Introduction

In the realm of manufacturing, few processes have evolved as dramatically as that of roll forming machinery. Originally developed for simple applications, today’s roll forming machines are sophisticated metal forming machines capable of producing everything from roof panels to intricate framing machines. This evolution has not only enhanced efficiency but has also paved the way for custom solutions tailored to meet diverse industrial needs.

The Evolution of Roll Forming Machinery

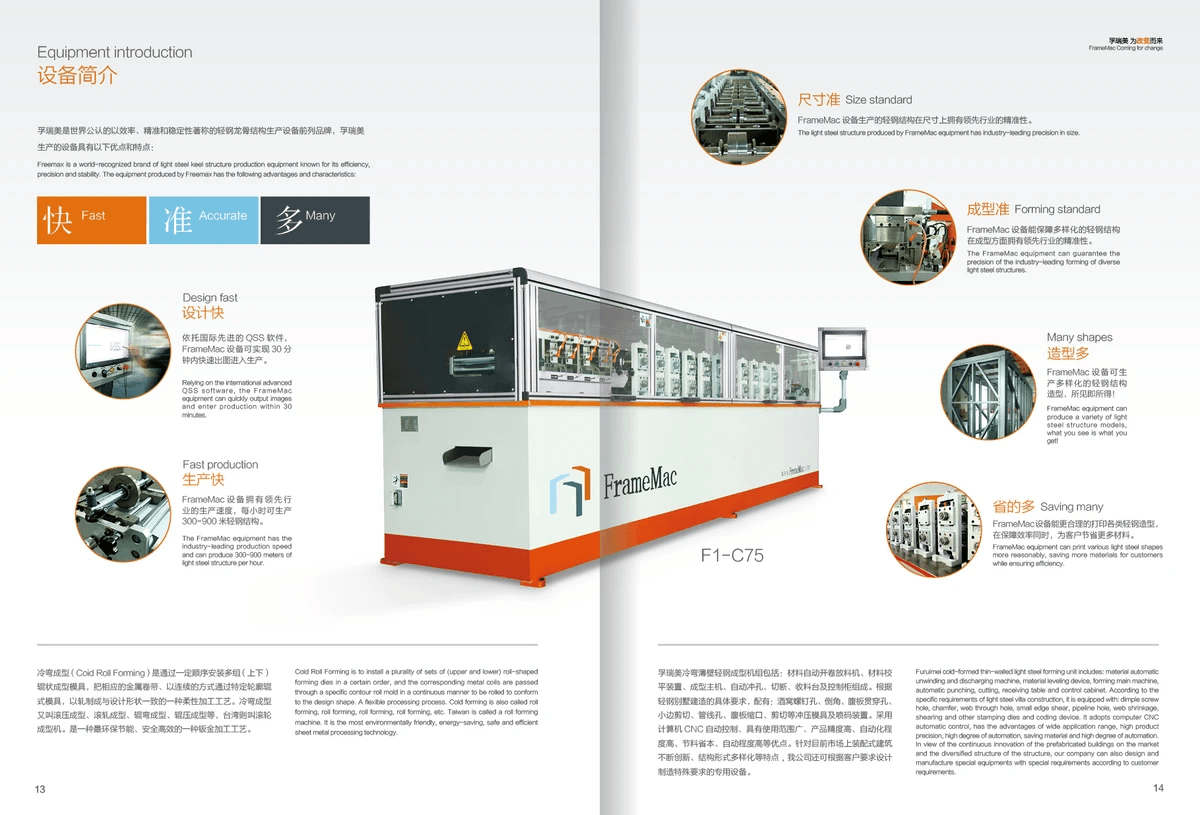

The journey of roll forming machinery began in the early 20th century when manufacturers sought efficient ways to produce metal components. Over the decades, advancements in technology have transformed basic framing machines into highly specialized tools that can create complex shapes with precision and speed. Modern steel roofing machines exemplify this progress, enabling producers to generate durable and lightweight roofing solutions that cater to a variety of architectural styles.

Why Custom Solutions Matter

In an increasingly competitive market, customization is no longer a luxury but a necessity for businesses looking to stand out. Custom roll forming solutions allow manufacturers to design products that meet specific project requirements while maximizing efficiency and minimizing waste. Whether it's a unique profile for metal roofing or specialized components for structural applications, tailored solutions ensure that companies can meet their clients' demands effectively.

Kiant Machinery: Your Trusted PartneWith years of experience and expertise in providing high-quality metal forming machinery, Kiant is committed to delivering custom solutions designed specifically for your needs. Their dedication goes beyond just selling equipment; they offer ongoing support and guidance throughout your manufacturing journey.

Understanding Roll Forming Machines

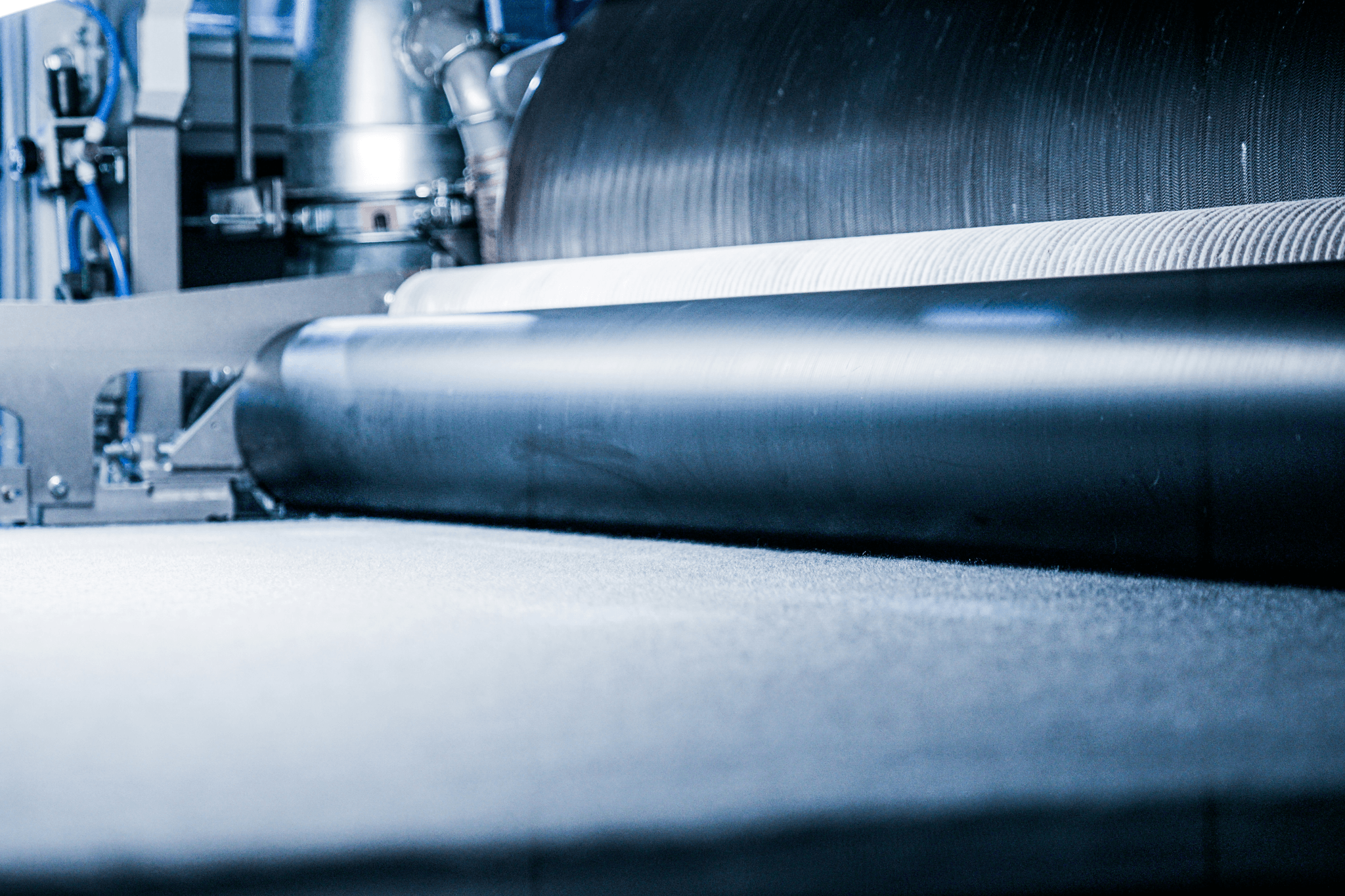

Roll forming machines are a sophisticated yet essential component in modern manufacturing, particularly in the production of metal products. This technology involves the continuous bending of sheet metal into specific shapes using a series of rollers, making it ideal for creating consistent and precise profiles. With applications ranging from roof panels to framing machines, roll forming is a go-to solution for many industries looking to streamline their processes.

Defining Roll Forming Technology

At its core, roll forming technology is all about efficiency and precision. The process begins with a flat strip or sheet of metal being fed through a series of rollers that gradually shape it into the desired profile without cutting or welding. This method not only enhances production speed but also minimizes waste, making it an attractive option for manufacturers who want to optimize their operations while maintaining high-quality standards.

Applications Across Industries

The versatility of roll forming machines allows them to cater to various sectors, including construction, automotive, and appliance manufacturing. In the construction industry, for instance, roofing machines are utilized to create durable roof panels that withstand harsh weather conditions while providing aesthetic appeal. Similarly, framing machines play a critical role in producing structural components that ensure the integrity and safety of buildings—demonstrating how integral these metal forming machines are across different applications.

Advantages of Using Roll Forming

Using roll forming offers several advantages that set it apart from other manufacturing processes. First and foremost is cost-effectiveness; by producing parts in high volumes with minimal waste, businesses can significantly reduce material costs and labor expenses associated with traditional methods like cutting or stamping. Additionally, roll formed products exhibit superior strength and consistency—qualities that are especially crucial when dealing with steel roofing machines designed for heavy-duty applications where durability is paramount.

Custom Solutions for Unique Needs

Tailoring Machines to Specific Projects

Every project has its own specifications and demands, which is why tailoring roll forming machines is essential for success. Our team at Kiant Machinery works closely with clients to understand their specific requirements, ensuring that each metal roofing machine or steel roofing machine is designed with precision and efficiency in mind. From custom tooling to specialized features, our metal forming machines can be adapted to produce everything from intricate designs to robust structures.

When you invest in a forming machine tailored for your project, you gain the advantage of increased productivity and reduced waste. This not only enhances your operational efficiency but also contributes positively to your bottom line. After all, a well-designed roofing machine can make all the difference between a good product and a great one.

Success Stories from Kiant Machinery

Kiant Machinery has a track record of success stories that highlight our commitment to providing custom solutions for unique needs in the roll forming industry. For instance, we partnered with a client looking for an innovative way to produce high-quality roof panels quickly and efficiently. By customizing their metal roofing machine with advanced technology and streamlined processes, we helped them increase production capacity by 40% while maintaining top-notch quality.

Another success story involves a customer who needed specialized framing machines for an unconventional project involving curved structures. Our team rose to the challenge by designing a flexible steel roofing machine capable of handling complex shapes without compromising on accuracy or speed. These examples illustrate how our dedication to customization has enabled clients across various industries to achieve remarkable results.

Importance of Flexibility in Manufacturing

Flexibility in manufacturing is no longer just an option; it's a necessity in today's fast-paced market environment where demands change rapidly. The ability of roll forming machines like ours at Kiant Machinery to adapt quickly can set businesses apart from their competitors who may be stuck with rigid systems unable to pivot when required. Customization allows manufacturers not only to respond swiftly but also proactively innovate new products tailored perfectly for emerging market trends.

Moreover, having flexible metal forming machines means you can diversify your offerings without significant overhauls or investments in entirely new equipment. As industries evolve—be it through shifts towards sustainable practices or advancements driven by Industry 4.0—having adaptable solutions will ensure you're always ahead of the curve rather than playing catch-up.

The Manufacturing Process Explained

Each step in the production line is designed to ensure that the final product meets the rigorous standards required in industries such as construction and automotive. From roof panels to framing machines, understanding these key steps can help you appreciate the craftsmanship involved in creating reliable metal forming machines.

Key Steps in Roll Forming Production

The first step in roll forming production involves designing a precise tooling setup that dictates how raw materials will be shaped into desired profiles. After tooling is established, strips of metal are fed through a series of rollers on a forming machine, gradually shaping them into components like roof panels or steel roofing sections. This continuous process allows for high-volume production while maintaining consistent quality, making it ideal for manufacturers looking to produce framing machines and roofing machines efficiently.

Once the metal has been formed, it undergoes additional processes such as cutting and finishing to meet specific project requirements. Quality checks are integrated at various stages to ensure that each piece adheres to strict tolerances and specifications—an essential aspect when dealing with metal roofing machines that must withstand environmental stresses. Ultimately, this streamlined approach not only enhances productivity but also reduces waste, making roll forming an attractive option for modern manufacturing.

Material Selection and Quality Control

Choosing the right materials is crucial when operating a roll forming machine; it directly impacts both performance and durability. Commonly used materials include steel, aluminum, and other alloys that can withstand bending without compromising structural integrity—essential for applications like roofing where durability is non-negotiable. Manufacturers often conduct rigorous testing during this phase to ensure that selected metals will perform effectively under real-world conditions.

Quality control doesn't stop at material selection; it's woven throughout every stage of production—from initial setup through final inspection of finished products like framing machines or metal roofing systems. Advanced techniques such as laser measurement tools are employed to monitor dimensional accuracy continuously while reducing human error during inspections. This meticulous attention ensures that every component produced by your metal forming machine meets industry standards and customer expectations.

The Role of Technology in Efficiency

In today’s fast-paced manufacturing environment, technology plays an indispensable role in enhancing efficiency within roll forming processes. Automation has revolutionized how we operate roll forming machinery; smart controls optimize speed and pressure settings based on real-time feedback from sensors embedded throughout the system. This not only improves throughput but also minimizes downtime by predicting maintenance needs before they become critical issues.

Moreover, advancements like computer-aided design (CAD) allow manufacturers to simulate various scenarios before physical production begins—saving time and resources while fine-tuning designs for products ranging from roof panels to complex framing solutions. As we look ahead towards Industry 4.0 integration with IoT capabilities within manufacturing systems, we can expect even greater levels of efficiency from our metal roofing machines and other equipment designed for precision work.

Choosing the Right Manufacturer

When it comes to investing in a roll forming machine, choosing the right manufacturer can make all the difference. With so many options available, it's crucial to find a partner that aligns with your specific needs, especially if you're in industries like roofing or framing. A reliable manufacturer not only provides quality machinery but also supports you through every stage of your project.

Why Kiant Machinery Stands Out

Kiant Machinery has carved out a niche for itself in the competitive landscape of roll forming machines, particularly with its innovative solutions for roof panels and framing machines. Their commitment to quality and customization ensures that each metal roofing machine is tailored to meet unique project specifications. With years of experience under their belt, Kiant has earned a reputation for delivering durable and efficient metal forming machines that stand the test of time.

Moreover, Kiant Machinery's focus on cutting-edge technology means their forming machines are equipped with features that enhance productivity and reduce waste. This is particularly beneficial for customers who demand high-quality output without compromising on efficiency. When you choose Kiant, you're not just investing in a roofing machine; you're partnering with an industry leader dedicated to your success.

Evaluating Manufacturer Credentials

Evaluating manufacturer credentials is essential when selecting a provider for your steel roofing machine or any other type of roll forming equipment. Look for certifications and industry affiliations that demonstrate a commitment to quality standards and innovation in manufacturing processes. A manufacturer with extensive experience in producing custom solutions will often have case studies or testimonials showcasing successful projects similar to yours.

Additionally, consider the range of products they offer; manufacturers who specialize in various types of metal forming machines may provide more comprehensive support than those focused on just one area. It's also wise to check their customer service reputation—after all, effective communication can save you time and money down the line if issues arise during production or installation.

Importance of After-Sales Support

After-sales support is often an overlooked aspect when choosing a manufacturer for your roll forming machine needs, but it’s critical for long-term success. The best manufacturers understand that their relationship with clients doesn’t end after the sale; they offer ongoing support to ensure your framing machines operate smoothly over time. This includes training on how to use new machinery effectively as well as assistance with maintenance and repairs when necessary.

In industries where precision is key—like those utilizing metal roofing machines—a small hiccup can lead to significant setbacks in production timelines or quality control issues. Therefore, having access to knowledgeable technicians who can quickly address concerns ensures you maintain operational efficiency while minimizing downtime. After all, investing in top-notch machinery is only part of the equation; securing reliable after-sales support completes it.

Future Trends in Roll Forming Machines

The future of roll forming machines is poised for exciting innovations that promise to redefine efficiency and capabilities in manufacturing. With advancements in technology, we can expect more sophisticated metal forming machines that cater to complex designs and diverse applications. This evolution will not only enhance the production of roof panels and framing machines but also streamline processes across various industries.

Innovations on the Horizon

Innovations in roll forming machines are set to revolutionize how we approach metal roofing and other structural components. Manufacturers are increasingly integrating automation and smart technology into their framing machines, resulting in enhanced precision and reduced lead times. Expect to see more versatile roofing machines capable of producing a wider array of profiles, all while maintaining high-quality standards.

Moreover, the introduction of advanced materials will allow steel roofing machines to achieve greater strength-to-weight ratios, making them ideal for modern construction needs. These innovations will empower manufacturers to meet rising demands while ensuring sustainability remains a core focus. As new techniques emerge, the capabilities of metal forming machines will expand dramatically, paving the way for even more creative architectural solutions.

Sustainability in Manufacturing

Sustainability is becoming a driving force behind the evolution of roll forming machinery, with manufacturers striving for eco-friendly practices throughout production cycles. The push towards using recycled materials in metal roofing machine production not only reduces waste but also lowers energy consumption during manufacturing processes. This shift aligns perfectly with global efforts toward sustainable development and responsible resource management.

Additionally, advancements in energy-efficient technologies are allowing framing machines to operate with significantly lower power requirements without sacrificing performance. As industries become increasingly aware of their environmental impact, investing in sustainable roll forming solutions will be vital for staying competitive while contributing positively to the planet’s health. Ultimately, embracing sustainability will ensure that future generations can continue benefiting from reliable roofing solutions.

The Impact of Industry 4.0

The advent of Industry 4.0 is transforming traditional manufacturing landscapes by integrating smart technologies into operations—this includes our beloved roll forming machines! By leveraging IoT (Internet of Things) devices and AI-driven analytics, manufacturers can monitor processes in real-time, optimizing performance like never before with metal forming machinery at their disposal. This level of connectivity translates into improved decision-making and resource allocation across all stages—from design through production.

Moreover, as data becomes more accessible through these intelligent systems, companies can quickly adapt their steel roofing machine configurations based on market trends or customer feedback—making customization easier than ever! Embracing Industry 4.0 means that businesses equipped with advanced framing machines will be able to respond swiftly to evolving demands while enhancing overall productivity levels across the board.

Conclusion

In the ever-evolving landscape of manufacturing, roll forming machines have emerged as a crucial asset for businesses aiming to gain a competitive edge. These versatile machines are not just tools; they are integral components that enhance production efficiency and product quality. Whether you're producing roof panels or framing machines, investing in advanced roll forming technology can significantly elevate your operational capabilities.

Roll Forming Machines for Competitive Edge

The use of roll forming machines allows manufacturers to produce complex shapes with precision and speed, which is essential in today’s fast-paced market. By utilizing specialized equipment like metal roofing machines and steel roofing machines, companies can streamline their operations and reduce material waste. This efficiency translates into lower production costs and faster turnaround times, giving businesses an undeniable competitive advantage.

The Importance of Customization

Customization is key when it comes to meeting unique project requirements in the realm of metal forming machines. Off-the-shelf solutions may not always meet specific needs, which is why tailored options are essential for success in projects involving roofing machines or framing machines. With custom roll forming machinery, manufacturers can create products that align perfectly with client specifications, ensuring satisfaction and fostering long-term partnerships.

Partnering with Experts for Success

Navigating the complexities of choosing the right roll forming machine requires expertise that goes beyond mere product knowledge; it demands a partner who understands your business goals deeply. Kiant Machinery stands out by offering not just high-quality machinery but also invaluable after-sales support to ensure your metal forming machine operates at peak performance. By collaborating with experts in the field, you position yourself for sustained success and innovation in an ever-competitive marketplace.