Introduction

In the ever-evolving world of construction, understanding the machinery that drives efficiency is essential. China roll forming machines have emerged as a pivotal player in this arena, particularly for steel structure construction and metal framing applications. With their advanced technology and adaptability, these machines are revolutionizing how we approach projects, especially in light gauge steel framing.

Understanding China Roll Forming Machines

China roll forming machines are specialized tools designed to create metal profiles with precision and speed. These machines utilize a continuous bending process to shape flat metal sheets into desired cross-sectional shapes, which are crucial for steel building construction. Their ability to produce consistent and complex designs makes them indispensable in modern steel structure construction.

The Role of Competitive Pricing

One of the standout features of China roll forming machines is their competitive pricing, which can significantly impact overall project budgets. By offering high-quality equipment at lower costs compared to Western counterparts, these manufacturers make it easier for businesses to invest in essential machinery without breaking the bank. This affordability allows companies to allocate more resources towards innovation and development within their light gauge metal framing projects.

Why Choose a Chinese Manufacturer

Choosing a Chinese manufacturer for your roll forming needs comes with numerous advantages beyond just cost savings. Chinese companies often lead the market in technological advancements and production capacity, ensuring that you receive not only an affordable framecad machine price but also cutting-edge equipment tailored to your specific requirements. Additionally, with strong support networks and extensive experience in steel framing applications, these manufacturers are well-equipped to assist you throughout your project lifecycle.

Overview of Roll Forming Technology

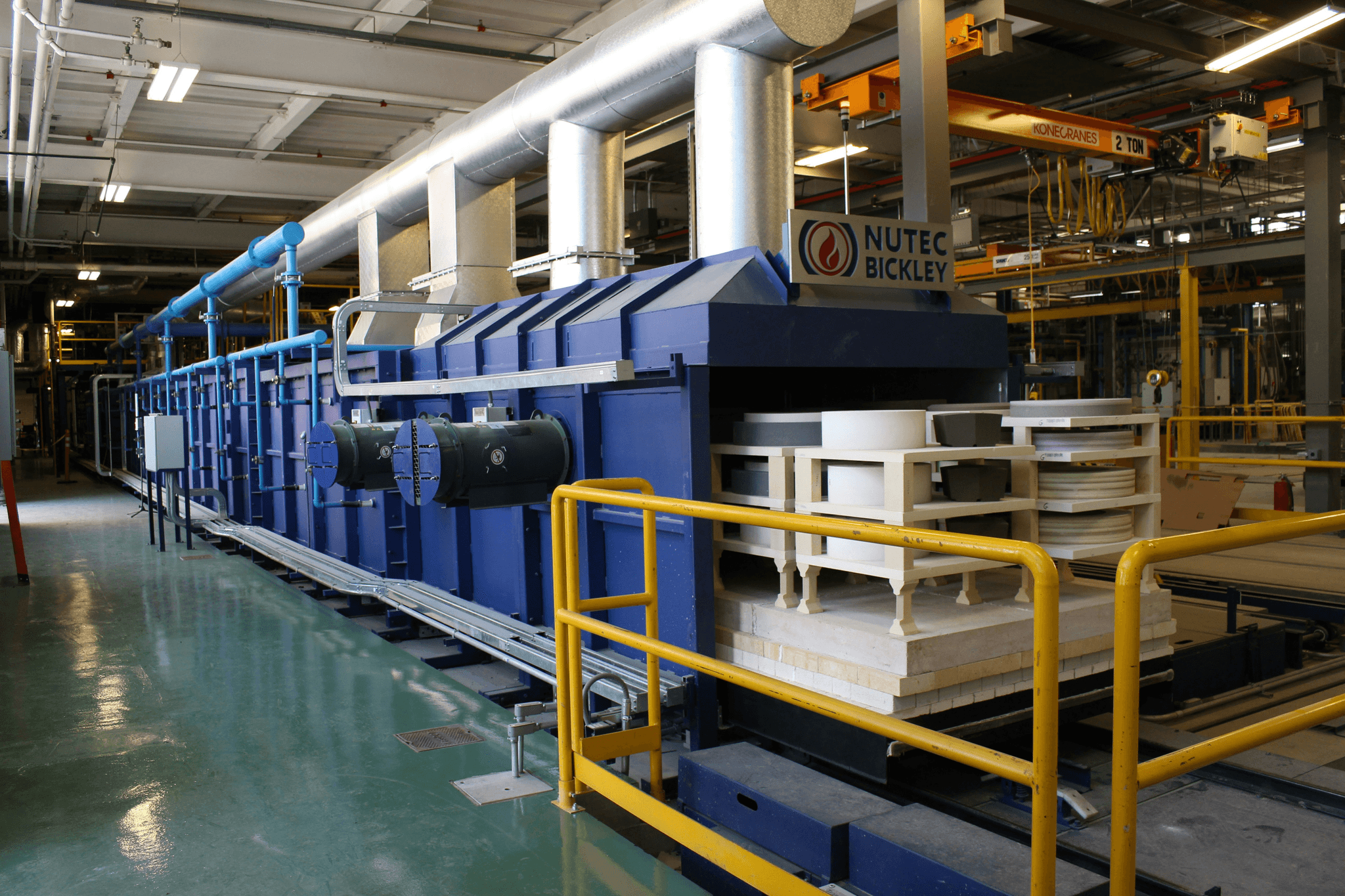

Roll forming technology is a manufacturing process that shapes metal into desired profiles by passing it through a series of rollers. This method is particularly advantageous for creating continuous lengths of metal framing components, which are essential in steel structure construction. The precision and efficiency of roll forming make it an ideal choice for producing light gauge steel framing elements used in various applications.

Definition and Process Explained

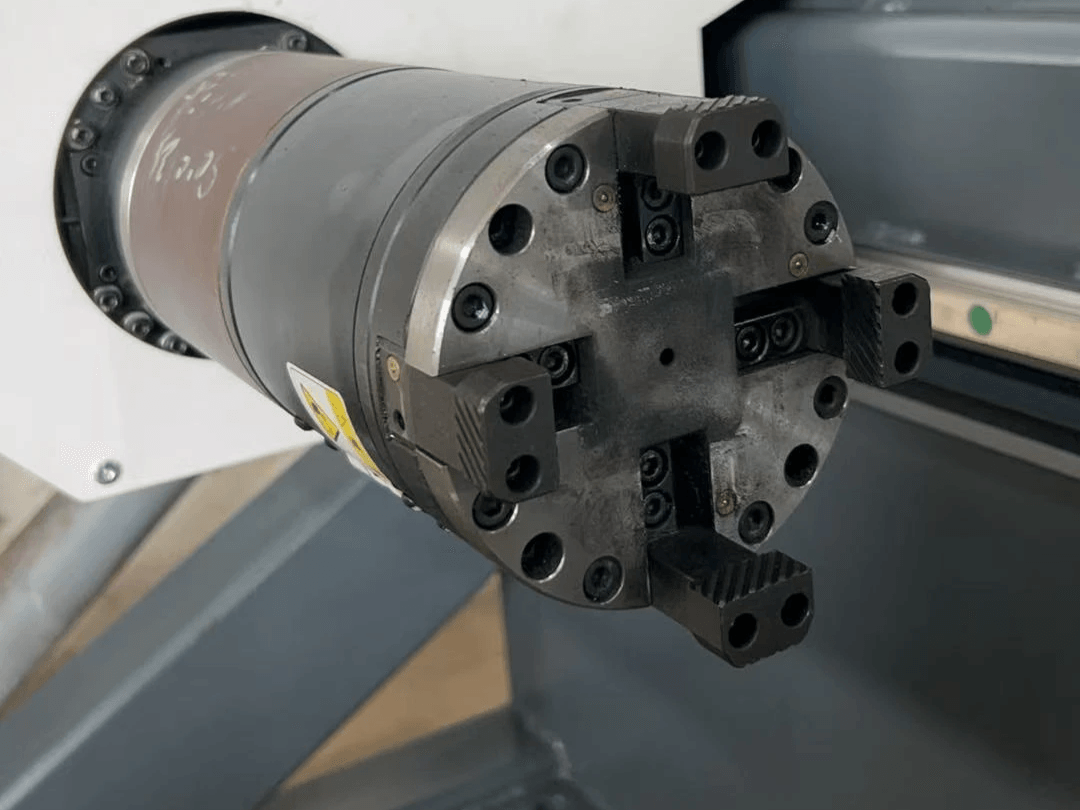

At its core, roll forming involves feeding a flat strip of metal through a set of rollers that gradually bend and shape the material into specific profiles. This continuous process allows for high-volume production with minimal waste, making it cost-effective—especially when considering framecad machine price. The versatility of roll forming means it can produce a wide range of products, from simple channels to complex shapes used in steel building construction.

The machinery involved in this process varies from basic manual setups to sophisticated automatic systems equipped with advanced controls. These machines can be customized to meet specific requirements, which is essential for manufacturers looking to optimize their production lines for light gauge metal framing materials. Understanding the intricacies of this process helps manufacturers make informed decisions about investing in roll forming technology.

Benefits for Metal Framing Applications

One significant advantage of roll forming is its ability to produce lightweight yet strong components that are perfect for steel structure applications. Light gauge steel framing offers durability while maintaining lower material costs compared to traditional methods, making it an attractive option for builders aiming to reduce overall project expenses. Furthermore, the precision inherent in the roll forming process ensures consistency across all produced parts—an essential factor in maintaining structural integrity during construction.

Another benefit lies in the speed at which components can be manufactured; this efficiency translates directly into quicker project timelines and lower labor costs on-site. As builders increasingly turn toward sustainable practices, using light gauge steel framing produced through roll forming aligns well with eco-friendly initiatives due to reduced waste generation during production processes. Ultimately, these advantages contribute significantly to why many opt for this technology when planning their next steel structure construction project.

Knowledge Gaps in Steel Structure Construction

Despite the numerous benefits associated with roll forming technology and light gauge metal framing, there remains a knowledge gap among some industry professionals regarding its full potential and application methods. Many still rely on traditional materials without fully understanding how modern techniques can enhance efficiency and reduce costs related to framecad machine price negotiations and investments. Bridging this gap requires ongoing education about advanced manufacturing processes and their implications within the realm of steel structure construction.

Moreover, misconceptions about the strength and applicability of light gauge framing persist; some believe it's only suitable for non-load-bearing walls or smaller structures when, in fact, it has been successfully employed in larger commercial projects as well. Addressing these misunderstandings is crucial as more companies consider integrating innovative practices into their workflows—ultimately leading them toward more sustainable approaches within the industry landscape. By fostering awareness around these topics, stakeholders can make better-informed decisions regarding their investments in equipment like framecad machines tailored specifically for efficient metal framing solutions.

Key Players in the Market

The landscape of roll forming and metal framing is rich with competition, especially in China, where several manufacturers have established themselves as leaders. These companies not only innovate but also drive competitive pricing strategies that benefit customers globally. Understanding who these key players are can help manufacturers make informed decisions when investing in equipment like frameCAD machines.

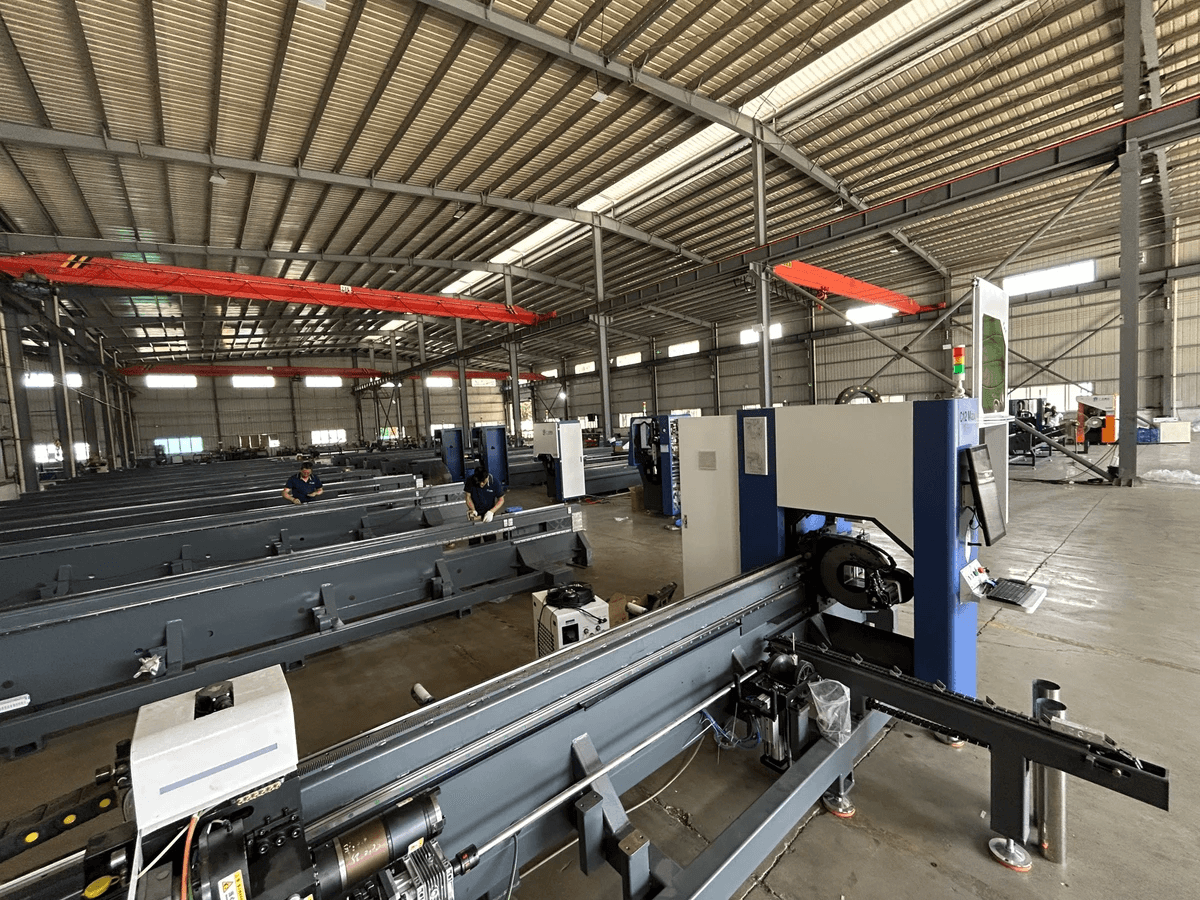

Leading Manufacturers in China

China is home to a plethora of leading manufacturers specializing in roll forming technology and light gauge steel framing solutions. Companies such as Hunan Dazheng, Cangzhou Zhongyi, and Jinan Xintian are at the forefront, offering a wide range of products tailored for steel structure construction. Their ability to provide high-quality machines at competitive prices has made them indispensable partners for businesses looking to invest in metal framing solutions.

These manufacturers utilize advanced technology and efficient production techniques to keep costs low while maintaining quality standards. As a result, they can offer attractive frameCAD machine prices that appeal to both domestic and international markets. For those considering steel building construction projects, partnering with these leading manufacturers ensures access to reliable machinery that meets evolving industry demands.

Spotlight on Kiant Machinery

Kiant Machinery stands out among the top players for its commitment to innovation and customer satisfaction within the roll forming sector. Specializing in light gauge metal framing systems, Kiant has developed a reputation for producing robust machines designed for efficiency and versatility in steel structure construction. Their focus on research and development allows them to stay ahead of market trends while offering competitive frameCAD machine prices.

Kiant’s products are particularly popular among builders seeking cost-effective solutions without compromising on quality or performance. The company’s dedication to customer service further enhances its appeal; clients receive comprehensive support from initial inquiry through installation and beyond. This level of commitment positions Kiant Machinery as a go-to manufacturer for anyone involved in metal framing projects.

Comparing Industry Titan FrameCAD

When discussing key players, it’s impossible not to mention FrameCAD—an industry titan known for its advanced technology tailored specifically for light gauge steel framing applications. FrameCAD machines have become synonymous with precision engineering and reliability, making them a preferred choice among contractors engaged in steel building construction worldwide. However, their frameCAD machine prices can sometimes be higher than those offered by other manufacturers.

While FrameCAD sets high standards with its innovative features and performance capabilities, it's essential for potential buyers to weigh these advantages against cost considerations. The investment may yield long-term savings through enhanced productivity and reduced material waste during projects involving steel structures or light gauge frameworks. By comparing FrameCAD’s offerings with other leading Chinese manufacturers like Kiant Machinery, businesses can make informed decisions that align with their budgetary constraints while ensuring they meet the demands of modern construction practices.

Factors Influencing FrameCAD Machine Price

When it comes to determining the frameCAD machine price, various factors come into play that can significantly affect the overall cost. Understanding these elements is crucial for manufacturers looking to invest in equipment for steel structure construction and metal framing projects. By dissecting these components, businesses can make informed decisions that align with their budgetary constraints and project requirements.

Material Costs and Production Techniques

The foundation of any frameCAD machine price is rooted in the costs of materials and the intricacies of production techniques employed during manufacturing. High-quality steel used in light gauge metal framing can drive up prices, but it also ensures durability and longevity in steel building construction. Additionally, advanced production techniques that enhance efficiency may come at a premium but often lead to lower operational costs over time.

Moreover, fluctuations in raw material prices can create a ripple effect on frameCAD machine price tags across the industry. As demand for light gauge steel framing continues to rise, manufacturers must adapt by sourcing materials wisely while keeping an eye on their bottom line. This balance between quality materials and cost-effective production methods is essential for those involved in steel structure construction.

The Role of Customization and Features

Customization plays a pivotal role in influencing frameCAD machine price, as tailored solutions often come with added costs but provide significant benefits for specific projects. Features such as automated controls, advanced software integration, or specialized tooling can enhance productivity but may also increase initial investments. Manufacturers must weigh the advantages of these features against their project needs and budget constraints when considering their options.

Furthermore, customizations that cater to unique requirements within metal framing applications can lead to greater efficiency during construction phases. While opting for standard configurations might be more budget-friendly initially, bespoke machines could yield higher returns through improved performance over time—especially in large-scale steel structure projects where precision is paramount. Ultimately, understanding how customization impacts frameCAD machine price is vital for making strategic investment decisions.

Import Duties and Shipping Considerations

When purchasing machinery from overseas manufacturers like those producing frameCAD machines in China, import duties and shipping considerations become critical factors influencing overall pricing strategies. These additional expenses can significantly inflate the final cost beyond just the listed frameCAD machine price—particularly if shipping logistics are not managed effectively or if tariffs fluctuate unexpectedly due to trade policies.

Moreover, delays or complications during shipping may lead to increased operational downtime—a costly consequence for companies engaged in ongoing steel building construction projects relying on timely delivery of equipment. To mitigate these risks, manufacturers should engage with experienced logistics partners who understand international trade regulations relevant to metal framing machinery imports.

Ultimately, understanding how import duties and shipping considerations impact pricing will enable businesses to make better-informed decisions about their investments while ensuring they remain competitive within the ever-evolving landscape of light gauge steel framing solutions.

Steel Framing Applications

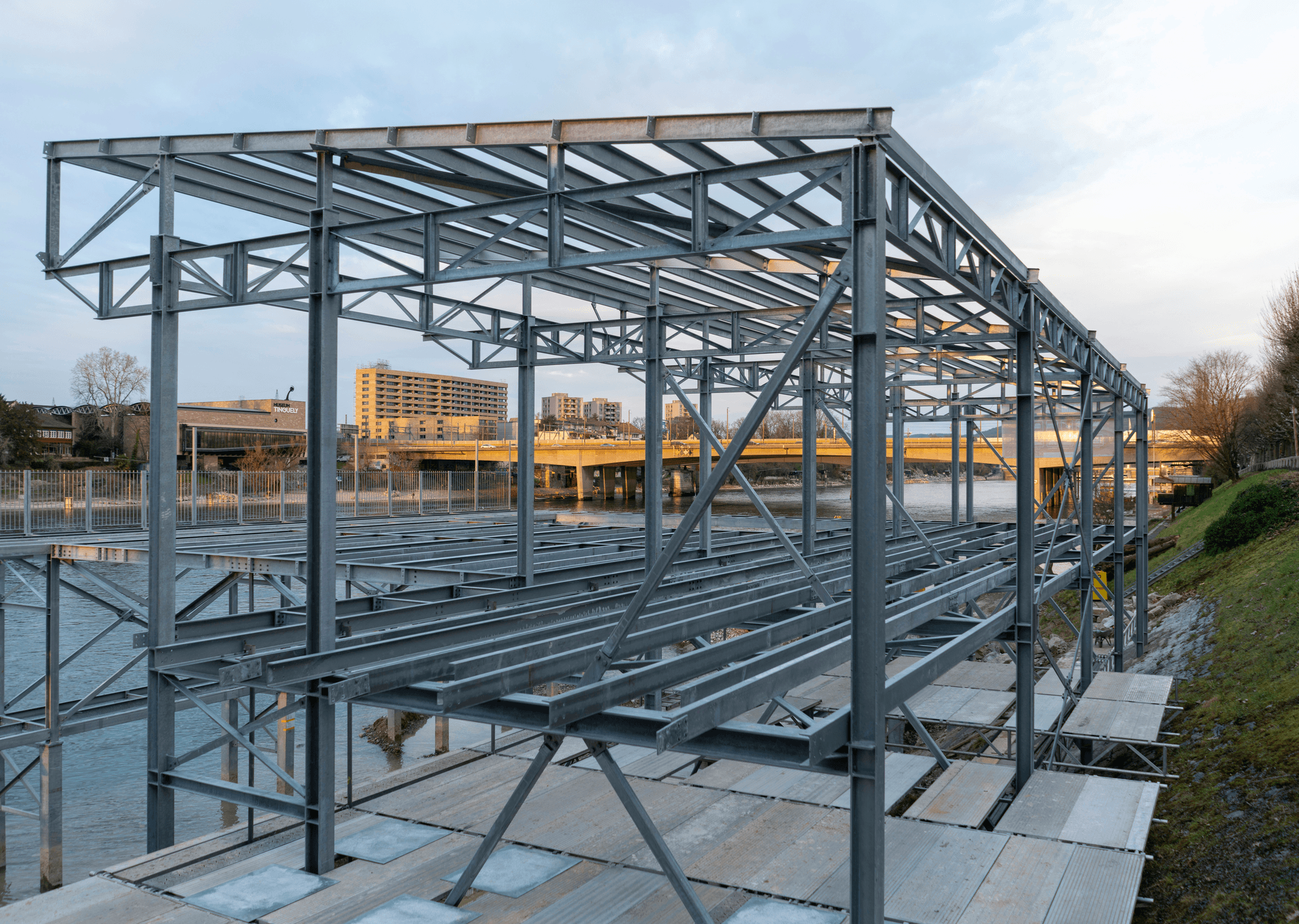

Steel framing has revolutionized the construction industry, particularly in the realm of light gauge steel framing. This method offers a plethora of advantages, making it a preferred choice for various building projects. With its durability and flexibility, light gauge metal framing is increasingly becoming synonymous with modern steel structure construction.

Advantages of Light Gauge Steel Framing

Light gauge steel framing stands out due to its strength-to-weight ratio, which allows for more efficient designs without compromising structural integrity. Unlike traditional materials, it is resistant to warping, shrinking, and insects, ensuring longevity in steel building construction. Additionally, this type of framing is often more cost-effective over time; while the initial framecad machine price might be higher than wood alternatives, the long-term savings on maintenance and repairs are undeniable.

Moreover, light gauge steel can be easily customized to meet specific project requirements. Its versatility means that architects and builders can create complex shapes and designs that would be challenging with other materials. As a bonus, this material is also recyclable—making it an eco-friendly option that appeals to environmentally conscious developers.

Use Cases in Steel Building Construction

The applications of light gauge metal framing are vast and varied across different sectors of steel structure construction. From residential homes to commercial buildings and even industrial facilities, this technology is adaptable enough to meet diverse needs. For instance, many urban developers are opting for light gauge steel in multi-story buildings due to its lightweight nature that reduces foundation costs.

In addition to new constructions, renovations using light gauge steel have become increasingly popular as they provide an excellent solution for retrofitting existing structures without excessive weight burdens. The ability to use these frames in tight spaces makes them ideal for urban environments where land is at a premium. Furthermore, their quick assembly speeds up project timelines—an attractive feature for builders mindful of labor costs associated with prolonged construction periods.

Innovations in Metal Framing Techniques

The landscape of metal framing continues to evolve with innovative techniques enhancing efficiency and sustainability within the industry. Advanced technologies such as automated roll forming machines have improved precision while reducing waste during production—a significant factor when considering framecad machine price against potential savings on raw materials. These innovations allow manufacturers to produce high-quality components rapidly while maintaining competitive pricing.

Additionally, smart technology integration into metal framing processes has led to better project management through real-time data analysis and monitoring systems that track progress seamlessly from start to finish. This level of oversight ensures that projects stay within budget while optimizing resource allocation throughout each phase of construction—further supporting the case for adopting advanced metal framing methods in future projects.

As we advance into a new era of building design and construction practices driven by innovation and sustainability goals, it’s clear that light gauge steel will play a crucial role in shaping our architectural landscape.

Cost-Effective Solutions for Manufacturers

In the competitive landscape of steel structure construction, manufacturers are constantly seeking ways to maximize profitability while maintaining quality. Investing in the right equipment, such as a frameCAD machine, can significantly influence operational costs and project timelines. Understanding how to assess these investments is crucial for any manufacturer aiming to thrive in the metal framing industry.

How to Assess Your Investment

When considering a frameCAD machine price, it's essential to evaluate not just the initial cost but also the long-term benefits it brings to your operations. Start by analyzing your current production capabilities and identifying bottlenecks that could be alleviated with better machinery. Additionally, consider factors such as energy efficiency, maintenance requirements, and potential output increases that can all contribute to a more comprehensive return on investment.

To make an informed decision about investing in light gauge steel framing equipment, manufacturers should conduct a thorough cost-benefit analysis. This includes estimating projected savings from reduced labor costs and shorter construction times associated with advanced machinery. Ultimately, aligning your investment strategy with your business goals will help ensure that your expenditure translates into tangible benefits.

Long-Term Savings through Quality Equipment

Investing in high-quality equipment like frameCAD machines can lead to substantial long-term savings for manufacturers involved in steel structure construction. These machines are designed for durability and efficiency, reducing the frequency of breakdowns and maintenance costs over time. Furthermore, reliable machinery often results in higher-quality outputs—essential when working with light gauge metal framing—leading to fewer reworks and increased customer satisfaction.

Quality equipment also enhances productivity by enabling faster production cycles without compromising on precision or structural integrity. For instance, incorporating advanced features like automated cutting or profiling can streamline processes significantly compared to traditional methods used in steel framing projects. As a result, manufacturers can take on more projects simultaneously without sacrificing quality or timelines.

Strategies for Reducing Overall Project Costs

To effectively reduce overall project costs in steel building construction, manufacturers should consider various strategies beyond just choosing affordable machinery like frameCAD machines. One effective approach is optimizing supply chain management—sourcing materials at competitive prices while ensuring timely delivery can drastically decrease overhead expenses associated with delays or excess inventory.

Another strategy involves investing in training programs for staff operating light gauge steel framing equipment; well-trained employees are less likely to make costly mistakes during production runs. Additionally, leveraging technology such as project management software can aid in tracking expenses more accurately throughout each phase of construction—allowing for adjustments before issues escalate into significant financial burdens.

Finally, exploring partnerships with other companies within the industry may provide opportunities for shared resources or bulk purchasing agreements that lower material costs across multiple projects involving metal framing techniques. By implementing these strategies alongside careful consideration of frameCAD machine price points, manufacturers can position themselves favorably within an increasingly competitive market.

Conclusion

In the ever-evolving landscape of steel structure construction, making informed decisions can significantly impact your project's success and profitability. As we wrap up our exploration of roll forming technology and its applications, it's essential to reflect on how you can maximize value in your equipment investments while keeping an eye on future trends. With the right strategies in place, manufacturers can leverage advancements in metal framing to achieve cost-effective solutions that stand the test of time.

Maximizing Value in Equipment Investment

Investing in high-quality machinery is paramount when it comes to maximizing value, particularly with frameCAD machine prices fluctuating based on features and customization options. By selecting a reliable manufacturer, you not only ensure superior performance but also enhance operational efficiency in steel framing projects. The long-term savings gained from durable equipment will far outweigh initial costs, making it a smart financial decision for any business focused on steel structure construction.

The Future of Steel Structure Construction

As we look ahead, the future of steel structure construction appears promising with innovations continuously reshaping the industry landscape. Light gauge steel framing is gaining traction due to its lightweight properties and ease of installation, providing builders with flexible solutions for various applications. Furthermore, advancements in roll forming technology will likely lead to even more efficient processes that reduce waste and enhance sustainability within metal framing projects.

Making Informed Choices in Metal Framing

Navigating the myriad options available for metal framing requires careful consideration and research into frameCAD machine prices as well as other critical factors like material quality and production techniques. Understanding your specific needs will empower you to make informed choices that align with your project goals while ensuring optimal performance from your equipment. Ultimately, investing time upfront into research will pay off significantly as you embark on successful steel building construction endeavors.