Introduction

In the ever-evolving world of construction, the introduction of light gauge steel roll forming machines has transformed how we approach metal framing. These machines produce steel framework that is not only lightweight but also incredibly strong, making them a popular choice for modern building projects. As we delve into this topic, it’s essential to understand the significance of light gauge steel framing and how it enhances the efficiency and durability of construction.

Understanding Light Gauge Steel Roll Forming

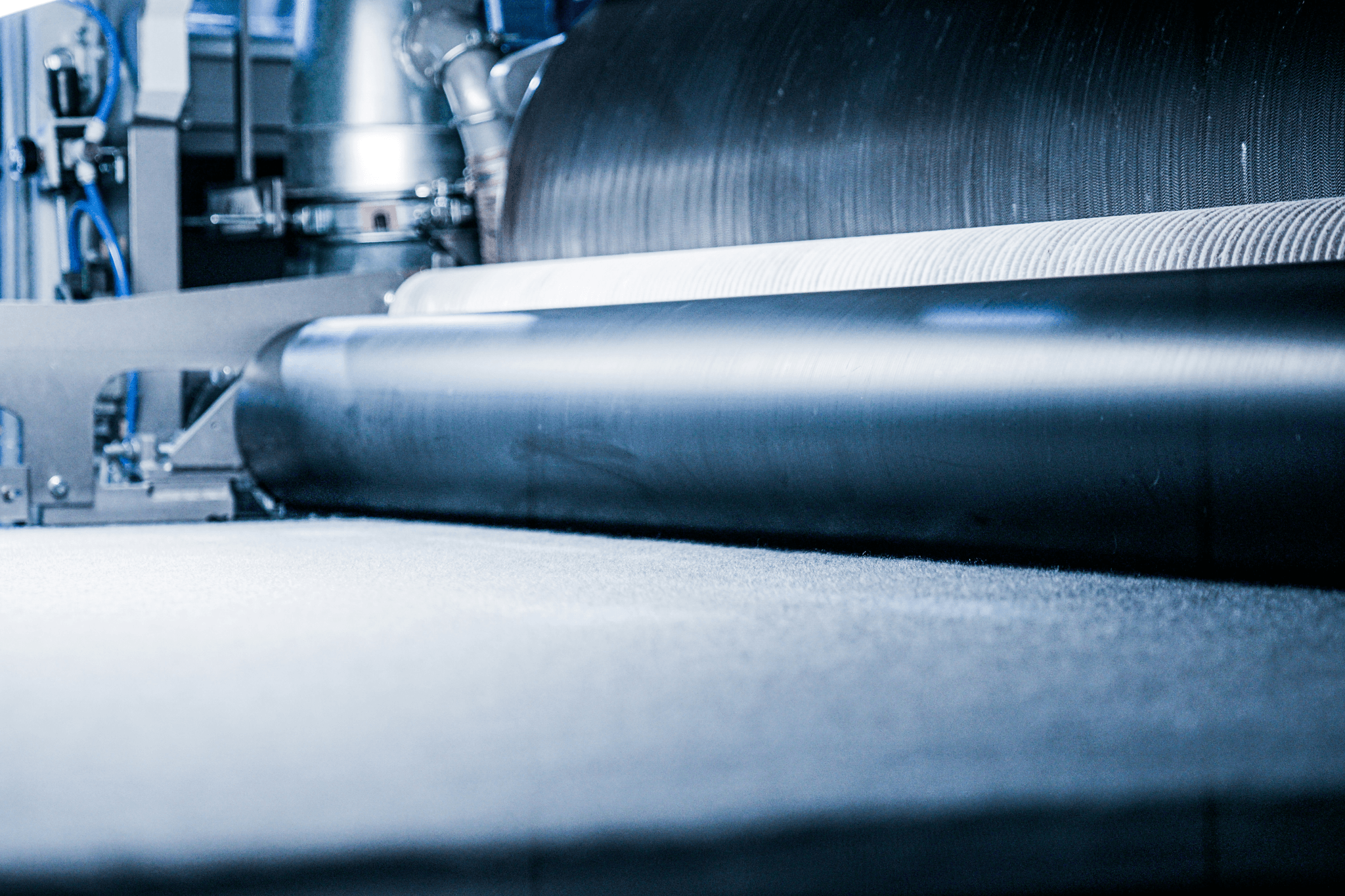

Light gauge steel roll forming refers to a process where thin sheets of steel are shaped into various structural components using specialized machinery. The light gauge steel roll forming machine plays a crucial role in this process, allowing for precise and efficient production of metal framing elements. This technology enables builders to create custom shapes and sizes tailored to specific project requirements, ensuring versatility in design while maintaining structural integrity.

Importance of Steel Framing in Construction

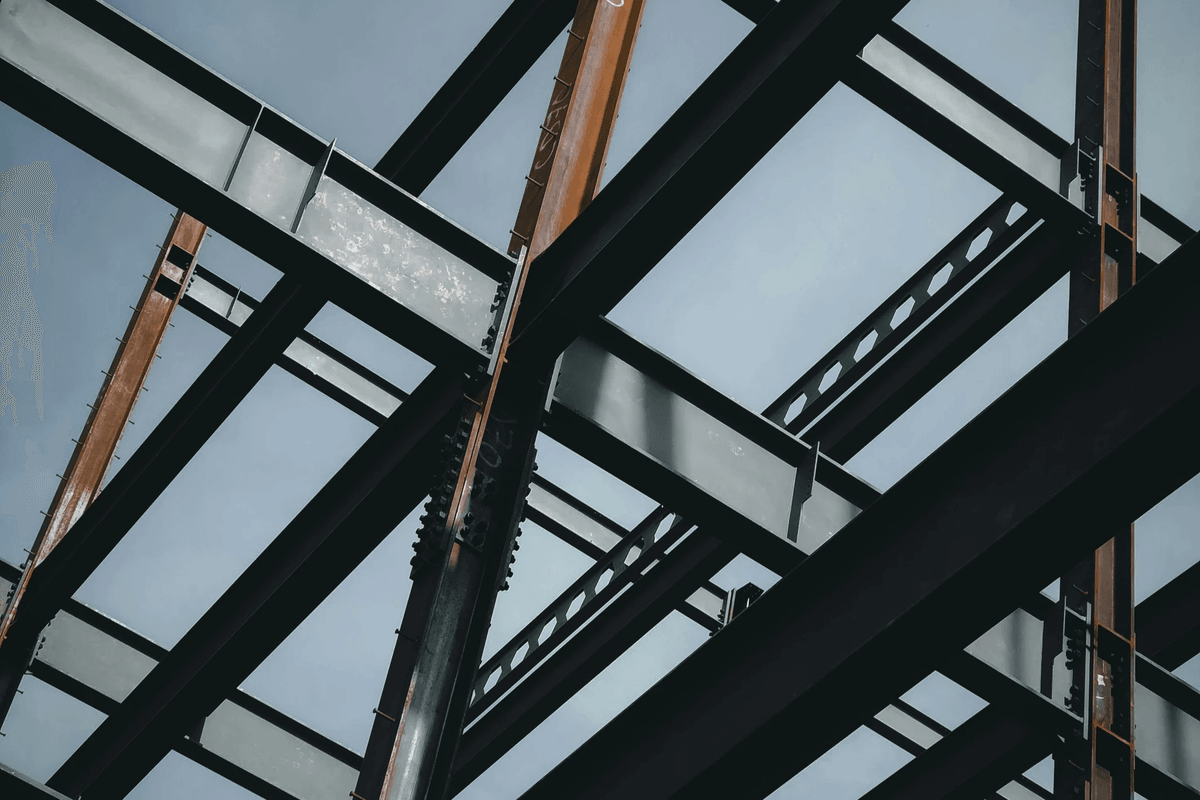

Steel framing has become a cornerstone in modern construction due to its strength, durability, and resistance to environmental factors such as fire and pests. The use of light gauge metal framing significantly reduces the overall weight of structures without compromising their stability or safety. Additionally, steel framework allows for quicker assembly times on-site, which can lead to substantial cost savings and faster project completion.

Benefits of Light Gauge Steel Technology

The adoption of light gauge steel technology offers numerous advantages over traditional building materials like wood or concrete. First and foremost, it provides exceptional strength-to-weight ratios, making it an ideal choice for both residential and commercial applications. Furthermore, light gauge steel is recyclable and environmentally friendly, aligning with sustainable building practices that are increasingly important in today’s construction industry.

Key Components of a Light Gauge Steel Roll Forming Machine

When delving into the world of light gauge steel roll forming machines, it’s essential to understand the key components that make these machines efficient and effective for metal framing applications. These machines are designed to produce high-quality steel framework with precision and speed, making them indispensable in modern construction. From roll design to control systems, each component plays a vital role in ensuring that light gauge metal framing meets industry standards.

Roll Design and Configuration

The roll design and configuration are crucial elements of any light gauge steel roll forming machine. The rolls shape the steel into desired profiles, allowing for versatile applications in steel framing projects. A well-designed roll configuration not only enhances production efficiency but also ensures that the resulting light gauge steel framework maintains structural integrity and precision.

Different configurations can be tailored based on specific project requirements, accommodating various thicknesses and widths of light gauge steel. This adaptability is key for contractors looking to implement customized solutions in their building processes. Ultimately, an optimal roll design contributes significantly to the overall quality of the finished product.

Material Handling Systems

Material handling systems are another vital component of a light gauge steel roll forming machine, streamlining operations from raw material input to finished product output. Efficient handling systems minimize downtime by ensuring that materials are properly fed into the machine without interruption. This is particularly important in large-scale projects where time is money; seamless material flow translates directly into increased productivity.

Moreover, advanced material handling systems can incorporate automated features that enhance safety and reduce manual labor requirements associated with moving heavy steel sheets. By investing in robust handling solutions, manufacturers can ensure consistent quality throughout the production process while maintaining a safe working environment for operators involved in metal framing tasks. In essence, effective material handling is foundational to achieving optimal results with light gauge steel.

Control Systems and Software

Control systems and software are at the heart of modern light gauge steel roll forming machines, enabling precise management of production parameters and processes. Advanced software allows operators to monitor real-time data on machine performance while adjusting settings as needed to maintain quality standards during production runs of light gauge metal framing components. This level of control not only enhances efficiency but also reduces waste—an essential factor when working with valuable materials like light gauge steel.

Additionally, smart technology integration within control systems can facilitate predictive maintenance by analyzing performance trends over time, thus preventing costly downtimes due to unforeseen breakdowns or malfunctions in your steel framework machinery. With user-friendly interfaces becoming commonplace, even those new to operating these sophisticated machines can quickly learn how to maximize their potential for producing high-quality products efficiently. Ultimately, robust control systems empower manufacturers by providing them with tools necessary for success in today’s competitive construction landscape.

The Role of Automation in Steel Framing

In the world of construction, automation is transforming how steel framing is done, particularly with light gauge steel roll forming machines. These machines streamline the production process, ensuring that metal framing components are manufactured with precision and speed. The integration of automated systems not only enhances productivity but also elevates the overall quality of steel framework.

Enhanced Efficiency with Automated Processes

Automated processes in light gauge steel framing significantly boost efficiency by minimizing human error and reducing production time. With a light gauge steel roll forming machine, manufacturers can produce uniform components rapidly, allowing for quicker assembly on-site. This efficiency means projects can be completed faster, leading to cost savings and improved project timelines.

Moreover, automated systems enable continuous operation without the fatigue that manual labor may introduce. This means that while traditional methods might slow down during peak hours or shift changes, automated machinery maintains a steady output rate. As a result, builders can rely on consistent delivery schedules and enhanced workflow across construction sites.

Integration of Smart Technology

The integration of smart technology into light gauge steel framing has revolutionized how manufacturers approach production. With advanced software controlling the light gauge steel roll forming machine, operators can monitor performance in real-time and make adjustments on-the-fly to maintain optimal conditions. This level of control ensures that every piece produced meets stringent quality standards.

Additionally, smart technology allows for predictive maintenance of equipment used in metal framing. By analyzing data from the machinery, companies can anticipate potential failures before they occur and schedule maintenance accordingly—saving both time and money while ensuring uninterrupted production flow. This proactive approach not only enhances the lifespan of equipment but also guarantees consistent output quality throughout the manufacturing process.

Reducing Labor Costs through Automation

One of the most significant advantages of automating processes within light gauge metal framing is the reduction in labor costs associated with traditional construction methods. With fewer workers needed to operate machinery like a light gauge steel roll forming machine, companies can allocate resources more efficiently across projects while still maintaining high standards for their steel frameworks.

Moreover, automation reduces reliance on skilled labor for repetitive tasks; instead, it allows workers to focus on more complex aspects of construction that require human expertise and creativity. This shift not only leads to cost savings but also fosters a safer work environment by minimizing manual handling risks associated with heavy materials like light gauge steel frames.

Ultimately, embracing automation in metal framing paves the way for innovative building practices that prioritize efficiency without sacrificing quality or safety standards.

Customization Options for Light Gauge Steel Solutions

In the world of construction, flexibility is key, especially when it comes to light gauge steel solutions. The ability to adapt machinery for specific projects can significantly enhance efficiency and output quality. A light gauge steel roll forming machine designed with customization in mind allows builders to create tailored components that meet unique project specifications, ensuring that every piece fits perfectly into the overall steel framework.

Adapting Machines for Specific Projects

One of the standout features of modern light gauge steel roll forming machines is their adaptability. These machines can be adjusted to produce various profiles and sizes, making them ideal for diverse applications in metal framing and light gauge steel framing. Whether it's a residential build or a large commercial structure, adapting the machinery ensures that each project receives precisely what it needs without unnecessary delays or waste.

By customizing the roll design and configuration, manufacturers can streamline production processes while maintaining high standards of quality in their steel framework. This adaptability not only boosts productivity but also allows construction teams to respond swiftly to changing project requirements or unexpected challenges. Ultimately, having a versatile light gauge metal framing machine at your disposal can be a game changer in completing projects on time and within budget.

Flexible Design Features

Flexibility doesn't just stop at machine adaptation; it extends into design features as well. Light gauge steel technology offers an array of customizable options that cater to various architectural styles and structural demands. Builders can select different gauges, profiles, and finishes tailored specifically for their projects, ensuring that every element aligns with both aesthetic preferences and functional needs.

Moreover, these flexible design features enable architects and engineers to innovate freely without being constrained by traditional materials or methods. With advanced software integrated into control systems, designers can visualize their concepts in real-time before any physical work begins—saving time and reducing errors during production phases of light gauge metal framing. This synergy between technology and creativity fosters an environment where exceptional designs become achievable realities.

Meeting Diverse Industry Requirements

The construction industry is as varied as it is dynamic; hence meeting diverse industry requirements is crucial for success in steel framing applications. Different sectors—ranging from residential housing to commercial buildings—demand specific solutions tailored to their unique needs regarding load-bearing capabilities, insulation properties, or fire resistance standards associated with light gauge steel structures.

Manufacturers are increasingly recognizing this need for versatility by offering customizable options that address these varying demands head-on. For instance, some may focus on producing lightweight frames suitable for quick assembly in residential projects while others might develop robust systems designed for industrial applications requiring enhanced durability under extreme conditions. By prioritizing customization in their offerings, companies ensure they remain competitive while providing clients with the best possible solutions tailored specifically for their industry challenges.

Quality Control in Steel Framework Production

Quality control in steel framework production is the backbone of ensuring that light gauge steel framing meets industry standards and customer expectations. Precision engineering plays a pivotal role in this process, as even minor discrepancies can lead to significant structural issues. By maintaining high-quality standards, manufacturers can enhance the durability and reliability of their steel light frame systems.

Importance of Precision Engineering

Precision engineering is essential when working with light gauge steel roll forming machines, as it guarantees that each component is manufactured to exact specifications. This level of accuracy is crucial for metal framing, where even slight variations can compromise the integrity of the entire structure. By investing in precision engineering techniques, manufacturers can produce steel frameworks that not only meet but exceed safety regulations.

Measuring and Testing Techniques

Effective measuring and testing techniques are vital for quality control in the production of light gauge metal framing. Utilizing advanced tools such as laser measurement systems and digital calipers ensures that every piece produced by the light gauge steel roll forming machine adheres to strict dimensional tolerances. Regular inspections and testing protocols help identify any deviations early on, allowing for timely adjustments before components are assembled into larger structures.

Ensuring Consistency in Light Gauge Steel

Ensuring consistency in light gauge steel production is critical for maintaining quality across all projects involving steel framing. This consistency is achieved through standardized processes and automated controls within modern manufacturing facilities equipped with sophisticated machinery like the light gauge steel roll forming machine. By adhering to these practices, manufacturers can guarantee that their products—whether they are used in residential buildings or commercial applications—offer reliable performance over time.

Choosing the Right Manufacturer for Your Needs

Selecting the right manufacturer for your light gauge steel roll forming machine is crucial for ensuring quality and efficiency in your metal framing projects. With a myriad of suppliers available, it's important to consider various factors that can impact the performance of your steel framework. From reliability to support services, making an informed decision will set the foundation for successful light gauge metal framing operations.

Key Considerations When Selecting a Supplier

When evaluating potential suppliers of light gauge steel roll forming machines, you should prioritize their experience in the industry and their reputation among clients. Look for manufacturers who specialize in steel framing solutions and have a proven track record of delivering high-quality products tailored to specific needs. Additionally, consider their ability to provide customization options, which can be essential for meeting diverse project requirements in light gauge steel construction.

Another important factor is the availability of advanced technology and automation features in their machines. Suppliers that invest in modern control systems can enhance efficiency and reduce labor costs associated with steel framework assembly. Lastly, don't overlook customer service; responsive support during installation and maintenance can make all the difference when navigating challenges with your light gauge metal framing equipment.

Kiant Machinery's Commitment to Quality

Kiant Machinery stands out as a reliable partner in the realm of light gauge steel roll forming machines, emphasizing quality at every stage of production. Their commitment to precision engineering ensures that each machine meets rigorous standards, resulting in durable and efficient solutions for metal framing projects. With extensive industry experience, Kiant Machinery has earned a reputation for excellence among contractors seeking dependable steel framing equipment.

Moreover, Kiant Machinery prioritizes innovation by incorporating cutting-edge technology into their designs. This integration not only enhances operational efficiency but also aligns with modern trends towards automation in construction processes involving light gauge steel frameworks. Their dedication to continuous improvement means clients receive state-of-the-art machinery that keeps pace with evolving market demands.

Long-term Support and Maintenance Services

A key aspect often overlooked when choosing a manufacturer is the availability of long-term support and maintenance services post-purchase. Kiant Machinery recognizes that investing in a light gauge steel roll forming machine is just the beginning; ongoing assistance is essential for maximizing productivity throughout its lifespan. Their comprehensive maintenance programs ensure that clients receive timely service while minimizing downtime on critical projects involving metal framing.

Furthermore, Kiant's team provides training sessions on operating their machines effectively, empowering users with knowledge about best practices in handling light gauge steel equipment safely and efficiently. This proactive approach not only enhances operational capabilities but also fosters strong relationships between manufacturers and clients within the competitive world of steel framework construction.

In conclusion, selecting the right manufacturer involves careful consideration of quality assurance measures, technological advancements, and long-term support offerings—all critical elements contributing to successful projects utilizing light gauge metal framing solutions.

Conclusion

The construction industry is undergoing a significant transformation, largely driven by the adoption of light gauge steel framing. This innovative approach to metal framing not only enhances structural integrity but also streamlines the building process, making it faster and more efficient. As builders embrace steel frameworks, they are discovering the myriad benefits that light gauge steel can offer in terms of durability and design flexibility.

Revolutionizing Construction with Steel Framing

Light gauge steel framing is redefining how structures are built, offering a sustainable alternative to traditional materials like wood. With its lightweight properties and exceptional strength, this method allows for quicker assembly while reducing waste on job sites. The versatility of light gauge metal framing means it can be adapted for various applications, from residential homes to large commercial buildings.

The Future of Light Gauge Steel Technology

The future looks bright for light gauge steel technology as advancements continue to emerge in roll forming machines and automation processes. Innovations in smart technology integration are paving the way for more precise manufacturing and enhanced efficiency in production lines. As industries increasingly recognize the value of steel light frames, we can expect a surge in demand for these solutions, further solidifying their place in modern construction.

Maximizing Efficiency with the Right Equipment

To fully harness the advantages of light gauge steel roll forming machines, choosing the right equipment is crucial for any project’s success. Investing in high-quality machinery tailored to specific needs can significantly boost productivity while ensuring consistent results across different builds. Ultimately, maximizing efficiency through state-of-the-art equipment will empower contractors to meet diverse industry requirements while maintaining top-notch standards.