Introduction

The world of metal fabrication is constantly evolving, and at the heart of this transformation lies the innovative technology of rollforming. With sheet metal roll forming machines for sale becoming increasingly accessible, businesses are discovering the myriad benefits that come with adopting these systems. Whether you're producing steel sheet panels or specialized roofing components, understanding the nuances of rollforming technology is essential for maximizing efficiency and quality in production.

Understanding Metal Rollforming Systems

Metal rollforming systems are designed to shape and cut metal sheets into desired profiles through a continuous process. These machines utilize a series of rollers to gradually form flat sheets into intricate shapes, making them invaluable in industries such as construction and manufacturing. From simple angles to complex curves, the versatility of a metal panel machine allows for endless possibilities in design and application.

The Benefits of Rollforming Technology

One of the standout advantages of rollforming technology is its ability to produce high volumes with remarkable precision and consistency. This not only reduces material waste but also enhances overall productivity, allowing companies to meet tight deadlines without compromising quality. Additionally, investing in a metal roofing machine for sale can significantly lower labor costs while ensuring superior results in creating durable steel sheet panels.

Key Components of Rollforming Machines

Understanding the key components that make up rollforming machines can help users appreciate their functionality better. Essential elements include feed mechanisms that guide raw materials through the system, forming stations that shape the metal, and cutting tools that ensure precise dimensions for finished products like roofing panels or other custom designs. By familiarizing oneself with these components, manufacturers can optimize their operations and select suitable equipment tailored to their specific needs.

Overview of Sheet Metal Roll Forming Machines

Sheet metal roll forming machines are essential tools in modern manufacturing, enabling the production of a wide range of metal products with precision and efficiency. These machines transform flat sheets of metal into various shapes and profiles through a continuous bending process, making them invaluable for industries such as construction, automotive, and appliance manufacturing. With numerous options available on the market, it's crucial to understand the different types of sheet metal roll forming machines for sale to find the right fit for your needs.

Types of Machines Available

When it comes to sheet metal roll forming machines for sale, you'll find several types designed for specific applications. From basic manual models to fully automated systems, each machine caters to different production scales and complexity levels. For instance, a roofing machine often specializes in producing steel sheet panels specifically designed for roofing applications, while a metal panel machine may focus on creating panels used in walls or facades.

Another popular option is the metal roofing roll former, which is engineered explicitly for crafting roofing materials like standing seam panels or corrugated sheets. These machines can vary in size and capability; some are compact enough for smaller operations while others are robust enough to handle large-scale production demands. Understanding these distinctions helps manufacturers select the most suitable equipment based on their unique requirements.

Features of Modern Rollforming Systems

Modern rollforming systems boast an array of innovative features that enhance efficiency and precision in production processes. Many contemporary models come equipped with advanced controls that allow operators to easily adjust settings like speed and material thickness on-the-fly—an essential capability when working with diverse materials such as steel or aluminum sheets. Additionally, some machines include integrated cutting systems that streamline workflows by eliminating separate cutting stations.

Another standout feature is the ability to produce complex profiles without sacrificing accuracy or speed; this is particularly important when creating custom designs for architectural projects or specialized industrial applications. Furthermore, many modern sheet metal roll forming machines offer real-time monitoring capabilities that provide insights into performance metrics—this data can help businesses optimize operations and reduce waste over time.

Applications in Various Industries

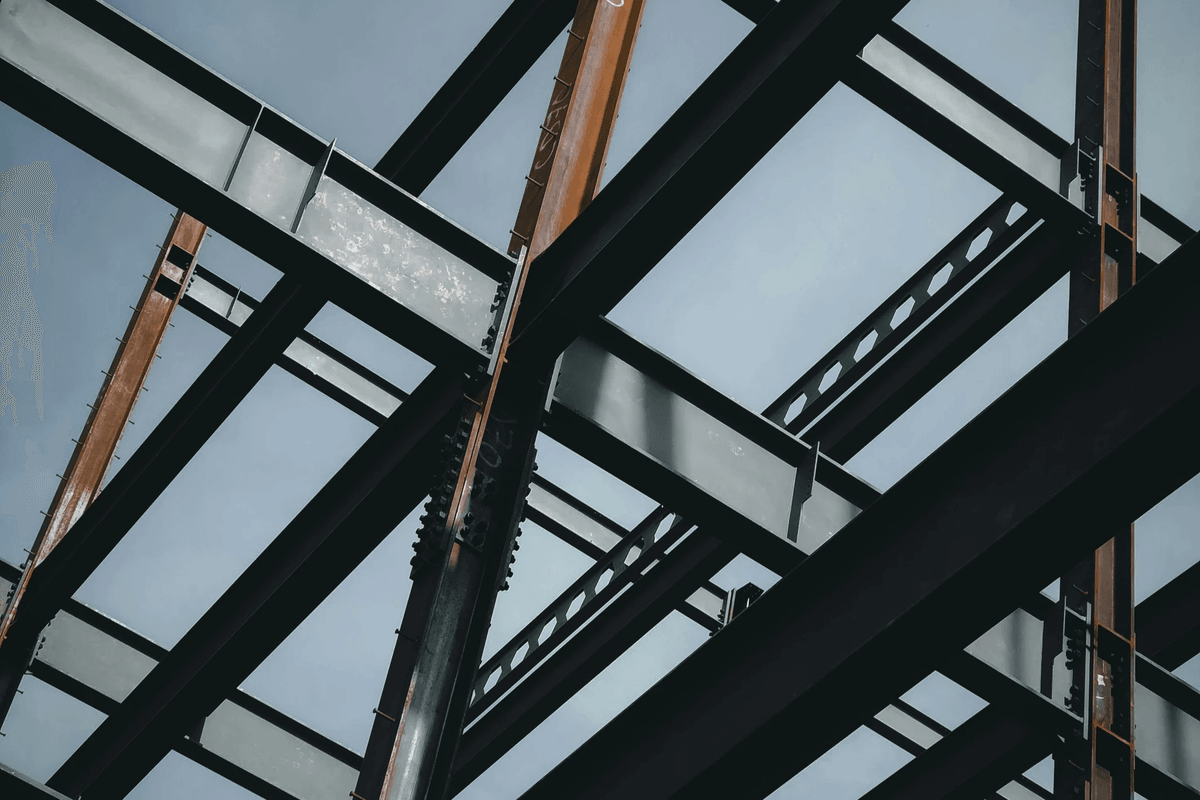

The versatility of sheet metal roll forming machines makes them suitable across numerous industries—from construction to automotive manufacturing and beyond. In construction, steel sheet panels produced by these machines serve critical roles in both structural support and aesthetic appeal; they are often used as exterior cladding or roofing materials due to their durability and weather resistance. Similarly, many manufacturers rely on specialized roofing machines to create high-quality products tailored specifically for residential or commercial building projects.

In addition to construction applications, metal panel machines have found their place in sectors such as HVAC (heating, ventilation, air conditioning) where custom ductwork requires precise fabrication techniques using rolled steel sheets. The automotive industry also benefits from these technologies by utilizing advanced rollforming systems that produce lightweight yet strong components essential for vehicle assembly lines—helping manufacturers meet both performance standards and fuel efficiency regulations.

How Steel Sheet Panels are Made

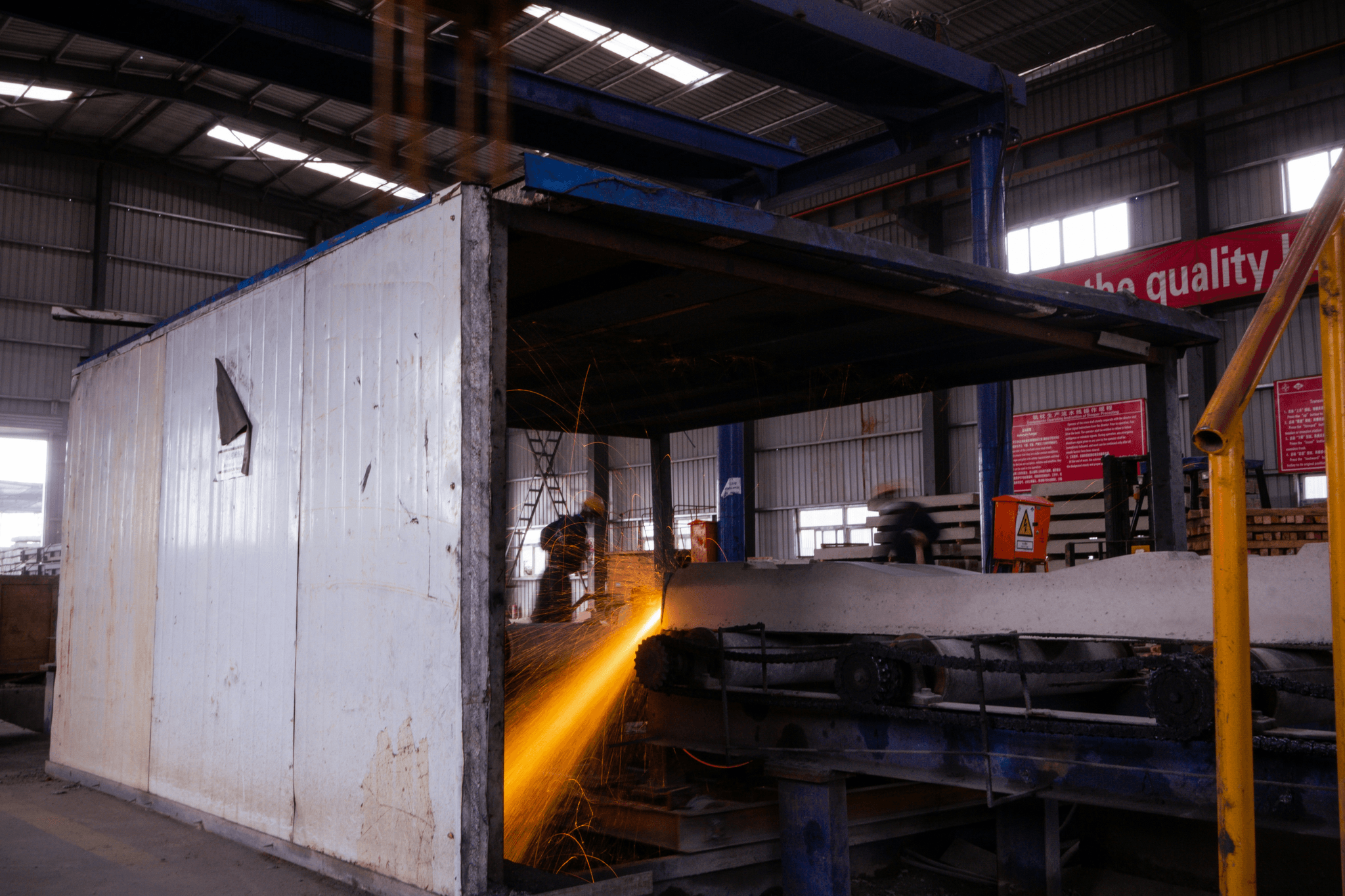

When it comes to creating steel sheet panels, the rollforming process is a marvel of modern engineering. This method involves feeding a continuous strip of metal through a series of rollers that progressively shape it into the desired profile. The result is a strong, uniform product that serves various applications, particularly in construction and manufacturing.

The Rollforming Process Explained

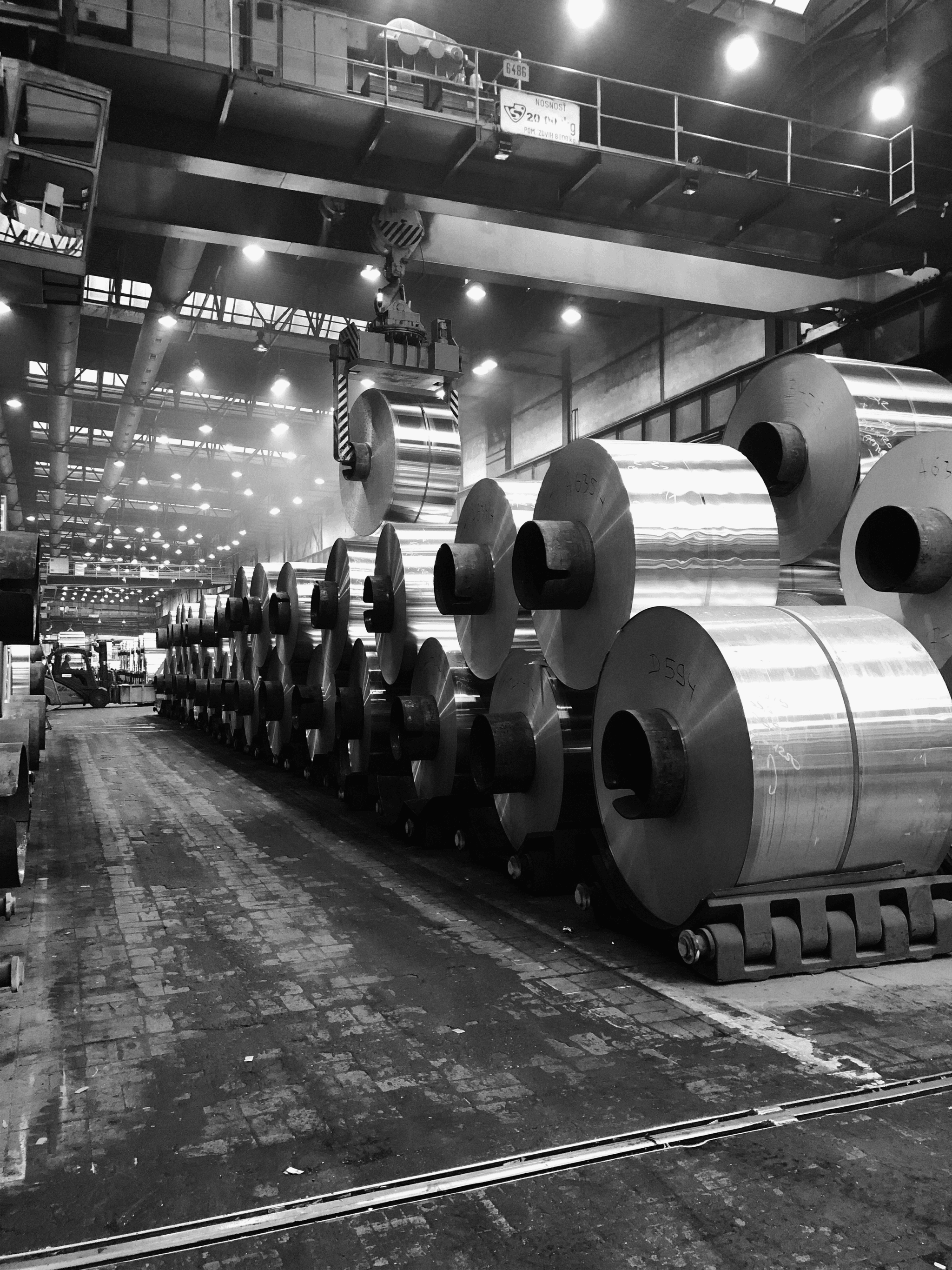

The rollforming process begins with coils of flat steel being fed into specialized sheet metal roll forming machines for sale. These machines are designed to bend and shape the metal as it passes through multiple sets of rollers, each performing a specific function to achieve the final profile. The precision and consistency achieved during this process ensure that every steel sheet panel meets stringent quality standards.

Once formed, the panels can be cut to length depending on their intended use, whether for roofing or siding applications. This adaptability makes rollformed products highly sought after in industries requiring durable materials. In addition, advancements in technology have led to more efficient metal roofing machines that can produce complex shapes with ease.

Importance of Precision in Metal Fabrication

Precision is paramount in metal fabrication, especially when dealing with components like steel sheet panels where even minor deviations can lead to significant structural issues. Utilizing high-quality metal roofing roll formers ensures that each panel maintains uniformity in thickness and dimensions throughout production. This level of accuracy not only enhances product performance but also reduces waste and rework costs.

Moreover, precise measurements are crucial when integrating these panels into larger structures such as roofs or walls. A well-fabricated panel fits seamlessly with others, contributing to overall stability and aesthetic appeal. Therefore, investing in reliable machinery such as advanced metal panel machines pays off by ensuring high-quality outputs consistently.

Use Cases for Steel Sheet Panels

Steel sheet panels produced via rollforming find their way into numerous applications across various industries, showcasing their versatility and strength. In construction, they are commonly used for roofing systems due to their durability against weather elements while providing excellent insulation properties when combined with appropriate materials. Additionally, these panels serve as siding solutions for commercial buildings where aesthetics meet functionality.

Another prominent use case involves manufacturing industrial equipment where robust yet lightweight materials are required for efficiency without compromising structural integrity. From agricultural buildings to residential homes and commercial establishments, the demand for reliable steel products continues to grow alongside technological advancements in production methods like those offered by modern metal roofing machines for sale.

In summary, understanding how steel sheet panels are made reveals not only the intricacies involved but also highlights the importance of choosing quality machinery like metal roofing roll formers or versatile metal panel machines that contribute significantly to successful projects across diverse sectors.

Choosing a Roofing Machine

Selecting the right roofing machine can feel like searching for a needle in a haystack, especially with so many options available in the market. When you're on the hunt for sheet metal roll forming machines for sale, there are several factors to consider that can significantly impact your productivity and efficiency. Understanding your specific needs, such as the type of steel sheet panels you intend to produce and the volume of output required, is crucial before making any decisions.

Factors to Consider When Selecting a Machine

First and foremost, evaluate the capacity of the roofing machine you’re considering; it should align with your production goals. Look into features such as speed, durability, and ease of operation—these will determine how effectively you can manufacture metal roofing products. Additionally, consider compatibility with existing systems if you're integrating new equipment into an established workflow; this will save you time and resources in the long run.

Another important factor is maintenance and support services offered by manufacturers or suppliers of metal roofing machines for sale. A reliable warranty or service plan can keep your operations running smoothly while minimizing downtime due to repairs or malfunctions. Don't forget to check customer reviews or testimonials about their experiences with specific models; real-world insights can be invaluable.

Lastly, assess whether advanced features like automation or digital controls are necessary for your production process. Investing in modern technology might come at a higher upfront cost but could lead to significant savings on labor and material waste over time.

Comparing Metal Roofing Machines for Sale

Once you've narrowed down your options based on essential factors, it’s time to compare specific models available on the market. Look closely at their specifications—such as maximum material thickness and width—to ensure they meet your requirements for producing high-quality steel sheet panels. Additionally, pay attention to energy consumption rates; efficient machines not only reduce operational costs but also contribute positively to environmental sustainability.

You may find that some metal panel machines come equipped with unique features like adjustable roll forming speeds or integrated cutting systems that enhance versatility during production runs. These innovations often set apart standard offerings from premium models that cater specifically to specialized applications within various industries.

When comparing prices among different suppliers of metal roofing roll formers, remember that cheaper isn't always better; focus on total value rather than just initial costs. Factor in aspects like customer support availability, warranty terms, and long-term reliability when making your final decision.

Advantages of Advanced Roofing Technologies

Investing in advanced roofing technologies offers numerous benefits that can elevate your business operations significantly. For instance, modern metal roofing machines often feature enhanced automation capabilities which streamline production processes while maintaining high precision levels—a must-have when fabricating steel sheet panels with tight tolerances.

Moreover, these innovative solutions frequently incorporate user-friendly interfaces that simplify training requirements for new operators; this means less downtime due to learning curves and quicker ramp-up times for new projects using these machines effectively right from day one!

Finally, advanced technologies generally lead to improved overall quality control throughout manufacturing processes—resulting in fewer defects and higher customer satisfaction rates over time! By choosing an upgraded option among available sheet metal roll forming machines for sale today’s market has plenty of choices catering specifically towards efficiency-driven businesses looking forward into future growth opportunities.

Exploring Metal Panel Machines

Metal panel machines are at the forefront of modern manufacturing, offering a remarkable level of versatility in production. These machines can create a wide range of products, from steel sheet panels used in construction to intricate designs for architectural features. The adaptability of metal panel machines allows manufacturers to cater to various industries, making them an essential investment for anyone looking to enhance their production capabilities.

Versatility in Metal Panel Production

One of the standout features of metal panel machines is their ability to produce different types of panels with ease. Whether you’re looking for metal roofing roll formers or specialized equipment for creating decorative panels, these machines can be tailored to meet specific needs. Moreover, the efficiency and speed at which they operate make them ideal for high-volume production runs without sacrificing quality.

Additionally, many sheet metal roll forming machines for sale come equipped with advanced technology that allows users to switch between different panel designs quickly. This versatility not only saves time but also reduces material waste, making it a win-win for both manufacturers and the environment. As businesses continue to seek cost-effective solutions, the demand for versatile metal panel machines is likely to grow even further.

Innovations in Metal Panel Manufacturing

The landscape of metal panel manufacturing is constantly evolving due to technological advancements and innovative practices. Modern metal roofing machines are now equipped with smart technology that enhances precision and minimizes errors during production processes. Features such as automated adjustments and real-time monitoring ensure that every steel sheet panel produced meets stringent quality standards.

Moreover, innovations like modular designs allow manufacturers to customize their machinery based on specific project requirements easily. This flexibility leads to improved productivity and faster turnaround times on projects involving various types of steel sheet panels or unique architectural features. As new technologies emerge, staying updated on innovations will be crucial for businesses aiming to remain competitive in this dynamic market.

Market Trends for Metal Panel Machines

As the demand for sustainable building materials increases, so does interest in efficient manufacturing processes involving metal roofing roll formers and other related machinery. Current market trends indicate a significant shift towards eco-friendly practices within the industry; companies are increasingly seeking out energy-efficient options when considering sheet metal roll forming machines for sale. This trend is driven by both consumer preferences and regulatory pressures aimed at reducing environmental impact.

Furthermore, there’s a notable rise in customization requests from clients who want unique designs tailored specifically for their projects—be it residential roofs or commercial facades made from durable steel sheet panels. Manufacturers who adapt quickly by investing in advanced technologies will likely see greater success as they meet these evolving demands head-on while maximizing ROI through quality equipment investments.

The Role of Kiant Machinery in the Industry

Kiant Machinery has established itself as a key player in the metal rollforming sector, providing innovative solutions that cater to a diverse range of manufacturing needs. Their extensive portfolio includes high-quality sheet metal roll forming machines for sale, designed to enhance productivity and efficiency. Whether you’re looking for a robust roofing machine or a versatile metal panel machine, Kiant Machinery has something to meet your requirements.

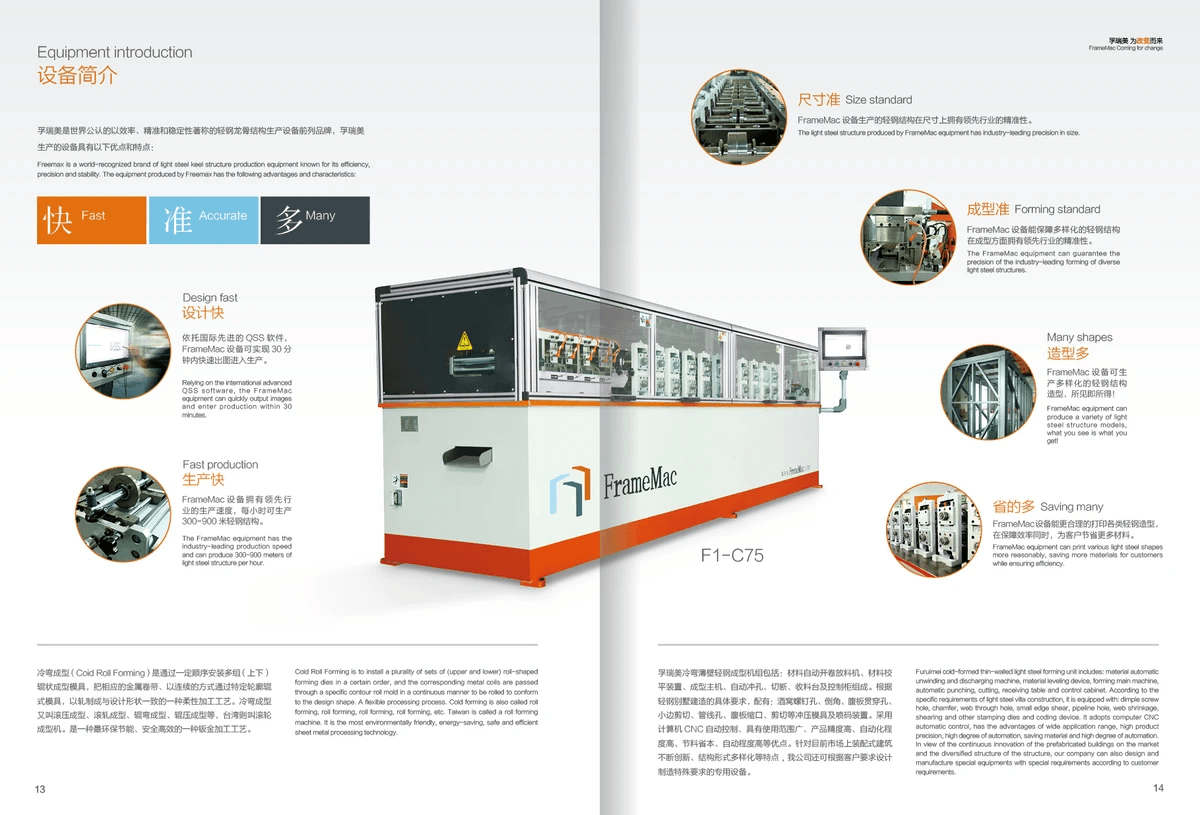

Overview of Kiant Machinery’s Offerings

Kiant Machinery offers an impressive array of products, including specialized metal roofing roll formers that are engineered for precision and durability. Their sheet metal roll forming machines for sale come equipped with advanced technology, ensuring consistent output and superior quality in steel sheet panels production. With options tailored for various applications, Kiant's offerings stand out in the competitive landscape of manufacturing machinery.

Customer Support and Training Services

One of the standout features of Kiant Machinery is their commitment to customer support and training services. They understand that purchasing a metal roofing machine is just the beginning; effective operation and maintenance are crucial for maximizing performance. Kiant provides comprehensive training programs that empower clients to fully leverage their investments in sheet metal roll forming machines for sale, ensuring they can produce high-quality products with confidence.

Success Stories from Kiant Machinery Clients

The success stories from clients who have invested in Kiant's machinery speak volumes about its impact on their businesses. Many have reported increased production rates and improved product quality after upgrading to a modern metal panel machine from Kiant. Testimonials highlight how these innovations not only streamline operations but also enhance profitability, showcasing why investing in a reliable metal roofing machine is essential for growth.

Conclusion

In conclusion, the future of metal rollforming is bright and full of potential innovations that promise to enhance productivity and efficiency across various industries. As we look ahead, trends such as automation, improved materials, and advanced technology will redefine how sheet metal roll forming machines are utilized. Embracing these changes will not only elevate production capabilities but also ensure that businesses stay competitive in a rapidly evolving market.

Future Trends in Metal Rollforming

The future trends in metal rollforming are leaning towards increased automation and smart technology integration. With the rise of Industry 4.0, manufacturers are incorporating IoT devices into their sheet metal roll forming machines for sale, allowing for real-time monitoring and data analytics. This shift not only enhances operational efficiency but also reduces downtime by predicting maintenance needs before they become critical issues.

Sustainability is another trend reshaping the industry; companies are focusing on eco-friendly practices by utilizing recyclable materials in their production processes. The demand for steel sheet panels made from sustainable sources is growing, driving innovation in material usage and waste reduction techniques within manufacturing facilities. As these trends continue to evolve, businesses that adapt will likely lead the way toward more responsible manufacturing practices.

Enhancing Efficiency with Modern Machines

Modern machines play a pivotal role in enhancing efficiency within the metal forming industry. Advanced features like automated feeding systems and computerized controls streamline operations, enabling manufacturers to produce high-quality products with minimal labor input. Investing in a modern roofing machine or a metal roofing machine for sale can significantly reduce production times while maintaining precision.

Moreover, these state-of-the-art machines often come equipped with energy-efficient technologies that minimize power consumption during operation—an essential consideration for any business aiming to lower operational costs while maintaining productivity levels. By integrating cutting-edge machinery into their workflows, companies can not only boost output but also improve overall product quality through enhanced control over the manufacturing process.

Maximizing ROI with Quality Equipment

Maximizing return on investment (ROI) begins with selecting quality equipment tailored to specific production needs—particularly when it comes to choosing a metal panel machine or a roofing machine designed for high performance and durability. Investing wisely means considering factors such as machine versatility, maintenance requirements, and available support services when evaluating options like a metal roofing roll former or other machinery on the market.

Quality equipment tends to have lower long-term operating costs due to reduced downtime and less frequent repairs or replacements needed over time—factors that directly contribute to improved profitability for manufacturers using steel sheet panels in their projects. Additionally, purchasing from reputable suppliers ensures access to ongoing customer support and training services that can further enhance operational efficiency.

By prioritizing investments in high-quality sheet metal roll forming machines for sale while keeping an eye on future trends, businesses can position themselves favorably within their respective markets while maximizing returns over time.