes.

For instance, when using a laser cutter on wood or acrylic materials for signage or decorative items, the results are stunningly detailed yet smooth-edged—qualities often unattainable through conventional cutting methods. Similarly, when engraving on metals like stainless steel or aluminum using advanced laser engraving equipment, you achieve deep and lasting impressions without compromising material integrity.

This versatility not only enhances creative possibilities but also allows businesses to diversify their offerings without investing heavily in multiple types of machinery. With just one industrial laser cutter or an advanced engraving machine at your disposal, you can tackle various projects across different industries seamlessly.

Cost-Effectiveness of Laser Carving

Investing in a laser carving machine may seem daunting at first glance due to initial costs; however, its long-term cost-effectiveness quickly becomes apparent. The efficiency offered by industrial laser cutters translates into faster production times and lower labor costs since fewer operators are needed compared to traditional methods that require more hands-on work.

Moreover, reduced material waste contributes significantly to overall savings over time—every cut made by a precise machine means less scrap left behind on the cutting room floor! Additionally, maintenance costs tend to be lower for modern lasers compared to older machinery requiring frequent repairs due to wear and tear from mechanical parts.

Lastly, as demand for customization increases across various sectors—from personalized gifts to bespoke furniture—a reliable machine capable of delivering high-quality results consistently positions your business favorably within competitive markets. Thus investing wisely in advanced technologies like a powerful laser cutter pays dividends down the line!

Kiant Machinery's Role in Laser Solutions

Kiant Machinery stands at the forefront of laser technology, offering a diverse range of products that cater to various industrial needs. Their lineup includes advanced industrial laser cutters, high-precision laser engraving machines, and versatile laser etching machines designed for efficiency and quality. With a commitment to innovation and user satisfaction, Kiant Machinery ensures that their equipment meets the evolving demands of modern manufacturing.

Overview of Kiant Machinery Products

Kiant Machinery provides an impressive array of products tailored for different applications in the realm of laser technology. From robust industrial laser cutters capable of handling thick materials to compact laser engraving equipment suitable for intricate designs, there's something for every requirement. Additionally, their state-of-the-art laser carving machines allow users to explore creative possibilities across various substrates.

Innovations in Laser and Engraving Machine Technology

Innovation is the name of the game at Kiant Machinery, where they continuously push the envelope with their laser and engraving machine technologies. Recent advancements include enhanced precision optics and faster processing speeds that significantly improve productivity while ensuring impeccable results with each cut or etch. Moreover, their latest machine models incorporate smart technology features that streamline operations and provide real-time feedback to users.

Customer Support and Training at Kiant Machinery

Customer support is paramount at Kiant Machinery; they understand that purchasing a machine is just the beginning of your journey with industrial laser cutters or any other equipment. They offer extensive training programs tailored to both new users and experienced operators who wish to refine their skills with a laser cutter or engraver. This dedication ensures customers maximize efficiency while using their machinery effectively, leading to higher satisfaction rates.

Future Trends in Laser Technology

The laser technology landscape is evolving rapidly, and the future holds exciting advancements that promise to enhance industrial applications significantly. From improved precision in laser cutting systems to the integration of automation, the capabilities of machines like laser engraving machines and laser carving machines are expanding. Additionally, sustainability is becoming a focal point, ensuring that these powerful tools not only perform well but also adhere to eco-friendly practices.

Advancements in Laser Cutting Systems

Recent innovations in industrial laser cutters are paving the way for more efficient and precise operations. New technologies such as fiber lasers and CO2 lasers are enhancing the speed and quality of cuts across various materials, making them ideal for industries ranging from automotive to aerospace. With advancements like adaptive optics and real-time monitoring systems, a laser cutter can now adjust settings on-the-fly for optimal performance.

These improvements not only boost productivity but also reduce waste, making it easier for businesses to meet their sustainability goals. The incorporation of intelligent software into laser cutting systems allows for better design integration, enabling seamless transitions from digital designs to physical products. As these technologies continue to advance, we can expect even greater capabilities from both traditional and modern laser engraving equipment.

The Rise of Automation in Laser Processes

Automation is revolutionizing how industries utilize laser technology, particularly with machine laser engraving processes becoming more streamlined than ever before. Automated systems can handle repetitive tasks with precision that far exceeds human capabilities while freeing up valuable labor resources for more complex activities. This trend is especially prevalent in large-scale manufacturing environments where efficiency is paramount.

Furthermore, automated industrial laser cutters are being paired with advanced robotics that allow for intricate designs and multi-material processing without manual intervention. As automation becomes standard practice within facilities utilizing a laser engraving machine or a laser etching machine, businesses will see significant reductions in production time and costs while maintaining high-quality outputs. With this shift toward automation, companies can focus on innovation rather than just execution.

Sustainability in Laser Equipment Usage

Sustainability has emerged as a critical consideration in the development of new technologies across all sectors—including those involving industrial laser cutters and other related machinery. Manufacturers are increasingly designing equipment that minimizes energy consumption while maximizing output efficiency; this means less waste generated during operations using a laser cutter or other types of engraving machinery.

Additionally, many companies are exploring ways to recycle materials processed by their machines—ensuring that every cut made by a machine laser engraving system contributes positively to environmental goals rather than detracting from them. By investing in eco-friendly practices within their production lines—such as using biodegradable materials or implementing closed-loop systems—industries can set themselves apart as leaders committed to sustainable growth while still harnessing the power of advanced technologies like laser carving machines.

Conclusion

In the ever-evolving landscape of manufacturing, industrial laser cutters are paving the way for enhanced productivity and creativity. As technology advances, we can expect these machines to become even more efficient, precise, and accessible. The future is bright for those who embrace laser technology in their operations.

The Future of Industrial Laser Cutters

The future of industrial laser cutters looks promising with advancements in speed, precision, and material compatibility. Innovations such as fiber lasers and improved software interfaces are making these machines more versatile than ever before. As industries continue to seek cost-effective solutions, the demand for high-performance laser engraving equipment will undoubtedly rise.

Choosing the Right Laser Engraving Equipment

Selecting the right laser engraving machine requires careful consideration of your specific needs and applications. Factors such as material type, desired precision, and budget play crucial roles in this decision-making process. Whether you need a compact laser etching machine or a robust laser carving machine for heavy-duty tasks, understanding your requirements will lead you to the perfect fit.

Maximizing Efficiency with Laser Technology

To truly maximize efficiency with a laser cutter or engraving machine, optimizing workflows is essential. Implementing automation where possible can streamline processes and reduce downtime significantly. Additionally, investing in training and support ensures that your team can operate these advanced tools effectively and safely.