Introduction

Light gauge steel framing has emerged as a revolutionary method in modern construction, offering a myriad of benefits that traditional materials simply can't match. This innovative approach utilizes cold formed steel, which not only enhances the structural integrity of buildings but also streamlines the construction process. With its lightweight nature and high strength-to-weight ratio, light gauge metal framing is quickly becoming the preferred choice for many builders and architects.

Benefits of Light Gauge Steel Framing

The advantages of light gauge steel framing are numerous and compelling. Firstly, it provides exceptional durability and resistance to environmental factors such as pests, fire, and moisture—issues that often plague wood framing systems. Additionally, cold formed steel allows for quicker assembly times on-site, which can significantly reduce labor costs and project timelines while maintaining a high-quality finish in steel frame construction.

Top Manufacturers in the Industry

As demand for light gauge steel frame construction rises, several manufacturers have established themselves as leaders in the industry. Companies like Kiant Machinery, FRAMECAD, and HEBEI NO.1 are at the forefront of producing advanced machinery designed specifically for efficient cold formed steel framing solutions. Their innovations not only enhance productivity but also ensure that builders have access to reliable equipment tailored to their specific needs.

Choosing the Right Machine

Selecting the right machine for your light gauge metal framing projects is crucial to achieving optimal results. Factors such as production capacity, automation features, and customization options should be carefully evaluated to align with your specific project requirements. By understanding your production needs and exploring various manufacturers' offerings, you can make an informed decision that will benefit your business in both efficiency and quality.

Overview of Light Gauge Steel Framing

Light gauge steel framing has emerged as a popular alternative to traditional wood framing in construction projects. This modern approach utilizes cold formed steel, which is lightweight yet incredibly strong, making it ideal for various applications. As the construction industry evolves, understanding the nuances of light gauge metal framing becomes essential for builders and developers alike.

What is Light Gauge Steel Framing?

Light gauge steel framing refers to a construction method that employs thin sheets of cold formed steel to create structural components such as walls, floors, and roofs. Unlike traditional wood framing, this technique offers enhanced durability and resistance to pests and rot. The use of light gauge steel frame construction allows for precise manufacturing and quicker assembly on-site, leading to efficient project timelines.

Advantages of Cold Formed Steel

First off, its strength-to-weight ratio is impressive; it provides robust support without adding unnecessary bulk or weight to structures. Additionally, cold formed steel is inherently fire-resistant and non-combustible, making it a safer option for building projects compared to traditional materials like wood.

Moreover, light gauge metal framing is highly resistant to environmental factors such as moisture and termites, significantly reducing maintenance costs over time. Builders can also benefit from its sustainability features; cold formed steel is recyclable and can be sourced from recycled materials. In an era where eco-friendliness is paramount in construction practices, these advantages make cold formed steel an appealing choice.

Applications in Modern Construction

The versatility of light gauge steel framing has led to its widespread application across various sectors in modern construction. From residential homes to commercial buildings and even industrial facilities, this innovative method adapts well to diverse architectural designs while maintaining structural integrity. Furthermore, the speed at which light gauge metal framing can be erected allows developers to meet tight deadlines without compromising quality.

In addition to new constructions, light gauge steel systems are increasingly used in renovations and retrofitting projects due to their lightweight nature and ease of installation. This adaptability makes them suitable for both small-scale residential renovations and large-scale commercial developments alike. As the demand for efficient building solutions continues rising globally, the role of cold formed steel framing will only become more prominent in shaping our urban landscapes.

Leading Light Gauge Steel Framing Machine Manufacturers

In the world of light gauge steel framing, choosing the right manufacturer can significantly influence the quality and efficiency of your projects. With an array of options available, it's essential to spotlight some of the leading players in this industry. These manufacturers not only provide advanced steel framing systems but also innovate continuously to meet modern construction demands.

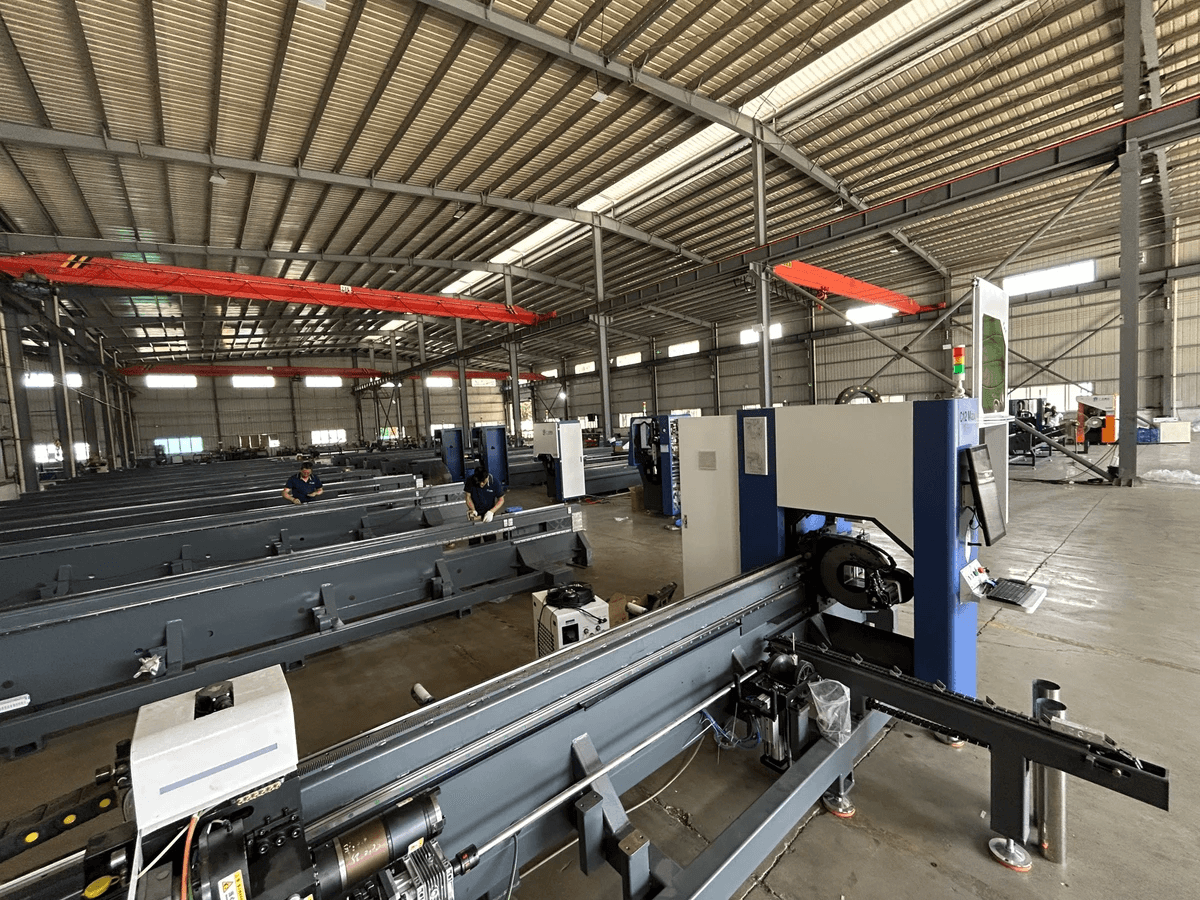

Kiant Machinery: Innovating Steel Frame Construction

Kiant Machinery has established itself as a frontrunner in light gauge metal framing technology. Their commitment to innovation is evident in their state-of-the-art machines designed for cold formed steel framing, which enhance production speed and reduce labor costs. With a focus on efficiency and adaptability, Kiant's equipment allows builders to tackle a variety of projects, from residential homes to commercial buildings.

The company’s machines are engineered for precision, ensuring that every piece of framing steel building meets stringent quality standards. Kiant Machinery also emphasizes user-friendly interfaces and automation features that streamline the manufacturing process, making it easier than ever for teams to produce high-quality steel frames quickly. As they continue to push boundaries in light gauge steel frame construction technology, Kiant remains a go-to choice for those serious about their projects.

FRAMECAD: Pioneers in Steel Framing Systems

FRAMECAD has been at the forefront of developing comprehensive solutions for light gauge steel framing since its inception. Known for their pioneering spirit, FRAMECAD offers integrated systems that encompass design software and manufacturing machinery tailored specifically for cold formed steel applications. This holistic approach allows builders to efficiently manage their projects from conception through completion.

Their machines are renowned not just for speed but also for precision engineering that minimizes waste—a crucial factor when working with materials like cold formed steel. FRAMECAD's dedication to training and support ensures that clients can fully leverage their advanced technologies, making them an invaluable partner in any construction endeavor involving light gauge metal framing. By continually innovating within the industry, FRAMECAD solidifies its position as a leader in modern building techniques.

HEBEI NO.1: Experts in Metal Framing Solutions

HEBEI NO.1 stands out as an expert manufacturer specializing in metal framing solutions tailored for various construction needs across the globe. Their extensive range of machines caters specifically to those looking to implement efficient light gauge steel frame construction processes without compromising on quality or performance. HEBEI NO.1 focuses on delivering robust machinery capable of handling large-scale production while maintaining precision throughout each manufacturing cycle.

The company prides itself on understanding the nuances of cold formed steel applications and provides customized solutions that fit specific project requirements perfectly—an essential aspect when considering different types of building structures or designs involving light gauge metal framing systems. With strong customer support and ongoing maintenance options, HEBEI NO.1 ensures clients remain satisfied long after installation is complete—making them a trusted choice among professionals seeking reliable partners in their endeavors.

Key Features of Steel Framing Machines

Efficiency in Manufacturing Processes

Efficiency is the name of the game in any production environment, especially when dealing with cold formed steel framing. Steel framing machines are designed to streamline processes, reducing waste and maximizing output. With rapid setup times and high-speed operation, these machines ensure that your light gauge steel frame construction projects stay on schedule without compromising quality.

Moreover, modern steel framing systems are built with precision engineering that minimizes errors during production. This means fewer costly mistakes and reworks, which can be a significant drain on resources. Ultimately, an efficient manufacturing process using advanced machinery translates to quicker project turnaround times and greater profitability for businesses involved in framing steel buildings.

Automation and Technology Integration

In today’s fast-paced construction environment, automation is essential for keeping up with demand while maintaining quality standards in light gauge steel framing. Many leading manufacturers incorporate cutting-edge technology into their machines, allowing for automated processes that enhance both speed and accuracy. From automatic cutting to real-time monitoring systems, technology integration ensures that every piece of cold formed steel is produced to exact specifications.

Additionally, automation reduces labor costs by minimizing manual intervention during production cycles. This not only leads to increased efficiency but also allows skilled workers to focus on more complex tasks that require human oversight. By embracing automation within your steel framing system, you position your business at the forefront of innovation in light gauge metal framing.

Customization Options for Project Needs

One size does not fit all when it comes to light gauge steel frame construction; different projects have unique requirements that necessitate tailored solutions. Fortunately, many modern steel framing machines offer extensive customization options to meet specific project needs effectively. Whether it’s adjusting dimensions or configuring profiles for various applications, flexibility is key in today’s competitive market.

Customizable features also allow businesses to adapt quickly as project scopes change or evolve over time—an invaluable asset when working on diverse types of projects like residential homes or commercial buildings using cold formed steel frameworks. Furthermore, having the ability to customize your equipment enhances overall productivity by ensuring that every machine works optimally for its intended purpose within your operations.

Comparison of Steel Framing Systems

When it comes to construction methods, the choice between light gauge steel framing and traditional framing techniques can significantly impact project outcomes. Light gauge metal framing offers a modern approach that leverages cold formed steel, which is not only lighter but also provides enhanced durability compared to conventional wood or concrete options. This section will delve into the differences between these two systems, highlighting their unique advantages and considerations.

Light Gauge vs. Traditional Framing Methods

Light gauge steel framing stands out against traditional methods primarily in terms of strength-to-weight ratio and resistance to environmental factors. Unlike wood, which can warp or rot over time, cold formed steel maintains its integrity even in challenging conditions such as moisture or pests. Additionally, the precision of light gauge steel frame construction allows for quicker assembly on-site, reducing labor costs and overall project timelines while ensuring a robust structural framework.

Traditional framing methods often rely on lumber, which can be subject to supply chain issues and fluctuating prices due to environmental factors like deforestation and climate change. In contrast, a steel framing system using light gauge materials provides a consistent supply and predictable pricing structure over time. Consequently, builders are increasingly turning towards light gauge metal framing as a reliable alternative that meets both performance standards and sustainability goals.

Cost-Effectiveness of Light Gauge Metal Framing

The cost-effectiveness of light gauge metal framing becomes apparent when evaluating long-term savings associated with maintenance and durability. While the initial investment in cold formed steel may be higher than traditional wood frames, the reduced need for repairs due to rusting or warping translates into significant savings over time. Moreover, projects utilizing light gauge steel framing often benefit from faster construction timelines, allowing for quicker returns on investment.

Another aspect contributing to the cost-effectiveness is energy efficiency; buildings framed with cold formed steel can better accommodate insulation solutions that enhance thermal performance. This leads to lower heating and cooling costs throughout the building's lifespan—a critical factor for budget-conscious developers and owners alike. Ultimately, while upfront costs are an important consideration in any project involving a steel framing system, the long-term financial benefits make light gauge metal framing an attractive option.

Sustainability Benefits of Steel Framing

Sustainability is increasingly becoming a priority in modern construction practices; here’s where light gauge steel frame construction shines brightly! Cold formed steel is 100% recyclable without loss of quality—this means that at the end of its lifecycle as part of your building’s structure, it can be repurposed rather than ending up in landfills like many traditional materials might do. Furthermore, using recycled materials reduces demand for new resources while minimizing carbon emissions associated with production processes.

In addition to recyclability, buildings constructed with light gauge metal framing are often designed with energy efficiency in mind—allowing for better insulation properties that reduce energy consumption during operation phases. This sustainable approach not only benefits the environment but also enhances occupant comfort through improved indoor climates year-round without excessive reliance on HVAC systems. As awareness grows around eco-friendly practices within the industry, opting for cold formed steel becomes not just an architectural choice but also an ethical one.

How to Select the Right Steel Framing Machine

Selecting the right steel framing machine is crucial for businesses looking to excel in light gauge steel framing. The decision involves a blend of understanding your production needs, evaluating support from manufacturers, and considering long-term maintenance. A well-informed choice can enhance efficiency and quality in your light gauge metal framing projects.

Assessing Your Production Needs

Before diving into the world of steel framing machines, it’s essential to assess your production needs thoroughly. Consider factors such as the scale of your operations, types of projects you typically handle, and the volume of cold formed steel components you intend to produce. Understanding these elements will help you choose a machine that aligns with your specific requirements in light gauge steel frame construction.

Additionally, analyze the speed and efficiency that different machines offer for producing framing steel building components. If you're frequently working on large-scale projects requiring quick turnaround times, investing in a high-capacity machine may be beneficial. Ultimately, aligning your equipment choice with your production goals will lead to improved productivity and profitability in the long run.

Evaluating Manufacturer Support and Training

Once you've pinpointed potential machines for light gauge metal framing, evaluate the level of manufacturer support available. Quality training programs are vital for ensuring that your team can operate new machinery effectively while maximizing its capabilities within cold formed steel applications. Look for manufacturers who offer comprehensive training sessions tailored to their specific machines.

Moreover, consider ongoing support options such as technical assistance or troubleshooting services that may be offered after purchase. This level of support not only enhances operational efficiency but also fosters a strong partnership between you and the manufacturer.

Considering Long-Term Maintenance and Upgrades

When selecting a machine for light gauge steel framing, don’t overlook long-term maintenance requirements and upgrade options available from manufacturers. Machines require regular upkeep to ensure optimal performance over time; therefore, understanding maintenance schedules is crucial before making an investment in cold formed steel machinery. Look for models designed with ease-of-maintenance features that allow quick access to parts needing service or replacement.

Additionally, consider whether the manufacturer provides upgrade paths as technology evolves within the industry—this can be particularly beneficial if you anticipate expanding your capabilities in light gauge metal framing down the line. Investing in a versatile system that accommodates future enhancements ensures you won’t have to replace expensive equipment prematurely due to obsolescence or changing project demands related to framing steel building applications.

By carefully assessing these factors—production needs, manufacturer support, and maintenance considerations—you’ll be well-equipped to select a suitable machine that meets both current demands and future growth opportunities in light gauge steel frame construction.

Conclusion

In the dynamic world of construction, the importance of quality in steel frame construction cannot be overstated. Light gauge steel framing offers a robust and reliable solution that meets modern building standards while ensuring longevity and resilience. As the demand for efficient and sustainable building practices grows, investing in high-quality materials and systems becomes essential for any successful project.

Importance of Quality in Steel Frame Construction

Quality in light gauge steel frame construction directly impacts the durability and safety of a structure. When using cold formed steel, it’s crucial to select materials that adhere to rigorous industry standards; this ensures that your framing system can withstand various environmental stresses over time. Moreover, a well-constructed framing steel building not only enhances structural integrity but also reduces maintenance costs in the long run.

Future Trends in Light Gauge Steel Framing

The future of light gauge metal framing looks promising with advancements in technology and design capabilities. Innovations such as automated production processes are streamlining manufacturing, making it easier to customize cold formed steel framing solutions for diverse applications. Additionally, sustainability is becoming a focal point; many manufacturers are now prioritizing eco-friendly practices that align with global green building initiatives.

Final Thoughts on Choosing the Right Manufacturer

Choosing the right manufacturer for your light gauge steel framing needs can make or break your project’s success. It’s essential to evaluate not just their product offerings but also their customer support and training programs—these factors play a vital role in ensuring smooth operations post-purchase. Ultimately, partnering with a reputable manufacturer means you’re investing in quality solutions that will stand the test of time.