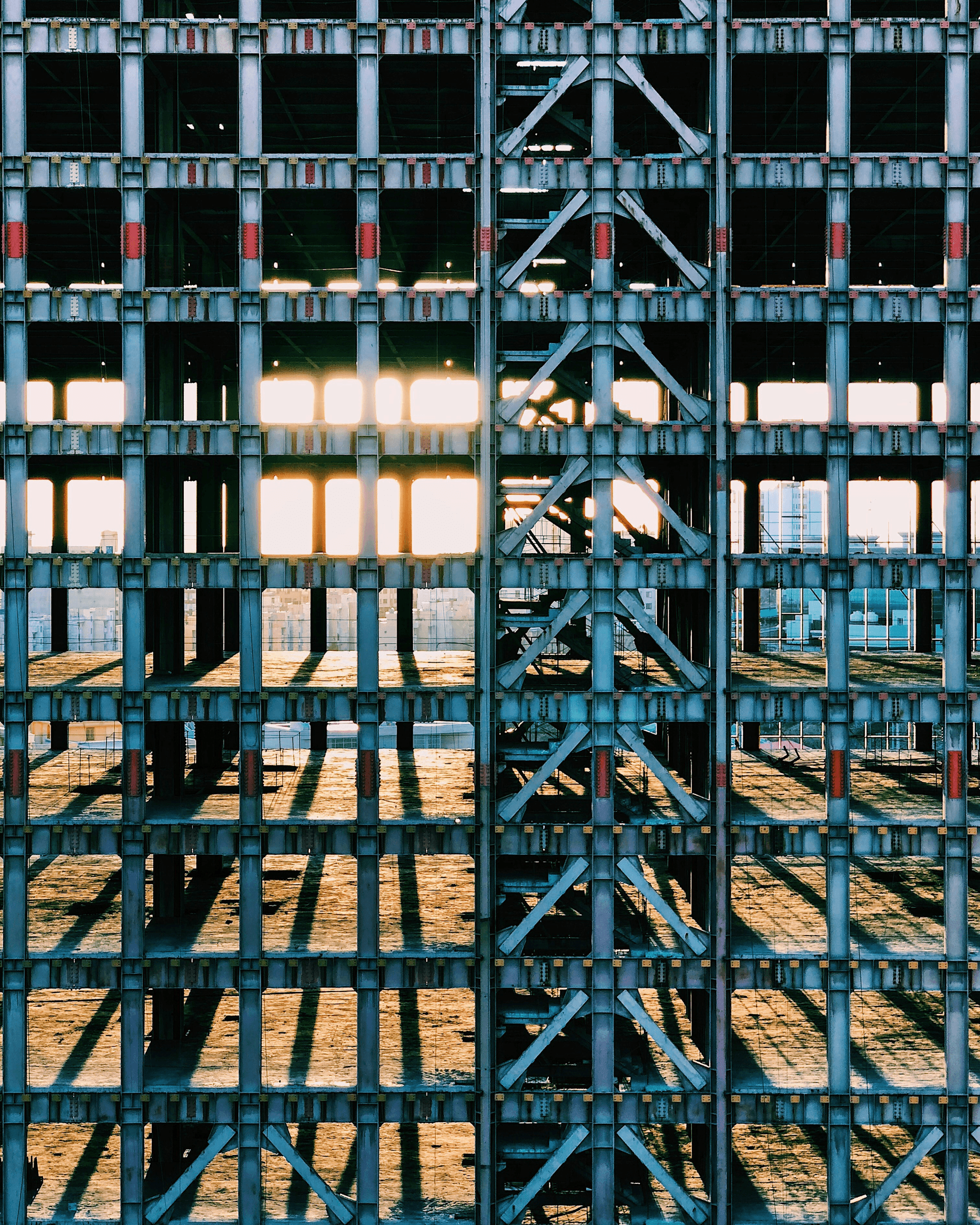

Introduction

In recent years, light gauge steel has emerged as a game-changer in the construction industry, reshaping how we think about building materials. This innovative approach to metal framing offers a lightweight yet robust solution that is quickly gaining traction among builders and architects alike. With its ability to streamline construction processes and enhance structural integrity, light gauge steel is proving to be an indispensable asset in modern steel building construction.

The Rise of Light Gauge Steel

The rise of light gauge steel can be attributed to its remarkable properties and versatility in various applications. As more builders seek efficient alternatives to traditional materials, cold formed steel has become a preferred choice due to its strength-to-weight ratio and ease of installation. This shift towards light gauge steel framing signifies not only an evolution in material choice but also a broader movement towards sustainable building practices.

Why Choose Metal Framing?

Choosing metal framing, particularly light gauge metal framing, comes with numerous advantages that appeal to both contractors and clients. Metal structures are less susceptible to issues like rot, pests, or warping compared to wood alternatives, making them a reliable choice for long-term durability. Furthermore, the precision engineering involved in light gauge steel frame construction allows for quicker assembly times and reduced labor costs on site.

Benefits of Light Gauge Steel

Light gauge steel offers several benefits that make it an attractive option for modern construction projects. Its lightweight nature not only simplifies transportation but also reduces the need for heavy equipment during installation, ultimately saving time and money on the job site. Additionally, the inherent strength of cold formed steel ensures that structures can withstand extreme weather conditions while maintaining their integrity over time.

What is Light Gauge Steel?

Light gauge steel is revolutionizing the construction industry, offering a versatile and innovative alternative to traditional building materials. This type of metal framing utilizes cold formed steel, which is shaped at room temperature into various profiles, making it an efficient choice for modern construction projects. Understanding the characteristics of light gauge steel is essential for architects and builders looking to maximize performance while minimizing costs.

Understanding Cold Formed Steel

Cold formed steel refers to the process where thin sheets of steel are shaped into structural components without being heated. This method allows for precise manufacturing of light gauge steel sections, ensuring uniformity and strength throughout each piece. The result? A lightweight yet robust material that can bear significant loads while remaining easy to handle during installation.

Composition and Properties

Light gauge steel is primarily composed of high-strength low-alloy (HSLA) steel, which offers excellent tensile properties and resistance to corrosion. Its composition also includes elements such as manganese and silicon, enhancing its durability in various environmental conditions. These properties make light gauge metal framing not only strong but also adaptable, allowing it to thrive in diverse applications ranging from residential housing developments to commercial buildings.

Common Applications in Construction

The versatility of light gauge steel frame construction makes it suitable for a wide range of building types and structures. Common applications include everything from single-family homes to multi-story commercial buildings, showcasing its adaptability across different scales and designs. Additionally, innovative uses in architecture often incorporate light gauge metal framing due to its ability to create intricate designs without compromising structural integrity.

Advantages of Light Gauge Steel Framing

Lightweight Yet Strong

One of the most compelling features of light gauge steel is its impressive strength-to-weight ratio. While it may seem counterintuitive, this type of metal framing is remarkably strong despite being lightweight, making it an ideal choice for various construction projects. The inherent properties of cold formed steel allow for designs that can support significant loads without the bulk associated with traditional materials.

This lightweight nature also translates into easier handling and transportation during construction projects. Builders can maneuver light gauge metal framing components with less effort, speeding up the overall construction process. Consequently, this efficiency not only saves time but also reduces labor costs—an appealing aspect for any project manager.

Moreover, the strength of light gauge steel ensures durability and longevity in building structures. Unlike wood or other traditional materials that may warp or degrade over time, cold formed steel remains stable under various environmental conditions. This reliability means fewer repairs and replacements down the line, further solidifying its position as a smart choice in modern construction practices.

Superior Resistance to Elements

Light gauge steel framing excels when it comes to resisting environmental challenges that can compromise building integrity. Unlike wood, which is susceptible to pests such as termites and rot from moisture exposure, light gauge metal framing stands resilient against these threats. This superior resistance means structures built with cold formed steel are less likely to require costly treatments or repairs over their lifespan.

Additionally, light gauge steel offers excellent fire resistance compared to traditional materials like wood or drywall. In regions prone to wildfires or urban settings where fire safety regulations are stringent, using metal framing can provide peace of mind knowing your structure meets safety standards effectively. This aspect not only protects investments but also ensures occupant safety—an invaluable benefit for homeowners and commercial property developers alike.

Moreover, light gauge steel’s ability to withstand extreme weather conditions—from heavy winds to torrential rain—makes it an excellent choice for various climates around the globe. Its durability allows builders to create structures that can endure harsh elements without compromising on design aesthetics or functionality. As climate change continues to impact weather patterns worldwide, choosing resilient building materials like light gauge metal becomes increasingly critical.

Cost-Effectiveness in Steel Building Construction

When evaluating options for construction projects, cost-effectiveness often tops the list of priorities—and rightfully so! Light gauge steel frame construction provides significant savings compared to traditional building methods due primarily to reduced material waste and shorter build times associated with its lightweight nature. The efficient use of cold formed steel means fewer resources are consumed during both manufacturing and installation processes.

Moreover, maintenance costs tend to be lower when using light gauge metal framing because its resistance properties reduce wear and tear over time significantly compared to conventional materials like wood or concrete blocks that require regular upkeep or replacement parts due deterioration factors such as moisture damage or pest infestations . This long-term financial advantage makes investing in light gauge steel a wise decision for both residential housing developments and commercial building projects alike.

Lastly , many builders find themselves drawn towards sustainable practices nowadays; utilizing recycled content found within cold formed steels aligns well with eco-friendly initiatives while still delivering high-performance results . By opting for lighter yet stronger solutions like those offered through metal framings , developers contribute positively towards reducing their carbon footprints without sacrificing quality craftsmanship – proving once again why this approach continues gaining traction across diverse sectors within architecture & engineering fields!

Light Gauge Steel Frame Construction Process

The construction process for light gauge steel framing is a multi-faceted journey that begins long before any steel is cut or installed. It involves meticulous planning, precise installation techniques, and rigorous quality control measures to ensure the integrity and durability of the structure. Each step is essential for achieving the benefits of light gauge steel, making it a preferred choice in modern metal framing.

Design and Planning Stages

The design and planning stages are crucial in any construction project involving light gauge steel frame construction. Architects and engineers collaborate to create detailed blueprints that consider load-bearing requirements, structural integrity, and aesthetic appeal—all while maximizing the advantages of cold formed steel. This stage also includes selecting appropriate materials and determining how light gauge metal framing will integrate with other building components.

Incorporating advanced software tools can streamline this phase, allowing for simulations that predict how different designs will perform under various conditions. The result is a well-thought-out plan that ensures efficient use of resources while minimizing waste—an essential aspect in today’s environmentally-conscious construction landscape. Ultimately, thorough design and planning pave the way for successful installation techniques down the line.

Installation Techniques

Skilled laborers utilize specialized tools to assemble cold formed steel components according to the pre-established plans, ensuring each piece fits perfectly into place. This lightweight material allows for faster assembly compared to traditional materials; workers can maneuver sections easily without compromising strength or safety.

One popular technique involves pre-fabricating components off-site before transporting them to the job site for quick assembly. This not only speeds up the overall construction timeline but also reduces on-site waste—a win-win situation! The adaptability of light gauge metal framing means it can be used in various applications ranging from residential housing developments to commercial projects with minimal modifications.

Quality Control Measures

Quality control measures are vital throughout the entire process of light gauge steel frame construction to ensure long-lasting performance and safety standards are upheld. Regular inspections occur at multiple stages—from material sourcing to final assembly—guaranteeing that each component meets industry regulations and specifications related to cold formed steel usage. This proactive approach minimizes risks associated with structural failures or costly repairs down the road.

Moreover, utilizing advanced testing methods such as non-destructive testing (NDT) can help identify potential weaknesses within assembled structures without causing damage—an invaluable asset in maintaining quality assurance during metal framing projects. By emphasizing quality control at every turn, builders can confidently deliver durable buildings that stand strong against environmental challenges while showcasing innovative architectural designs.

Comparing Light Gauge Steel to Traditional Materials

Weight and Load-Bearing Capacity

One of the standout features of light gauge steel is its impressive strength-to-weight ratio. Unlike traditional materials like wood or concrete, light gauge metal framing is significantly lighter while still maintaining exceptional load-bearing capacity. This means that structures built with cold formed steel can support heavy loads without the added bulk, making it an ideal choice for modern construction.

Moreover, the lightweight nature of light gauge steel allows for easier transportation and handling on-site, reducing labor costs and time delays during construction. Builders can also take advantage of this reduced weight when designing foundations, as less mass means lower requirements for structural support. In essence, when it comes to load-bearing capabilities combined with ease of use, light gauge steel outshines many traditional materials.

Sustainability and Environmental Impact

In today's eco-conscious world, sustainability is more than just a buzzword; it's a necessity in construction practices. Light gauge steel is often produced from recycled materials and is itself fully recyclable at the end of its life cycle, making it a sustainable option compared to many traditional building materials like concrete or virgin timber. By opting for metal framing using cold formed steel, builders contribute to reducing waste and promoting environmental responsibility.

Additionally, the energy efficiency associated with light gauge steel frame construction cannot be overlooked. The thermal performance can be optimized through proper insulation techniques that enhance energy conservation within buildings. This not only reduces operational costs but also minimizes the overall carbon footprint associated with heating and cooling structures over time.

Longevity and Maintenance

Durability is another area where light gauge steel excels compared to traditional building materials. Steel's inherent resistance to pests such as termites or rodents ensures that structures remain intact without requiring frequent repairs or replacements—a common issue with wood framing systems over time. Moreover, light gauge metal framing does not warp or shrink like wood does under varying moisture conditions.

Maintenance requirements for structures built using cold formed steel are minimal compared to those constructed from other materials that may suffer from weather-related wear or decay over time. This longevity translates into cost savings for property owners who would otherwise face ongoing maintenance expenses associated with traditional building methods. Ultimately, choosing light gauge steel frame construction not only enhances structural integrity but also provides peace of mind regarding long-term durability.

Real-World Applications of Light Gauge Steel

Light gauge steel has carved out a significant niche in the construction industry, showcasing its versatility across various applications. From residential homes to commercial structures, light gauge steel framing offers a myriad of benefits that enhance efficiency and sustainability. Let's dive into some of the most compelling real-world uses of this innovative material.

Residential Housing Developments

In recent years, light gauge steel has become increasingly popular in residential housing developments due to its lightweight nature and strength. Builders are turning to light gauge metal framing for single-family homes and multi-family units alike, allowing for quicker construction times without sacrificing durability. With cold formed steel providing exceptional resistance to pests and decay, homeowners can enjoy peace of mind knowing their investment is protected.

Moreover, the design flexibility offered by light gauge steel frame construction allows architects to create unique layouts that maximize space and functionality. This adaptability is particularly beneficial in urban environments where land is at a premium. As a result, many developers are embracing light gauge steel as a go-to solution for modern housing needs.

Commercial Building Projects

The ability to prefabricate components off-site streamlines the construction process significantly, reducing labor costs and project timelines. Additionally, the inherent strength of cold formed steel ensures that these structures can withstand heavy loads while maintaining structural integrity over time.

Light gauge metal framing also offers superior resistance against environmental factors such as fire and moisture—critical considerations in commercial spaces that often have higher foot traffic or specific safety regulations. As businesses increasingly prioritize sustainability, using materials like light gauge steel aligns with eco-friendly practices by reducing waste during construction phases.

Innovative Uses in Architecture

The architectural world is witnessing an exciting renaissance thanks to the creative possibilities presented by light gauge steel framing. Architects are leveraging this material not just for traditional structures but also for avant-garde designs that push boundaries and challenge norms. With its lightweight properties allowing for intricate designs without compromising stability, cold formed steel has become a favorite among those looking to make bold statements.

From eye-catching facades to complex roof structures, innovative uses of light gauge metal framing can be seen across various projects worldwide—each one showcasing how this material can transform ordinary buildings into extraordinary works of art. Furthermore, its recyclability adds another layer of appeal for architects who prioritize sustainable design principles in their work.

Conclusion

The construction landscape is evolving, and light gauge steel is at the forefront of this transformation. As builders and architects increasingly embrace metal framing, they are discovering that light gauge steel framing offers a myriad of advantages that traditional materials simply cannot match. With its lightweight yet robust nature, cold formed steel is not just changing how we build; it's revolutionizing modern construction practices.

Transforming Modern Construction Practices

Light gauge steel frame construction has become a game-changer in the building industry, allowing for faster and more efficient project timelines. The inherent strength and flexibility of light gauge metal framing make it suitable for diverse applications, from residential homes to commercial buildings. This versatility means that architects can push creative boundaries while ensuring structural integrity, ultimately leading to innovative designs that were once thought impossible.

Kiant Machinery's Role in Efficiency

Kiant Machinery plays a pivotal role in enhancing the efficiency of steel building construction by providing cutting-edge technology tailored for light gauge steel applications. Their advanced machinery streamlines the fabrication process, reducing waste and increasing precision in every project phase—from design to installation. By investing in such innovative tools, builders can maximize productivity while minimizing costs associated with traditional materials.

The Future of Light Gauge Steel Framing

As we look ahead, the future of light gauge steel framing appears bright and promising. With an increasing emphasis on sustainability and eco-friendly practices in construction, cold formed steel presents an excellent alternative due to its recyclability and reduced environmental impact compared to conventional materials. As more industry players recognize these benefits, we can expect light gauge metal framing to become a standard choice for future projects.