Introduction

In the realm of modern manufacturing, rollforming machines play a pivotal role in shaping metal into various forms, making them indispensable in the equipment industry. These versatile machines transform flat metal sheets into intricate profiles with precision, catering to industries ranging from construction to automotive. Understanding the nuances of roll machining is essential for manufacturers looking to enhance efficiency and product quality.

Understanding Rollforming Machines

Rollforming machines are specialized manufacturing equipment designed to continuously shape metal through a series of rollers and dies. These machines can produce a wide array of products, including metal roofing panels, structural components, and custom profiles tailored to specific needs. As manufacturing technology evolves, so do these form rolling machines, integrating advanced features that significantly improve their operational capabilities.

Importance of Choosing the Right Features

Selecting the right features for your rollforming machine can make or break your production line’s efficiency and output quality. With numerous options available—ranging from automation capabilities to precision controls—it's crucial for manufacturers to assess their specific needs before investing in any equipment. The right combination of features not only enhances performance but also ensures that your metal forming machine remains competitive in a rapidly evolving market.

How Features Impact Manufacturing Success

The features integrated into a rollforming machine directly influence its overall performance and the success of manufacturing operations. Advanced technology such as automated controls and real-time monitoring systems can lead to significant reductions in waste and downtime while boosting productivity levels. Ultimately, choosing a rollforming machine equipped with cutting-edge features can propel businesses forward by streamlining processes and ensuring high-quality output.

Core Functionality of Rollforming Machines

When it comes to manufacturing machines, rollforming machines stand out for their remarkable versatility and efficiency in various applications. They are integral to the equipment industry, serving a plethora of sectors from construction to automotive. Understanding the core functionality of these metal forming machines is crucial for manufacturers looking to optimize their production processes.

Exploring Versatility in Applications

Rollforming machines are not just one-trick ponies; they excel across a diverse range of applications. From creating metal roofing sheets to producing intricate profiles for automotive parts, these form rolling machines are designed to handle different materials and shapes with ease. This versatility allows manufacturers to cater to specific customer needs while maintaining high production rates.

In addition, roll machining can adapt seamlessly between projects, making them ideal for businesses that require flexibility in their manufacturing equipment. Whether it's producing lightweight components or heavy-duty structural elements, the adaptability of a rollforming machine ensures that manufacturers can respond quickly to market demands without compromising quality. Ultimately, this versatility translates into increased profitability and customer satisfaction.

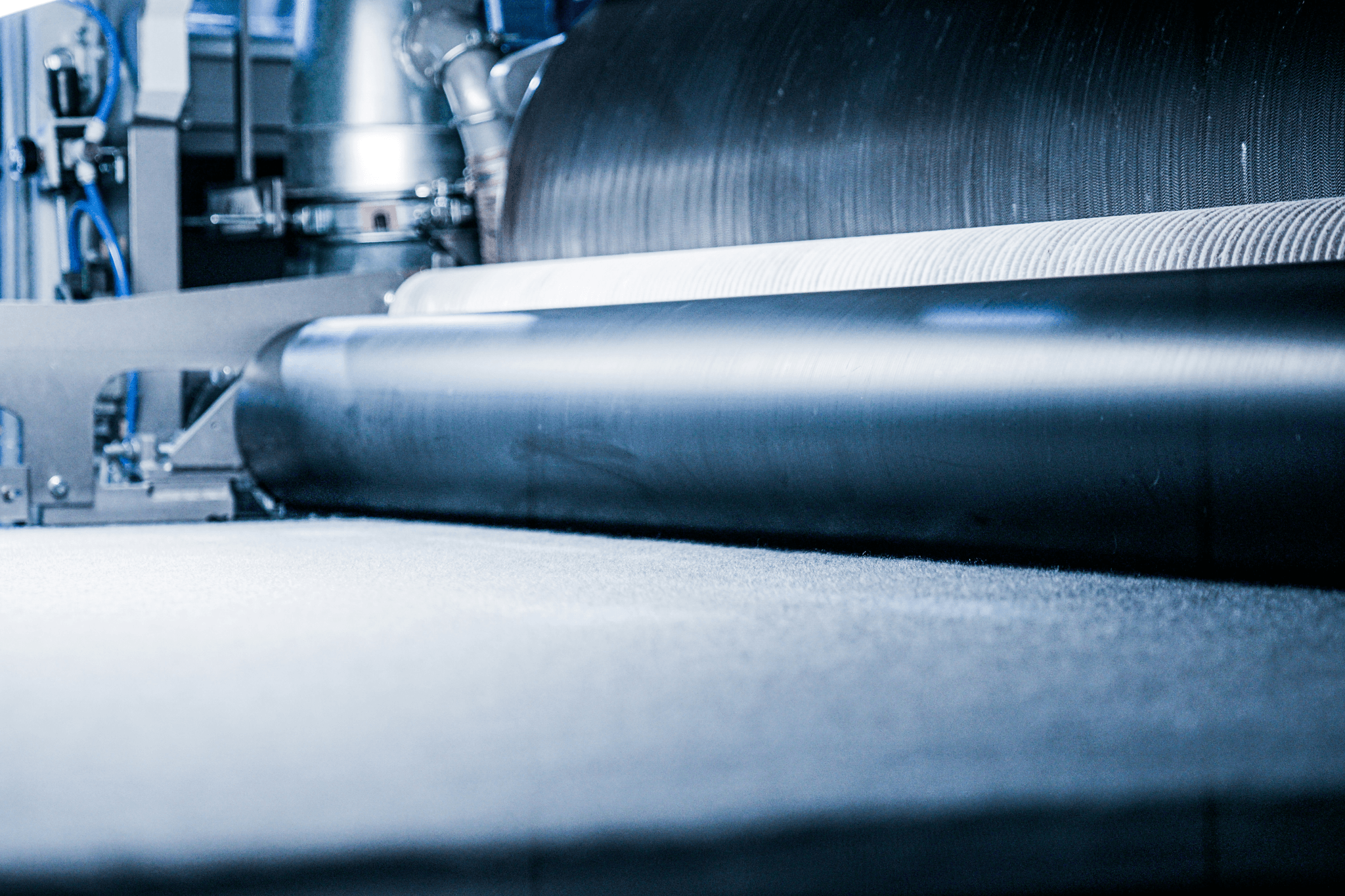

The Role of Precision in Metal Forming

Precision is the name of the game when it comes to metal forming, and rollforming machines deliver on this front like no other manufacturing equipment. The ability to create consistently accurate profiles is essential for industries where even minor deviations can lead to significant issues down the line. Manufacturers rely on high-precision rollforming machines not only for aesthetic appeal but also for functional integrity.

Moreover, precision affects everything from material waste reduction to assembly efficiency; a well-formed component fits better with other parts and requires less rework or adjustment during final assembly stages. As such, investing in precision-engineered form rolling machines is vital for any manufacturer aiming for top-notch quality control and operational excellence. In an industry where margins are tight, every millimeter counts!

Types of Form Rolling Machines

The world of form rolling encompasses various types of rollforming machines tailored for specific tasks and industries. For instance, there are dedicated metal roofing machines designed specifically for producing roofing panels with unique profiles that meet architectural specifications. Other types include structural rollformers that create components like beams and channels essential in construction.

Each type varies not only in design but also in functionality; some may offer more automation features while others focus on manual adjustments suited for smaller operations or custom jobs. Understanding these distinctions helps manufacturers choose the right machine based on their production goals—whether that's speed or customization capabilities—ensuring they remain competitive within the equipment industry landscape.

Technology and Innovation in Manufacturing Equipment

In the rapidly evolving world of manufacturing, staying ahead means embracing technology and innovation. Rollforming machines are no exception, as modern advancements have transformed how these machines operate, enhancing efficiency and precision. The integration of cutting-edge features into manufacturing equipment can make a significant difference in production capabilities.

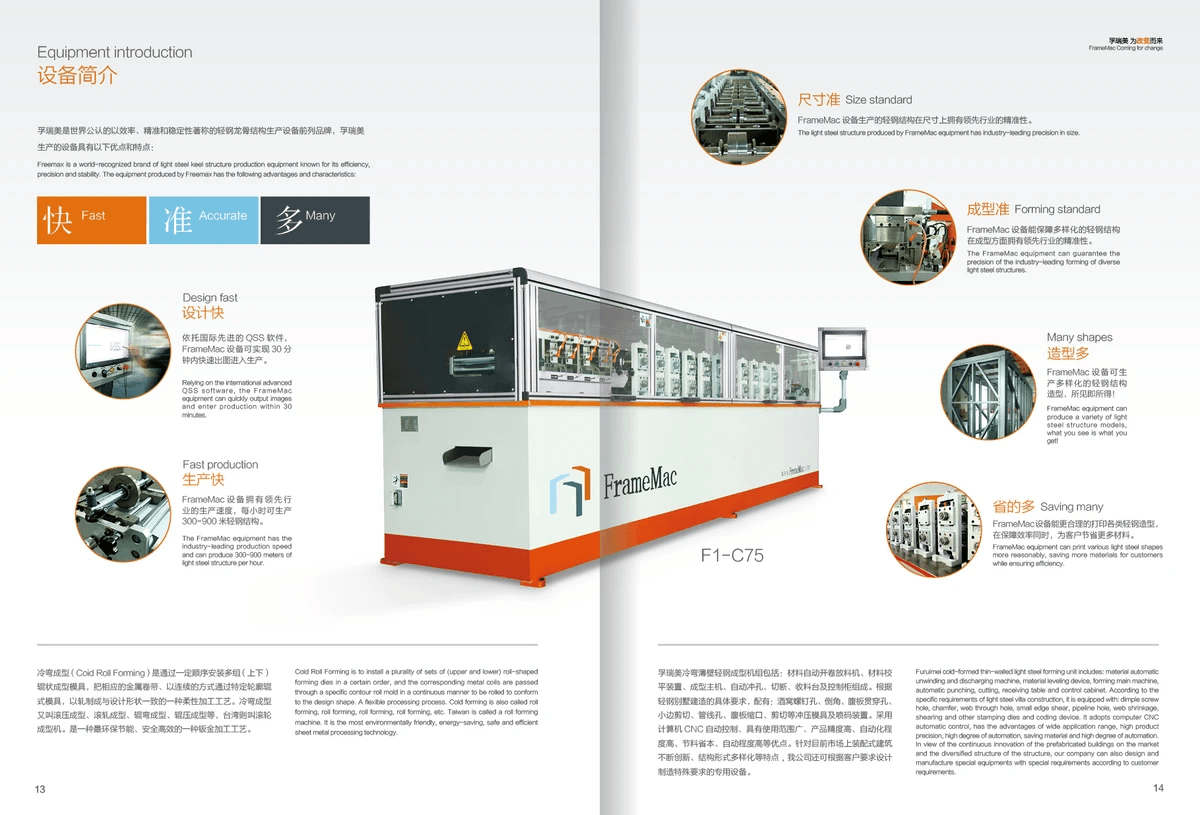

Modern Controls and Automation Features

The introduction of modern controls in rollforming machines has revolutionized the way manufacturers approach metal forming processes. These advanced systems allow operators to manage multiple parameters with ease, ensuring that every aspect of the form rolling machine functions optimally. Automation features not only reduce human error but also enhance production speed, making it possible to keep up with the demands of the equipment industry.

Moreover, automated rollforming machines can be programmed for various tasks, allowing for quick changes between different metal profiles. This flexibility is crucial for manufacturers who need to adapt to changing market needs without investing heavily in new machinery each time. As a result, companies can maximize their output while minimizing downtime—an essential factor for success in today’s competitive landscape.

The Impact of Advanced Sensors

Advanced sensors play a pivotal role in enhancing the functionality of rollforming machines and other manufacturing equipment. These sensors provide real-time feedback on various parameters such as temperature, pressure, and material thickness during operation. By continuously monitoring these factors, manufacturers can ensure that their metal forming machines operate within optimal ranges—reducing waste and improving product quality.

Additionally, these sensors contribute significantly to predictive maintenance strategies by identifying potential issues before they escalate into costly breakdowns or production halts. This proactive approach not only saves money but also extends the lifespan of manufacturing machines like form rolling machines or metal roofing machines. Ultimately, integrating advanced sensor technology leads to smoother operations and higher productivity levels across the board.

Importance of Software Integration

Software integration is another critical component that enhances the performance of roll machining processes within manufacturing environments. Seamless software solutions enable operators to control various aspects of their rollforming machine from a centralized interface—making it easier to adjust settings on-the-fly based on real-time data analysis. This level of control ensures that manufacturers can respond quickly to any fluctuations in material properties or production requirements.

Furthermore, robust software systems allow for better inventory management by tracking raw materials used during production runs while providing insights into operational efficiency metrics over time. With this data at hand, companies can refine their processes continually and adapt their strategies accordingly—ultimately driving down costs associated with inefficiencies inherent in traditional manufacturing methods. As a result, investing in comprehensive software solutions is vital for businesses aiming to stay competitive within the ever-evolving equipment industry.

Build Quality and Durability

When investing in a rollforming machine, the importance of build quality and durability cannot be overstated. High-quality manufacturing machines are essential for ensuring that your equipment can withstand the rigors of production while maintaining precision and efficiency. A robustly built metal forming machine not only enhances performance but also contributes to long-term cost savings by reducing downtime due to repairs or replacements.

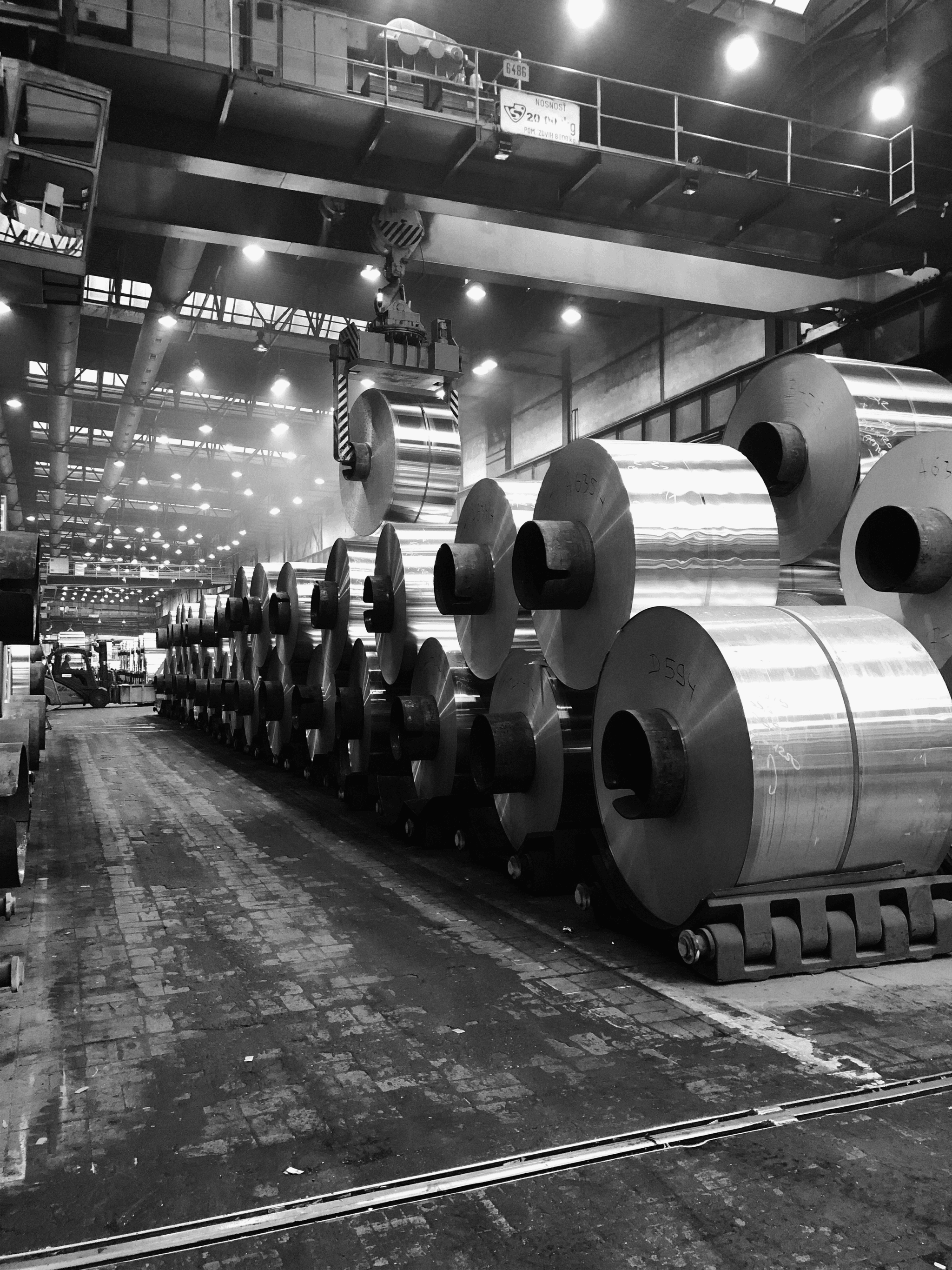

Materials Used in Metal Forming Machines

The materials used in constructing rollforming machines play a crucial role in their overall performance and longevity. Premium-grade steel and alloys are commonly employed to enhance strength and resistance to wear, which is vital for any form rolling machine operating under heavy loads. Additionally, incorporating high-quality components ensures that your metal roofing machine can handle various materials without compromising on quality or precision.

Manufacturer Reputation and Reliability

Choosing a manufacturer with a solid reputation in the equipment industry is key to securing a reliable rollforming machine. Established manufacturers often have proven track records of producing durable manufacturing equipment that meets industry standards, ensuring you get value for your investment. Furthermore, reputable brands typically offer better customer support and service options, which can be invaluable when it comes time for maintenance or troubleshooting.

Maintenance Considerations

Regular maintenance is essential for maximizing the lifespan of any metal forming machine, including rollforming machines. Implementing a proactive maintenance schedule helps identify potential issues before they escalate into costly repairs or downtime during production runs. It’s also worth considering manufacturers that provide comprehensive maintenance guidelines or support services, as this can make managing upkeep much easier while keeping your equipment running smoothly.

Customization and Adaptability

In the world of manufacturing machines, customization and adaptability are not just perks—they're necessities. The ability to tailor a rollforming machine to specific needs can significantly enhance production efficiency and product quality. Businesses that recognize this need often find themselves ahead in the competitive equipment industry.

Need for Custom Roll Profiles

Custom roll profiles are essential for manufacturers aiming to produce specialized products that meet unique market demands. Standardized profiles may suffice for some applications, but many industries require bespoke designs that enhance functionality or aesthetic appeal—think metal roofing machines with intricate shapes or components for architectural projects. By investing in a rollforming machine capable of creating custom profiles, companies can expand their offerings and cater to niche markets, ultimately driving growth.

Adjustability to Various Material Thicknesses

Another critical feature of modern form rolling machines is their ability to adjust to various material thicknesses without sacrificing precision or performance. This adaptability allows manufacturers to work with different metals and materials while optimizing their production processes. A versatile metal forming machine can save time and resources by accommodating varying specifications, making it an ideal choice for businesses looking to streamline operations in a dynamic manufacturing environment.

Role of Kiant Machinery in Custom Solutions

Kiant Machinery has established itself as a leader in providing customized solutions tailored specifically for the demands of the manufacturing equipment sector. Their expertise in designing rollforming machines ensures that each piece of equipment is adaptable to clients' unique requirements, whether it's creating custom roll profiles or adjusting for different material thicknesses. With Kiant Machinery's commitment to innovation and quality, manufacturers can trust they are investing in reliable machinery designed for today's ever-evolving market landscape.

Efficiency and Productivity Boosters

In the competitive landscape of manufacturing, efficiency and productivity are paramount. Rollforming machines have evolved to meet these demands, integrating advanced features that enhance energy consumption and operational output. Understanding how these machines can optimize production processes is crucial for any manufacturer looking to stay ahead in the equipment industry.

Energy Consumption and Cost Efficiency

Energy consumption is a significant factor in the overall cost of operating manufacturing machines, including rollforming machines. Modern metal forming machines are designed with energy-efficient technologies that not only reduce electricity usage but also lower operational costs. By investing in a high-quality roll machining system, manufacturers can achieve substantial savings while minimizing their environmental footprint.

Cost efficiency doesn't just stop at energy savings; it extends to maintenance and operational longevity as well. A well-designed form rolling machine will require less frequent repairs and downtime, translating into increased productivity over time. Manufacturers should carefully evaluate the energy profiles of different models to ensure they select a rollforming machine that aligns with their cost-efficiency goals.

Cycle Time Efficiency for Maximum Output

Cycle time efficiency is another critical aspect when assessing manufacturing equipment performance, especially in fast-paced industries like metal roofing production. The quicker a rollforming machine can complete its tasks without sacrificing quality, the more products it can generate within a given timeframe. This efficiency directly correlates with profitability, making it essential for manufacturers to choose equipment that excels in this area.

Advanced automation features contribute significantly to cycle time improvements by streamlining operations and reducing manual intervention. With sophisticated controls integrated into modern metal forming machines, manufacturers can achieve rapid setup times and swift adjustments between different production runs. Investing in such technology ensures maximum output while maintaining high standards of precision.

Comparing Production Speeds of Equipment Industry Leaders

When comparing production speeds among various rollforming machines on the market, it's essential to consider both the capabilities of individual models and their overall reliability within real-world applications. Industry leaders often showcase impressive speeds that set benchmarks for others; however, these numbers must be viewed through the lens of quality control as well. Fast doesn't always mean better if it compromises product integrity or leads to higher defect rates.

Leading manufacturers often employ cutting-edge technology that allows their form rolling machines to operate at peak performance levels consistently while ensuring minimal waste during production cycles. By analyzing metrics such as throughput rates alongside customer feedback on durability and serviceability, businesses can make informed decisions about which metal forming machine best suits their needs. Ultimately, choosing equipment with proven speed advantages will help manufacturers maintain competitiveness within the ever-evolving equipment industry.

Conclusion

In the world of manufacturing, selecting the right rollforming machine is crucial for achieving efficiency and precision. With a myriad of options available, understanding the core features and benefits can significantly impact your production capabilities. By prioritizing factors such as technology, build quality, and customization, manufacturers can ensure they invest in equipment that meets their specific needs.

Key Takeaways for Selecting Rollforming Machines

When choosing a rollforming machine, consider its versatility in applications and precision in metal forming to optimize your production line. The importance of advanced controls and automation features cannot be overstated; they are pivotal in enhancing operational efficiency and reducing downtime. Lastly, always evaluate the manufacturer’s reputation—investing in reliable manufacturing machines ensures long-term performance and support.

Future Trends in Roll Machining Technology

The future of roll machining technology is leaning towards greater automation and integration of smart technologies. As manufacturers adopt IoT-enabled devices, we can expect enhanced monitoring capabilities that lead to improved predictive maintenance strategies for metal forming machines. Additionally, advancements in materials science will continue to evolve rollforming machines' design, allowing for even more complex profiles with higher durability.

How Kiant Machinery Stands Out in the Market

Kiant Machinery distinguishes itself through its commitment to innovation and customer-centric solutions within the equipment industry. Their customizable rollforming machines offer unique adaptability to various material thicknesses while ensuring high precision across diverse applications like metal roofing machinery. With a strong focus on quality materials and robust build quality, Kiant Machinery remains a trusted name among manufacturers seeking reliable metal forming machines.